Titus BAC-8007 User manual

Redefine your comfort zone. ™ | www.titus-hvac.com

Alpha Dual-Duct

VAV Controller

BAC-8007/BAC-8207

INSTALLATION &

OPERATION MANUAL

2IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Table of Contents

SECTION 1

About the Controllers

Specifications ..................................................................................................................................................... 4

Safety Considerations ........................................................................................................................................ 7

SECTION 2

Installing the Controller

Setting the Rotation Limits ................................................................................................................................ 9

Mounting ............................................................................................................................ ............................. 10

Connecting Inputs ............................................................................................................. .............................. 11

Connecting Outputs ......................................................................................................................................... 12

Connecting to Sensors ..................................................................................................................................... 13

Connecting to an Ms/Tp Network ................................................................................................................... 14

Connecting an Airflow Sensor ......................................................................................................................... 17

Connecting Power ............................................................................................................................................ 17

Dual-Duct Connections .................................................................................................................................... 18

SECTION 3

Setting Up Dual-Duct Controllers

Network Communications ............................................................................................................................... 19

Setting Temperature Setpoints .......................................................................................... ............................. 20

Setting Airflow Setpoints ................................................................................................... ............................. 21

Setting the Vav Terminal Unit Parameters .................................................................... .................................. 22

Setting Up Local Lighting Control ..................................................................................... .............................. 23

Balancing Airflow ............................................................................................................... ............................. 23

3

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 1 — About the Controllers

This section provides a description of the Titus Alpha BAC-8007 and BAC-

8207 VAV controllers. It also introduces safety information. Review this

material before installing or operating the controllers.

The BAC-8007 and BAC-8207 are native BACnet, direct digital controllers

designed for VAV terminal units. An integrated actuator and the supplied

programs make these ideal controllers for temperature setback, overrides,

reheat and other HVAC sequences. Install these versatile controllers in

stand-alone environments or networked to other BACnet devices. As part

of a complete facilities management system, the BAC-8007 and BAC-8207

controllers provide precise monitoring and control of connected points.

•BACnet MS/TP compliant

•Standard VAV control sequences are incorporated to provide pressure

independent control of a dual-duct VAV unit to control heating and

cooling

•On-board airflow sensor for use with a single or multi-point differential

pressure measuring station or pitot tube.

•Control indoor air quality and local lighting

Models:

BAC-8007 Dual-duct VAV controller with 90

second actuator

BAC-8207 Dual-duct VAV controller with 60 second

actuator and UL 864 smoke control application

4IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 1 — About the Controllers

Analog inputs All inputs are configured as analog

Active inputs 2

Passive inputs 4

Air flow sensor 1

Actuator position 1

Key features Standard units of measure

Overvoltage input protection

Connector Spade connectors, 0.25 inch

Conversion 12–bit analog–to–digital conversion

Input range 0–12 volts DC

Outputs, analog 2

Key features Output short protection

Configured as BACnet analog objects

Standard units of measure

Connector Spade connectors, 0.25 inch

Conversion 12–bit analog–to–digital conversion

Output voltage 0–10 volts DC

Output current 30 mA per output, 30 mA total for all

analog outputs

Outputs, binary 4 triacs for external equipment

2 for the internal actuator

Key features Optically isolated triac output

Conversion 12–bit analog–to–digital conversion

Connector Spade connectors, 0.25 inch

Output range Maximum switching 24 VAC at 3 amperes

Communications

BACnet MS/TP EIA–485 operating at rates up to 76.8 kilobaud

Removable screw terminal block

Wire size 12–24 AWG

Sensor jack RJ-45 jack compatible with model STE-8000 and

STE-6000 models with RJ-45 jacks

Supported objects See PIC statement for supported BACnet objects

Control Basic 5 program areas in BAC-8007

6 program areas in BAC-8207

PID loop objects 8

Value objects 60 analog, 32 binary, and 12 multistate

Memory Programs and program parameters are stored

in nonvolatile memory

Auto restart on power failure

SPECIFICATIONS

5

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 1 — About the Controllers

Applications programs

Titus Controls supply the BAC-8x07 with programming sequences for

dual-duct VAV applications:

• Dual-duct VAV heating and cooling

• Monitor CO2 to control indoor air quality

•

Control local lighting with motion sensing

• Fan control

• Balancing

• UL 864 smoke controll (BAC-8207 only)

Air flow sensor features

Configured as BACnet analog input object. CMOS differential

pressure 0-2 inches of water (0-500 Pa) measurement range.

Internally linearized and temperature compensated. Span accuracy

4.5% of reading. Barbed connections for 1/4 FR tubing. Range

dependent upon DP pickup, tubing size/length and connections.

Actuator specifications

Torque 40 in-lb. (4.5 N•m)

Angular rotation 0 to 95°

Adjustable end stops at 45° and 60° rotation

Motor timing,

BAC-8007 90 sec./90° at 60 Hz

108 sec./90° at 50 Hz

Motor timing,

BAC-8207 60sec./90° at 60 Hz

72 sec./90° at 50 Hz

Shaft size Directly mounts on 3/8 to 5/8 inch

(9.5 to 16 mm) round or 3/8 to 7/16 inch (9.5 to

11 mm) square damper shafts

Regulatory UL 916 Energy Management Equipment

FCC Class B, Part 15, Subpart B

BACnet Testing Laboratory listed as an

application specific controller (ASC)

UL 864 smoke controls (BAC-8207 only)

Installation

Supply voltage 24 volts AC, -15%, +20% 5 VA

Weight 13.2 ounces (376 grams)

Case material Flame retardant plastic

Environmental limits

Operating 32 to 120° F (0 to 49° C)

Shipping –40 to 140° F (–40 to 60° C)

Humidity 5–95% relative humidity (non-condensing)

SPECIFICATIONS (continued)

6IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 1 — About the Controllers

DIMENSIONS

Table 1-1 BAC- 8000 dimensions

A B C D E F G

6.53 in . 4 .89 in . 4 .25 in . 0 .77 in . 6 .00 in . 2 .14 in . 1 .92 in .

166 mm 124 mm 108 mm 19 mm 152 mm 54 mm 49 mm

A

B

D

G

F

E

C

7

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 1 — About the Controllers

SAFETY CONSIDERATIONS

Titus assumes the responsibility for providing you a safe product and

safety guidelines during its use. Safety means protection to all individuals

who install, operate, and service the equipment as well as protection of

the equipment itself. To promote safety, we use hazard alert labeling in this

manual. Follow the associated guidelines to avoid hazards.

DANGER Danger represents the most severe hazard

alert. Bodily harm or death will occur if danger

guidelines are not followed.

WARNING Warning represents hazards that could result in

severe injury or death.

CAUTION Caution indicates potential personal injury or

equipment or property damage if instructions are

not followed.

NOTE Notes provide additional information that is

important.

DETAIL Provides programing tips and shortcuts that may

save time.

8IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 2 — Installing the Controller

This section provides important instructions and guidelines for installing

the BAC-8007 and BAC-8207 controllers. Carefully review this information

before installing the controller.

Installing the VAV controller includes the following topics that are covered

in this section.

•Setting the rotation limits on page 9

•Mounting on page 10

•Connecting Inputs on page 14

•Connecting Outputs on page 12

•Connecting to an MS/TP Network on page 14

•Connecting an Airflow Sensor on page 17

•Connecting Power on page 17

In addition to the topics, see the section Dual-duct connections on page

18 for connecting the controllers to a TSP-8000 actuator for dual-duct

operation.

9

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Before mounting the controller, set the rotation limits with the supplied

stop screw. Installing the stop screw limits the shaft rotation to either 45

or 60 degrees.

CAUTION

Before setting the rotation limits on the controller, refer to the damper

position specifications in the VAV control box to which the controller

will be attached. Setting rotation limits that do not match the VAV

damper may result in improper operation or equipment damage.

To set the rotational limits:

1. Turn the controller over so you have access to the back.

2. Manually rotate the actuator fully clockwise as viewed from the back.

3. Remove the stop screw from its storage location and clean any debris

from the threads.

4. Insert the screw into the correct stop position hole.

5. Tighten the screw only until the head touches the plastic in the

bottom of the recess.

Section 2 — Installing the Controller

SETTING THE ROTATION LIMITS

Illustration 2-1 Controller stop selections

10 IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 2 — Installing the Controller

Mount the controller inside of a metal enclosure. To maintain RF emissions

specifications, use either shielded connecting cables or enclose all cables

in conduit.

Mount the controller directly over the damper shaft. A minimum shaft

length of 2.0 inch (51 mm) is required.

NOTE

The controller is designed to directly mount to 3/8 to 5/8 inch (9.5

to 16mm) round or 3/8 to 7/16 (9.5 to 11mm) square damper shafts.

Mount the controller close enough to the pitot tubes to keep the tubing

length to a minimum. In typical installations the controller’s inputs and

sensors are within 24 inches of each other.

Mount the controller as follows:

1. Loosen the nuts on the U-bolt until the shaft can fit through the collar.

2. Place the controller on the damper shaft in the approximate final

position. Position the controller loosely against the mounting surface

so that the mounting bushing can float freely in the mounting tab.

3. Center the mounting bushing in the slot of the mounting tab and

secure it using a #8 self-tapping screw.

4. Manually position the damper in the full open position.

5. Adjust the drive hub as follows:

a. If the damper rotates counter clockwise to close, depress the

gear disengagement button and rotate the drive hub to the full

clockwise position then release the button.

b. If the damper rotates clockwise to close, depress the gear

disengagement button and rotate the drive hub to the full

counter clockwise position then release the button.

6. Lock the hub to the shaft by evenly tightening the V-bolt nuts to 30

to 35 in-lbs.

MOUNTING

Illustration 2-2 Controls and indicators

11

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 2 — Installing the Controller

Discharge air temperature: Connect a 10k , Type 3 thermistor temperature

probe to the discharge air temperature input. The input includes the internal

pull-up resistor. An STE-1405 sensor is suitable for this application. Follow

the instructions supplied with the sensor for installation. See Temperature

Setpoints on page 20 for setting up discharge air temperature limiting that

requires this input sensor.

Space Temperature Input: The space temperature input is connected only

through the RJ-45 thermostat and sensor input jack. It is a configured

as an analog input for STE-6010, STE-6014, and STE-6017 sensors. If an

STE-8000 sensor is connected to the controller, this input is ignored. See

Connecting to Sensors on page 13.

Space Setpoint: The space setpoint input is connected only through the

RJ-45 thermostat and sensor input jack. It is a configured for the setpoint

dials on STE-6014 or STE-6017 sensors. If an STE-6010 or STE-8000 sensor

is connected to the controller, this input is ignored. See Connecting to

Sensors on page 13.

The BAC-8007 and BAC-8207 controllers have preconfigured analog inputs to support the supplied programs. The inputs cannot be changed to binary or

accumulator inputs. Only six inputs have externally available physical terminals. All of the inputs are preconfigured for the application programs supplied

in the dual-duct controllers and are listed in Table 2-1.

Primary Duct Pressure: The primary duct pressure input is an internal

measurement from the airflow sensor.

Secondary Duct Pressure: The secondary duct pressure input is an analog

input preconfigured to connect to the P Out terminal of a TSP-8000 series

actuator for dual-duct operation. The TSP-8000 P Out represents actual

airflow detected by the TSP-8000 airflow sensor. See the section Dual-duct

Connections on page 18 for connection details.

Secondary Damper Position: The secondary damper position input

is preconfigured to connect to the position potentiometer of an TSP-

8000 series actuator for dual-duct operation. See the section Dual-duct

Connections on page 18 for connection details.

CO2 input: Connect a CO2 sensor with an active output to the CO2 input.

Set the sensor for a voltage output. An STE-1001 sensor is suitable for this

application. Follow the instructions supplied with the sensor for sensor

power, installation and calibration.

Primary Damper Position: The primary damper position input is

preconfigured as an analog input that represents the position of the

internal damper. Primary Duct Pressure The primary duct pressure input is

an internal measurement from the airflow sensor.

CONNECTING INPUTS

Table 2-1 BAC-8007 and BAC-8207 input objects

Illustration 2-3 Discharge air temperature

Illustration 2-4 Connections for CO2 sensor

Object Function Name Unit Location Pull up

AI1 Discharge Air Temperature DISCHARGE AIR °F Terminal block 10kΩ

AI2 Space Sensor SPACE SENSOR °F RJ-45 10kΩ

AI3 Space Setpoint SPACE SETPOINT °F RJ-45 10kΩ

AI4 Primary Duct Pressure PRIMARY DUCT wc Internal airow sensor N/A

AI5 Secondary Duct Pressure SECONDARY DUCT wc Terminal block None

AI6 Secondary Damper Position SECONDARY POS Volts Terminal block 10kΩ

AI7 CO2 CO2 PPM Terminal block None

AI8 Primary Damper Position PRIMARY POS Volts Internal damper position N/A

12 IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Damper Clockwise and Clockwise: The damper outputs are binary output

objects that control the motion of the internal damper.

Analog Heat: The analog heat output controls modulating analog reheat.

This output is active only if the controller is set up for reheat. For staged

reheat applications, use an REE-5001 relay.

Fan Speed: Controls the speed of a variable speed fan if the controller is

set up for fan operation.

Fan Start/Stop: The fan start output is preconfigured to either start or stop

a single speed fan or enable a multispeed fan. The output is a triac that

can switch up to 1 ampere at 24 volts AC.

Secondary Damper Clockwise and Counterclockwise: The secondary

damper output terminals are preconfigured to control the position of the

damper of a TSP-8000 series actuator for dual-duct operation. The outputs

are triacs that can switch up to 1 ampere at 24 volts AC. See the section

Dual-duct Connections on page 18.

Section 2 — Installing the Controller

The BAC-8007 and BAC-8207 controllers have eight preconfigured outputs to support the supplied programs. Only six have externally available physical

terminals. All of the outputs are preconfigured for the application programs supplied in the in the dual-duct controllers and are listed in Table 2-2.

Table 2-2 BAC-8007 and BAC-8207output objects

Illustration 2-5 Modulating heat output

Illustration 2-7 Fan start output

Illustration 2-6 Fan speed output

Object Function Name False Value True Value Default Value Type

BO1 Damper Clockwise DAMPER CW Neutral Clockwise Neutral Internal

BO2 Damper Counter Clockwise DAMPER CCW Neutral Counterclockwise Neutral Internal

AO3 Analog Heat ANALOG HEAT 00-10 VDC

AO4 Fan Speed FAN SPEED 0 0-10 VDC

BO5 Fan Start/Stop FAN On Off Off Triac

BO6 Secondary Damper Clockwise SEC damper cw Neutral Clockwise Neutral Triac

BO7 Secondary Damper Counterclockwise Sec damper ccw Neutral Counterclockwise Neutral Triac

BO8 Lighting Heat/lite On Off Off Triac

CONNECTING OUTPUTS

13

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 2 — Installing the Controller

Connect any of the following sensors to the RJ-45 thermostat and sensor jack.

•STE-8001STE-8201

•STE-6010

•STE-6014

•STE-6017

Link the controller to sensors with standard straight-through Ethernet

cables up to 75 feet long. See the installation guide supplied with the

sensors for complete sensor installation instructions.

No programming or configuration is required for the supported sensors.

The controller is configured to automatically detect which type of sensor

is connected to it.

Local lighting: The lighting output is preconfigured to work with the

motion sensor in an STE-8201 sensor to automatically control lights

located in the same space as the VAV. The output is a triac that can switch

up to 1 ampere at 24 volts AC.

Illustration 2-8 Lighting output

CONNECTING TO SENSORS

Illustration 2-9 Connecting to a sensor

14 IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 2 — Installing the Controller

The BAC-8000 series controllers are BACnet MS/TP compliant controllers.

Connect them only to a BACnet MS/TP network.

See Application Note AN0404A, Planning BACnet Networks for additional

information about installing controllers.

Connections and wiring

Use the following principles when connecting a controller to an

MS/TP network:

•Connect no more than 128 addressable BACnet devices to one MS/TP

network. The devices can be any mix of controllers or routers.

•To prevent network traffic bottlenecks, limit the MS/TP network size

to 60 controllers.

•Use 18 gauge, twisted pair, shielded cable with capacitance of no

more than 51 picofarads per foot for all network wiring. Belden cable

model #82760 meets the cable requirements.

•Connect the -A terminal in parallel with all other - terminals.

•Connect the +B terminal in parallel with all other + terminals.

•Connect the shields of the cable together at each controller. For KMC

BACnet controllers use the S terminal.

•Connect the shield to an earth ground at one end only.

•Use a KMD–5575 repeater between every 32 MS/TP devices or if the

cable length will exceed 4000 feet (1220 meters). Use no more than

four repeaters per MS/TP network.

•Place a KMD–5567 surge surpressor in the cable where it exits a

building.

CONNECTING TO AN MS/TP NETWORK

Illustration 2-10 MS/TP network connection

15

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 2 — Installing the Controller

NOTE

The MS/TP terminals are labeled -A, +B and S. The S terminal is

provided as a connecting point for the shield. The terminal is not

connected to the ground of the controller. When connecting to

controllers from other manufacturers, verify the shield connection is

not connected to ground.

Illustration 2-11 MS/TP network wiring

16 IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 2 — Installing the Controller

End of the line termination switches

The controllers on the physical ends of the EIA-485 wiring segment must

have end-of-line termination installed for proper network operation. Set

the end-of-line termination to On using the EOL switches.

Illustration 2-13 shows thez position of the BAC-8000 End-of-Line switches

associated with the MS/TP inputs.

CONNECTING TO AN MS/TP NETWORK (CONTINUED)

Illustration 2-12 End of line termination

Illustration 2-13 Location of EOL switch

17

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 2 — Installing the Controller

Power

terminals

Illustration 2-14 Airow sensor inputs

Illustration 2-15 Power terminals and jumper

Illustration 2-16 Power connections

An airflow sensor is incorporated as one of the inputs to the controller.

Remove the plugs and connect the tubing from the pitot assembly to the

airflow sensor inputs next to the drive hub. (See Illustration 2-14). The

airflow sensor is programmed as Input 1.

The controllers require an external, 24 volt, AC power source. Use the

following guidelines when choosing and wiring transformers.

•Use a Class-2 transformer of the appropriate size to supply power to

the controllers. Titus recommends powering only one controller from

each transformer.

•Do not run 24 volt, AC power from within an enclosure to

external controllers.

Connect the 24 volt AC power supply to the power terminal block on

the lower right side of the controller near the power jumper. Connect

the ground side of the transformer to the ground terminal and the AC

phase to the phase ~ terminal. Power is applied to the controller when the

transformer is powered.

CONNECTING AN AIRFLOW SENSOR

CONNECTING POWER

18 IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 2 — Installing the Controller

The BAC-8007 and BAC-8207 controllers are configured by the manufacturer for dual-duct operation. Connect the controllers to a TSP-8000 series

actuator as shown in the illustration Dual-duct wiring diagram below.

DUAL-DUCT CONNECTIONS

Illustration 2-17 Dual-duct wiring diagram

19

IOM - ALPHA CONTROLLER

Redefine your comfort zone. ™ | www.titus-hvac.com

Section 3 — Setting up Dual-Duct Controllers

Before connecting the controller to a BACnet MS/TP network, configure the

following network parameters with either a BACnet operator workstation

or temporarily connecting an STE-8001 or STE-8201 to the controller.

Device instance: Set from 0 to 4,194,302. A device instance number

must be unique across the BACnet internetwork.

Baud: Valid baud settings are 9600, 19200, 38400, and 76800.

MAC: Set from 0 to 127. Must be unique on the MS/TP network to

which the controller is connected.

NETWORK COMMUNICATIONS

The topics in this section cover setting up the BAC-8007 and BAC-8207

for dual-duct VAV operation. These are advanced topics for controls

technicians and engineers.

The BAC-8007 and BAC-8207 dual-duct VAV controllers are set up by the

manufacturer to operate as soon as power is applied and connected as

described in the section Installing the Controller beginning on page 9.

Setting up the dual-duct VAV controllers may include setting BACnet

objects with a BACnet Operator Workstation such as TotalControl. The

objects may also be set up with a STE-8001 or STE-8201. The following

topics are covered in this section.

•Setting Temperature Setpoints on page 20

•Setting Airflow Setpoints on page 21

•Setting the VAV Terminal Unit Parameters on page 22

•Setting Up Local Lighting control on page 23

•Network Communications on page 19

CAUTION

Change only the present values of the objects listed in this section.

Changing any other objects or properties will result in improper

operation.

20 IOM - ALPHA CONTROLLER Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

BAC-8007/BAC-8207

Section 3 — Setting up Dual-Duct Controllers

The space temperate setpoints listed in Table 3-1, “Temperature setpoints,”

below are used to control the controller VAV operation. The temperature

setpoints have default values, but may be manipulated depending on

which type of wall sensor is connected to the controller.

Occupied cooling and heating setpoints: These setpoints are user

controlled space setpoints that originate from an attached sensor. If no

sensor is attached the values for these setpoints are manually entered by

a controls technician.

Unoccupied cooling and heating setpoints: The unoccupied setpoints

are manually entered values to set the heating and cooling temperature

when the space is unoccupied.

Minimum cooling setpoint: A manually entered value to limit the

occupied cooling setpoint regardless of the value entered by the user.

Maximum heating setpoint: A manually entered value to limit the

occupied heating setpoint regardless of the value entered by the user.

Minimum setpoint differential: Sets the minimum temperature separation

between occupied heating and cooling setpoints.

Standby differential: This differential is added or subtracted from the

occupied temperature setpoints to calculate the standby setpoints.

SAT changeover temperature: Sets the supply air temperature at which

the controller will change from heating to cooling. The changeover takes

place when the supply air temperature is 2° above or below the discharge

air temperature setpoint.

SETTING TEMPERATURE SETPOINTS

Object Description Name Default

AV5 Occupied Cooling Setpoint OCC CL STPT 74°F

AV6 Occupied Heating Setpoint OCC HT SPT 70°F

AV7 Unoccupied Cooling Setpoint UNOCC CL STPT 80°F

AV8 Unoccupied Heating Setpt UNOCC HT STPT 64°F

AV9 Minimum Cooling Setpt MIN CL STPT 70°F

AV10 Maximum Heating Setpoint MAX HT STPT 76°F

AV11 Minimum Setpoint Differential MIN STPT DIFF 4°F

AV12 Standby Differential STBY DIFF 3°F

AV37 SAT Changeover Temp SAT CHANGEOVER 75°F

Table 3-1 Temperature setpoints

This manual suits for next models

1

Table of contents

Other Titus Controllers manuals

Popular Controllers manuals by other brands

Whelen Engineering Company

Whelen Engineering Company 295SHA1 installation guide

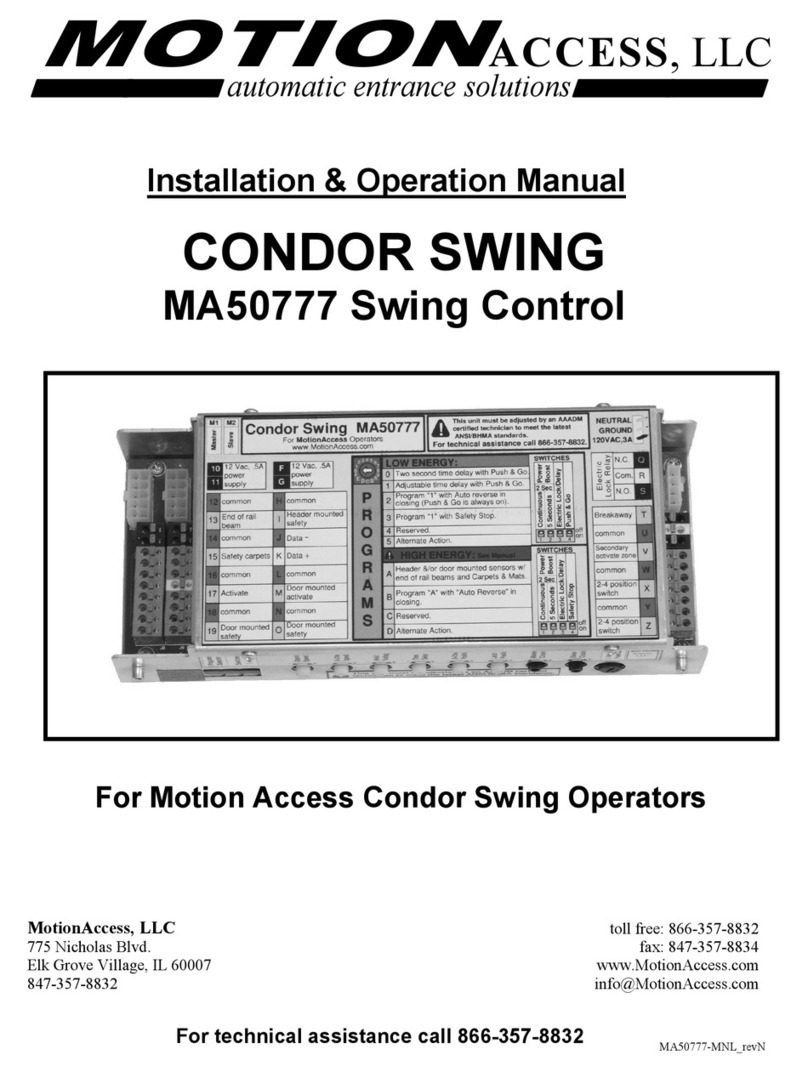

Motion Access

Motion Access CONDOR SWING MA50777 Installation & operation manual

KMC Controls

KMC Controls BAC-7003 installation guide

Luster Teraband Photonics

Luster Teraband Photonics CableTRAN MoCA1.1 user manual

SLV

SLV 470674 operating manual

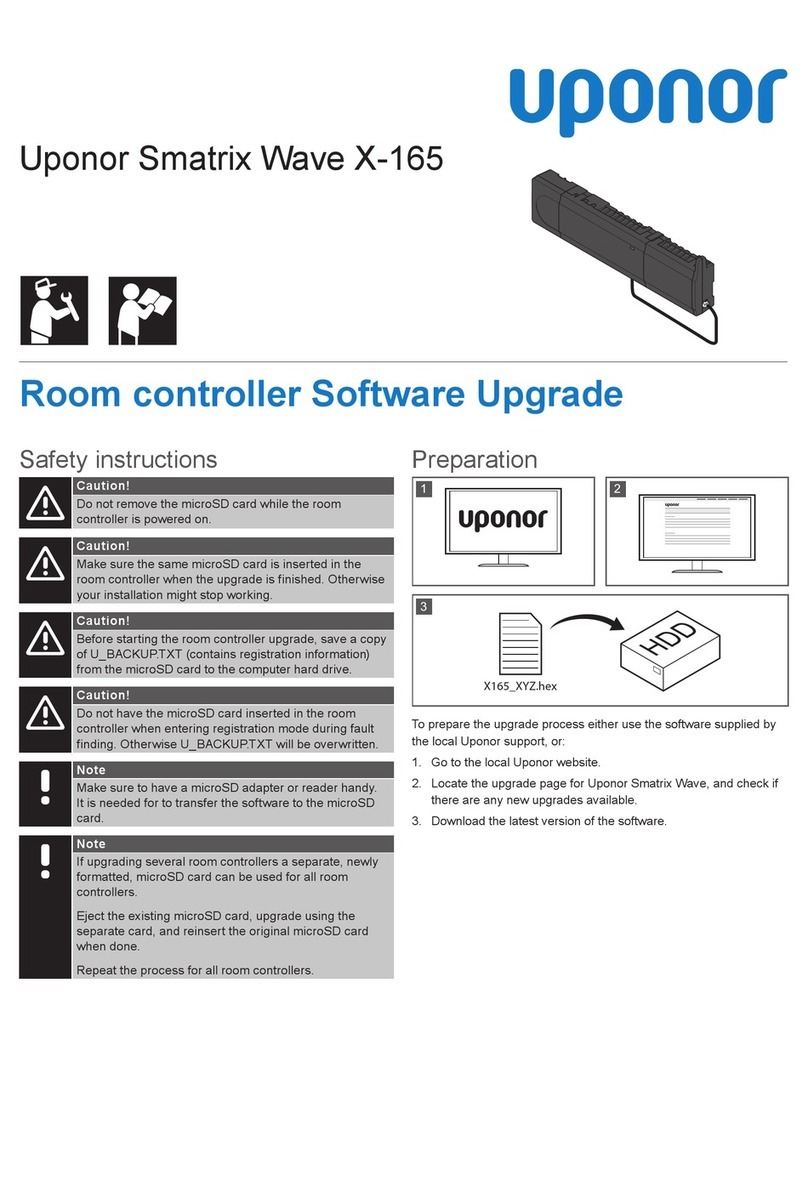

Uponor

Uponor Smatrix Wave X-165 Software Upgrade