SER 7345 High-Capacity Reel

Revision (10-12) 4 Alemite LLC

CAUTION

The base of the reel must be at a height no greater than

16 feet (4.9 m) from the floor to comply with the warranty.

This reduces torque load on the Power Spring

Assembly and eliminates the tendency of the

hose to stack on one side of the Sheave.

8. Rotate the Sheave Assembly (10) to coil the delivery hose

onto it.

9. Install a control valve onto the delivery hose.

10. Pressurize the system.

• Check for leaks.

11. Install and secure the Hose Stop (46) to the delivery hose at

the desired position.

Spring Tension

12. Check to ensure the tension on the power spring is

sufficient to properly hold the hose stop against the hose

guide.

Should the power spring tension require adjustment:

CAUTION

Do not overwind the power spring. Too much tension

reduces the life of the spring.

When the hose is fully extended from the reel, the

power spring should be a minimum of 1/2 turn from a

fully wound condition.

13. Release all pressure within the system.

14. Remove the control valve and the hose stop from the

delivery hose.

15. Pull the free end of the delivery hose through the guide.

16. Rotate the Sheave Assembly in the required direction.

17. Install the control valve and the hose stop.

18. Pressurize the system.

19. Check to ensure the tension on the power spring is

sufficient to properly hold the hose stop against the hose

guide.

20. Repeat steps 13 - 20 until the proper tension is achieved.

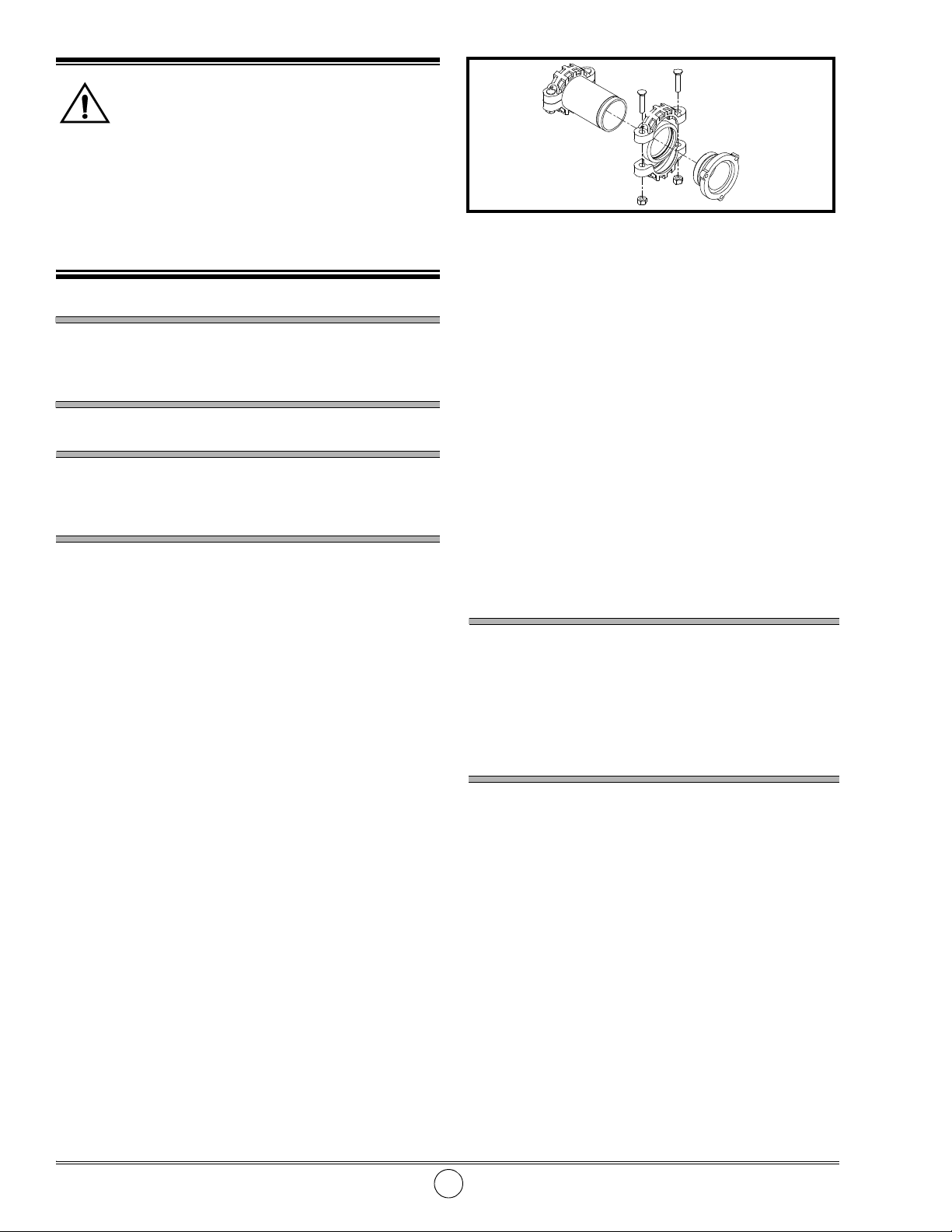

Figure 3 Victaulic Connection

Installation

WARNING

Release all pressure within the system prior to

performing any overhaul procedure. Personal injury can

occur.

Do not attempt to disassemble the Power Spring Assem-

bly. Personal injury can occur.

Read each step of the instructions carefully. Make sure a

proper understanding is achieved before proceeding.

Inlet Connection

CAUTION

Never connect rigid piping to the Swivel assembly. Dam-

age to components can occur.

Threaded

1. Screw a connecting hose (with thread sealant) into Inlet

Adaptor (23).

2. Attach the connecting hose to the supply line.

Victaulic

NOTE: Victaulic - Type swivel joint inlet connec-

tions must be carefully aligned. Two victaulic con-

nections, correctly installed, allow adequate

flexibility for smooth rotation.

1. Attach victaulic coupling to Inlet Adaptor (23) and supply

line.

2. Adjust supply line to verify flexibility exists for proper

alignment.

NOTE: Failure to use flexible connector with any

live reel will void warranty.

3. Lubricate Ring Seal (24) with NLGI2 lithium grease.

4. Insert Ring Seal into Inlet Adaptor.

5. Attach Inlet Adaptor to Bearing Housing Assembly (20) using

three Screws (22).

6. Feed the inlet end of delivery hose through the guide

assembly.

7. Connect the delivery hose (with thread sealant) to the outlet

riser.

HINT: Orient the hose to allow its natural curve to

match the Sheave.

Delivery Hose