1. General Notes

The Pulsors are to be used in keeping with the technical recommendations and documentation of ALBR CHT

Ingenieurbüro. No liability is accepted for improper use of the equipment and consequential damage.

The instructions concerning function tests and troubleshooting in chapter 4 of the operation manual must be

followed (http://www.pulsoren.com/english/operating instructions.pdf)

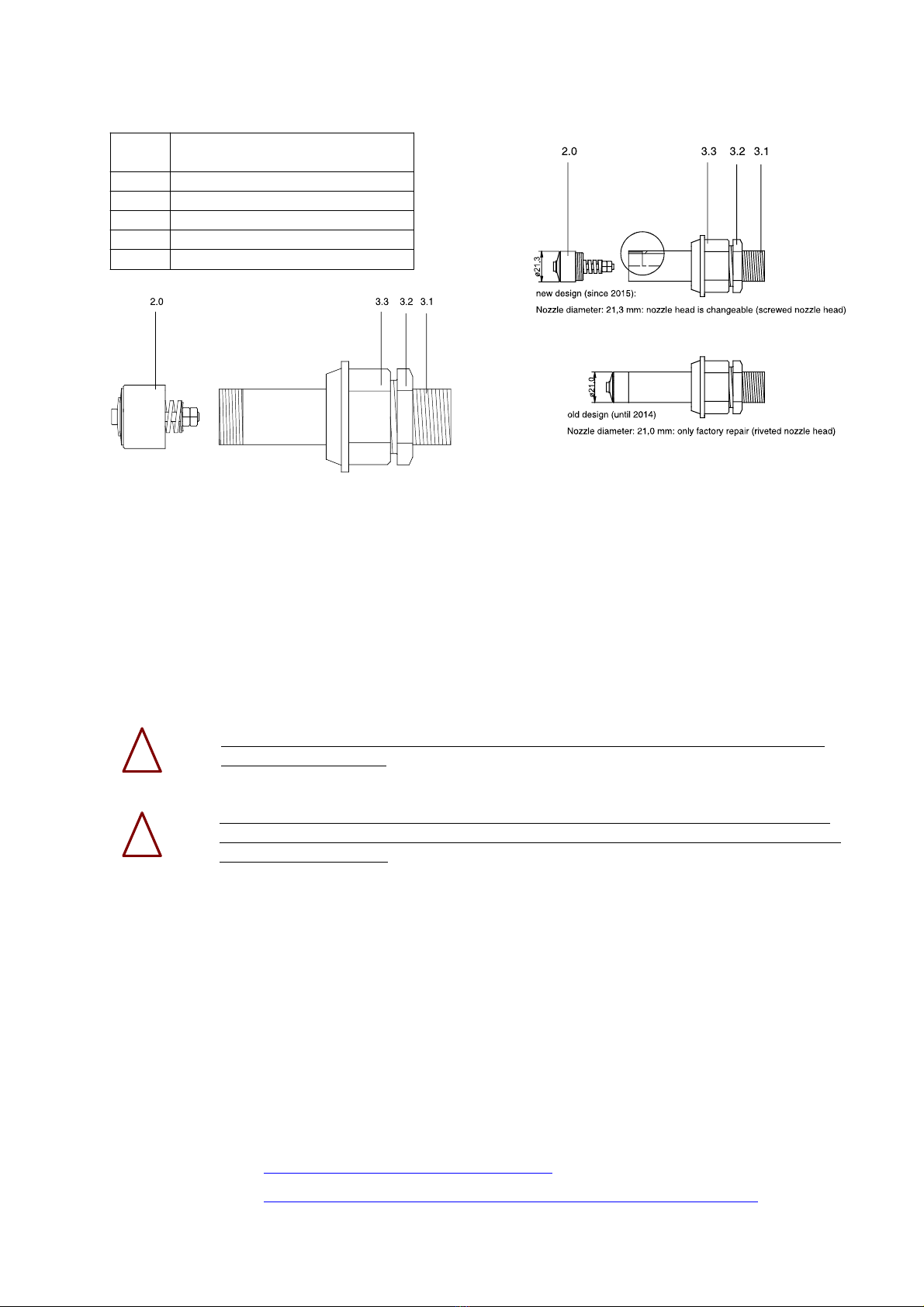

2. xchange of Pulsor and Impulse Nozzle

2.1 Replacement of the Pulsor body without nozzle (nozzle remains installed):

Before starting, shut off the compressed air supply and vent the feed pipe.

Disassembly:

a) Loosen and remove the solenoid valve plug.

b) Open the pipe union between Pulsor and valve. Detach the valve from the Pulsor and carefully hang valve

with hose aside.

c) Unscrew the Pulsor body from the nozzle. To do so, insert a suitable lever tube into the air inlet opening

and jerk suddenly in the counterclockwise direction (or briefly hit against the air inlet union with a rubber

hammer in the counterclockwise direction). After that, the Pulsor body can easily be screwed off the

nozzle tube.

Re-Assembly:

d) Screw the Pulsor onto the nozzle without using a sealant and first tighten it by hand. Use a lever tube or

rubber hammer to tighten it by 1/8 - 1/4th of a revolution.

e) The air inlet union must now be aligned so that the solenoid valve can be installed without tension and

torsion in the pipe. To do so, slightly loosen the union nut of the assembly union at the nozzle without

unscrewing it completely. Loosen the conical pipe union with light strokes (rubber hammer!) till the nozzle

with the Pulsor can be turned inside the weld-on nipple. Align the Pulsor and the nozzle in such a way that

the valve can be installed easily. Firmly tighten the union nut of the assembly union again.

f) Attach the valve, tighten the pipe union and fit the solenoid valve plug back on again.

2.2 Replacement of the impulse nozzle with or without Pulsor:

The nozzle can be dismantled together with the Pulsor body or separately after unscrewing the Pulsor body (see

above).

When the impulse nozzle will be dismantled, there is always the danger that the product will flow

out of the silo. As far as possible, empty the silo before replacing a nozzle. Never dismantle the

impulse nozzle when product has just been filled or with a fluidised product. Switch off all fluidi-

sation devices, make the tank pressure-less and wait for the product to get vented of air. Always

wear safety glasses. With irritating, poisonous or corrosive products, wear protective clothing wi-

thout fail (eyewear, mask, etc.).

Before starting, shut off the compressed air supply and vent the feed pipe.

Disassembly:

a) Loosen and remove the solenoid valve plug.

b) Open the pipe union between Pulsor and valve. Detach the valve from the Pulsor and carefully hang valve

with hose aside.

c) Loosen the union nuts of the assembly union. Loosen the conical pipe union with light blows (rubber ham-

mer) and pull out the Pulsor with the impulse nozzle.

!

!

!