The 212 class has become increasingly popular since its release, this is true for the original boat as well as the miniaturised

model.

This new ENGEL submarine offers besides radial parting with bayonet lock ring and Tech Rack© very compact dimensions

and easy handling. Hull, sail and all other attaching parts are highly detailed. The Tech Rack© slides into the front part of the

hull offering easy access to most of the boat's internal components.

Building is straight forward and quite simple as all parts are prefabricated . Hull, bayonet lock rings, control planes and hull

attachments are cast in resin and require little to no adjustment. The Tech Rack© is constructed of sturdy CNC-machined,

interlocking parts, reinforced with ready-made brass bars. Piston Tank included features AutoStop, meaning that the piston

drive will automatically stop at an instant as soon as the tank is completely filled or emptied. Piston Tank and electronic switch

unit CTS are both fully built forming a compact unit without extensive and frail wiring.

Hull unit, bayonet lock ring, control planes and main bulk head are all cast in resin. Except for the control planes, all other

resin cast parts should be glued with a slower setting two-component adhesive such as 1-Hour Epoxy (item no. 9507).

Consistency of adhesive can be adjusted by adding a filling agent such as Micro Balloons (item no. 9567). This combinati-

on will set after about 1 hour. Full adhesive strength will be reached after 12-24 hours.

Less demanded joints can be glued with Cyano (also called CA or Superglue). Abottle of high, medium and low viscosity CA

is available as set (item no. 960246). All surfaces to be bonded must be thoroughly cleaned with white spirit or thinner.

Dive Set with Piston Tank and CompactTankSwitch CTS

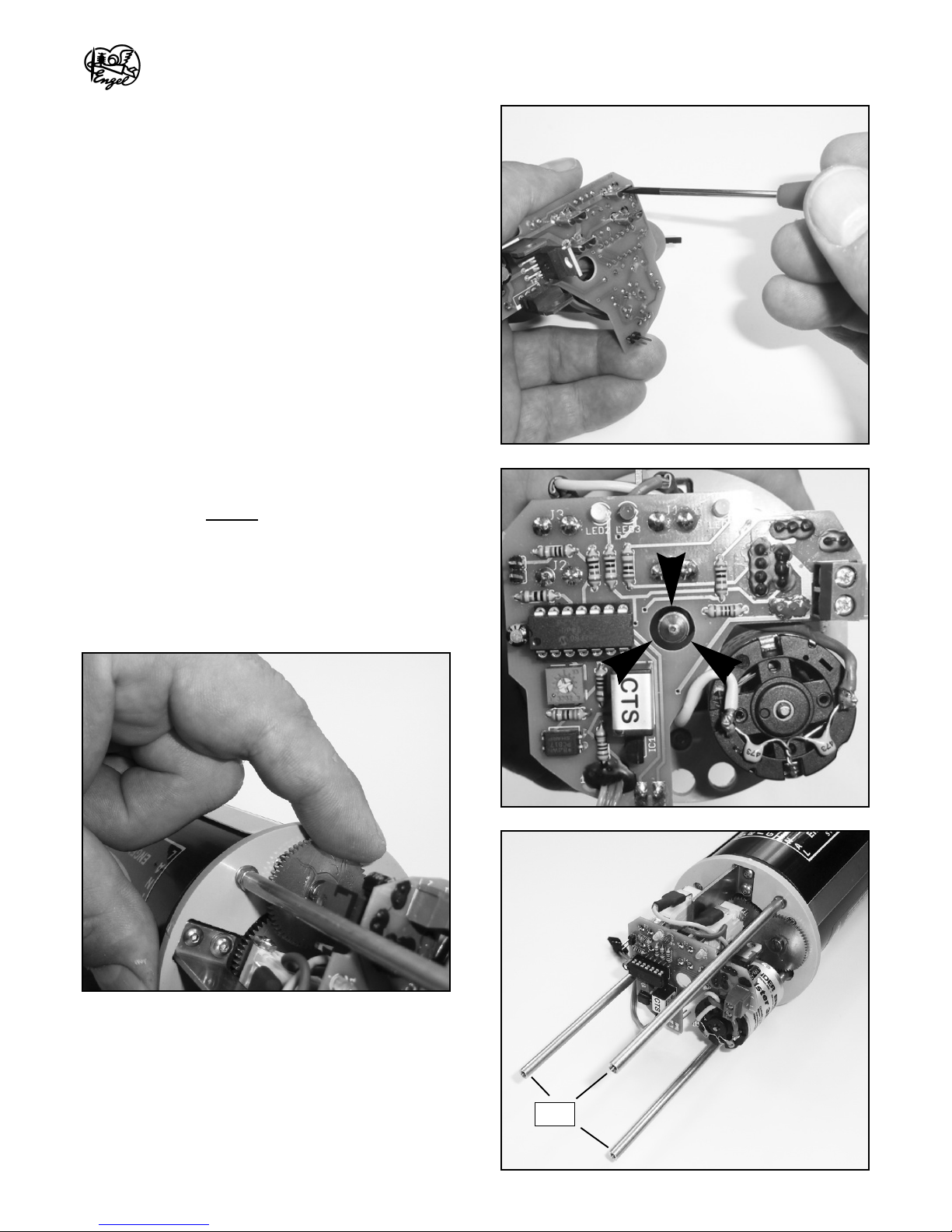

The 212 is equipped with a Piston Tank type EA500-123 in 12 Volt featuring AutoStop. This ensures that the piston drive will

automatically stop at an instant as soon as the cylinder is fully filled or empty.

CompactTankSwitch CTS and Piston Tank form a compact unit. The CTS can be operated via a control stick or a 3-position

switch (on-off-on) on the transmitter.

The CTS is fitted with high amp PROFETs offering excessive power reserves. The CTS can easily cope with a stalled Piston

Tank motor for several minutes without any damage.

This compact unit offers all necessary fail-safe features such as

• Low Battery Monitor

• Loss of Transmitter Signal

• Optional Automatic Resurfacing if model dives below approx. 1.8 m

If voltage drops below a preset value (factory setting approx. 9V for 12V operation) the Piston Tank is automatically switched

to empty. This so-called threshold voltage can be adjusted via the potentiometer on board of the CTS. However, a regulated

power supply is recommended to achieve an exact setting. Turning the screw of the potentiometer (slowly!) in clockwise

direction will increase threshold voltage, turned anti-clockwise will decrease this value.

With battery voltage already lower than threshold value when system is powered up will lead to deactivation of this safety

device. This mode is indicated by the red LED flashing. However, the CTS will be in service despite low voltage. This mode

will prove helpful for verifying correct direction of flow of the Piston Tank.

If the receiver signal is lost - due to increased depth or other circumstances - the CTS will also switch to "blow" (empty) the

Tank.

With the Pressure Switch connected, maximum depth is limited to approx. 1.8 meters (6 ft). If the model dives below this

level, the CTS will automatically switch to the "resurface" and empty the Piston Tank. The model will then resurface unless

the switch is set back to its upper position. Otherwise, with the switch left at "submerge" the model will emerge to a depth

above 1.8 meters after which the Tank will start filling again (and so on). Furthermore, the Pressure Switch acts as a second

safety device. Should the over pressure which builds-up within the hull while submerging (by filling the Tank) be lost due to

a leakage, the "submerge mode" will be terminated. In this case, the red LED blinks steadily, and the system does not allow

the model to dive again until this has been corrected.

Functional Principle of Conning Tower Mechanism (optional, item no. 1599-1)

This mechanism drives periscopes, radar, snorkel and antennas in- and outwards of the conning tower.

When the model submerges, i. e. Piston Tank is filling, the pressure within the model increases. At about 80% filling volume

the pressure within the boat activates piston movement in a cylinder built into the mechanism. This movement moves a slide

into the conning tower on which the devices are mounted.

Copyright ©2011 ALEXANDER ENGEL KG

212

Item No. 1599

3