Allegro AC7392 User manual

USER MANUAL

PWM REGULATOR OF THE HEATER POWERED

FROM SOLAR PANELS ACTii AC7392

FIRMWARE VIEW: F1.0

1. SAFETY CONSIDERATIONS

-Before starting it for the first time, please read this instruction manual.

-All connections and changes should be made with the voltage disconnected

from the panels.

-Proper operating conditions must be ensured, in accordance with the specification of the

device, such as: supply voltage, temperature, maximum current consumption.

-Installation and setting of the device require appropriate skills, so they can only be

done by qualified people, after reading the instruction manual in full.

-An incorrectly connected device may be damaged.

-The responsibility for the correct installation lies with the person assembling.

Make sure that you meet all the guidelines and standards in force in your

country.

-Electrostatic discharge can damage the device. Appropriate safeguards shall

be in place.

-It is necessary to protect the installation from discharges by disconnecting the

regulator from the panels during the storm.

-Any unauthorized alterations, modifications and attempts at repairs will void

the warranty.

-The regulator must be absolutely disconnected from the panels when we leave

the apartment for more than a day!!!

-The power plant must be equipped with fuses mounted on both wires from the

panels. It should be possible to quickly disconnect the panels in the event of a

failure.

2. DESCRIPTION AND CHARACTERISTICS OF THE PRODUCT

The heater regulator is used to regulate the load of the panels by changing the PWM

filling factor, and in combination with the charge buffer as an active load. This

allows the panels to work at the MPPT point, i.e. the largest power factor. The

condition for proper operation and the highest energy yields is to ensure the

appropriate load for the regulator. The regulator should be loaded with a heater with

a strong nominal adapted to the power of the panels and a voltage appropriate to the

MPPT voltage of the panels. The regulator is an element that reduces the load on the

panels in the event of insufficient sunlight, and thus allows the panels to be

maintained at an optimal point of operation.

The regulator also acts as a thermostat preventing the boiler from overheating.

In the case of insufficient cooling (e.g. in the case of contamination of the heatsink),

an additional protection was used in the form of an emergency shutdown at a

temperature of 60 degrees, which is to protect the actuators from damage by high

temperature. The device also monitors the supply voltage, and when it is too low

(insufficient to put transistors into saturation mode) I activate the procedure for

turning off the transistors. This prevents operation in active conduction mode and

thus exposure to the secretion of too much heat, which could lead to damage to the

actuators.

The device has been equipped with an additional relay output (without potential),

enabling notification of external devices that water heating has been completed

(reaching the set temperature) or entering the emergency mode (failure of the

actuating element) ER.1. As additional safety elements, the SSR DC relay is used,

which gives the possibility of emergency shutdown of water heating in the event

of a puncture of the actuating element.

Such a solution guarantees the safety of the solar power plant.

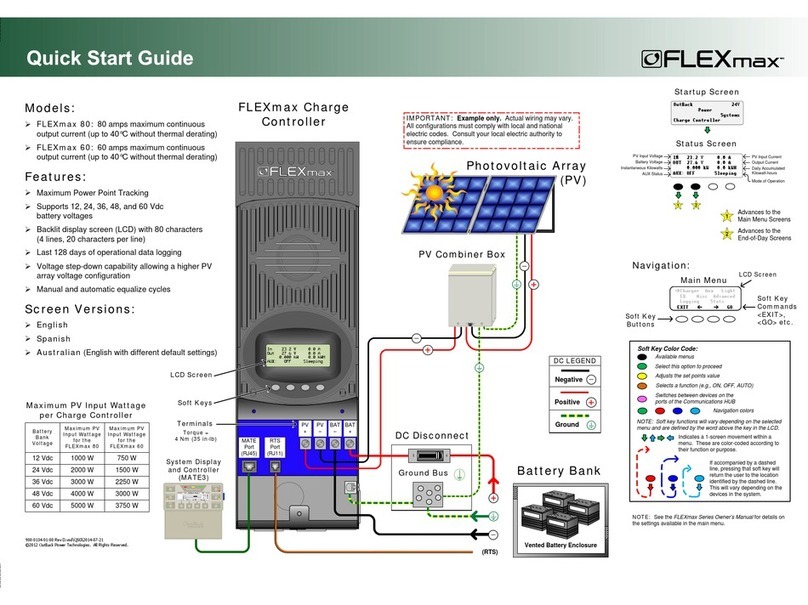

3. INSTALLATION AND CONNECTION

The device for proper operation requires proper connection. The final place of

installation is the wall inside the building. The regulator should be mounted near the

boiler so that there is no need to extend the temperature sensor cable.

The recommended connection system of the regulator is below. It does not

present the possibility of using an additional RELAY output used, for

example, to disconnect panels (via SSR DC relay) in the event of a regulator

failure.

The regulator should be connected as in the figure below.

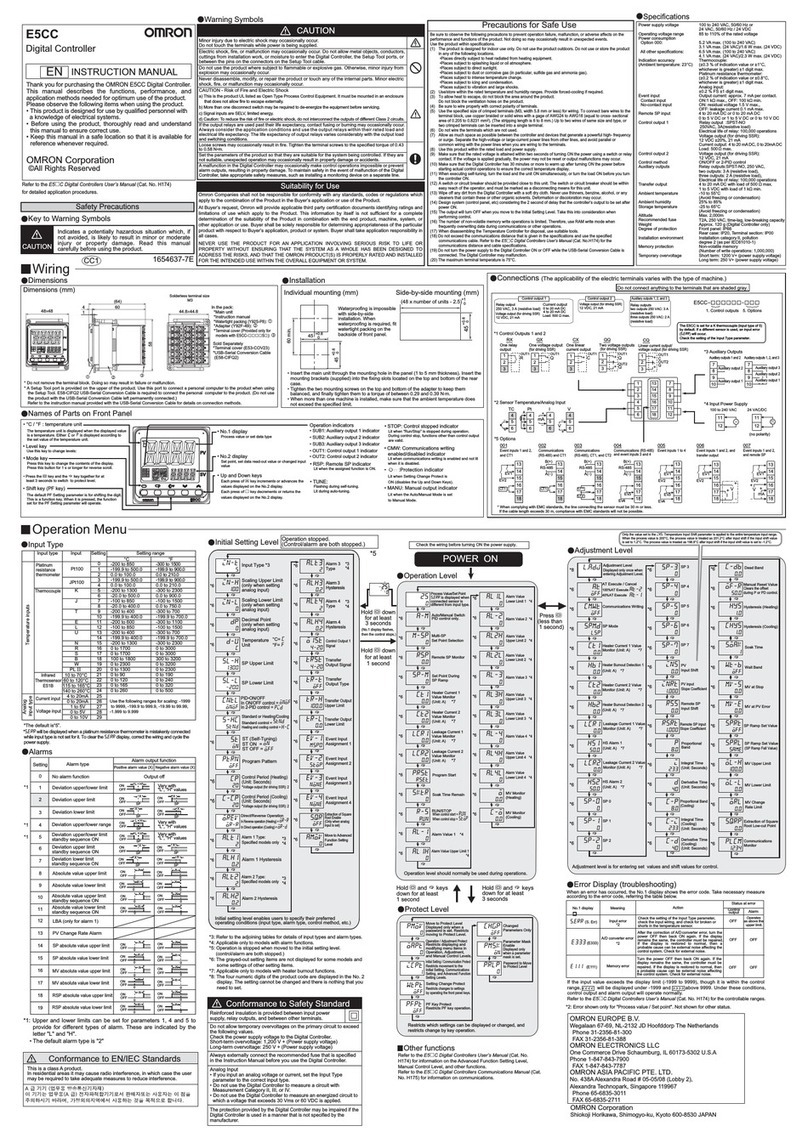

4.KONFIGURACJA

The configuration consists in setting the set temperature to be reached by utility

water. This is done by pressing the MENU button until an intermittent sound from

the controller appears. Then the inscription "S.tE" appears on the top display, which

means setting the set temperature. It is possible to reduce the voltage of the regulator

to work, however, this option is recommended when using an external power source.

The start voltage can be reduced by holding down the minus button until an

intermittent signal appears from the buzzer. The default start voltage is 150V.

Turning the regulator on and off:

The regulator can be switched off by short pressing the MINUS button (the voltage

on the heater is no longer supplied)

Switching on is done by short pressing the PLUS button.

By default, when the power is turned on, the regulator automatically takes up work

(supplying current to the heater) if the voltage exceeds the minimum value. The

regulator can only work with photovoltaic installations, it cannot be used for wind

turbines.

The controller, apart from the above-described settings, does not require additional

maintenance. Adjustment of operating parameters takes place automatically and

depends on the capabilities of the panels and the load. The regulator should be

absolutely loaded ONLY with heaters used in boilers. Do not use air resistance

heaters or other electronic devices.

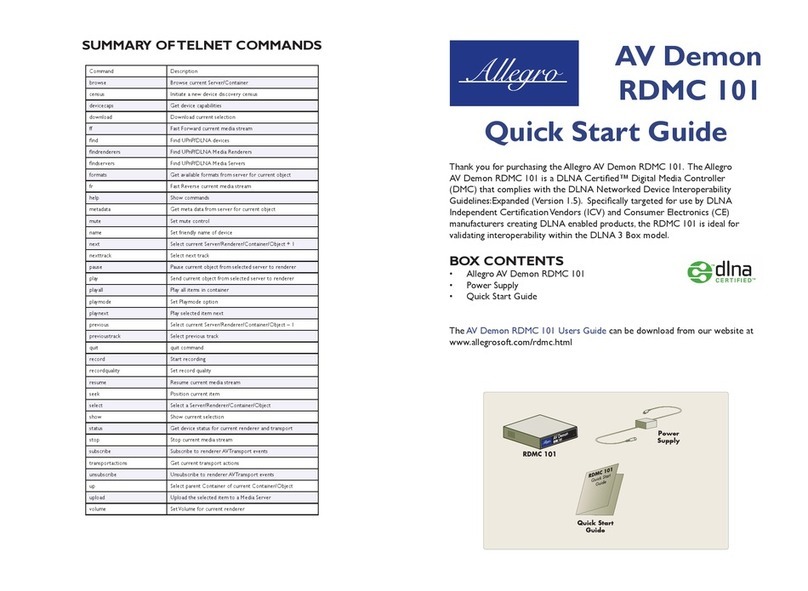

5 COMMUNICATION:

The heater controller enables communication via RS485 interface in ASCIImode. A

description of the RJ45 socket pins is provided below.

The RJ45 socket can also be used to power the controller when there is no voltage

from the panels.

The method of communication is not related to any communication protocol. In

order to read the operating parameters, a query should be sent to the regulator in

the form of one byte of data.

Transmission parameters are: 9600 8n1.

Sending one byte to the driver with the following information: ASCII 'a' (97

decimals)

results in the answer:

AA; Current power (in watts); Current CWU temperature(should be divided

by 10); Current power gain from device start or data reset (kWh); Current

work status (value 1 when working or 0 when not working)

Send one byte to the driver with the following information: ASCII 'S' (83 decimal)

results in the answer:

SR; Current voltage from the panels (in Volts); Current current (divide by 10

to be in amperes); Current power (in watts), The maximum power that has

been achieved in the history of this device (in watts); Maximum temperature

that was measured in the device (in degrees Celsius);Number of operations of

the low voltage detector of control transistors; Current PWM value(0-255);

Current heatsink temperature (divide by 10 to be in Celsius)

Send one byte to the driver with the following information: ASCII 'W' (87 decimal)

results in stopping the work of the regulator.

Sending one byte to the driver with the following information: ASCII 'Q' (81

decimal)

results in the resumption of regulator operation.

Send one byte to the driver with the following information: ASCII 'R' (82 decimals)

results in resetting the accrued kilowatthours.

REMARK!!!

The changed settings are saved in the non-volatile memory and are still active

after the device is restarted.

During normal operation, the following parameters, current power and CWU

temperature are displayed on the display. Flashing out LED indicates that power

is feeding to the heater.

RESTORE FACTORY SETTINGS

To perform a factory reset, hold the MENU button when you turn on the device and

hold until "dEF" appears on the top display. This feature will erase all user settings.

5. TECHNICAL DATA

Secondary supply voltage

11 V to 14V

Panel tension

From 120V to 350V DC

Panel current

From 13A

Maximum heater power

3kW

Maximum power of the panels

3kW

Dimensions

140 x 120 x 130mm

Input power

< 5 W

Temperature measurement accuracy

0.1 degrees

6. SERVICE INFORMATION REMARK!!

!

The inscription ER.0 indicates an emergency shutdown of the controller due to too

low supply voltage, which could lead to damage to the transistor controlling the

heater. REMARK!!

!

ER.1 Means damage to the control transistor, immediately disconnect the

regulator and send it back to the service. At the time of displaying this error, the

heater is constantly powered from the panels and the regulator is not able to turn

it off!

Leaving the regulator with this error can lead to its melting and even fire.

REMARK!!

!

ER.2 Means an unstable supply voltage or damage to the power supply of the device.

It can also mean damage to the filter capacitors.

The CE symbol on the device indicates the compliance of the

device with the Electromagnetic Compatibility Directive EMC

2004/108/EC (Electromagnetic Compatibility Directive).

This mark on the device informs about the prohibition of placing

the used device together with other waste. The equipment must be

handed over to designated disposal points. (In accordance with the

Waste Electronic Equipment Act of 29 July 2005)

Table of contents

Other Allegro Controllers manuals

Popular Controllers manuals by other brands

ACV

ACV Solar Unit 200 Installation, operation, functions and options, troubleshooting

Sundstrom

Sundstrom SR 507 Training

Synapse

Synapse DIM10-087-06 install guide

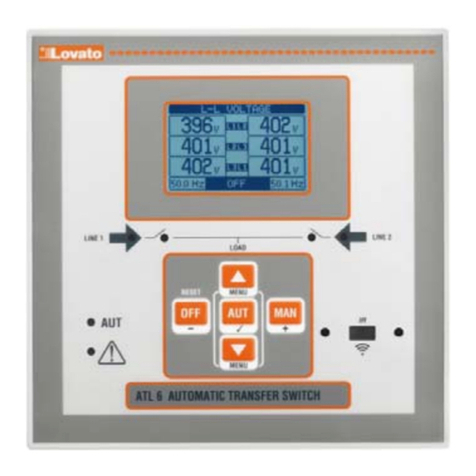

LOVATO ELECTRIC

LOVATO ELECTRIC ATL 601 instruction manual

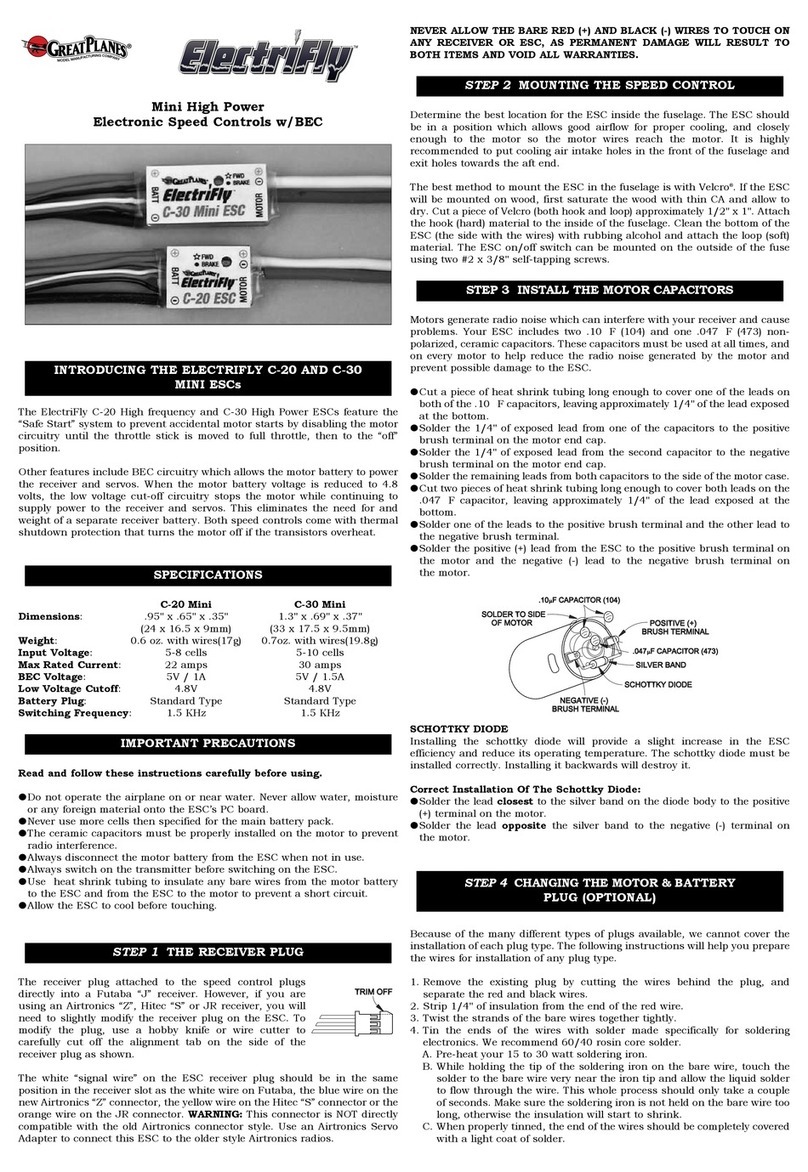

GREAT PLANES

GREAT PLANES ElectriFly C-30 Mini quick start guide

CAT Pumps

CAT Pumps 7350 quick start guide