ACV Solar Unit 200 User manual

*11216042*

11216042

Thank you for buying this product.

Please read this manual carefully to get the best performance from this unit.

Please keep this manual carefully.

Solar Unit 200

Manual

en

Solar controller

Manual for the

specialised craftsman

Installation

Operation

Functions and options

Troubleshooting

2

en

© 20220722_11216042_ACV_Solar_Unit_200.monen.indd

Safety advice

Please pay attention to the following safety advice in order to avoid danger and

damage to people and property.

Danger of electric shock:

• When carrying out works, the device must rst of all be disconnected from the

mains.

• It must be possible to disconnect the device from the mains at any time.

• Do not use the device if it is visibly damaged.

The device must not be used by children or persons with reduced physical, sensory

or mental abilities or without any experience and knowledge. Make sure that child-

ren do not play with the device!

Only connect accessories authorised by the manufacturer to the device.

Make sure that the housing is properly closed before commissioning the device.

Target group

These instructions are exclusively addressed to authorised skilled personnel.

Only qualied electricians are allowed to carry out electrical works.

Initial commissioning must be effected by authorised skilled personnel.

Authorised skilled personnel are persons who have theoretical knowledge and ex-

perience with the installation, commissioning, operation, maintenance, etc. of elec-

tric/electronic devices and hydraulic systems and who have knowledge of relevant

standards and directives.

Instructions

Attention must be paid to the valid local standards, regulations and directives!

Information about the product

Proper usage

The solar controller is designed for electronically controlling standard solar thermal

systems in compliance with the technical data specied in this manual.

Any use beyond this is considered improper.

Proper usage also includes compliance with the specications given in this manual.

Improper use excludes all liability claims.

Note

Strong electromagnetic elds can impair the function of the device.

ÎMake sure the device as well as the system are not exposed to strong

electromagnetic elds.

EU Declaration of conformity

The product complies with the relevant directives and is therefore

labelled with the CE mark. The Declaration of Conformity is available

upon request, please contact the manufacturer.

Scope of delivery

The scope of delivery of this product is indicated on the packaging label.

Storage and transport

Store the product at an ambient temperature of 0 … 40 °C and in dry interior

rooms only.

Transport the product in its original packaging only.

Cleaning

Clean the product with a dry cloth. Do not use aggressive cleaning uids.

Decommissioning

1. Disconnect the device from the power supply.

2. Dismount the device.

Subject to technical change. Errors excepted.

3

en

Disposal

• Dispose of the packaging in an environmentally sound manner.

• At the end of its working life,the product must not be disposed of as urban waste.

Old appliances must be disposed of by an authorised body in an environmentally

sound manner. Upon request we will take back your old appliances bought from

us and guarantee an environmentally sound disposal of the devices.

Description of symbols

Warnings are indicated with a warning symbol!

Signal words describe the danger that may occur, when it is not avoided.

WARNING means that injury, possibly life-threatening injury, can occur.

ÎIt is indicated how to avoid the danger described.

ATTENTION means that damage to the appliance can occur.

ÎIt is indicated how to avoid the danger described.

Note

Notes are indicated with an information symbol.

ÎTexts marked with an arrow indicate one single instruction step to be carried

out

1. Texts marked with numbers indicate several successive instruction steps to be

carried out.

4

en

Contents

1 Overview .............................................................................................. 5

2 Installation ........................................................................................... 6

2.1 Mounting ........................................................................................................................6

2.2 Electrical connection ...................................................................................................7

2.3 VFD Grundfos Direct Sensor™...............................................................................8

2.4 PWM outputs................................................................................................................8

2.5 Data communication / Bus ..........................................................................................8

2.6 System overview...........................................................................................................9

2.7 Systems........................................................................................................................ 10

3 Operation and function .................................................................... 48

3.1 Buttons ........................................................................................................................ 48

4 System-Monitoring-Display .............................................................. 48

4.1 Flashing codes ............................................................................................................ 49

5 Commissioning.................................................................................. 50

6 Channel overview .............................................................................. 52

6.1 Display channels......................................................................................................... 52

6.2 Adjustment channels ................................................................................................ 55

7 Troubleshooting................................................................................. 66

8 Index ................................................................................................... 69

Solar controller Solar Unit 200

The Solar Unit 200 has been especially developed for the speed control of high-

efciency pumps in standard solar and heating systems.

It is equipped with two PWM outputs and an additional input for a VFD Grundfos

Direct SensorTM that enables a precise heat quantity measurement.

5

en

1 Overview

• Especially designed for the speed control of high-efciency pumps

• 1 input for aVFD Grundfos Direct SensorTM

• System-Monitoring-Display

• Up to 4 Pt1000 temperature sensors

• 2 semiconductor relays for pump speed control

• HE pump control

• Heat quantity measurement

• Commissioning menu

• 10 basic systems to choose from

• Function control

• Optional thermal disinfection function

• Drainback option

• Unit °F and °C selectable

Technical data

Inputs: 4 Pt1000 temperature sensors, 1 VFD Grundfos Direct SensorTM

Outputs: 2 semiconductor relays, 2 PWM outputs

PWM frequency: 512 Hz

PWM voltage: 10.5 V

Switching capacity: 1 (1) A 240 V~ (semiconductor relay)

Total switching capacity: 2 A 240 V~

Power supply: 100 – 240 V~ (50 – 60 Hz)

Supply connection: type X attachment

Standby: 0.64 W

Temperature controls class: I

Energy efciency [%]: 1

Mode of operation: type 1.C.Y action

Rated impulse voltage: 2.5 kV

Data interface: VBus®

VBus®current supply: 35 mA

Functions: function control, operating hours counter, tube collector function,

thermostat function, speed control and heat quantity measurement

Housing: plastic, PC-ABS and PMMA

Mounting: wall mounting, mounting into patch panels is possible

Indication / Display: System-Monitoring-Display for visualisation of systems,

16-segment and 7-segment display, 8 symbols for indication of system status

Operation: 3 buttons

Ingress protection: IP 20 / EN 60529

Protection class: I

Ambient temperature: 0 … 40 °C

Pollution degree: 2

Fuse: T2A

Maximum altitude: 2000 m above MSL

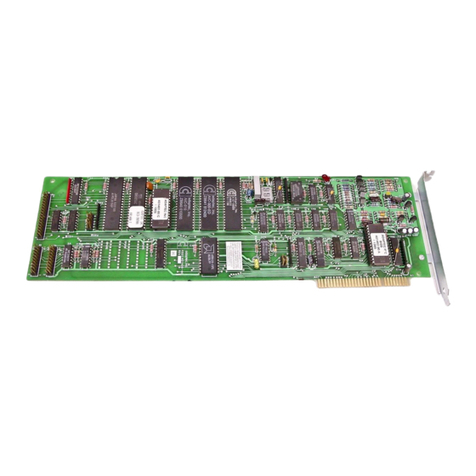

Dimensions: 172 x 110 x 46 mm

110

30

62

172

46

130

130

Upper fastening

Lower fastening

Dimensions and minimum distances

en

6

Installation Indications, functions and options MessagesCommissioningOperation and function

2 Installation

2.1 Mounting

WARNING! Electric shock!

Upon opening the housing, live parts are exposed!

ÎAlways disconnect the device from power supply

before opening the housing!

Note

Strong electromagnetic elds can impair the function of the device.

ÎMake sure the device as well as the system are not exposed to strong

electromagnetic elds.

The unit must only be located in dry interior rooms.

If the device is not equipped with a mains connection cable and a plug,the device must

additionally be supplied from a double pole switch with contact gap of at least 3 mm.

Please pay attention to separate routing of sensor cables and mains cables.

In order to mount the device to the wall, carry out the following steps:

1. Unscrew the crosshead screw from the cover and remove it along with the

cover from the housing.

2. Mark the upper fastening point on the wall. Drill and fasten the enclosed wall

plug and screw leaving the head protruding.

3. Hang the housing from the upper fastening point and mark the lower fastening

point (centres 130 mm).

4. Insert lower wall plug.

5. Fasten the housing to the wall with the lower fastening screw and tighten.

6. Carry out the electrical wiring in accordance with the terminal allocation (see

chapter 2.2).

7. Put the cover on the housing.

8. Attach with the fastening screw.

display

cable conduits with

strain relief

cover buttons

fuse T2A

en

7

InstallationIndications, functions and optionsMessages Commissioning Operation and function

2.2 Electrical connection

WARNING! Electric shock!

Upon opening the housing, live parts are exposed!

ÎAlways disconnect the device from power supply be-

fore opening the housing!

ATTENTION! ESD damage!

Electrostatic discharge can lead to damage to electronic com-

ponents!

ÎTake care to discharge properly before touching the

inside of the device!

Note

Connecting the device to the power supply must always be the last step

of the installation!

Note

The mains connection must be carried out with the common ground of

the building to which the pipework of the solar circuit is connected.

Note

The pump speed must be set to 100% when auxiliary relays or valves are

connected.

Note

It must be possible to disconnect the device from the mains at any time.

ÎInstall the mains plug such that it is accessible at any time.

ÎIf this is not possible, install a switch that can be accessed.

If the mains cable is damaged, it must be replaced by a special connection

cable which is available from the manufacturer or its customer service.

Do not use the device if it is visibly damaged!

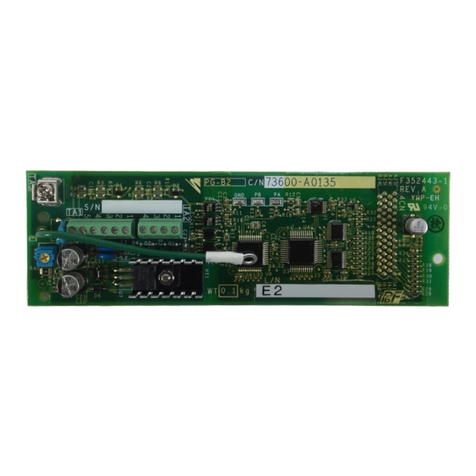

Seriennummer 1 (1) A 240 V~

1 (1) A 240 V~

R1

R2

LN

R1

N

2019

18

171615

14131212

NR2

IP 20

T2A

100 – 240 V~

50 – 60 Hz

Temp. Sensor Pt1000

S2S1 S3 S4 VBus

PWM 1/2

VFD

345678910

Fuse

VBus®mains

terminals

load

terminals

sensor terminals protective earth

conductor terminal

The power supply of the device must be 100 – 240 V~ (50 – 60 Hz). Attach exible

cables to the housing with the enclosed strain relief and the corresponding screws.

The controller is equipped with 2 semiconductor relays to which loads such as

pumps, valves, etc. can be connected:

Relay 1 Relay 2

18 = Conductor R1 16 = Conductor R2

17 = Neutral conductor N 15 = Neutral conductor N

13 = Protective earth conductor ⏚14 = Protective earth conductor ⏚

The mains connection is at the following terminals:

19 = Neutral conductor N

20 = Conductor L

12 = Protective earth conductor ⏚

Connect the temperature sensors (S1 to S4) to the corresponding terminals

with either polarity:

1 / 2 = Sensor 1 (e. g. collector sensor 1)

3 / 4 = Sensor 2 (e. g. store sensor 1)

5 / 6 = Sensor 3 (e. g. store sensor top)

7 / 8 = Sensor 4 (e. g. return sensor)

The cables carry low voltage and must not run together in a cable conduit with

cables carrying a voltage higher than 50 V (please pay attention to the valid local

regulations).The cable lentghs depend on the cross sectional area.

Example: up to 100 m at 1.5 mm², up to 50 m at 0.75 mm².The cables can be ex-

tended with a two-wire cable.

en

8

Installation Indications, functions and options MessagesCommissioningOperation and function

2.5 Data communication / Bus

The controller is equipped with the VBus®for data transfer and energy supply

to external modules.The connection is to be carried out at the terminals marked

VBus (either polarity).

One or moreVBus®modules can be connected via this data bus.

2.3 VFD Grundfos Direct Sensor™

The controller is equipped with 1 input for a digital VFD Grundfos Direct Sensor™

for measuring the ow rate and the temperature. Connection is made at the VFD

terminal.

2.4 PWM outputs

Speed control of a HE pump is possible via a PWM signal.The pump has to be con-

nected to the relay as well as to one of the PWM outputs of the controller. Power

is supplied to the HE pump by switching the corresponding relay on or off.

The terminals marked PWM 1/2 are control outputs for pumps with PWM control

input.

2 4

1 3

1 (1) A 240 V~

1 (1) A 240 V~

R1

R2

LN

R1

N

2019

18

17161514131212

NR2

IP 20

T2A

100 ... 240 V~

50-60 Hz

Temp. Sensor Pt1000

S2S1 S3 S4 VBus

PWM 1/2

VFD

Made in Germany

DeltaSol®CS Plus

345678910

1 = PWM output 1, control signal

2 = PWM output 1, GND

3 = PWM output 2, GND

4 = PWM output 2, control signal

R1

N

X

PWM 1/2

PWM signal

cable

blue

blue brown

brown

yellow/green

pump signal

input

pump power

supply

230V~ power

supply

black (not

used)

9

en

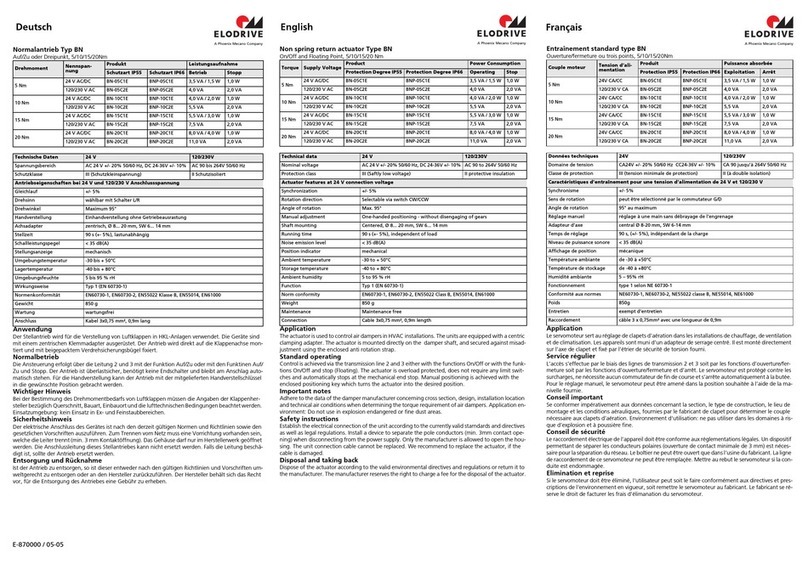

1

Standard solar system (page 10)

2

Solar system with heat exchange

(page 13)

3

Solar system with backup heating

(page 19)

4

Solar system with store loading in

layers (page 24)

5

Solar system with 2 stores and valve

logic (page 27)

6

Solar system with 2 stores and pump

logic (page 30)

7

Solar system with east-/west collectors

and 1 store (page 33)

8

Solar system with backup heating by

solid fuel boiler (page 36)

9

Solar system with heating circuit

return preheating (page 42)

10

Standard solar system with heat dump

(page 45)

2.6 System overview

en

10

Installation Indications, functions and options MessagesCommissioningOperation and function

2.7 Systems

S1

S3

S2

R1 R2

exemplary

drainback system layout

(with booster pump)

Arrangement 1: Standard solar system

The controller calculates the temperature difference between collector sensor S1

and store sensor S2. If the difference is larger than or identical to the adjusted

switch-on temperature difference (DT O), the solar pump will be activated by relay

1, and the store will be loaded until the switch-off temperature difference (DT F) or

the maximum store temperature (S MX) is reached.

Sensors S3 and S4 can optionally be connected. S3 can optionally be used as the

reference sensor for the store emergency shutdown option (OSEM).

If heat quantity measurement (OHQM) is activated, S4 is used as the return sensor.

If the drainback option (ODB) is activated, relay 2 can be used for activating a

booster pump. For this purpose, the booster function (OBST) has to be activated.

910

VBus

PWM 1/2

VFD

S1

S2

S4 / VFD / TR

S4 / VFD / TFL

R1 S3 /TSTT

en

11

InstallationIndications, functions and optionsMessages Commissioning Operation and function

Display channels

Channel Description Connection terminal Page

INIT x* ODB initialisation active - 52

FLL x* ODB lling time active - 52

STAB x* ODB stabilisation in progress - 52

COL x Temperature collector S1 53

TST x Temperature store S2 53

S3 x Temperature sensor 3 S3 53

TSTT x* Temperature store top S3 53

S4 x Temperature sensor 4 S4 53

TFL x* Temperature ow sensor S1 / S4 / VFD 53

TR x* Temperature return sensor S4 / VFD 53

VFD x* Temperature Grundfos Direct Sensor™ VFD 53

L/h x* Flow rate Grundfos Direct Sensor™ VFD 54

n % x Speed R1 R1 54

hP x Operating hours R1 R1 55

hP1 x* Operating hours R1 (if OBST is activated) R1 55

hP2 x* Operating hours R2 (if OBST is activated) R2 55

kWh x* Heat quantity in kWh - 54

MWh x* Heat quantity in MWh - 54

TIME x Time - 55

Adjustment channels

Channel Description Factory setting Page

Arr x System 1 55

DT O x Switch-on temperature difference R1 6.0 K [12.0 °Ra] 56

DT F x Switch-off temperature difference R1 4.0 K [8.0 °Ra] 56

DT S x Set temperature difference R1 10.0 K [20.0 °Ra] 56

RIS x Rise R1 2 K [4 °Ra] 56

PUM1 x Pump control type R1 PSOL 57

nMN x Minimum speed R1 30 % 57

nMX x Maximum speed R1 100 % 57

S MX x Maximum store temperature 60 °C [140 °F] 57

OSEM x Store emergency shutdown option OFF 58

EM x Collector emergency temperature 130 °C [270 °F] 58

Collector emergency temperature if ODB is activated: 95 °C [200 °F] 58

OCC x Collector cooling option OFF 58

CMX x* Maximum collector temperature 110 °C [230 °F] 58

OSYC x System cooling option OFF 59

en

12

Installation Indications, functions and options MessagesCommissioningOperation and function

Adjustment channels

Channel Description Factory setting Page

DTCO x* Switch-on temperature difference cooling 20.0 K [40.0 °Ra] 59

DTCF x* Switch-off temperature difference cooling 15.0 K [30.0 °Ra] 59

OSTC x Store cooling option OFF 59

OHOL x* Holiday cooling option OFF 59

THOL x* Holiday cooling temperature 40 °C [110 °F] 59

OCN x Collector minimum limitation option OFF 60

CMN x* Collector minimum temperature 10 °C [50 °F] 60

OCF x Antifreeze option OFF 60

CFR x* Antifreeze temperature 4.0 °C [40.0 °F] 60

OTC x Tube collector option OFF 61

TCST x* OTC starting time 07:00 61

TCEN x* OTC ending time 19:00 62

TCRU x* OTC runtime 30 s 62

TCIN x* OTC standstill interval 30 min 62

GFD x Grundfos Direct Sensor™ OFF 62

OHQM x Heat quantity measurement option OFF 62

SEN x* VFD allocation 2 63

FMAX x* Maximum ow rate 6.0 l/min 62

MEDT x* Antifreeze type 1 63

MED% x* Antifreeze concentration (only if MEDT = propylene or ethylene glycol) 45 % 63

ODB x Drainback option OFF 64

tDTO x* ODB switch-on condition - time period 60 s 64

tFLL x* ODB lling time 5.0 min 64

tSTB x* ODB stabilisation time 2.0 min 64

OBST s* Option booster function OFF 64

MAN1 x Manual mode R1 Auto 65

MAN2 x Manual mode R2 Auto 65

LANG x Language dE 65

UNIT x Temperature unit °C 65

RESE x Reset - back to factory settings 65

######## Version number

Legend:

Symbol Description

x Channel is available

x* Channel is available, if the corresponding option is activated.

s* System-specic channel, only available if the corresponding option is activated

en

13

InstallationIndications, functions and optionsMessages Commissioning Operation and function

Arrangement 2: Solar system with heat exchange

The controller calculates the temperature difference between collector sensor S1

and store sensor S2. If the difference is larger than or identical to the adjusted

switch-on temperature difference (DT O), the solar pump will be activated by relay

1, and the store will be loaded until the switch-off temperature difference (DT F) or

the maximum store temperature (S MX) is reached.

Heat exchange from store 1 to store 2 will be operated by relay 2, if the tempera-

ture difference between sensors S3 and S4 is larger than or identical to the adjusted

switch-on temperature difference (DT3O), until the adjusted minimum (MN3O)

and maximum (MX3O) temperature thresholds of the respective store are reached.

S3 can optionally be used as the reference sensor for the store emergency shut-

down option (OSEM).

If heat quantity measurement (OHQM) is activated, S1and VFD are used as the ow

and return sensors respectively.

910

VBus

PWM 1/2

VFD

R2

S1

S3 / TSTT

S4

R1

VFD / TR

S2

Store 1 Store 2

en

14

Installation Indications, functions and options MessagesCommissioningOperation and function

Display channels

Channel Description Connection terminal Page

INIT x* ODB initialisation active - 52

FLL x* ODB lling time active - 52

STAB x* ODB stabilisation in progress - 52

COL x Temperature collector S1 53

TST1 x Temperature store 1 base S2 53

TSTT x Temperature store 1 top S3 53

TST2 x Temperature store 2 base S4 53

TFL x* Temperature ow sensor S1 53

TR x* Temperature return sensor VFD 53

VFD x* Temperature Grundfos Direct Sensor™ VFD 53

L/h x* Flow rate Grundfos Direct Sensor™ VFD 54

n1 % x Speed R1 R1 54

n2 % x Speed R2 R2 54

h P1 x Operating hours R1 R1 55

h P2 x Operating hours R2 R2 55

kWh x* Heat quantity in kWh - 54

MWh x* Heat quantity in MWh - 54

TIME x Time - 55

Adjustment channels

Channel Description Factory setting Page

Arr x System 2 55

DT O x Switch-on temperature difference R1 6.0 K [12.0 °Ra] 56

DT F x Switch-off temperature difference R1 4.0 K [8.0 °Ra] 56

DT S x Set temperature difference R1 10.0 K [20.0 °Ra] 56

RIS x Rise R1 2 K [4 °Ra] 56

PUM1 x Pump control type R1 PSOL 57

n1MN x Minimum speed R1 30 % 57

n1MX x Maximum speed R1 100 % 57

S MX x Maximum store temperature 60 °C [140 °F] 57

OSEM x Store emergency shutdown option OFF 58

PUM2 x Pump control type R2 OnOF 57

n2MN x* Minimum speed R2 30 % 57

n2MX x* Maximum speed R2 100 % 57

EM x Collector emergency temperature 130 °C [270 °F] 58

Collector emergency temperature if ODB is activated: 95 °C [200 °F] 58

OCC x Collector cooling option OFF 58

CMX x* Maximum collector temperature 110 °C [230 °F] 58

OSYC x System cooling option OFF 59

DTCO x* Switch-on temperature difference cooling 20.0 K [40.0 °Ra] 59

DTCF x* Switch-off temperature difference cooling 15.0 K [30.0 °Ra] 59

en

15

InstallationIndications, functions and optionsMessages Commissioning Operation and function

Legend:

Symbol Description

x Channel is available

x* Channel is available, if the corresponding option is activated.

sSystem-specic channel

Adjustment channels

Channel Description Factory setting Page

OSTC x Store cooling option OFF 59

OHOL x* Holiday cooling option OFF 59

THOL x* Holiday cooling temperature 40 °C [110 °F] 59

OCN x Collector minimum limitation option OFF 60

CMN x* Collector minimum temperature 10 °C [50 °F] 60

OCF x Antifreeze option OFF 60

CFR x* Antifreeze temperature 4.0 °C [40.0 °F] 60

OTC x Tube collector option OFF 61

TCST x* OTC starting time 07:00 61

TCEN x* OTC ending time 19:00 62

TCRU x* OTC runtime 30 s 62

TCIN x* OTC standstill interval 30 min 62

GFD x Grundfos Direct Sensor™ OFF 62

OHQM x Heat quantity measurement option OFF 62

MEDT x* Antifreeze type 1 61

MED% x* Antifreeze concentration (only if MEDT = propylene or ethylene) 45 % 63

DT3O s Switch-on temperature difference R2 6.0 K [12.0 °Ra] 56

DT3F s Switch-off temperature difference R2 4.0 K [8.0 °Ra] 56

DT3S s Set temperature difference R2 10.0 K [20.0 °Ra] 56

RIS3 s Rise R2 2 K [4 °Ra] 56

MX3O s Switch-on threshold for maximum temperature 60.0 °C [140.0 °F] 41

MX3F s Switch-off threshold for maximum temperature 58.0 °C [136.0 °F] 41

MN3O s Switch-on threshold for minimum temperature 5.0 °C [40.0 °F] 41

MN3F s Switch-off threshold for minimum temperature 10.0 °C [50.0 °F] 41

ODB x Drainback option OFF 64

tDTO x* ODB switch-on condition - time period 60 s 64

tFLL x* ODB lling time 5.0 min 64

tSTB x* ODB stabilisation time 2.0 min 64

MAN1 x Manual mode R1 Auto 65

MAN2 x Manual mode R2 Auto 65

LANG x Language dE 65

UNIT x Temperature unit °C 65

RESE x Reset - back to factory settings 65

######## Version number

en

16

Installation Indications, functions and options MessagesCommissioningOperation and function

System-specic functions

The following adjustments are used for the specic functions in system 2.

∆T control for the heat exchange between 2 stores

DT3O

Switch-on temperature difference

Adjustment range: 1.0 … 20.0 K [2.0 … 40.0°Ra]

Factory setting: 6.0 K [12.0 °Ra]

DT3F

Switch-off temperature difference

Adjustment range: 0.5 … 19.5 K [1.0 … 39.0°Ra]

Factory setting: 4.0 K [8.0 °Ra]

S3 and S4 are used as the reference sensors for this function.

In system 2 the controller is equipped with an additional differential control for heat

exchange between two stores.The basic differential function is adjusted using the

switch-on (DT3O) and switch-off (DT3F) temperature differences.

When the temperature difference exceeds the adjusted switch-on temperature

difference, relay 2 switches on. When the temperature difference falls below the

adjusted switch-off temperature difference, relay 2 switches off.

Note

The switch-on temperature difference must be at least 0.5 K [1°Ra] high-

er than the switch-off temperature difference.

Speed control

DT3S

Set temperature difference

Adjustment range: 1.5 … 30.0 K [3.0 … 60.0 °Ra]

Factory setting: 10.0 K [20.0 °Ra]

Note

For pump speed control of the heat exchange pump, the operating mode

of relay 2 must be set to Auto in the adjustment channel MAN2.

RIS3

Rise

Adjustment range: 1 … 20 K [2 … 40 °Ra]

Factory setting: 2 K [4 °Ra]

If the switch-on difference is reached, the pump switches on at full speed for 10 s.

Then, the speed is reduced to the minimum pump speed value (n2MN).

If the temperature difference reaches the adjusted set value (DT3S), the pump

speed increases by one step (10%). Each time the difference increases by the adjust-

able rise value RIS3, the pump speed increases by 10 % until the maximum pump

speed of 100% is reached.

Note

The set temperature difference must be at least 0.5 K [1 °Ra] higher than

the switch-on temperature difference.

en

17

InstallationIndications, functions and optionsMessages Commissioning Operation and function

PUM2

Pump control type R2

Selection: OnOF, PULS, PSOL, PHEA

Factory setting: OnOF

With this parameter, the pump control type can be adjusted.The following types

can be selected:

Adjustment for standard pump without speed control

• OnOF (pump on / pump off)

Adjustment for standard pump with speed control

• PULS (burst control via semiconductor relay)

Adjustment for high-efciency pump (HE pump)

• PSOL (PWM prole for a HE solar pump)

• PHEA (PWM prole for a HE heating pump)

n2MN

Minimum speed R2

Adjustment range: (10) 30 … 100 %

Factory setting: 30 %

A relative minimum pump speed can be allocated to the output R2 via the adjust-

ment channel n2MN.

Note

The pump speed must be set to 100% when auxiliary relays or valves are

connected.

n2MX

Maximum speed R2

Adjustment range: (10) 30 … 100 %

Factory setting: 100 %

In the adjustment channel n2MX a relative maximum speed for a pump connected

can be allocated to the output R2.

Note

The pump speed must be set to 100% when auxiliary relays or valves are

connected.

en

18

Installation Indications, functions and options MessagesCommissioningOperation and function

Maximum temperature limitation heat exchange

MX3O / MX3F

Maximum temperature limitation

Adjustment range: 0.0 … 95.0 °C [30.0 … 200.0 °F]

Factory setting:

MX3O: 60.0 °C [140.0 °F]

MX3F: 58.0 °C [136.0 °F]

S4 is used as the reference sensor for the maximum temperature limi-

tation.

The maximum temperature limitation function provides a maximum temperature

setting, usually to reduce scald risk in a store. If MX3O is exceeded, relay 2 is

switched off until the temperature at sensor 4 falls below MX3F.

Minimum temperature limitation heat exchange

MN3O / MN3F

Minimum temperature limitation

Adjustment range: 0.0 … 90.0 °C [30.0 … 190.0 °F]

Factory setting (only if Arr = 2):

MN3O: 5.0 °C [40.0 °F]

MN3F: 10.0 °C [50.0 °F]

S3 is used as the reference sensor for the minimum temperature limi-

tation.

The minimum temperature limitation function provides a minimum temperature

setting for the heat source in system 2. If the temperature at sensor 3 falls below

MN3O, relay 2 is switched off until the temperature at sensor 3 exceeds MN3F.

Both switch-on and switch-off temperature differences DT3O and DT3F are valid

for the maximum and minimum temperature limitation.

en

19

InstallationIndications, functions and optionsMessages Commissioning Operation and function

Arrangement 3: Solar system with backup heating

The controller calculates the temperature difference between collector sensor S1

and store sensor S2. If the difference is larger than or identical to the adjusted

switch-on temperature difference (DT O), the solar pump will be activated by relay

1, and the store will be loaded until the switch-off temperature difference (DT F) or

the maximum store temperature (S MX) is reached.

Sensor S3 is used for a thermostat function, which operates relay 2 for backup

heating or heat dump purposes, when the adjusted thermostat switch-on tempera-

ture (AH O) is reached.This function can optionally be combined with up to three

adjustable time frames.

Sensor S3 can optionally be used as the reference sensor for the thermal disinfec-

tion function (OTD) or the store emergency shutdown option (OSEM).

Sensor S4 can optionally be connected. If heat quantity measurement (OHQM) is

activated, S4 and VFD are used as the ow and return sensors respectively.

VBus

910

PWM 1/2

VFD

R2

S1

S2

R1

S3 / TSTT

S4 / VFD / TR

S4 / VFD / TFL

en

20

Installation Indications, functions and options MessagesCommissioningOperation and function

Display channels

Channel Description Connection terminal Page

INIT x* ODB initialisation active - 52

FLL x* ODB lling time active - 52

STAB x* ODB stabilisation in progress - 52

COL x Temperature collector S1 53

TSTB x Temperature store 1 base S2 53

TSTT x Temperature store 1 top S3 53

TDIS s* Thermal disinfection temperature (thermal disinfection) S3 53

S4 x Temperature sensor 4 S4 53

TFL x* Temperature ow sensor S1 / S4 / VFD 53

TR x* Temperature return sensor S4 / VFD 53

VFD x* Temperature Grundfos Direct Sensor™ VFD 53

L/h x* Flow rate Grundfos Direct Sensor™ VFD 54

n1 % x Speed R1 R1 54

h P1 x Operating hours R1 R1 55

h P2 x Operating hours R2 R2 55

kWh x* Heat quantity in kWh - 54

MWh x* Heat quantity in MWh - 54

CDIS s* Countdown of monitoring period (thermal disinfection) - 54

SDIS s* Starting time display (thermal disinfection) - 54

DDIS s* Heating period display (thermal disinfection) - 54

TIME x Time - 55

Adjustment channels

Channel Description Factory setting Page

Arr x System 3 55

DT O x Switch-on temperature difference R1 6.0 K [12.0 °Ra] 56

DT F x Switch-off temperature difference R1 4.0 K [8.0 °Ra] 56

DT S x Set temperature difference R1 10.0 K [20.0 °Ra] 56

RIS x Rise R1 2 K [4 °Ra] 56

PUM1 x Pump control type R1 PSOL 57

n1MN x Minimum speed R1 30 % 57

n1MX x Maximum speed R1 100 % 57

S MX x Maximum store temperature 60 °C [140 °F] 57

OSEM x Store emergency shutdown option OFF 58

EM x Collector emergency temperature 130 °C [270 °F] 58

Collector emergency temperature if ODB is activated: 95 °C [200 °F] 58

OCC x Collector cooling option OFF 58

CMX x* Maximum collector temperature 110 °C [230 °F] 58

OSYC x System cooling option OFF 59

DTCO x* Switch-on temperature difference cooling 20.0 K [40.0 °Ra] 59

DTCF x* Switch-off temperature difference cooling 15.0 K [30.0 °Ra] 59

OSTC x Store cooling option OFF 59

OHOL x* Holiday cooling option OFF 59

THOL x* Holiday cooling temperature 40 °C [110 °F] 59

Table of contents

Other ACV Controllers manuals