Allegheny GeoVISION User manual

GeoVISION

Deluxe Borehole Video System

User’s Manual

1/15

TM

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

3

Introduction........................................................................................................................................................................................ 4

Quick Setup Guide ............................................................................................................................................................................ 7

System Setup..................................................................................................................................................................................... 15

System Operation.............................................................................................................................................................................17

Maintenance......................................................................................................................................................................................19

Troubleshooting...............................................................................................................................................................................21

Appendix A Deluxe Winch........................................................................................................................................................... 23

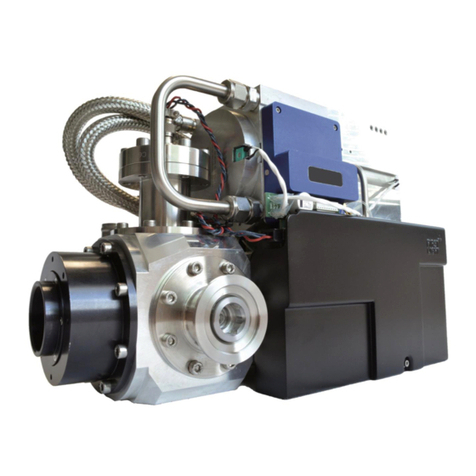

Appendix B Standard Stainless Steel Cameras........................................................................................................................... 29

Appendix C Standard Plastic Cameras........................................................................................................................................37

Appendix D Nano Camera ...........................................................................................................................................................45

Appendix E Nano Rotating Mirror .............................................................................................................................................51

Appendix F Dual-Scan Camera.................................................................................................................................................... 55

Appendix G Pan-Tilt Control.......................................................................................................................................................61

Appendix H Fixed Camera Mount ..............................................................................................................................................79

Appendix I Tilting Camera Mount .............................................................................................................................................. 83

Appendix J Standard Centralizer.................................................................................................................................................. 87

Appendix K Cable Support Clamp.............................................................................................................................................. 91

Appendix L Auxiliary Single Light...............................................................................................................................................95

Appendix M Auxiliary Double Light...........................................................................................................................................99

Appendix N Auxiliary Fixed Eight Light..................................................................................................................................103

Appendix O Auxiliary Adjustable Eight Light.........................................................................................................................107

Appendix P Emergency Crank Handle.....................................................................................................................................113

Appendix Q Cable End Replacement Kit ................................................................................................................................119

Limited Warranty ...........................................................................................................................................................................123

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

4

Introduction

Thank you for purchasing an Allegheny Instruments, Inc., GeoVISIONTM Borehole Video System. Allegheny

Instruments is committed to providing the world’s highest quality borehole video systems along with the industry’s

best warranty and technical support. If you have any questions regarding your GeoVISIONTM system, please contact

us. Our office hours are Monday through Friday, 8:00 am to 5:00 pm Eastern Time and our contact information is as

follows:

Support: Sales:

(800) 343-3479 (800) 255-1353

(540) 468-3740 (802) 626-5302

Repair@AlleghenyInstruments.com Sales@AlleghenyInstruments.com

Allegheny Instruments, Inc. Allegheny Instruments, Inc.

1509 Jackson River Road 1509 Jackson River Road

Monterey, VA 24465 Monterey, VA 24465 USA

Terminology

This manual uses the following conventions to highlight

the presence of hazards, potential risk and important

information concerning the operation and maintenance

of this system.

DANGER: Denotes an imminently hazardous

situation which, if not avoided, can result in death or

serious injury.

WARNING: Denotes the presence of a condition

that can cause significant personal injury and/or

property damage and may void the product warranty if

ignored.

CAUTION: Denotes the presence of a condition

that can cause personal injury and/or property damage.

Note:Indicates supplemental information worthy of

attention.

Be sure to follow all instructions and related precautions.

They are intended for your safety and protection.

Foreword

This manual is to be used as a guideline for operation

and maintenance of a GeoVISIONTM Deluxe Borehole

Video System. It is divided into six sections for easy

reference.

Section 1 –Quick Setup Guide

Section 2 –System Setup

Section 3 –System Operation

Section 4 –Maintenance

Section 5 –Troubleshooting

Section 6 –Appendices

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

5

Important Precautionary Information

The information contained on this page appears throughout this manual. Be sure to read and

understand these precautions prior to using the system.

DANGER

This system is not designed for use in

explosive atmospheres.

WARNING

The GeoVISIONTM Deluxe Winch and Control

Panel are not waterproof; both parts should

be protected from water and moisture.

Exposure to excessive moisture can cause a

safety hazard and/or system failure. If these

components are exposed to water, power to

the system should be removed, the power

supply panel should be removed from the

winch, and the components should be dried

immediately.

Failure to clean and dry system components

before placing them in the carrying case can

cause premature failure and void the

warranty.

If the interior of the carrying case is damp or

wet, it should be allowed to dry thoroughly

before the case is closed.

WARNING

This system must be powered from an AC

sine wave power source such as a generator,

commercial power, or a pure sine wave

inverter.

WARNING

Never support a camera by the 3-pin

connector. Always use the camera’s built in

clamp, if it has one, or use a Cable Support

Clamp.

CAUTION

Before using the system, be sure that the

“Camera Select” switch is in the correct

position for the camera you are using. Refer

to figure #6A.

CAUTION

This system is designed for use in potable

water wells. It should not be used in

environments where the plastic components

will come in contact with solvents, oils, or

fuels. Solvents, oils, or fuels can damage

plastic components and be absorbed into the

plastic, allowing contaminants to be

transferred from one well to another.

CAUTION

Chemical damage is not covered by the

warranty.

CAUTION

If the system is used in salt water, all

submerged electrical connections must be

protected using silicon grease. Coat both the

pins on the male connector(s) and the

contacts on the mating connector(s) with

grease. The connectors must be cleaned with

fresh water and dried after each such use.

Damage from use in salt water is not covered

by the warranty.

CAUTION

Plastic cameras should not be subjected to

thermal shock. If a plastic camera is very

cold, it should be allowed to warm to the

borehole temperature in air before it is placed

in the bore. If a plastic camera is hot, it is

best to turn the camera off for about 5

minutes inside the borehole, before it is

submerged. Damage resulting from thermal

shock is not covered by the warranty.

CAUTION

The operating temperature range for plastic

cameras is 32° F (0C) to 100° F (37C). Use

of plastic cameras in temperatures outside

this range can damage the camera and is not

covered by the warranty.

CAUTION

Plastic cameras will warp and leak if operated

or stored at temperatures above 120° F (49°

C). Temperature warped cameras are not

covered by the warranty.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

6

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

7

Quick Setup Guide

Camera Configuration

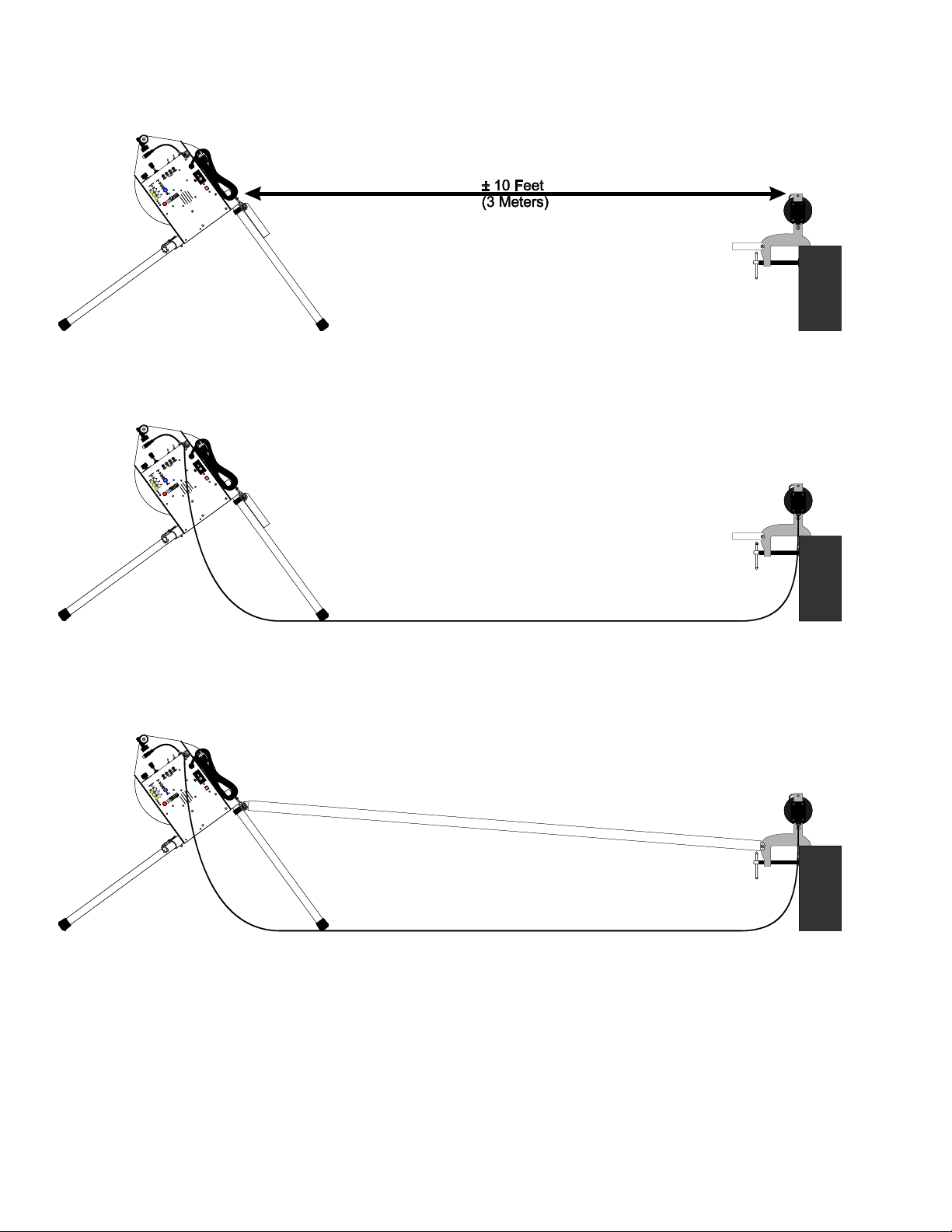

The following image illustrates some common ways to configure various cameras based on the type of camera, bore

diameter and intended use. For a detailed description on how to configure each camera, see the appendix for the

camera.

Typical Camera Configurations

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

8

Winch Setup

Set the switches on the top of the Control Panel.

Set the switches on the side of the Control Panel.

Set the Video Source switch

to “FROM CAMERA.”

Turn the Volume knob all

the way down.

Set the Camera switch for

the camera you are using.

Turn off the System

Power switch.

Set the Input Voltage switch

for the proper source

voltage, 115V or 230V.

Turn on all three light switches.

Set the Exposure Control switch to “Normal.”

Turn off the Winch Motor switch.

Rotate the Winch Control knob straight up to

the “Stop” position.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

9

Insert the winch legs.

Clamp the Depth Encoder to the well casing or a tripod placed over the bore.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

10

Place the winch on level ground approximately 10 feet (3 meters) from the Depth Encoder.

Connect the Encoder Cable between the winch and the Depth Encoder.

If the borehole is deeper than 600 feet (200 meters), we recommend placing a spacer pipe between the winch and the

Depth Encoder.

Plug in the winch and turn on the System Power switch.

With the Winch Control knob in the “Stop” position, turn on the Winch Motor switch.

Turn the Winch Control knob counterclockwise toward “Down” and spool off enough cable to reach

approximately 3 feet (1 meter) beyond the Depth Encoder.

Turn off the Winch Motor switch and, if necessary, return the Winch Control knob to the “Stop” position.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

11

Set the Camera switch for the camera you are using and attach the camera to the winch cable.

Mount the monitor on the winch.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

12

If glare makes viewing the monitor difficult, attach the Sunshade to the top of the monitor. A microphone can also

be attached to the hole in the Sunshade.

Lower the camera into the bore, place the winch cable over the Depth Encoder pulley, and secure it in place with the

pin.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

13

If desired, connect a video recorder.

If desired, connect a true sine wave inverter to a battery or a vehicle and plug the winch into the inverter.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

14

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

15

System Setup

Install the Tripod Legs

This step is easier if the winch is placed on an elevated

surface with the rear leg sockets hanging over the

edge. The carrying case makes an acceptable work

surface for this purpose.

Insert the two rear tripod legs into their mating

sockets. The rear legs are the two identical ones and

do not have a brace pole bracket attached to them.

Insert the quick release pins to lock the legs in place.

Lift the winch by its handle and rock it back so that

the two rear legs are on the ground and supporting

the weight of the winch.

Insert the front tripod leg with the brace pole

attachment bar facing away from the winch spool and

insert the quick release pin.

Lower the winch so that it is supported by all three

legs.

Locate the Winch

Place the winch approximately 10 feet from the

borehole keeping it as level as possible.

Remove enough cable from the winch to allow the

end of the cable to extend 3 feet beyond the borehole.

Check the Winch Switches

Check that the Voltage Select switch is set to the

voltage you will be using, 115 or 230 volts AC.

Check that the System Power switch is turned off.

Check that the Winch Motor switch is turned off.

Check that the Winch Control knob is set to “0” or

“Stop.”.

Check that the Camera switch is set to the camera you

will be using.

Check that the Video Source switch is set to “FROM

CAMERA.”

Check that all three light switches are turned on.

Check that the Exposure Control switch is set to

“Normal.”

Install a Brace Pole

If you are logging deeper than 600 feet, it is

recommended that you install a brace pole between

the winch and the Depth Encoder using the

aluminum brackets attached to each.

Install the Depth Encoder

Attach the Depth Encoder to either the well head or

to a tripod positioned over the well.

Connect the grey telephone cord between the winch

and the Depth Encoder. Note that the ends of the

cord are different; the wide connector plugs into the

Depth Encoder, and the narrow connector plugs into

the winch.

Attach the Monitor

If you purchased a monitor with your system, follow

these steps to mount it to the winch.

Thread the bolt on the monitor mount into the hole

on the bottom of the monitor, just enough to engage

the threads.

Position the monitor so it faces the operator, and

tighten the bolt to lock the monitor in position.

Plug the monitor into the mating cord on the Control

Panel.

If glare makes it difficult to see the monitor, attach

the Sunshade to the monitor using the Velcro™ strips

along the top of both the monitor and the Sunshade.

Connect a Microphone

If your microphone requires a battery, be sure that the

battery is installed correctly.

If you purchased a monitor with your system, you can

use a small microphone clip to attach the microphone

to the hole in the Sunshade, so that the microphone is

mounted to the outside of the Sunshade facing the

operator.

Plug the microphone into the jack labeled

“MICROPHONE”on the Control Panel.

Set Up the Camera

Each camera can be configured in a number of ways,

depending on the size of the bore. Refer to the

Appendix that covers the camera you are using for

complete setup instructions. Appendices for the

cameras are as follows:

Appendix B –Standard Stainless Steel Cameras

Appendix C –Standard Plastic Cameras

Appendix D –Nano Camera

Appendix E –Dual-Scan Camera

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

16

Place the Camera in the Bore

Remove the retaining pin from the top of the Depth

Encoder.

Place the camera in the bore and lay the winch cable

over the Depth Encoder pulley. Make sure there is

no twist in the cable between the winch and the

Depth Encoder.

Replace the retaining pin in the Depth Encoder.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

17

System Operation

Initial Settings

Check that the Voltage Select switch is set to the

voltage you will be using, 115 or 230 volts AC.

Check that the System Power switch is turned off.

Check that the Winch Motor switch is turned off.

Check that the Winch Control knob is set to “0” or

“Stop.”

Check that the Camera Select switch is properly set

for the camera attached to the cable.

Check that the

Video Source switch is set to “FROM CAMERA.”

Turn on all three light switches.

Set the Exposure Control switch to “Normal.”

Turn on the System Power switch.

Testing and On-Screen Depth Display

(OSD) Initialization

Press the “Screen Position” button repeatedly until

you see the OSD numbers on the screen and in the

position you desire.

Rotate the Winch Control knob so that it points

straight up in the “0” position.

Turn on the Winch Motor switch.

Slowly turn the Winch Control knob

counterclockwise to lower the camera into the bore.

Turn the knob back to “0” or turn off the Winch

Motor switch to stop the winch.

When the camera reaches the depth that will serve as

the reference depth, press and hold the two red

buttons to zero the OSD count.

Now is a good time to test the winch controls. If you

are using a Dual-Scan Camera or a Pan-Tilt Control,

test that the joystick is controlling the camera properly

and that the exposure control is functioning correctly.

Check that the light(s) is(are) working properly as

well.

If you plan to record the session, now is the time to

make a short recording (including audio if desired)

and to play it back to be sure everything is working

correctly. For more information on connecting a

video recorder, see Appendix A.

Logging the Bore

Use the Winch Control knob to lower the camera

down the bore. If the camera is going to be

submerged, keep in mind that the first trip down will

see the least amount of sediment. It is often best to

record video on this pass.

In an emergency, the Winch Motor switch or the

System Power switch can be used to stop the winch;

however, using the Winch Control knob rather than

the switches reduces wear and tear on the motor.

Turning off the System Power switch does not reset

the OSD count; however, if the cable is spooled out

or in while the power is off, the change will not be

reflected in the OSD count when power is restored.

When lowering into a bore for the first time, it is

always a good idea to look straight down the bore. If

you are using a Dual-Scan Camera or Pan-Tilt Control

and would like to look sideways, it is a good idea to

stop the winch before doing so.

Retrieving the Camera

When raising the camera out of the bore, it is very

important to dry the cable and wind it neatly on the

winch. Paper towels are an effective way to dry the

cable. Hold the cable in the fold of several paper

towels as you guide the cable neatly onto the winch.

After use, the paper towels can be discarded to reduce

the risk of cross contamination of wells.

WARNING

The GeoVISION Deluxe Winch and Control

Panel are not waterproof and should be

protected from water and moisture. Exposure

to excessive moisture can cause a safety

hazard and/or system failure. If these

components are exposed to water, power to

the system should be removed immediately,

the Control Panel should be removed from the

winch, and the components should be dried

thoroughly.

Failure to clean and dry system components

before placing them in the carrying case can

cause premature failure and void the

warranty.

If the interior of the carrying case becomes

damp or wet, all items should be removed

from the case, and it should be allowed to dry

thoroughly before it is used again.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

18

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

19

Maintenance

Camera

After each use, flush the 3-pin connector on the rear

of the camera with clean, fresh water. When the

connector is dry, lightly coat the pins with silicone

grease and cover the connector with one of the yellow

nylon caps to protect it from dirt.

Occasionally check for a buildup of silicone grease

inside the 3-pin connector. If a buildup occurs, gently

remove it before cleaning.

Winch Cable

Always use one hand and a clean rag or paper towels

to guide the cable back onto the winch when

retrieving the camera. Wind the cable in neat rows to

ensure that all of the cable fits back on the winch; this

also helps you locate damaged sections in the cable.

Wiping the cable clean and dry extends the life of the

cable and helps prevent cross contamination between

wells.

Control Panel

The Control Panel should be kept clean and dry. If

the foam in the case becomes damp, remove it from

the case and allow it to dry thoroughly before

repacking the case.

Allegheny Instruments, Inc. www.AlleghenyInstruments.com

20

Table of contents