ALLCUT HOLE MATIC HoleMatic 31 User manual

THANKS FOR PURCHASING ALLCUT MAGNETIC DRILL MACHINE

Hole Matic

Operating Instructions for

ALLCUT HoleMatic 31/65

General instructions

Machine overview

Safety measures

Before using for the

first time

Preparing

Starting on the machine

Using the machine

Removing blockages

Cleaning

Maintenance

Storage

Technical data

Wiring drawing

Accessories

2

3

4

5

6

7

7

9

9

9

10

10

12

13

GENERAL INSTRUCTIONS

The ALLCUT HoleMatic 31/65 magnetic drilling machine

is uniquely designed to be used for drilling operations

using twist drills and annular cutters on magnetic

metals and reaming within the limits specified in the

technical data.

Any other use of the machine except stated above is

inappropriate.

INTENDED USE

WARNING

Danger resulting from improper use

If the machine is not used as stated above, and if used

in any other way, the machine may become a source of

danger.

Use the machine as described in the operating

manual.

TABLE OF CONTENT

DEAR CUSTOMER,

Please read the instruction regarding the

startup, safety, cleaning, and other details

mentioned in this operating manual. Ignoring

this may cause serious injury to the operator as

well as the machine.

Keep this instruction manual for future use.

The manufacturer is not responsible for

damage of the machine or accident caused due

to not reading this instruction manual properly,

using the machine other than its purpose, third

party repair, modifying the machine without

our consent or using of unauthorized spare

parts, tools and accessories.

Hole Matic 31/652

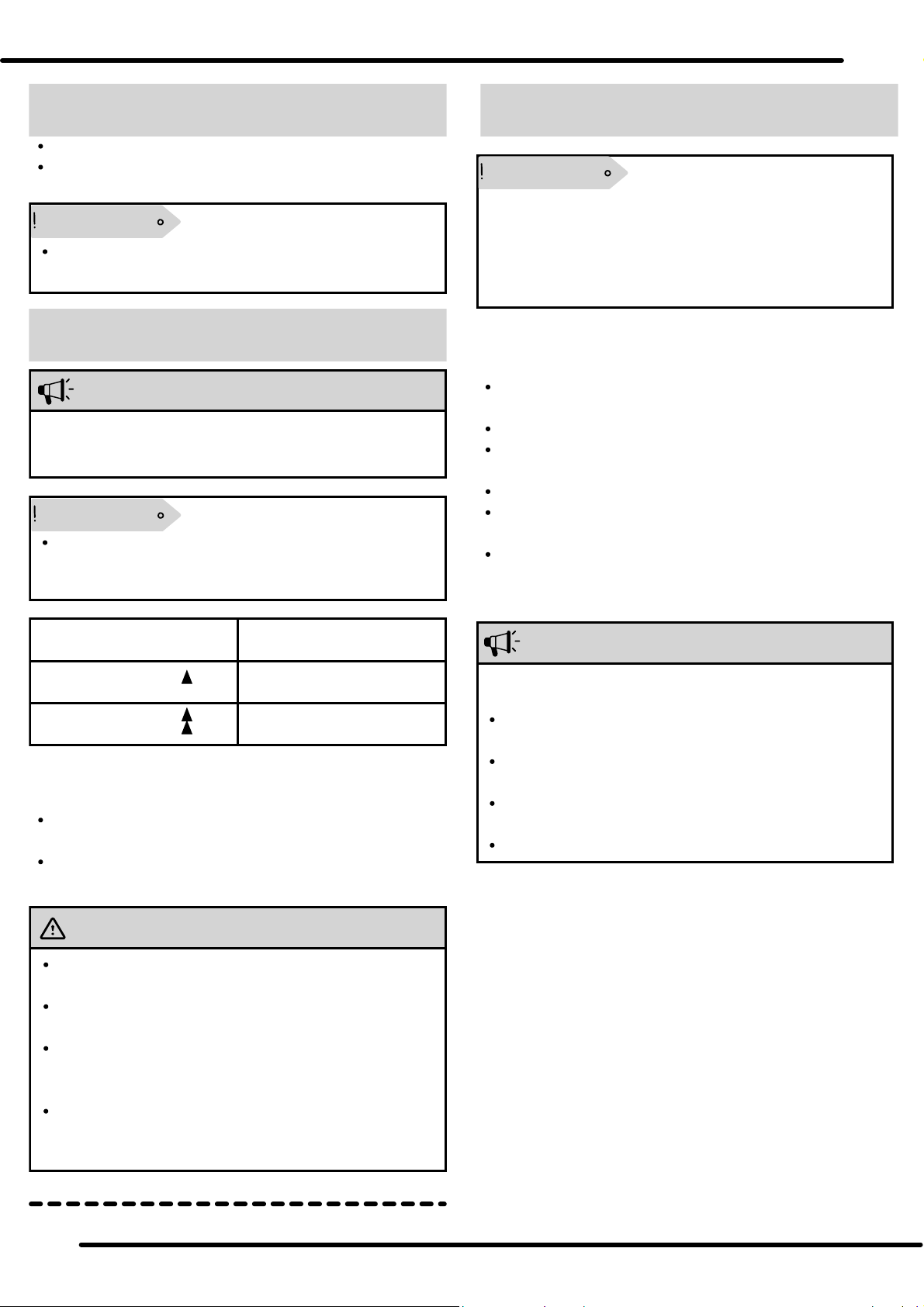

SR. NO.

MACHINE PART

1

MAIN BODY

2

PINION

3

HANDLE

4

PANEL

5

ELECTROMAGNET

6

STEEL WEDGES

7

ANNULAR CUTTER (TCT)

8

CUTTER ADAPTER

9

COOLANT BRACKET

10

SPINDLE WITH MT-3 SHANK

11

OPENING FOR EJECTOR PIN

12

GEAR CHANGER

13

DRILL MOTOR

14

STEEL SLIDE

SR. NO.

PANEL

4.1

MOTOR ON/OFF SWITCH

4.2

FUSE HOLDER

4.3

MAGNET ON/OFF SWITCH

1

2

3

4

5

6

9

11

13

14

4.1

4.2

4.3

MACHINE OVERVIEW

7

8

10

12

3Hole Matic 31/65

NOTE

When using electrical tools, please read and follow the

following precautions to prevent any type of injury, fire or

electric shock.

SAFETY MEASURES

BASIC SAFETY MEASURES

Do not use the machine on or near flammable

environment.

Person with heart diseases or medical conditions should

use the machine under supervision or prevent using the

machine.

Person who is unable to operate the machine safely,

should use it under supervision of a responsible person.

Children are not allowed to use the machine.

Before using the machine, check for any visible damages.

Do not operate a damaged machine.

Before beginning the work, check the condition of the

safety chain and the function of the switches on the

machine.

Repairing of the connecting cables should be performed

by a qualified electrician.

Repairs of the machine should be carried out by an

approved specialist workshop or by the manufacturer.

Unapproved repairs can lead to considerable damage to

the operator.

Repairs to the machine during the guarantee period can

only be performed by the manufacturer, otherwise the

guarantee is invalid.

Damaged parts should be replaced by original spare

parts. This ensures the safety of the machine.

Keep an eye on the machine during the operation.

Store the machine in a dry environment.

Make sure the machine is cleaned and free of metal chips

after every operation .

Do not expose the machine to moisture environment.

Do not exceed the capacity of the machine. Refer to the

technical data for the information.

Keep the machine clean, dry and free of oil and grease.

Make sure the machine and main plug is beyond the

reach of water or any other liquid.

Do not operate the machine with panel or motor

housing opened.

If using extension cable, make sure the extended wire is

of 1.5 mm².

Check the condition of the extension wire regularly and

replace it if damaged.

Danger from electric current!

Contact with live wires or components may lead to

serious injury to the operator.

Read the following safety precaution to avoid any electric

shock.

DANGER

Press the red button (O) of the motor switch(4.1) after

every operation.

Switch off the machine with magnet switch (4.3) so the

motor doesn't start.

Risk of accident due to starting of the motor

unintentionally!

Pay attention to the following measures to avoid injuries

due to starting of the motor unintentionally.

Operate the machine with the protective equipment

mentioned below.

Do not wear protective gloves when the machine is on.

The rotating part may catch the glove and torn off the

hand.

Risk of injury due to improper handling of the machine!

Pay attention to these instructions in order to avoid any

type of injury.

ATTENTION

Always carry the machine with the handle.

Before plugging on the machine, check whether the

voltage supply is proper (refer to the technical data

sheet).

Do not pull the main cable to remove the plug from the

main socket.

Potential damage to the machine due to improper use.

Read these instructions to avoid damage to the machine.

WARNING

WARNING

MEANING OF THE SYMBOLS:

1. Wear protective googles.

2. Wear proper hearing protection equipment.

3. Do not put your hand near cutting area

4. Beware of electric shock.

5. Beware of rotating parts machine parts.

1 2 3 4 5

ALWAYS READ THIS MANUAL

BEFORE OPERATING THE MACHINE.

REMEMBER THIS SYMBOLS

4Hole Matic 31/65

SAFETY MEASURES, BEFOR USING FOR THE FIRST TIME

Always switch off the machine when changing tool,

conducting maintenance or cleaning. Wait till the

machine has completely stopped to avoid unintentional

stating of the machine.

Do put your hand into the machine while the machine is

in operation. Remove the metal chips only when the

machine is standstill. Wear the protective gloves when

removing metal chips.

When using a temporary plate for drilling, make sure the

supplied voltage is stable. For more safety, use a safety

belt so the machine holds the plate securely.

Secure the machine with a safety chain when working in

an inclined or vertical position and during overhead

operation. The machine could fall down if the magnet is

loosened or the power drops.

Check that the tool is securely tightened before using.

Do not allow the connecting cable to hang over the

edges.

Do not crush the power cord.

Do not put the main power cord near heated objects or

chemical liquids.

Do not drag the power cord across sharp edges or hot

surfaces.

Put the power cord in such a way that it cannot be

caught by rotating parts of the machine.

The machine stops automatically when the magnet

switch (4.3) is switched off.

Check for any visible signs of damage or missing items on

delivery. Report an incomplete or damaged delivery to your

dealer/supplier/manufacturer.

Preparation

Read the following instructions carefully and take the safety

precautions before starting the machine.

Additional safety measures for

special jobs.

Drilling Vertically

When working on inclined or vertical position or

overhead position, the machine should be secured with

a safety chain to prevent it from falling.

Tighten the safety chain as much as possible around the

handle of the machine.

Check the secure fitting of the safety of the safety chain

before starting the work.

Use proper protection equipment as mentioned on the

machine.

Risk of injury due to machine falling down.

Additional safety measures for

special jobs.

Drilling using temporary plate

Securing the machine with the plate using the safety

chain.

Clamping the plate tightly with the surface that is to be

drilled.

Wear proper safety equipment.

When working of the machine is on scaffolding, the machine

can make sudden vibrations and could slip off the plate,

causing danger. Prevent these by:

NOTE

Make sure to make a pilot punch before drilling.

Always use cutting oil or coolant when drilling.

WARNING

WARNING

WARNING

NOTE

ATTENTION

5Hole Matic 31/65

PREPARING

Check the condition of

the surface

The plate should be magnetic.

the electromagnet (5) should be free from grease, oil,

metal chips, or any other dirt.

The plate should be smooth and levelled.

When drilling into low thickness steel plate, we recommend

to use an additional steel plate with 200X200X20 mm

dimensions. Secure the additional plate tightly with the

surface to prevent it from falling.

The magnetic force is dependent on the condition of the

surface/plate to be drilled. If the surface/plate is painted,

coated, uneven or rusted, the magnetic force will be reduced.

To increase the magnetic force of the electromagnet, the

surface/plate should be:

The electromagnet best works with low-carbon steel surface

with a thickness of at least 20mm.

Plate with low thickness

Inserting the tool

Do not use damaged, spoiled or worn out tools.

Change the tools only when the machine is switched off

and at standstill.

After inserting, make sure the tool is engaged tightly.

Only use the tools that are compactible with the

machine.

Risk of injury!

The machine is equipped with MT-3 shank. USE ONLY

TOOLS WITH MT-3 SHANK ON THE MACHINE.

INSERTING THE TOOLS

Before fitting the tool, make sure to clean the shank and

the tool.

Insert the tool into the spindle taper (10) of the machine

from below.

REMOVING THE TOOLS

Turn the tool until the ejector pin slips into the opening

for ejector pin (11).

Loosen the tool by tapping on the ejector pin with a

hammer.

WARNING

INSERTING THE CUTTER

First remove the tool, if any, from the spindle taper (10)

using ejector pin.

Insert the cutter adapter (8) provided into the spindle

taper (10).

Insert the cutter with the pilot pin into the Weldon shank

of the adaptor.

Tighten the grub screws of the Weldon shank.

USING THE MACHINE WITH ANNULAR

CUTTERS.

REMOVING THE CUTTER

Untighten the grub screws using the Allen key and

remove the cutter from below.

Remove the cutter adapter using ejector pin.

Do not use damaged, spoiled or worn out cutters.

Insert or remove the adapter only when the machine is

switched off and at standstill.

Make sure the adapter is engaged tightly.

Make sure that the rod of coolant bracket (9), is

between the steel wedges (6).

Make sure that the grub screws of the Weldon shank is

properly aligned with the flat surface of the cutter.

Assure that the grub screws are tightened properly.

Refer to the figure below.

Risk of injury!

If the cutter is not aligned properly, the cutter will come

out of the shank during the operation, causing injury to

the operator.

Starting on the machine with unaligned cutter will

break the cutter in between the operation.

Risk of injury!

WARNING

ATTENTION

Weldon shank

Grub screws

Flat surface

of the cutter

6Hole Matic 31/65

ATTENTION

STARTING ON THE MACHINE, USING THE MACHINE

Switching the machine ON/OFF

First turn on the magnet switch (4.3).

Then turn ON the machine with the green button (I) on

the drill switch (4.1).

The machine can only be turned on when the

electromagnet is active or turned on.

Selecting the speed range

The machine is equipped with two speed

transmission.

Select the speed according to the material and the

diameter of the hole. Refer to the table below for speed

range.

NOTE

NOTE

ATTENTION

Drilling with the machine

The ALLCUT Hole Matic 31/65 is designed to be used

for drilling with twist drills and annular cutters, and

reaming purposes. Read these instructions to

proceed for your purposes of using of the machine.

Drilling with twist drills

Push the twist drill with MT-3 taper shank into the spindle

taper (10) from below.

Position and fix the machine at the location of the use.

Switch ON the electromagnet by switching ON the

magnet switch (4.3).

Select a suitable gear stage.

Switch ON the drill switch (4.1) by pressing the green

button (I).

Direct the drill to the surface/plate by pulling down the

handle (3).

When drilling with twist drills, proceed as follows:

Under excessive pressure, the drill can wear out and the

machine can be overloaded.

Make sure to remove the metal chips regularly,

especially when with higher drilling depths.

USE PROPER CUTTING OIL OR COOLANT FOR LONGER

TOOL LIFE.

Follow proper drilling direction.

Observe the following instructions when drilling with twist

drill:

NOTE

Changing the gears

First OFF the machine by turning off the drill switch (4.1).

Let the machine is at standstill.

Push in the gear changer (12), and slide up or down the

gear changer.

To change the gears, proceed as follows:

Change the gears only when the machine is turned off

and make sure the spindle taper (10) is not rotating.

Changing gears while spindle is rotating, will crush the

gears of the gear box.

Make sure that the gear changer (12) is slide up or down

till the end and the gears are engaged properly. If not it

will wear out the gears.

If the gears does not engage properly, rotate the spindle

taper (10) a little bit using hand, and slide up or down

the gear changer.

WARNING

GEAR STAGE

SPEED

GEAR 1

260 rpm

GEAR 2

460 rpm

7Hole Matic 31/65

USING THE MACHINE

Drilling with Annular cutter

Reaming with the machine

The ALLCUT HoleMatic 31/65 is a multi-purpose magnetic drill

machine, that can also be used for reaming purpose.

When reaming with the machine, look out for the limits

stated in the technical data.

Reamers with MT-3 taper shank should only be used

with the machine.

Always use proper cutting oil or coolant while reaming

with the machine.

ATTENTION

Insert the appropriate pilot pin into the annular cutter

and insert the cutter into the cutter adapter from below

(8).

Align the cutter and tighten the grub screws of the

Weldon shank.

Put the machine on the surface to be drilled on.

Switch ON (4.3) the magnet switch to enable the

electromagnet. Check that the machine sticks to the plate

properly.

Switch ON the machine by pressing the green button (I)

on the drill switch (4.1).

Slowly feed the handle (3) without exerting much

pressure, directing the cutter to the material to be drilled

on.

When drilling with core drills, proceed as follows:

The cutter adaptor of the ALLCUT HoleMatic 31/65 is

equipped with internal cooling system for the annular

cutter. Always cool down the tool while drilling for

better cutter life.

Turning ON the cooling system

Attach the coolant bottle provided, on the machine.

Connect the tube of the coolant bottle to the brass nipple

on coolant bracket (9) on cutter adapter, by pushing the

tube into the nipple.

Fill up the coolant bottle with coolant or lubricating oil and

screw on the bottle cap.

Turn on the cock on the coolant bottle and let the coolant

pass through the tube.

To turn on the cooling system, proceed as follows:

If the coolant doesn't pass the tube easily, loosen the

bottle cap a little bit. Let the air in the bottle escape.

Assure that the coolant or oil you are using is free of

metal chips or any dirt, to prevent the wearing out of

the tube.

The coolant will come out from the bottom of the cutter

adapter (8), cooling the cutter directly.

The cooling system will only work when you use the

cutter with proper pilot pin.

Use the pilot pin for every operation. It assure proper

rotation of the cutter and enables the cooling system.

The cooling system will not work when drilling in

overhead position.

NOTE

Drilling with annular cutters does not require much

pressure.

Do not apply too much pressure on the cutter. Doing so

will reduce the cutter life, or even break the cutter. And

also the machine will be overloaded.

Always use high performance coolant for better drilling.

Make sure to remove the metal chips regularly, so that

the metal chips do not come in the way of the cutter

while cutting.

Observe the following instructions when drilling with

annular cutter:

ATTENTION

8Hole Matic 31/65

REMOVING BLOCKAGES, CLEANING, MAINTENANCE

Removing blockages

Always use protective gloves when using the machine.

Risk of injury due to broken tool or metal chips.

Switch OFF (4.1) the machine and remove the plug from

the main socket.

Move the machine slide up with the help of the handle

(3).

Remove the metal chips and replace the broken tools.

Switch OFF the drill motor (4.1). Let the electromagnet be

on.

Move the machine slide up with the help of the handle

(3).

Remove the metal chips and check for the tool damage.

Blockages caused by broken tool:

Other blockages:

Always use good quality drill bits and cutters for better

performance.

Do not use damaged or worn out drill bits and cutters.

Do not exert more pressure on the handle (3), if the drill

bit or cutter is worn out or damaged. Doing so will

damage the machine.

Cleaning the machine

Make sure to switch OFF (4.3) completely and remove

the main cord from the main socket.

When using compressed air for cleaning or removing

metal chips, wear the protective goggles and gloves for

safety. Protect other persons in the working area too.

Never use water to clean the electric panel or electric

components.

Prevent the machine from water or other liquids.

Remove the inserted drill bit or tool.

Remove the metal chips and coolant residues.

Clean the tool and the spindle taper (10) on the machine.

Clean the machine slide (14) with clean cloth.

Clean the electromagnet (5) base and let it be free of oil,

metal chips or dirt.

Clean the whole machine and remove all the dirt and

grease.

After each use:

Maintenance

Repairs of electrical components should only be carried

out by the manufacturer or by skilled person.

Danger Caused by unqualified repairs !

Unqualified or third-party repairs leads to serious damage

for the operator and the machine too.

Take the M5 Allen key provided with the tools kit.

Look out for hex bolts on steel wedges (6).

Tighten the hex bolts a little bit and check the slide.

If the slide is too tight loosen the bolts.

Check out for the worn out carbon brushes. Replace the

carbon brushes if needed. Unauthorized carbon brushes will

damage the drill motor (13).

Adjusting the machine slide:

If the machine slide (14) slips down easily, it must be

adjusting. To do this, proceed as follows:

Replacing the carbon brushes

WARNING

WARNING

WARNING

NOTE

ATTENTION

The pilot pin attached to the cutter removes the slug

from the cutter automatically.

But always make sure that the slug is always removed

from the cutter.

DO NOT hammer the cutter if the slug is not ejected.

If the slug is stuck, take a punch and slightly hammer

that punch, to remove the slug without damaging the

cutter (Refer to the figure below).

Always remove the slug from the cutter after every

operation.

WARNING

Slug

Cutter

Pilot pin

Punch

9Hole Matic 31/65

STORAGE, TECHNICAL DATA

Customer service/service

If the machine is too damaged or cannot be repaired by you,

please contact ALLCUT team/dealer/supplier. We will be

happy to provide you with best service.

Storage

If you are not planning to use for a long time, clean the

machine as described in the CLEANING SECTION. Store the

machine and all its accessories in a dry, clean and non-

moisture environment, to prevent it from rusting.

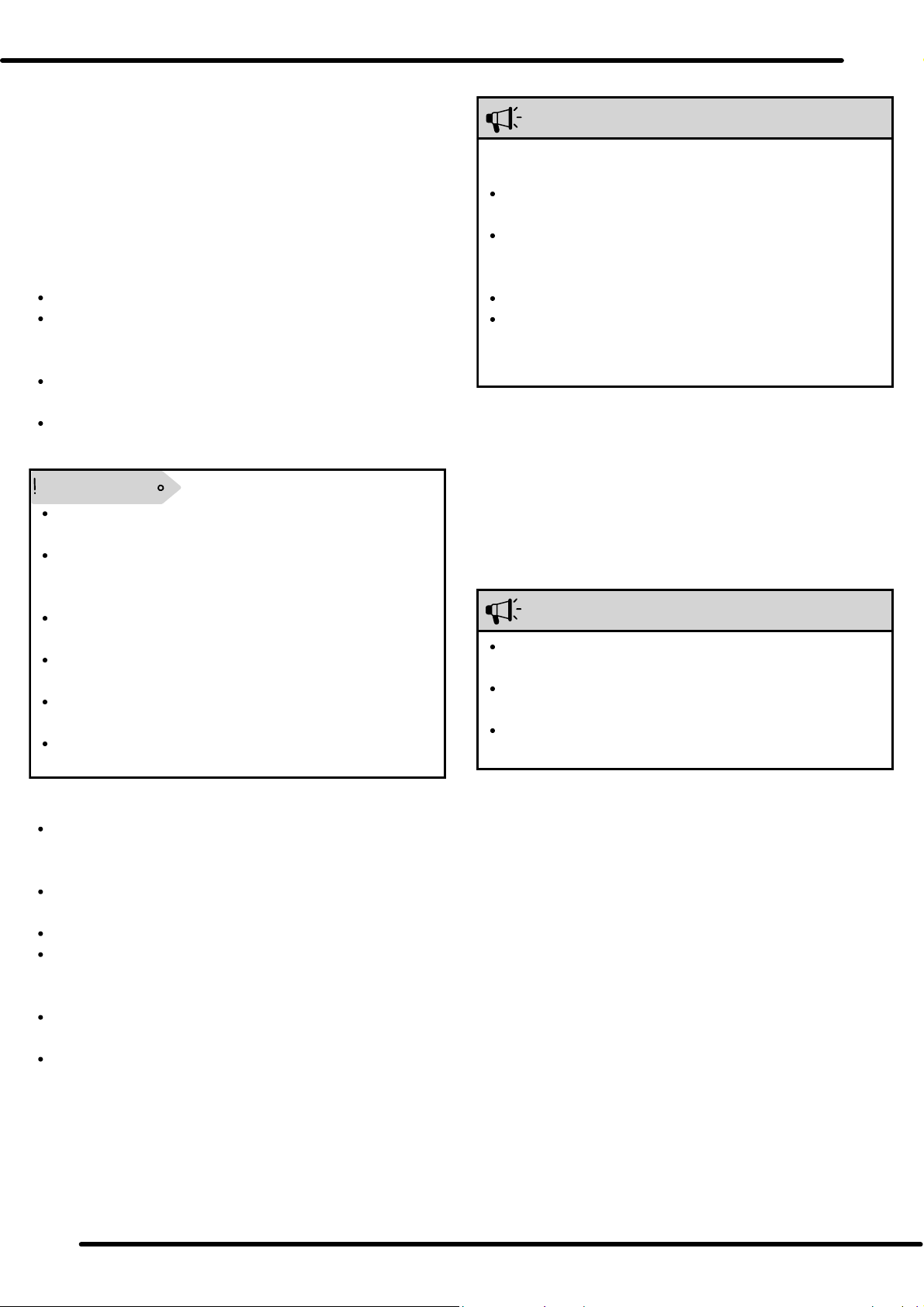

The speed range described in technical data is NO-LOAD speed. the speed may vary at the time drilling

by 20%.

NOTE

Technical data

Drilling capacity:

Tapping capacity

Reaming capacity ( ):

Speed range (NO-Load)

Reverse/forward

Spindle taper

Main cord length

Drilling depth:

Twist drill ( ):

Annular cutter ( ):

Model

Dimensions (L X W X H)

Electromagnet (L X W X H)

Weight

Power supply

Motor W

Noise emission

NO

31

260/460

NO

MT-3

2

ALLCUT 31/65

335 X 190 X 480

235 X 120 X 65

28

220 V single phase

1800

90

m

W

db

mm

mm

kg

mm

rpm

250

50

31

65

Twist drill ( ):

Annular cutter ( ):

mm

mm

mm

mm

10 Hole Matic 31/65

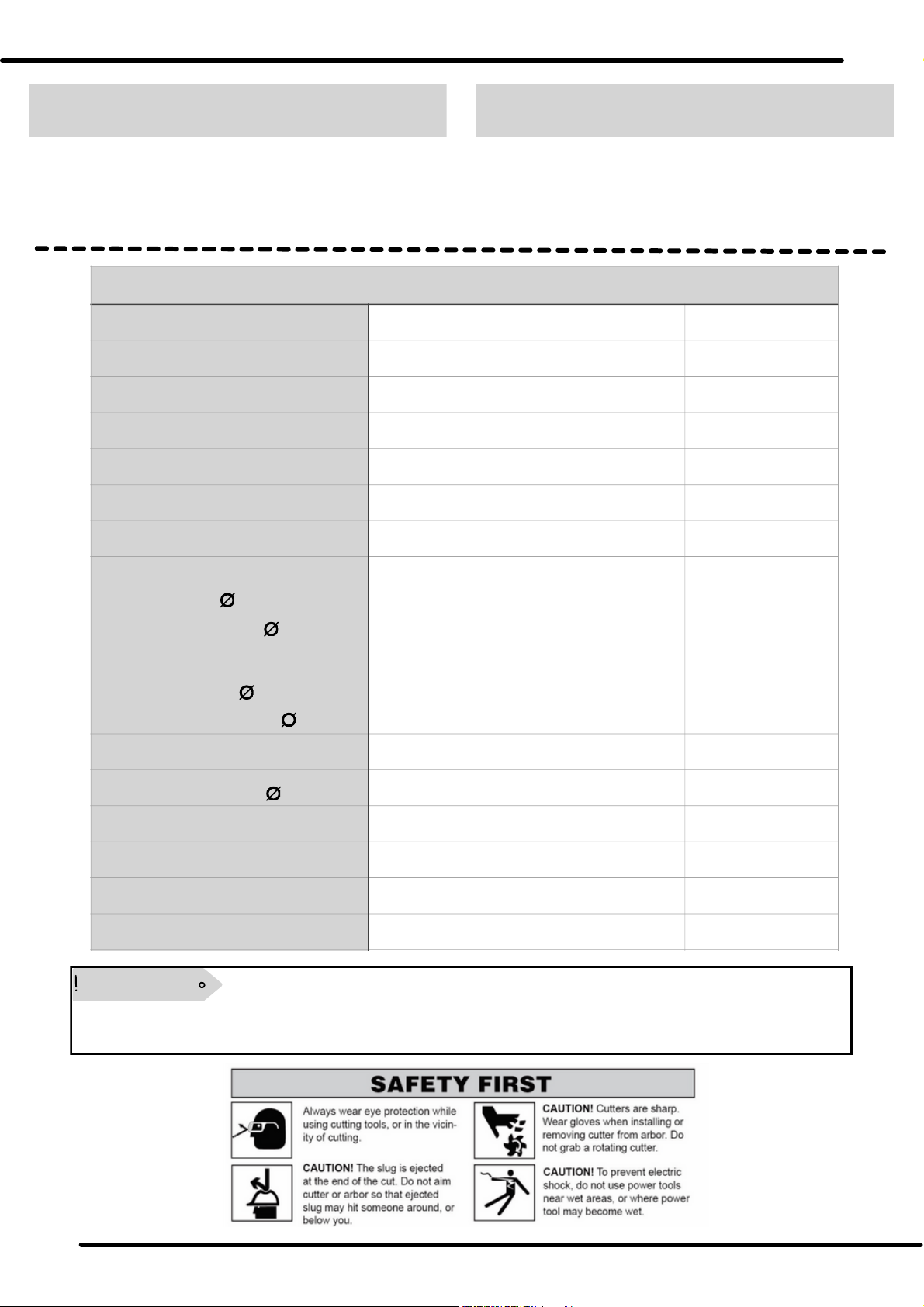

Rectifire

Drill motor

WIRING DRAWING

Electromagnet

Fuse

Holder

Drill Switch

Magnet Switch

Main plug

E1 E2

E2

E1

M1 M2

M1

M2

M3 M4

M4

M3

D1 D2

D3

D4

D1 D2

D4

D3

P1

P1

11Hole Matic 31/65

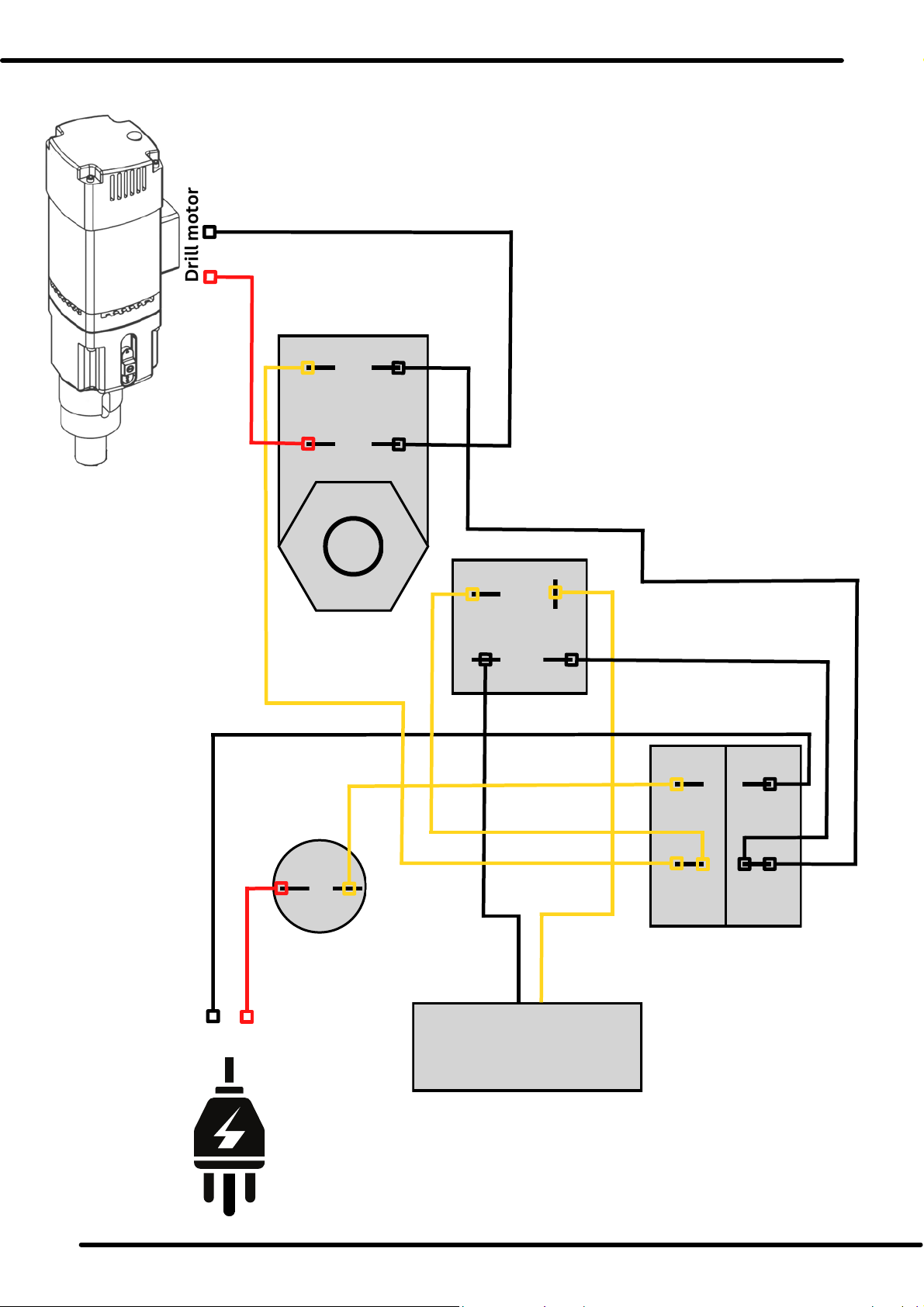

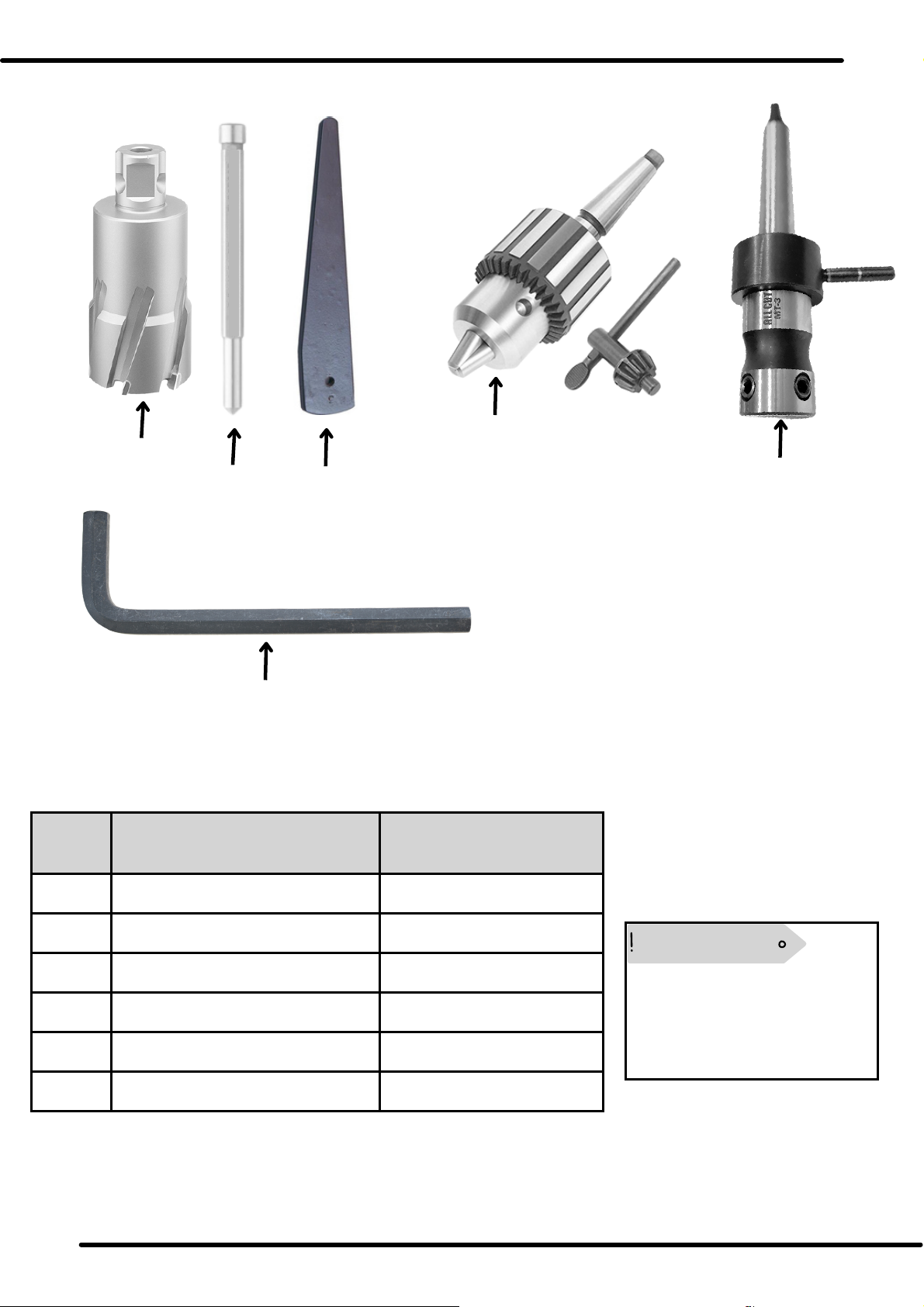

SR. NO.

ACCESSORIES

1

ANNULAR CUTTER (HSS/TCT)

AAC (ALL SIZES)

2

PILOT PIN

AAC

3

EJECTOR PIN

INC

4

DRILL CHUCK ARBOR

AAC

5

CUTTER ADAPTER

INC

8

ALLENN WRENCHES

INC

ACCESSORIES

12

4

5

8

3

(INC= INCLUDED) (AAC= AVAILABLE AS ACCESSORY)

The products which are

marked with AAC are extra

accessory and have to be

paid for each of them.

NOTE

12 Hole Matic 31/65

12Hole Matic 31/65

EXPERIENCE HAPPY AND SAFE DRILLING WITH ALLCUT MAG DRILLS

sales

www.allcut.in

IM_ALLCUT Hole Matic 31/65_A4 2023 ALLCUT MAGNETIC DRILLS

This manual suits for next models

1

Table of contents

Other ALLCUT Drill manuals

Popular Drill manuals by other brands

Makita

Makita HB500 Original instruction

Baier Elektrowerkzeuge

Baier Elektrowerkzeuge BST 200 Translation of the original instruction manual

Makita

Makita HP331D Repair manual

Parkside

Parkside SCHLAGBOHRMASCHINE PSBM 500 A1 Operation and safety notes

B+BTec

B+BTec KARAT 180 Series Translation of the original instructions

Makita

Makita FD02ZW instruction manual