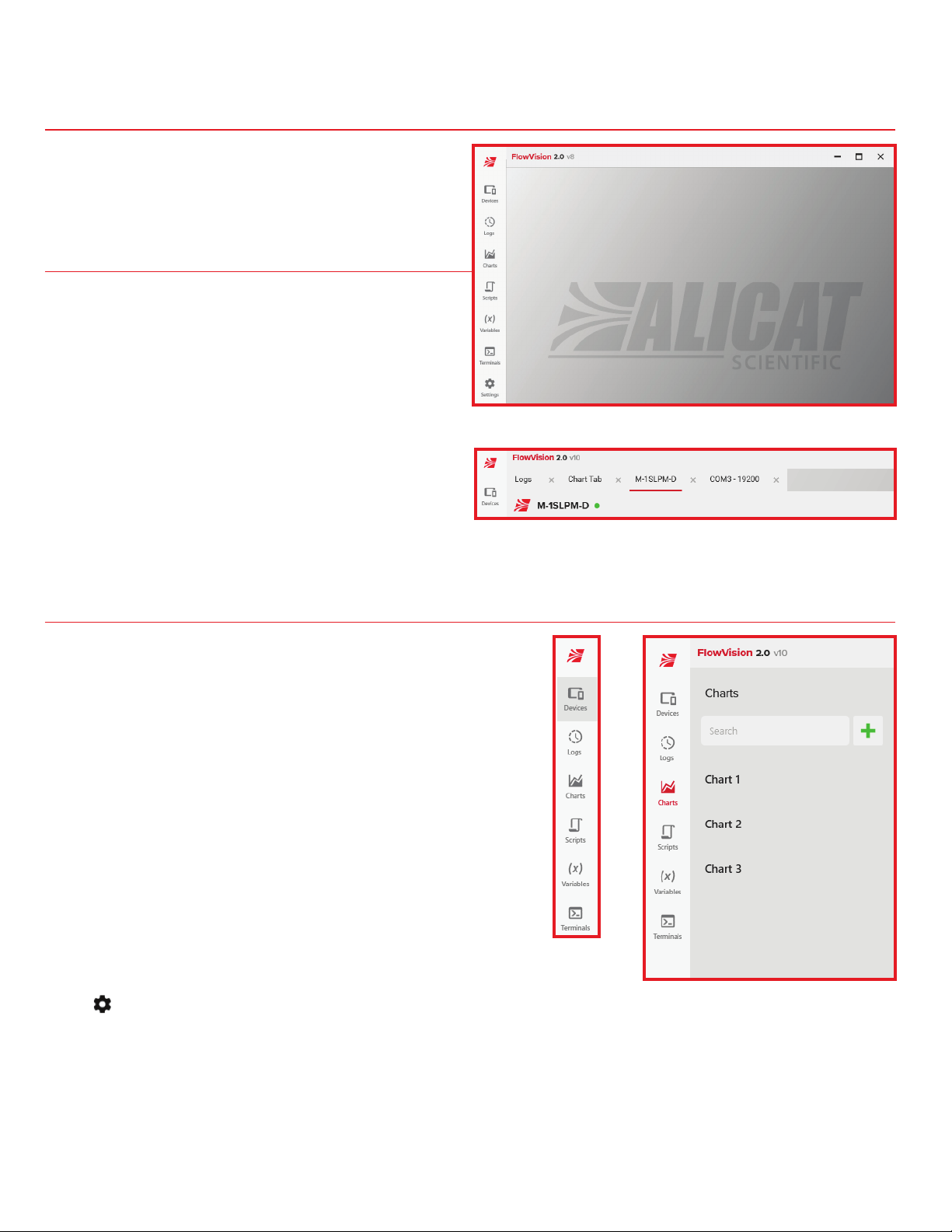

Devices September, 2022 • Rev. 2 • FlowVision 2.0™ user manual 9

Devices Tab

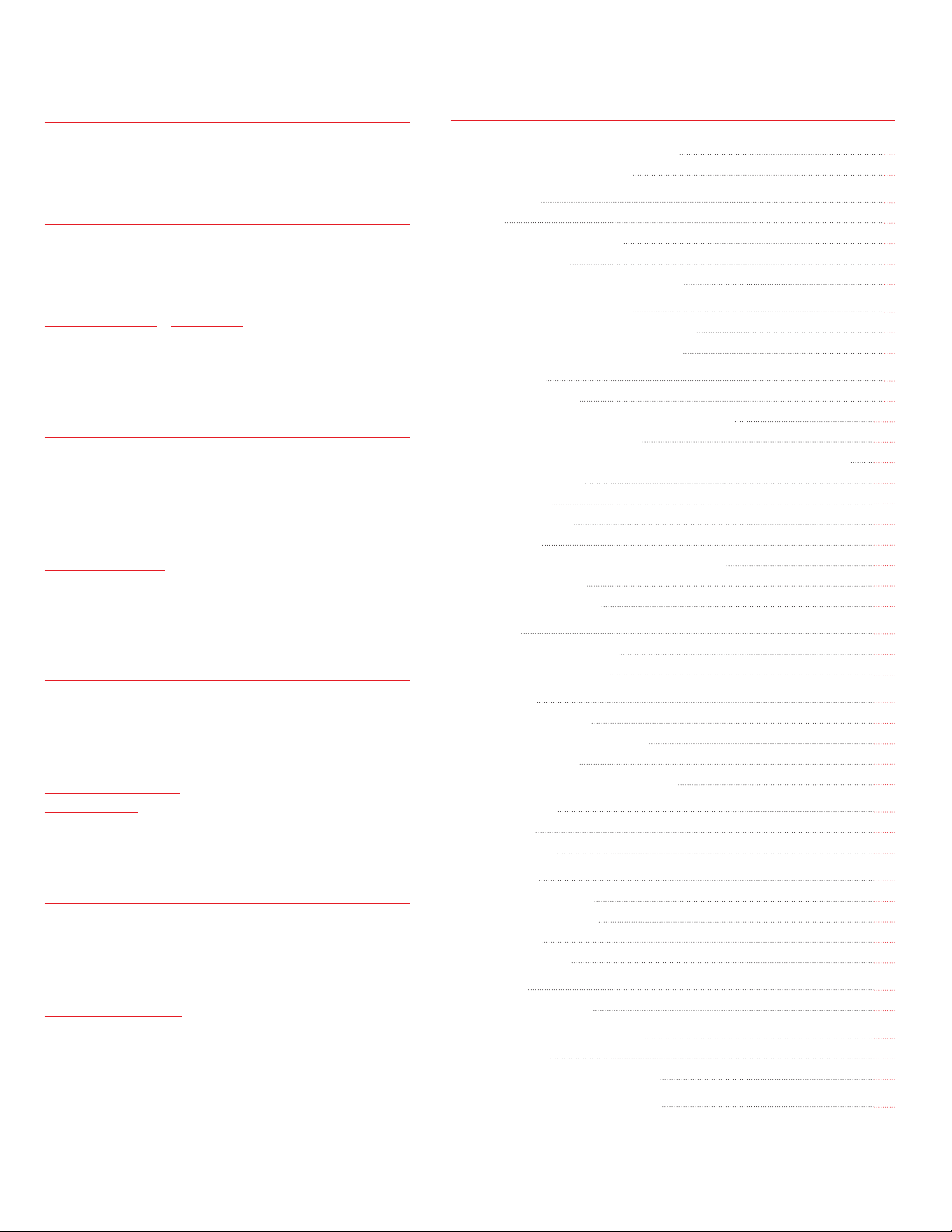

See Figure 10

Open the device tab by clicking a device’s name in the

Devices module saved items.

• The colored circle to the right of the

device name is the status indicator.

• The indicator is green if the device

is communicating properly.

• The indicator is red if the device is in

error or not communicating.

• Below the device name is a row of buttons. This

is referred to as the device actions panel.

• These are items like reset totalizer, lock screen,

refresh, and more depending on the device.

• The left side has buttons and fields that

you can use to control the device.

• Depending on the device, this can include items

like setpoint, gas selection, batch, and more.

• The right side of the tab shows live measurements

from the device (updated every 150ms by default).

• To obtain information on the device (Model, serial

number, firmware version, and full scale range), click

the information button in the top right hand of the tab

(figure 11).

Device Actions

Just beneath the device name are the device actions. These

are quick functions that perform simple tasks on the device

or in the tab. Not all actions are available on all devices.

Reset the Totalizer

Devices that have an enabled totalizer can track the total

mass and volume that flows through the device. When this is

the case, the Reset Totalizer button appears in the device

actions panel.

• Reset the totalizer by clicking Reset Totalizer. The

value resets immediately, without confirmation.

• This will also resets the amount that’s

been batched, starting a new batch if it

has been completed (page 10).

Lock/Unlock the Screen

If your Alicat device is equipped with a screen, it can be

locked and unlocked using FlowVision 2.0™. The Lock

Screen option is located in the device actions panel near

the Reset Totalizer and Refresh buttons.

• Lock/Unlock the screen by toggling Lock

Screen. The icon has a check mark in the bottom

right when the device’s screen is locked.

Refresh Device

The refresh button manually polls the device and updates

the live measurements.

Tare Function

The tare function sets the zero flow reading on a meter or

gauge and is not present on controllers. Tare the meter by

clicking the Tare button. Taring occurs immediately, with no

confirmation. Controllers use the auto-tare function found

in the device settings (page 12).

! Note: The tare function is discussed in detail

in the instruction manual for your device.

▲Warning: Tare flow only when there is no

flow through the unit. Tare pressure only

when the device is venting to atmosphere.

Duplicate

The Duplicate button creates a second tab for the device

and adds it to the tabs group.

Figure 10. Device tab.

Figure 11. Device information.