Certication and declaration

The i-trap 120E WP complies with the EU-directive on machine safety.

The unit and spare part components are all in full compliance with the CE directive and

the WEEE / RoHS directives. The EC declaration of conformity is listed below:

CE declaration of conformity.

We, Alcochem Hygiene,

Declare, under our responsibility, that the i-trap 120E WP insect control unit

complies with the following European standards:

* EN 60335-1 Safety of household and similar electrical equipment.

Part 1: General requirements.

* EN 60335-2/59 Safety of household and similar electrical appliances.

Part 2: Particular requirements for insect killers.

* EN 55014 Limits and methods of measurement of radio disturbance characteristics

of electrical motor-operated and thermal appliances for household and similar

purposes, electrical tools and similar electric apparatus.

* EN 61000-4-5 Surge immunity requirements (1.2/50 µs and 70/100 µs surge)

* EN 61000-3-2 Electromagnetic compatibility (EMC) Part 3: Limits Section 2:

Limits for harmonic current emissions (equipment input current <16 A per phase)

(IEC 1000-3-2:1995)

* DIN 40050 - IP classication for the units. WP units are executed in an IPX5 execution

* EN 2015/863/EU Restriction of hazardous substances

All according to the denition of the Low Voltage Directive 73/23/EEC, the EMC Directive

2014/30/EU, the RoHS Directive 2015/863/EU and the 2012/19/EU /WEEE Directive

Attention

•indoor use only

•recycle lamps

For questions:

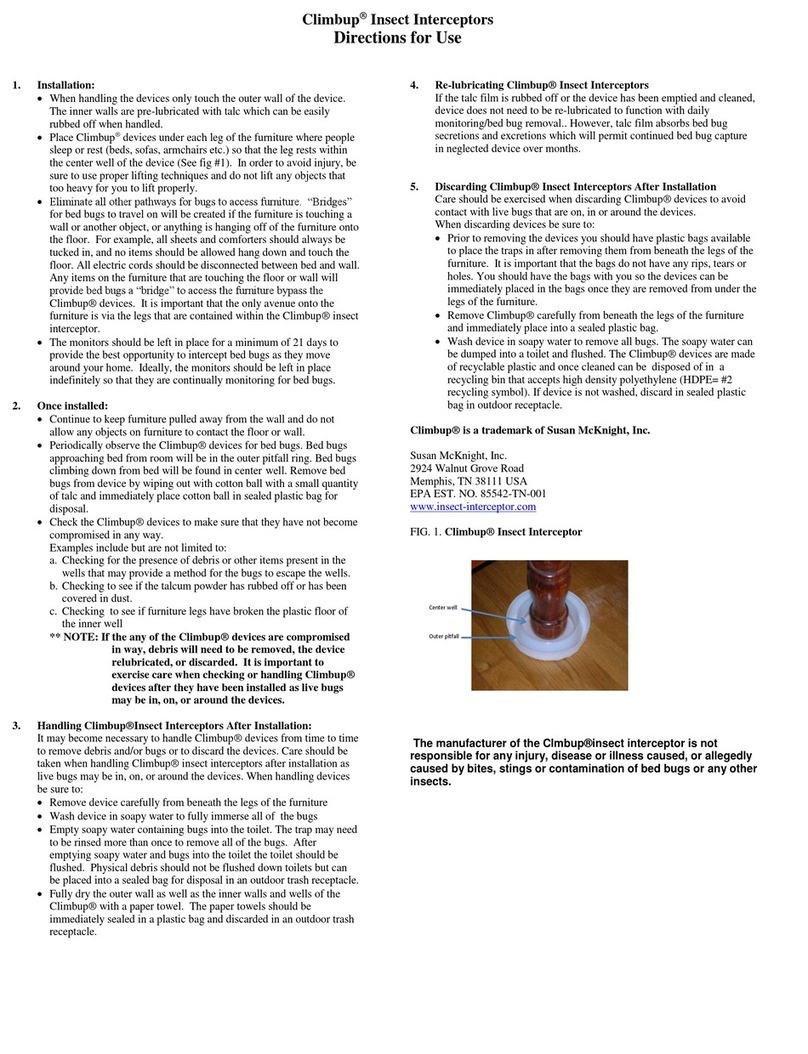

Exploded view

Descriptions of exploded view parts see section

Pos. Description

1 Cover housing

2 Glue board

3 Housing

4 Electronic Ballast

Pos. Description

5 UV-A Lamps

6 Lamp holders IP X5

7 Main plug

8 Bottom housing to

change glue board

Spare parts list

Pos. Description

2 Glue board

5 4x 15 watt UV-A shatterproof

Article number of assembled unit: 2.05.0060

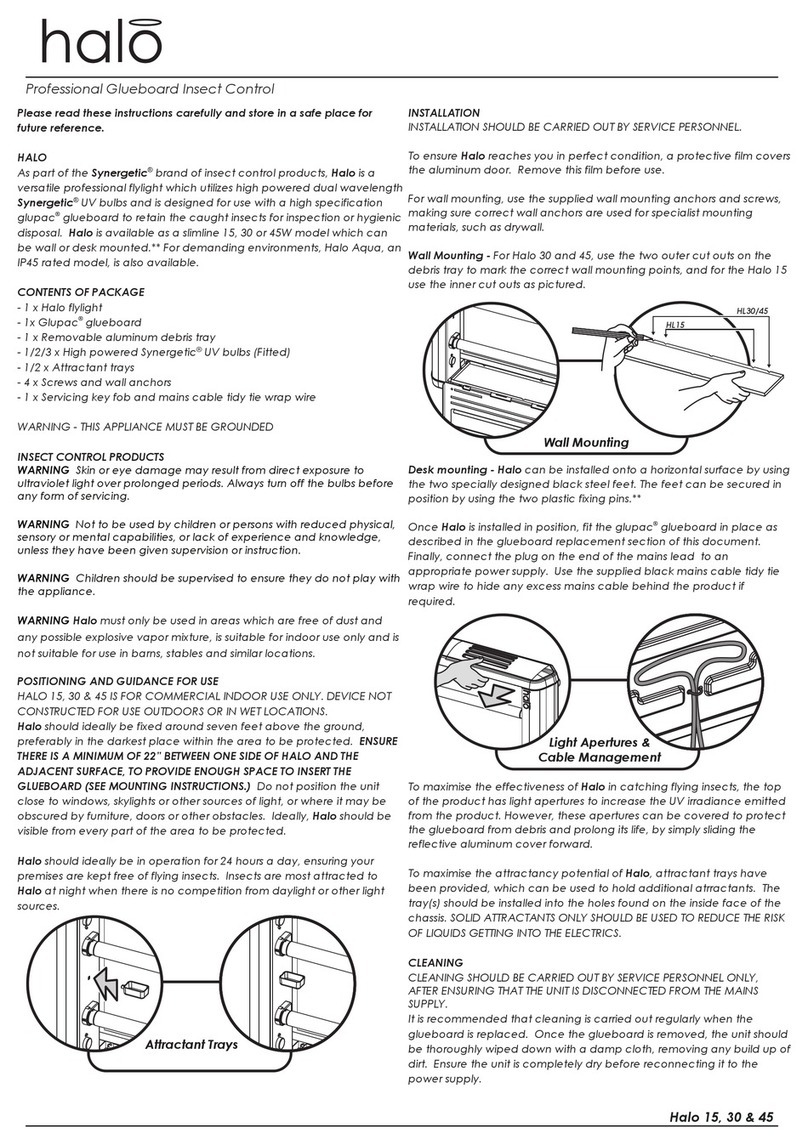

Installation

To achieve maximum eectiveness, the following installation notes must be followed:

• Choose a place where the unit can be reached and cleaned, that is at least 1.2 m

o the ground and out of the reach of children

• Avoid areas where obstacles will limit the ability of insects to reach the unit.

• Avoid air currents from fans or air-conditioners, and avoid direct sunlight.

• Use good quality mounting materials.

• Use a safe mains connector with earth pin.

Note: insect control unit should never be placed directly above uncovered food!!

Maintenance/Replacement

The i-trap 120E WP insect trap requires little maintenance other than cleaning,

and replacing the glueboard and lamp.

1) Cleaning

a) Disconnect the unit from the mains.

b) Remove dead insects from the collection tray.

c) Wipe the collection tray and casing clean with a damp cloth or one moistened

with methylated spirits.

2) Changing the Glueboard [C]

a) The glueboard can be replaced once the collection tray has been removed

b) Remove the old glueboard and insert a new glueboard.

The protective sheet must be removed before the new glueboard

is inserted in the unit.

c) Put the collection tray back in position.

3) Lamp replacement [E]

We recommend replacing the Philips UV-A lamps once every year

before the main insect season starts:

The Philips Long-life UV-A lamp should in any case be replaced after 9000 burning hours.

a) Disconnect the unit from the mains power.

b) Remove the collection tray

c) Remove the front grid from the unit by clicking it out of its slotted position

d) Take the lamp(s) from the lamp holder and remove the lamp(s).

e) Place a new lamp(s) in the lamp holder.

f) Mount all replacement parts in reverse sequence.

Note:

When replacing the lamp use components of the same specications.

Only use genuine lamps and spare-parts supplied by Alcochem for service and maintenance.