5

AD since 1928

1.3 - SAFETY

IMPORTANT !

The pump must not be used for other purposes than recommended and quoted for without consult-

ing your ALBIN PUMP distributor.

Liquids not suitable for the pump can cause damages to the pump unit and imply risk of serious

personal injury. Always consult your ALBIN PUMP distributor if you are not sure of the compatibility of

uids with the pump materials including the elastomers.

HAZARD WARNING - POSSIBLE EXPLOSION HAZARD can result if 1, 1, 1-Trichloroethane, Methy-

lene Chloride or other Halogenated Hydrocarbon Solvents are used in pressurized uid systems hav-

ing Aluminium wetted parts. Death, serious bodily injury and/or property damage could result.

The pump must always be installed and used in accordance with existing local and national sanitary

and safety regulations and laws.

The pump can create uid pressures equal to the air supply pressure. Do not exceed the maximum

permissible air supply pressure of 7 bar. The total hydraulic pressure (system pressure + differential

pressure) must never exceed 7 bar.

Do not exceed the recommended operating temperatures of the pump. The maximum temperature

limitations are based on mechanical stress only and various liquids/chemicals may reduce the maxi-

mum safe operating temperatures of the pumps.

Diaphragms : PTFE can operate continuously between -30°C and +85ºC.

Pump housing : PP (polypropylene) can be used in the interval ±0°C and +85 ºC.

Aluminium can be used in the same interval as the diaphragms.

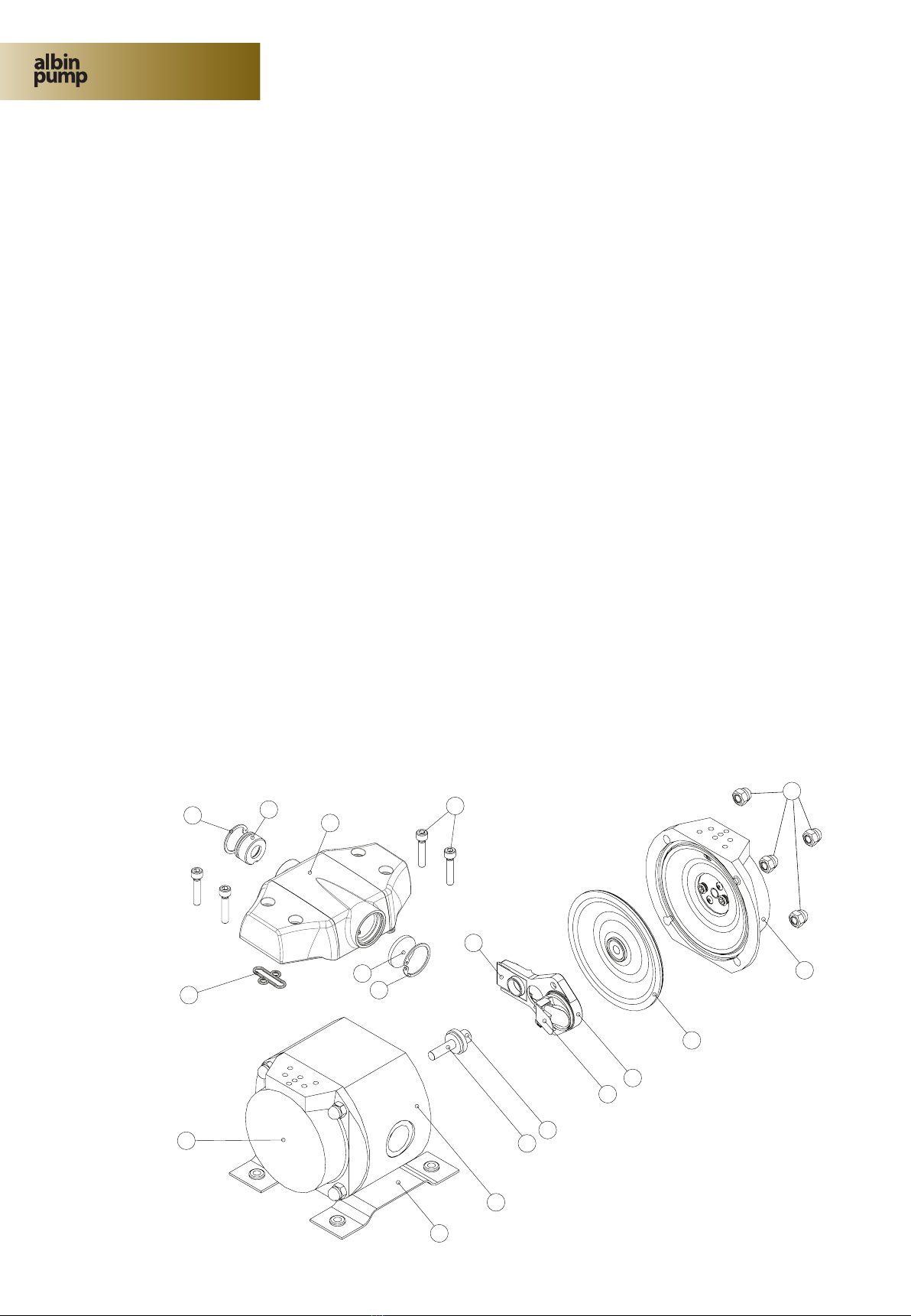

Inside the pump two diaphragms are separating the pumped liquid from the air supply.

When a diaphragm ruptures uid may be expelled through the air exhaust port. If dangerous liquids

are handled always connect the air exhaust port with a suitable container in a safe location. When the

product source is at a higher level than the pump (ooded suction), the exhaust should be piped to a

higher level than the product to prevent spills caused by siphoning.

Never operate a pump that is leaking, damaged, corroded or otherwise unable to contain the internal

uid or air pressure.

Never exceed the recommended service and inspection intervals for the diaphragms and air motor

parts.

Never put your face or body near the pump air exhaust while the pump is operating.

Always shut off the air supply and disconnect it from the pump before making repairs to the pump.

Be sure to relief all pressure from the discharge and suction pipes/hoses prior to disconnecting the

pump from the system.

Static electricity can be created when the pump is operating. Always use conductive polypropyl-

ene pumps in hazardous environments or for ammable uids. Pumps must be properly grounded.

Strictly follow the local safety regulations for hazardous environments.

AD Instruction Manual-2011EE-GB.indd 5 25/07/11 09:45