since 1928

1 | HOW TO USE THIS MAINTENANCE MANUAL .................................... 4

2 | PUMP USE AND TRAINING .................................................. 4

2.1 - Use of the pump ....................................................4

2.2 - Responsibility ......................................................4

2.3 - Training and instructions..............................................4

3 | DESCRIPTION ............................................................. 5

3.1 - Product identication ................................................5

3.2 - Operation principle ..................................................5

3.3 - Pump construction ..................................................6

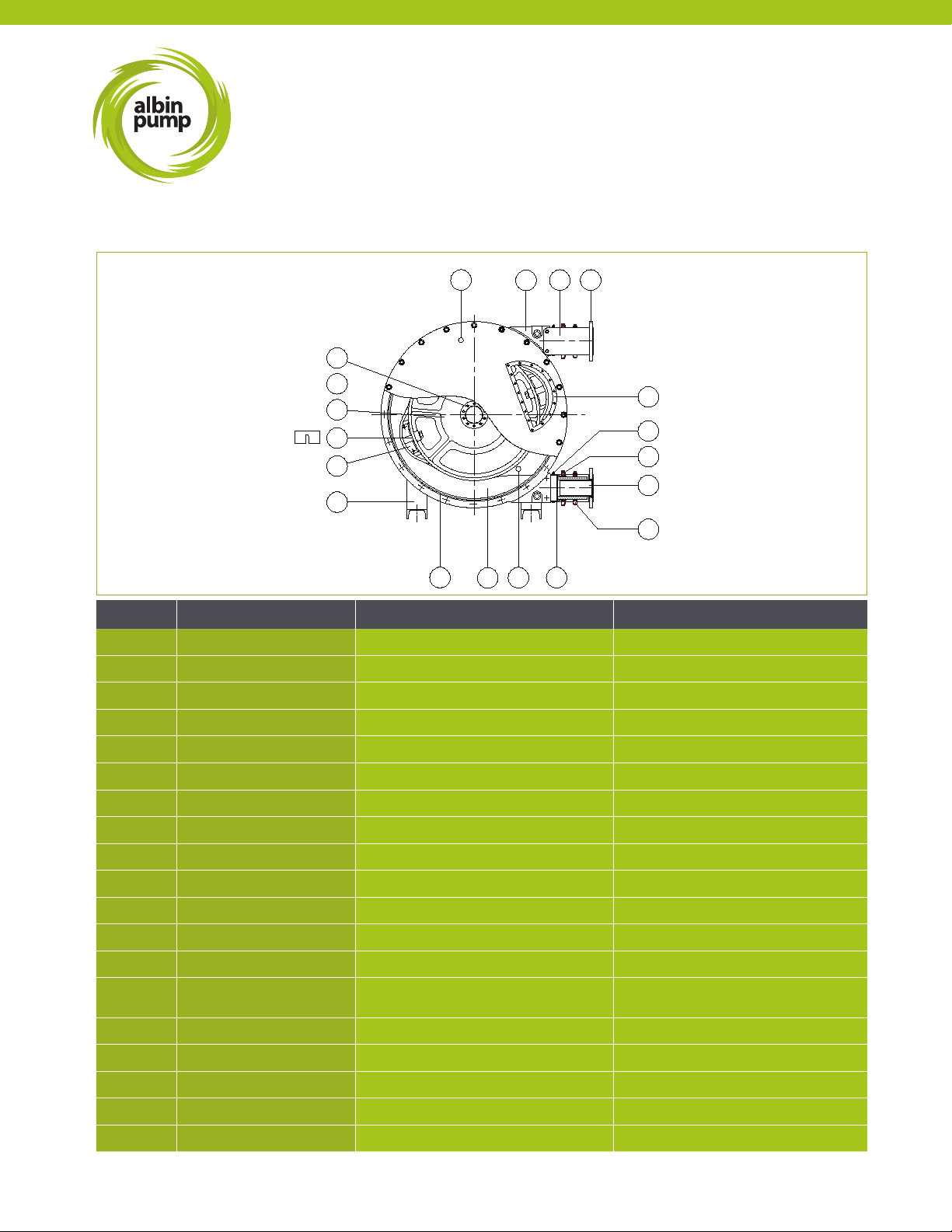

3.3.1 - Pumps ALH05 to ALH20 .........................................6

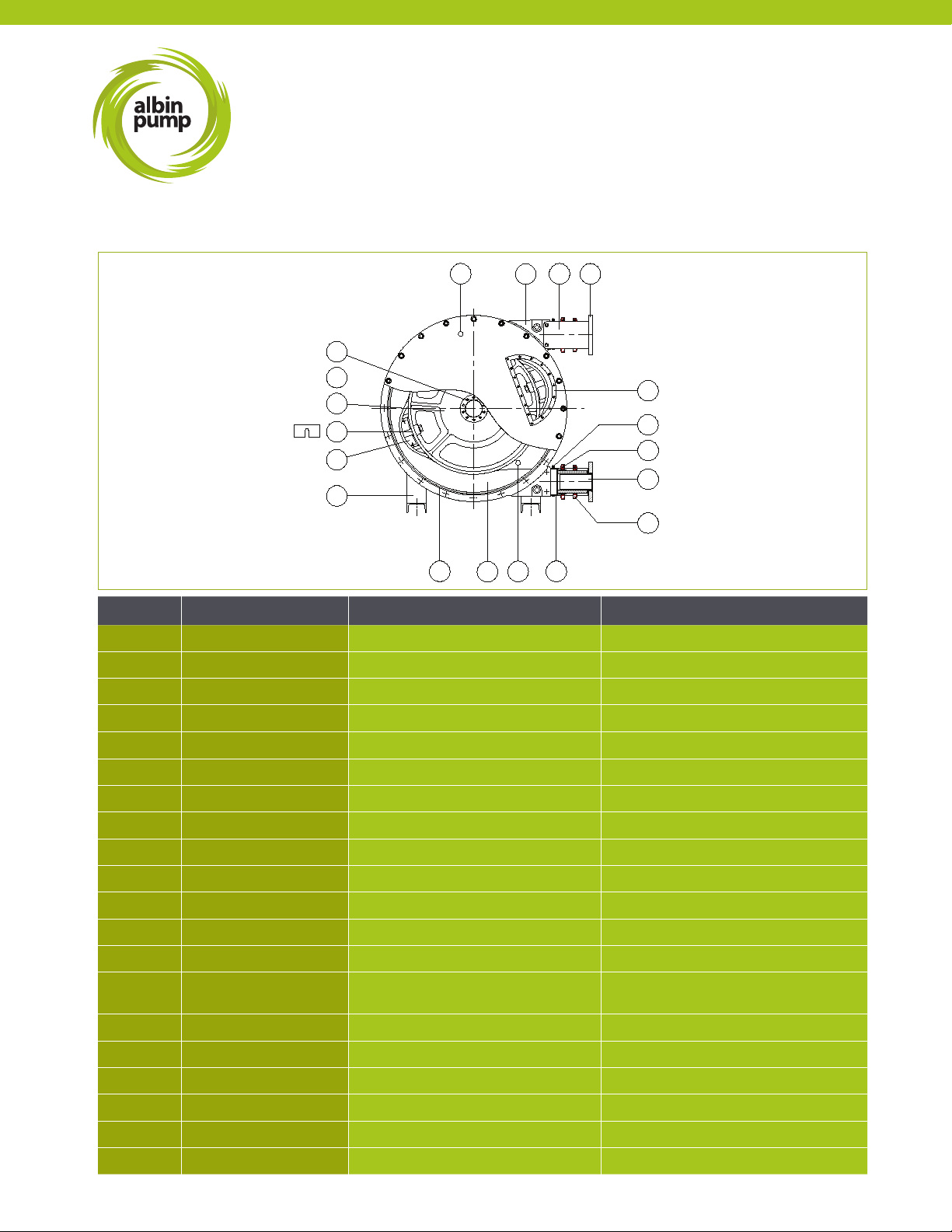

3.3.2 - Pumps ALH25 to ALH65 .........................................7

3.3.3 - Pumps ALH80 to ALH125 ........................................8

3.4 - Pump hose ........................................................9

3.5 - Pump gearbox .....................................................9

3.6 - Electrical Motor.....................................................9

3.7 - Available Options ...................................................9

4 | INSTALLATION .............................................................10

4.1 - Unpacking and control ..............................................10

4.2 - Conditions of installation ............................................10

4.3 - Setup ...........................................................10

4.4 - Piping ...........................................................10

4.5 - Pump lifting.......................................................11

5 | PUMP START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 - Preparations ......................................................11

5.2 - Pump start-up.....................................................11

6 | MAINTENANCE ............................................................11

6.1 - Emptying and lling of the lubricant ....................................11

6.2 - Hose cleaning .....................................................13

6.3 - Hose replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3.1 - Removing the hose ............................................13

6.3.2 - Cleaning of the pump casing ....................................15

6.3.3 - Reassembly of the hose ........................................15

6.4 - Replacement of spare parts ..........................................17

6.4.1 - Replacement of pump shoes (except ALH05, ALH10, ALH15, ALH20) ....17

6.4.2 - Replacement of the seal ring (REF 27) and the shaft seal (REF 26) .......18

6.5 - Shoe shimming....................................................21

6.6 - Maintenance and periodical controls ...................................22

6.7 - ALHS series complementary information ................................23

6.7.1 - Set up ......................................................23

6.7.2 - Pump starting ................................................23

6.7.3 - Bearing case dismantling and lip seal (REF 26) replacement ............23

6.7.4 - Maintenance and periodical controls .............................. 23

ALH

Table of Contents