Table of Contents

105460 - Ed 02

iii

Table of Contents

■Safety Procedures and Precautions.............................................................1

■Chapter One: General Information...........................................................3

■Introduction................................................................................................................. 3

■How This Manual is Organized .................................................................................... 4

■Customer Support ....................................................................................................... 4

■Chapter Two: Installation .........................................................................5

■How To Unpack The Transducer .................................................................................. 5

•Unpacking Checklist ................................................................................................ 5

■Alcatel Companion Products ........................................................................................ 6

■Fittings........................................................................................................................8

■Setup .......................................................................................................................... 9

•Dimensions ........................................................................................................... 10

•Electrical Installation .............................................................................................. 10

•Interface Cables .................................................................................................... 12

•Checking the Transducer Zero................................................................................ 13

■Chapter Three: Overview .......................................................................15

■General .................................................................................................................... 15

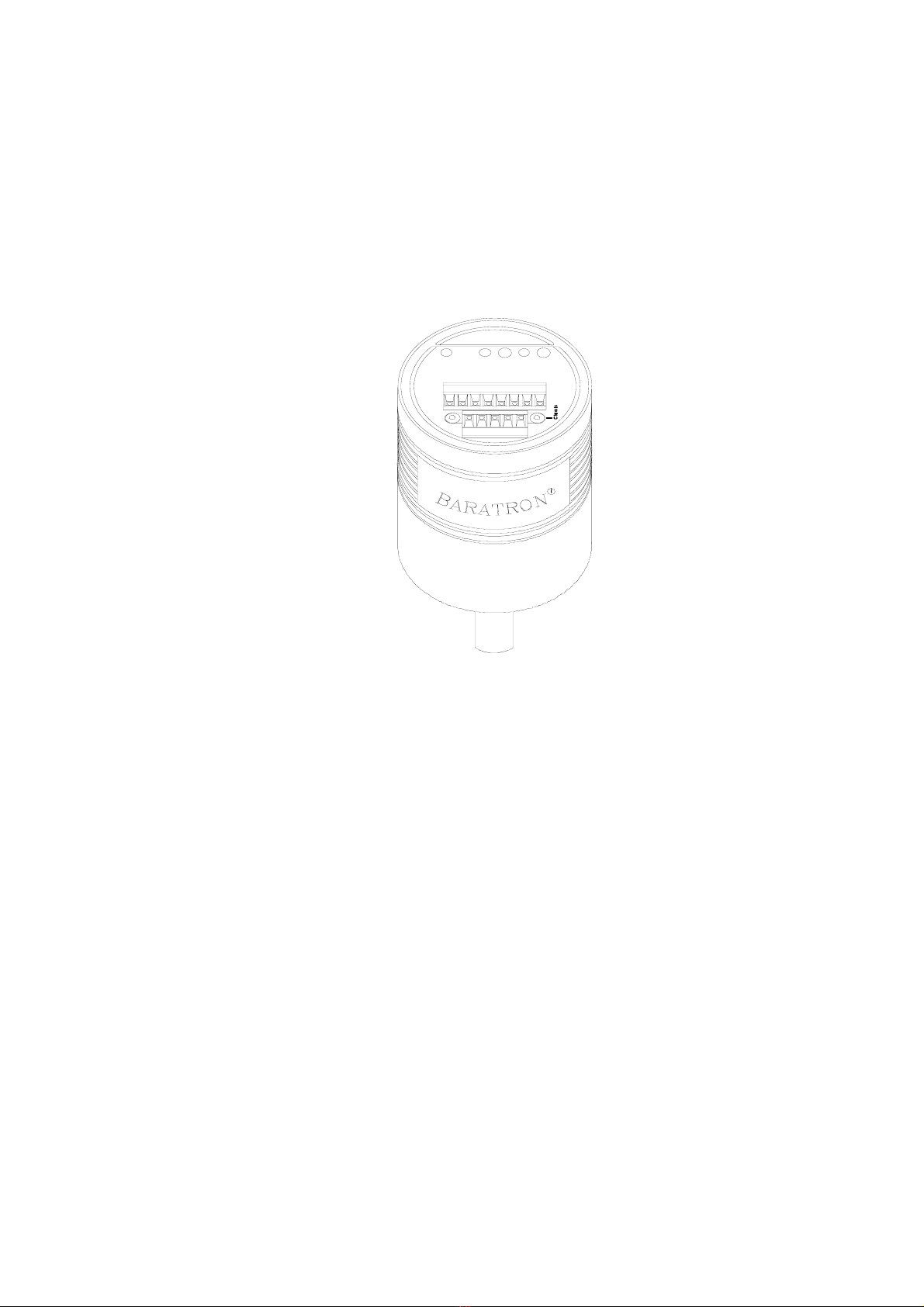

■Sensor ...................................................................................................................... 15

■Signal Conditioner/Electronics.................................................................................... 16

■The Endcap............................................................................................................... 16

■Chapter Four: Operation .......................................................................17

■General .................................................................................................................... 17

•Lowest Suggested Pressure Available for Reading .................................................... 17

•Lowest Suggested Pressure to Use for Control ......................................................... 17

■How To Set the Trip Points ......................................................................................... 19

■How To Adjust the Trip Point Direction ........................................................................ 21

■How To Adjust the Trip Point Hysteresis....................................................................... 25

■Chapter Five: Maintenance and Troubleshooting .....................................29

■General .................................................................................................................... 29

■Zero Adjustment........................................................................................................ 29

■Troubleshooting Chart............................................................................................... 31

■Appendix A: Product Specifications .........................................................33

■ALCATEL Type 623A.................................................................................................. 33

■ALCATEL Type 624A.................................................................................................. 34

■ALCATEL Type 625A.................................................................................................. 35

■Appendix B: CE Declaration of Conformity ...............................................37