Observe the echosounder’s performance and compare it to the

baseline. Look for a stable depth reading that is similar to the

baseline. Compare the thickness and intensity of the bottom trace.

If the performance is close to the baseline, this is a good mounting

location. Remember, some energy is lost transmitting through the

hull. If the test reading differs markedly from the baseline, you will

need to find another location to install the transducer.

Note

: If there is no reading or it is erratic, the transducer may be

positioned over coring which is absorbing the acoustic energy.

Choose another location. If no other location is available, check

with the boat manufacturer to be certain coring is present.

Installation

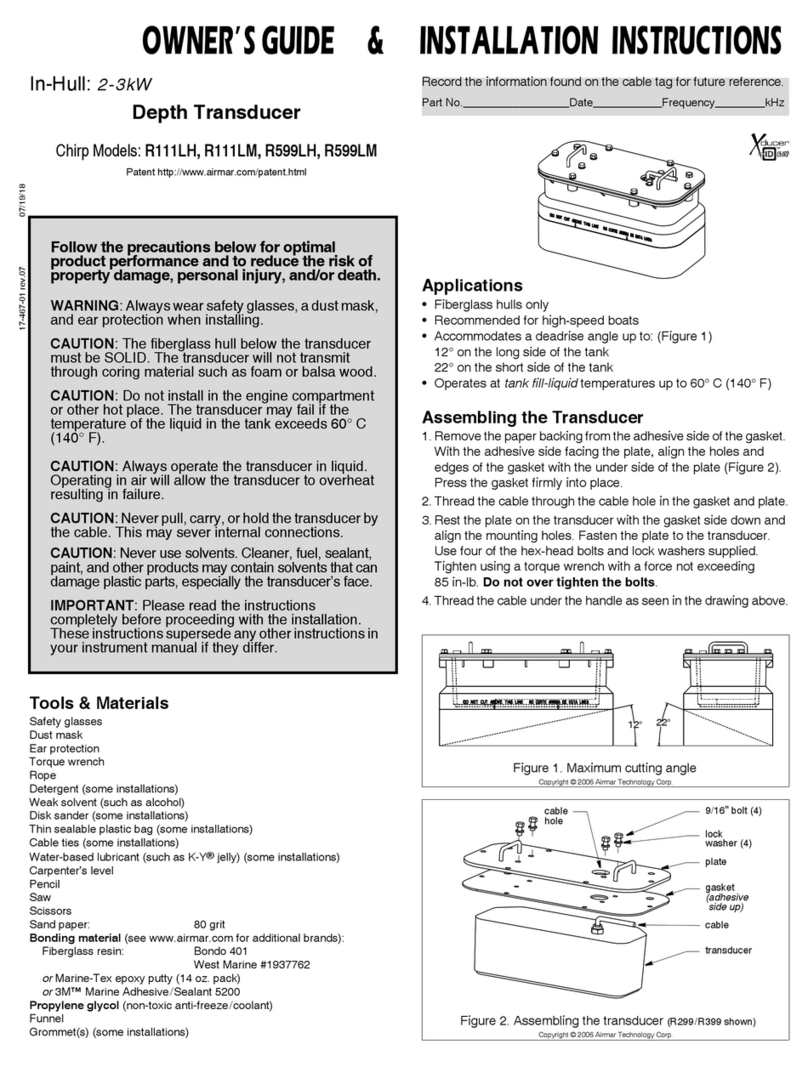

Marking & Cutting

Caution

: For optimal performance, the transducer must be installed

so the beam will be aimed straight down. This is accomplished by

cutting the tank to match the deadrise angle of the hull.

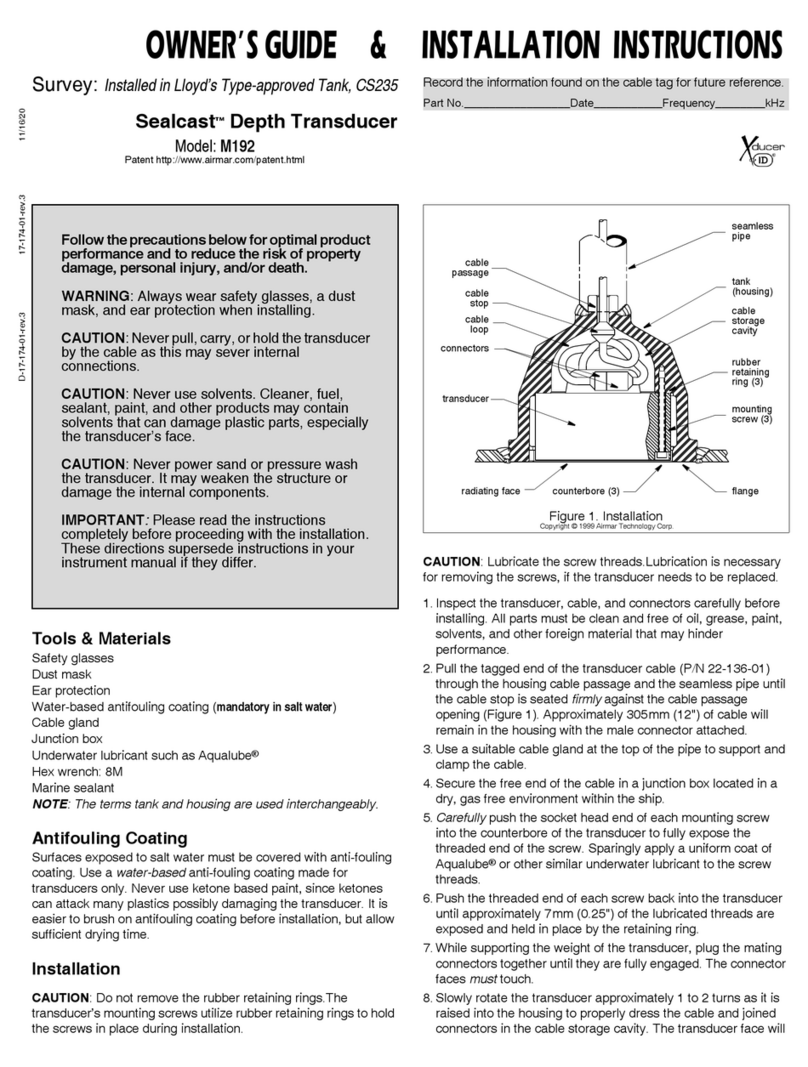

1. The tank can be disassembled for installation in tight places.

Do not disassemble the tank unless it is necessary

. If the tank

will be installed as one unit, lightly tighten the socket-head cap

screws that hold the two halves of the tank together using the

Allen wrench supplied (see Figure 1). (Use a blade screwdriver to

remove the Allen wrench from the handle of the transducer. After

use, replace the Allen wrench in the recess.)

2. When you are satisfied that the selected mounting location is

optimal, place the tank

up-side-down

on the hull (see Figure 5).

The tank can be placed with either a short side or a long side

parallel to the centerline of the boat.

Caution

: Do not mark or cut the tank in the space labeled

“Do not cut above this line.”

3. Holding a carpenter’s level even with the

lower

corner of one of

the sides to be cut, draw a

level

line on the tank. Repeat this

process on the opposite side of the tank.

Connect the two

lines to form the SHORTEST side of the tank.

Be sure the

lines are level

. They will be the cutting guidelines.

Warning

: Always wear safety goggles and a dust mask.

4. Before cutting the tank,

be sure the TALLEST side will be

closest to the centerline (keel) of the boat after the tank is

installed

. And

be sure

to observe the “Do not cut above this

line.” Using a saw, cut the three sides of the tank along the

guidelines drawn. It may be necessary to further shape the tank

to the hull to ensure a liquid tight bond.

5. The tank is provided with a cork liner to reduce sound echoes.

After the tank has been cut, wrap the cork liner around the

inside

of the tank (see Figure 6). Butt the sides of the liner along

the center of the tallest side.

Note: There may be a gap

between the edges which will not affect performance.

Push the

cork liner up against the step on the inside of the tank. Trace the

bottom edge of the tank onto the liner.

6. Remove the cork liner from the tank. Use scissors to cut the

liner along the line drawn.

Bonding the Tank

Warning

: Always wear safety goggles and a dust mask.

1. To ensure a tight bond, the hull under and around the tank

must

be smooth and free of paint or any other finish

. If the surface is

rough, use a disk sander to smooth an area slightly larger than

the tank. Remove any dust, grease, or oil from the hull surface

with a weak solvent, such as alcohol. Dry the effected area.

2. Use 80 grit sand paper to sand the outside and inside of the tank

up 50mm (2") above the bottom edge. Remove the dust with a

weak solvent, such as alcohol. Dry the effected area.

Caution

: The tank must be liquid-tight

.

3. Use an approved bonding material (see Tools & Materials on

page 1). Glass the tank to the hull with fiberglass resin, using

standard fiberglass technique. Alternatively, apply a generous

bead of marine putty/sealant to the bottom edge of the tank

following the manufacturer’s instructions (see Figure 7). Press

the tank firmly in place. Apply a second bead around the inside of

the tank. And apply a third bead around the outside of the tank.

4. Allow the bonding material to cure. The seal

must

be liquid-tight.

3

Figure 5. Marking the cutting guidelines

(30º deadrise angle shown)

top

hull

carpenter’s

level

draw a level line

Do not mark

below this line

Copyright © 2006, 2007 Airmar Technology Corp.

even with the

Figure 6. Fitting the cork liner

(30º angle shown)

trace bottom

edge of tank

onto cork liner

gap

Copyright © 2006 Airmar Technology Corp.

Figure 7. Bonding the tank

fiberglass

hull

in place

or

apply

three beads

of marine

after bonding

putty/sealant

Copyright © 2006, 2007 Airmar Technology Corp.

material cures,

insert cork liner

lower corner of

opposite sides

of tank