2021.05.26 REV. LIQUID FLOW METER OPERATING MANUAL 3

Introduction

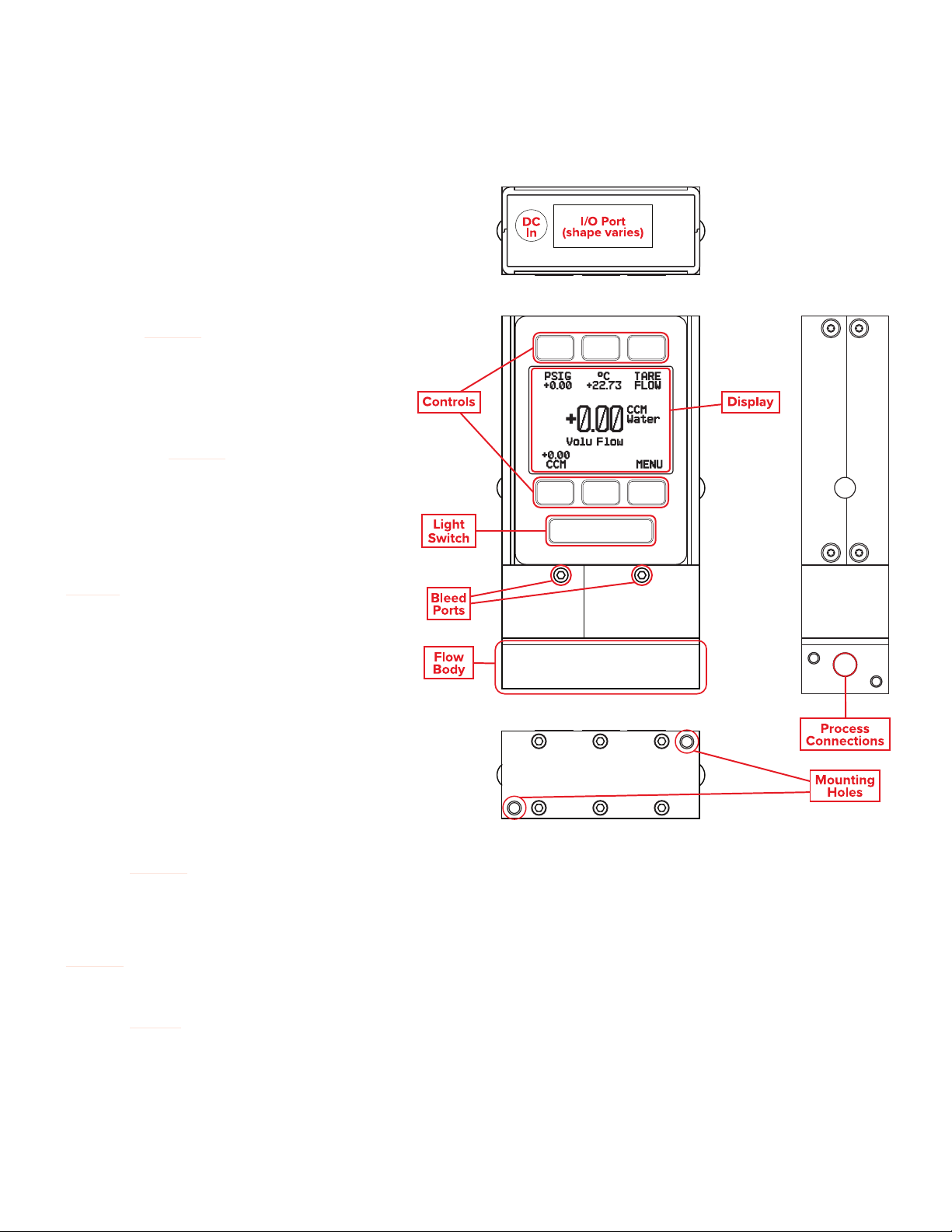

Your new flow meter has a variety of innovative features:

• 1000 readings per second guarantees high resolution

data, page 9.

•

Monitor live pressure and temperature during flow

measurement, page 10.

•

Backlit display with adjustable contrast is easy to read

even in direct sunlight. In dimly lit areas, press the logo

to turn on the backlight, page 13.

•

Connection to a computer for control and data logging

to capture all pressure data for logging and analysis,

page 14.

This manual covers the following instruments:

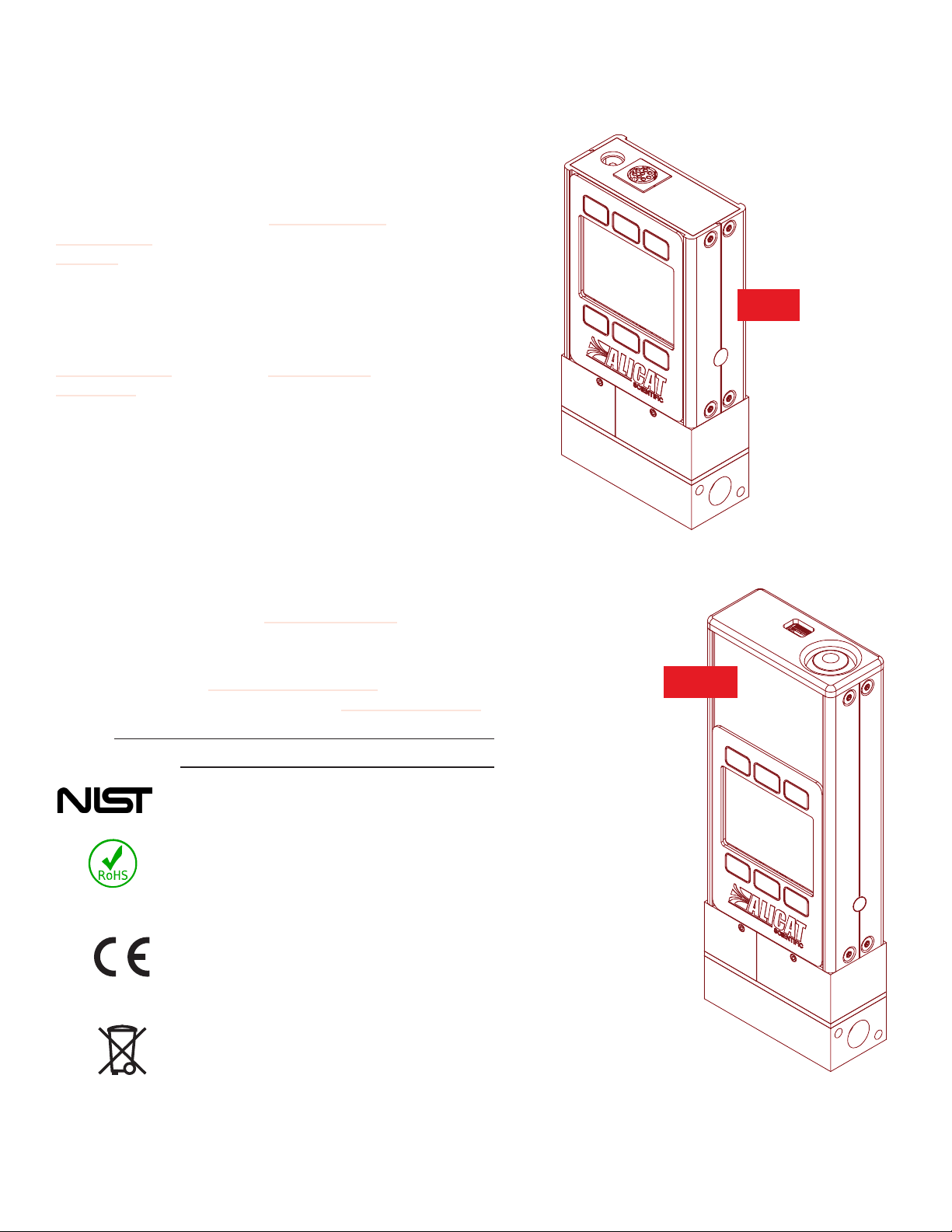

• L-Series: liquid flow meters

• LB-Series: portable liquid flow meters

• LS-Series: anti-corrosive liquid flow meters

• LBS-Series: portable anti-corrosive flow meters

Using Laminar Liquid Flow Devices

THE DEVICE IS ONLY CONFIGURED FOR ONE

TYPE OF LIQUID, AND WILL ONLY FUNCTION

PROPERLY WHEN USING THAT ONE LIQUID.

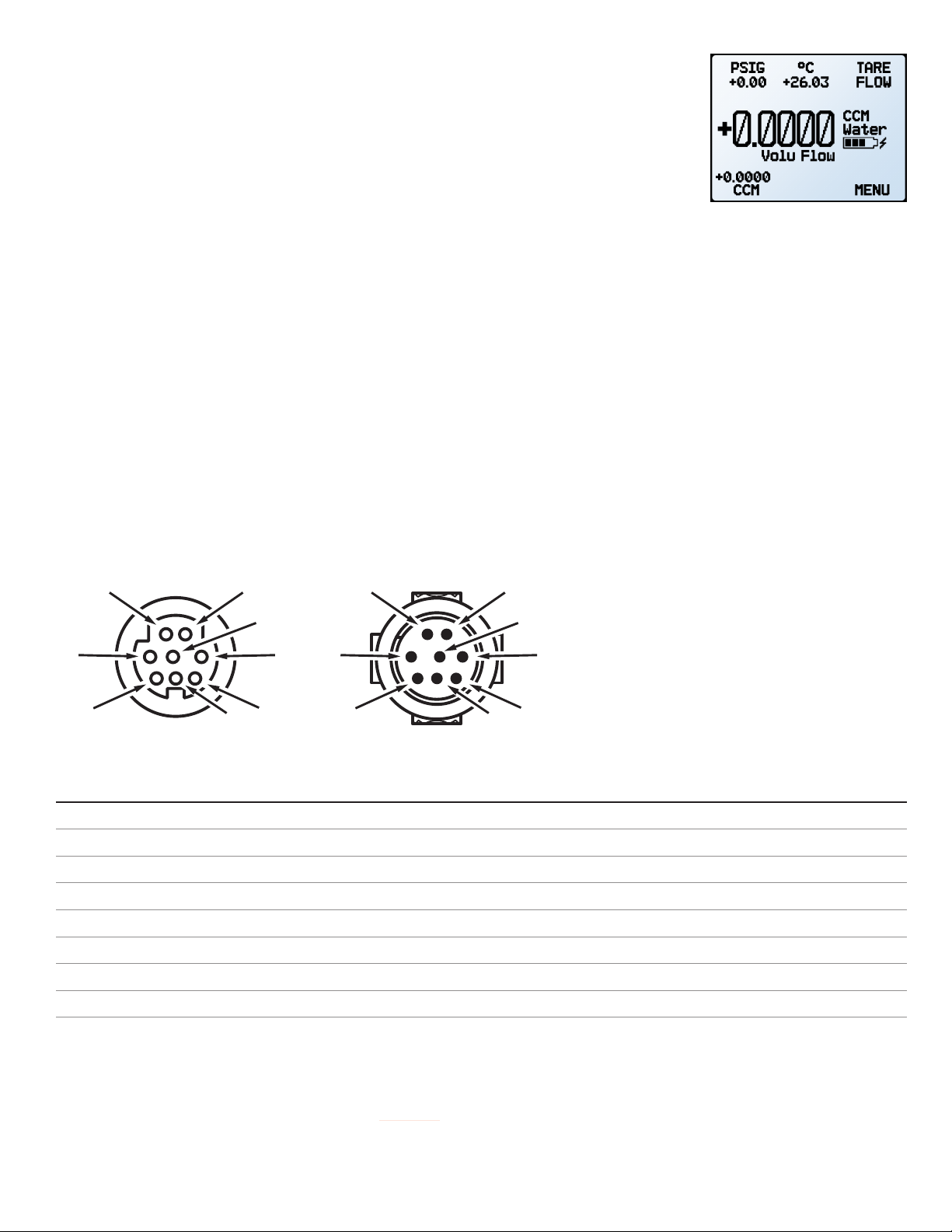

By default, liquid devices are configured only for use with

pure water, such as distilled, de-ionized, Type I (Ultrapure),

Type II, and Type III. If a device is used for any liquid other

than the liquid it was specifically engineered for, readings

will be incorrect

Minimize contaminants and liquid variations. For water

devices, DO NOT use tap water or water with any biological

components, minerals, or oils. Any of these substances

will aect the viscosity of the liquid, leading to inaccurate

flow measurements. More importantly, these impurities

will quickly build up in the laminar flow zone, cause

corrosion, and degrade the measurement accuracy

of the device.

For support or questions regarding the use or operation

of this device, please contact us using the information

on page 2.

Alicat oers countless combinations of device sizes, acces-

sories, connections, and configurations. These custom

solutions are oered to meet a variety of application chal-

lenges brought forth by users pushing the boundaries of

our standard oerings.

If you have an idea for a new process or a challenging

application, contact Alicat for specialized engineering and

application support.

L-10LPM