Allied Radio KNIGHT VTVM User manual

THEKNIGHT

vTvi

AtLI

ED

RADIO

IOO N. WESTERN AVE.. CHTCAGO SO, tLL. HAYMARK€T t-6eoo

HOWTOREADCOI.OR

(ODT

OlIRTSISIORS

A}IDCOIIDE}ISTRS

All carbon resistorsare produced and color<od.d under standardsset by ihe RTMA {Radio and TelevisionManu-

facturers'Association).Undcr thesestandardsthe useris assurd of a wide rangc of valu€s

atrd of a univenal color-

coding systemthat permits casy idrntification of any carbon r*tor. To detemine the value of a resistor,hold it

with the colorcd bandsreadinefron the left end. as illustrated.and refer to the chart.

BANDA BANDB BANDC IAND D

Color Color Color

Eloct

Gr.y

0

I

2

3

5

6

7

9

slock

R.d

8lu.

0

I

2

3

1

5

6

7

I

9

Blo.t

R.d

Bluc

Gold

Silv.r

0

xt0

xl00

xt.000

xt0,000

xr00,000

X |0Million

- r0

_ t00

Silv.r ):20%

+ t0%

Thc first band (A) shows

the firlt 6gure of the resistor

value, the secondband (B) showsth€ second6gure,the thi.d

band (C) iDdicatcsthe number of zerosto add. The fourth band (D), which js not included on all resiston,mrrely

indicatcstolcran.c: silver for a (plus or minus) l0%, gold fot t 5%. lf the (D) band is omitted, thc tol.ran(c

n :! 20/..

Hereisanexamplc:BandA yellow,

bandB violet,

bandC yellow,

bandD silver: (4) (7) (X10,000)(110%)

or 470,000

ohms,i l0% tolerance.

Mica condrnsen arc frequently color-.oded. The colored dots havethc sane figure meaning asfor resistors

(that is,

black is 0, brown is l, elc.) but the.e are three systemsfor reading thc complete values.

OLD RMA SIX

DOTSYSTEM RTMA

PROPOSED

ANDJAN-C-5

THREE

DOT SYSTEM

tr

ooo

ooo

ooo

ooo

Enti,eConrenhCoptrighr6d 1956,

b),ALIIEDiADIO CORP, p'i{sd ii U.S,A.

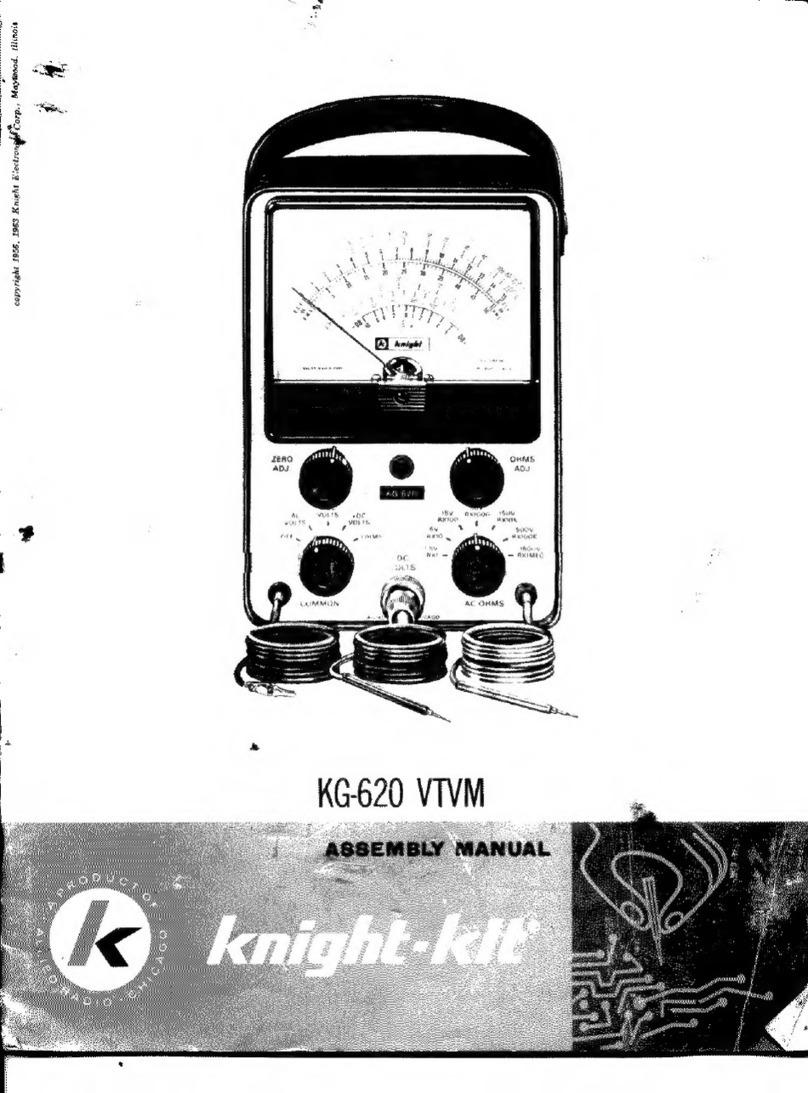

SPECIFICATIONS

DC

Ranses-.........-...-.....-..-.-.C€nter

scaleat 10 with

multiptiersXl,Xl0,

x 100,x 1000,

x 10K,

X 100K,X 1Mes.

PrintedCirGuill

Tube Complemenl:

Bortery:

Ranaes............-...... .... 1.5,

5, 15,50, 150,

500,

and 1500volts full scale.

Input Resistance ..........11Megohms (1 Megohm

in probe) on all ranges.

Circr1it....-...-..... ... Push -Pull batanced

bridge with 12AU7 t\rin

triode.

Accuracy ..... ... 13% full scale.

RMS Ran9es..................-1.5, 5, 15, 50, 150, 500,

1500 volts full scale.

Accuracy.............-.............15t;futl scale,

Peak-to-PeakRanges.....4,14,40,140,400,1400,

4000 volts.

4Y." 200aA mov€m€nt.

1% pr€cision

type.

Copperetchedotr lami

12AU7,

twin triode me-

6AL5, twin diode fuu

105-125volts,50-60cy-

clesAC.

1.5

volt "C" battery.

voltage, rcsistance,and AC voltage after rectification

by the fullwave rectifier. \

The meter employed

is an €xtremely stable,sensitive

200 microampere movement. The muttipliers are 1%

precision

type. Overall accuracjr

of tl1eDC functions is

13% of full scalereadins, and :!5% on AC functions.

A wide choice

of measurements

is provided arvDa you

seven ranses on DC, AC, and resistance. Bot}l RMS

and peak-to-peakAC voltages may b€ measurcd.

Your KNIGHT VTVM, through the useof the print-

cd circuit. saves

a greal d"at of t,dious wiring, as;ures

you ot a finisl'ed,nstrument

which compsres

closety

lo rhe original ensinFerina

modet,

ana irov:aes yoir

wrth an instl.ment \ orlh manv limes

irs low cost.

Before startina to build your KNIGHT VTVM,

check each palt against the Palts List on page 23. If

you are unableto identify someof the parts by sight,

locate them on the pictorial diagrams. Capacitor and

r€sistor values,if not printed on the part, canbe found

with the aid of the color codechat.

Hardware is listed in the last part of the parts List.

To keep our kits at the lowest possiblepdce, we frc,

quently weigh hardware raiher than to count it.

Therefore, do not be concerned if more nuts anar

machine screws, for example, are supplied than are

specified in the Parts List.

The only tools required for buildins your KNIGHT

VTVM are: Long-nosepliels, diasoral cutters, screw-

driver,

sei-scrF$d.ivcr. rnd a 50-wa||soldering

iron.

You may want to use a larger iron for soldedna the

contacts other than the pdnted circuit, but DO NOT

USE AN IRON LARGER THAN 50 WATTS FOR

MAKING THE SOLDER CONNECTIONS ON TIIE

PRINTED CIRCUIT. A good set of tools is listed at

t]le erd of tlje Parts List.

Study the pictorial diasrams and notehow the palts

are mounted.These

pictorial diagrams showthe actuat

location of all parts and wirirs. The schematic dia-

gram shows how the parts are cormect€d electrica.lly

aDd is helpful in understanding how Urc circuitg work.

The step-by-Etepinstructions wer€ prepaled by a

skilled techDicianwhite he was actually building the

KNIGHT VTVM. Therefore, they are the best and

fastest way of assembling this instrum€nt. We suggest

that you read throuah the instructions b€fore building

the VTVM. This will €nable you to Jamiliarize yourseu

with the proc€du.e and avoid possible erroru. We

invite you to use the blank parentheses,( ), beforc

eachstep to check it off ajter you have completedit.

Each step is clearly illustraLedon an accompanying

line drawing. Somebuilders prefer to "cross out" each

wire and component on the drawings with a colored

pencil after it is instaUed.While an excellent way to

avoid mistakes, atrd hiAhly recommendedby us, this

procedure .esults in drawinAs that are difficult to re-

use.Fo! this reasor eachwiring view is reproducedon

a sepamte,folded sheetof paper.

You arenowreadyto build your KNIGHT VTVM.

AC

HOW TO BUITDTHE

KNIGHT

VTVM

Your KNIGHT VTVM usesa p nted circuit which

assuresyou that the VTVM will be an accurate, reti

abletest instrument regardlessof age.A sheetof cop-

per is bondedto a sheet of phenolic.When the wiring

pattern has been determined, the unused portion of

the coppe. sh€et is etched off leaviDgan exact dupli-

cation of the enginee ng prototype. Exact duplication

is one of the Areatest advantages of pdnted circuits,

and pr€vents variation in wiring aDd performance

from instrument to instrument.

Your KNIGHT VTVM is ait eiectronic. That is, the

bridge ci.cuit is used for every measurement of DC

PIII JACX OETAIL

10K

t(-za

OHMS

ADJ

10K

ZERO

ADJ

5@,,o

<b-s

FIGUREI. MOUNTING

THEPARTS

ON TflEPANEI.

MOUNTINGTHE

Before you begin mounting t]le parts, place a pad

or a soft cloth on your work table to protect the finish

on the front panel.

SEEFIGURESI AND 2

( ) Insert the Ehort flat head screw throush the hole

in the top center of the panel. Placean extenal

iockwasher over the screw. Next put one of the

cable clampsove. the screw. Now, put on an in'

temal lockwasher and tighten a nut over it very

securely. SeeFiFrre 2.

S *ut

rnr€RflaL

Locxw

sHaR

@CABINET

MOUNIING

CLIP

<-€>i1{cAB.E cLAMp)

YFJ

I

ETTERNAL

LOCT*ASHER

€D

I

$..o, ".o0."".*

FIGURE2. HOWTOASSEI,ISLETHECABINETCLAMP

( ) MountR-25,

10KohmsOHMSADJUSTpotenti-

omete.,

in thelalAe

hole

in theleft centerof the

paDel.Use two nuts to hoDnt this coDtlol as

showtrin Eigure3.

PARTs

ON THEPANEI"

( ) Mount J-3, the black pin jack, ir the lower right

corner of the parcl in the

( ) Mount J-2, the chassis connecto. in tte lart€

hole in the lower center of the panel. This con-

nector is supplied with a shoulderedfiber wash-

er. Take this vasher off and throw it away.

Place the flat fib€r washer over the sma-ll

threaded end of the conn€ctor. Scnpe the paint

from around this hol€ on the .ear of the parcl.

Insert the small thr€aded end t}lloush the hole

in the panel. Place the solder lua and the flat

metal washer on the connector and tiahten the

rut securely. SeeFigure 4.

WIRINGAND SOLDERING

HINIS

How well a pieceof electronic equipm€nt works of-

t€n deperdson the quality of workmanship usedin it!

construction. It is for this reason that the following

sugge6tions

are made. Thesehints are mainly for the

besinDer, however, even experienced persons mav

beDefit from a brief review.

5

FIGURE4. HOW TO MOUNTTHE

CHASSISCONNECTOR

( ) Mount S-1,the lons triple wafer RANGE switch

i! the hole in the lower left corner of the panet.

The long contact on the endwsfer must be posi-

tioned as shown in Figure 1. Th€ blank spaceon

the wafer near the shaft end must be toward

J-1. Use a larse nut and a lockwasher on tbe

inside of the panel. Fasten it securely witb

another la.ge nut. Place a large knob on th€

shaft. Be sure the line on the knob lines up ex-

actty with the printed dots on the panel. ff not,

rotate S-1so the scaleon the panel and the lir€

otr the knob cor?*pond.

( ) Mouni S-2, the other tdpie waler FUNCIION

switch, in the other hole on the riaht of the

panel. Us€another large nut and Iockwasher ir-

sidet}Ie panel. Usea large nut outside the pan€1.

Again place

a knob on the shaft alld be Bure

that

the line on the knob lines up with the scale on

You hav€ finished mounting the parts oD the pan€I

until aft€r the switches are wired.

/zcoNrRoL

FIGURE3. HOW TO MOUNTA CONTROL

( ) Mount R-27, 10K ohm ZERO ADJUST potenti-

ometer, in the large hole in the right center of

the panel, in the same manner.

( ) Mount the pilot liAht socket betveen R-25 and

R-27. The bracket must be lositioned as shown

in Figure 1.

( ) Mount J-1, the red pin jack, in the lower left

corner of t]1e panel. Use a shoutilered liber

washer on the inside oI the panel to insulate the

jack f.om the panel. Now, tighten a nut against

the washer- Refer to the pin jack detail in the

upper left comer of Figure 1.

FRONT

PANEL

The insulated wire furnish€d wit}1this kit is cut to

lensth and th€ ends are st pped. Each different col-

ored wire is a different lensth, ther€fore, be sure to

usethe color specifiedin eachof the wiring steps

A lotrg piece

of bare wire is inctuded.

whenever it is

necessa.y to use some of it, the exact letrgth of the

pi€cer€quir€d is given.

The flexible tubing Eupplied is called "spash€tu".

SpaAhetti 's us€d to cover the bare end leads of some

of the components and portions of some of tbe bare

wi.es when there is danger they will touch oth€r bare

wires or the chassis.

The proper way to conn€cta wire or lead to a solder

terminal is shown in Figure 5. To insure a good me-

chanical connection,

squeeze

the wire agarnst tbe ter-

minal wit]l your long nose pliers after it has been

hook€d on. Make sure the wires, leads, and terminals

are cleanbefore connectins them. If necessarv,

s€rape

them witli a pocket knife until any foreiAn substance,

such as wax, is removed.Be extremely careful not to

nick the wirc with the knife, or it may brcak wh€D it

B€foresoldelinA,thetip of yoursolderingironmust

beprop€rlytinned.To do this, cleanthe surfaces

of

the tip with Bteelwool,or a fine file, until the bright

copp€rsurface is exposed.Plug the iron in ard allow

it to heat until it melts solder. Apply solder to the tip

until it is weu cove.ed with a thiD coat. Wipe off the

excess solder with a ra8. The tip should now be

"shiny". Re-tintle tip whenever

it becom€g

covered

with a layerof scale

(flakes

of gray matte.).

FIGURE5. HOW TO CONNECIA WIRE

IO A TERMINAL

Unless otherwise stated, all the leads or the resis-

to.s, capacitorE,and tmnsformer should be ar short

as possible. Figure 6 illustrates the b€st way to con-

nect a component. As shown, the end leadsshould be

pulled through the ternimls so ti.Iat the parts are

tiAhtly mounted. After a lead is pulled tl.ougb a

teminal, bend it amund t]Ie termiml and cut off the

USEONI.Y

ROSINCORESOLDER

IF YOUAREIN DOUETABOUTTHESOLDER

YOU

/VIAY

ALREADYHAVE,WE RECOA,TMENDTHATYOU

OBTAIN

A NEW ROLIPLAINLYMARKED:

"ROSIN

CORE50LDER".KITSWIRED

WITH ACID CORE

gOLDER

ORACIDFI.UXWILI CORRODE

ANDWILL

NOTWOR( LONG.SUCHKITSARENOT ELIGISLE

FORREPAIRORSERVICE.

6

'it;,. -*""". *^'

FIGURE6. THEBESIWAY TO

CONNECTA COMPONENT

Before soldering a connection

besure the iron is hot

erough to melt solder. Preheat the CONNECTION by

hotdirg the tip of tlle iron against the joint to be

soldered.

After the joint is heated,apply solder to tho

joht, NOT to the iron tip. Use onry enough solder to

fill tl1ecrevices

and cover all of tte wires and t}}e ter-

minal. Do Dot solder any connection until all wires

have beeDcomected to it.

After you have soldercd a connection, push ary

insulation or spaghetti as ctoseto t}le connectioDas

possible. This will prevent close connecuots ftom

lou.hing oneanotberand csusing

a shor(

wren wiring the contacts of the switches,becar€ful

not to bendthe switch contacts which will reducetle

spriDgpressure of tlle contacts. If the flux runs out

around the contacts,it will caNe a leakagepath

The precision *sistors furnished with your lT\a[

are sensitiveto heat. When you make a solderconDec_

tion closeto the body of one of these resistors, hold

tbe lead wiUr the lons nose pliers betw€entle body

ud the coDDection

to be soldered The jaws of tlxe

plieru will corduct the heat away fmm t]Ie body of

You are now ready to beain wiring your KNIGHI

VTVM. As you are wiring, we would lik€ you to keep

the foltowins in miDd: Do your best to positior the

palts as shown in tle wirins diagrams, and, ebove

all, USE ONLY ROSIN CORESOLDER

wlRlNGswlTcH5-l

S-1is the tluee wafer switcb in th€ lower left corrcr

of the panel.The openspacebetweentwo of the ter_

minals,ontlle wafer nesrerthe shafted, is us€da!

the refereDce

poirt for numbedng the terminals.

5EEFIGUREZ.

( ) Connect,

but do not solde., one end of R-2, g20K

ohm resistor, to terminat 1 of S-1. Connect,but

do not solder,the other end to terminat 4 of S-1.

PositioD R-2 as shown in Fig!.e 7.

( ) Conlect, but do not solde., on€ end of R-3, 900K

ohm, 1 watt, resistor, to teminal 1. Connect,

but do not Bolder,the other end to terminal 6.

Position R-3 as showtr in Figu.e 7.

( ) Solder one end of a 2 inch bare wire to terminal

1.Insert the other end throush a 1ri inch lenath

of spaahetti. Solder it to terminat 5.

( ) Solderoneend of R-1, 150K ohm reFistor,.o rcr-

hinal 4. Connect, but do not solde., the other

end to terminal 13.

( ) Connect,

but do trot solder,one endof R-16,10K

ohm resistor, to terminal 13. Inse.t the other

end

throuAh

a rz incblengih

of spaghetti.

Con_

npcr,

but do not solder,it lo r.rm,nat tZ.

( ) Connect,

but do not solder,oneend of R-20, 90K

ohm resistor, to terminal 14. Connect, but do

not solder, the other end to terminal 25.

( ) Connect,but do not solder, oDeend of a 2 inch

bare wire to teminal 14. Solder the other end

to terminal 26.

( ) Solder one end of R-21, 9K ohm resislor ro rcr-

minal 14. Connect,but do not solder, the other

end to teminal 2?.

( ) Conneci,but do not solder, one end of R"22, 900

ohm iesistor, to terminal 16. Solder the other

end to terminal 27.

( ) Connect,but do not solder, one end of a Z inch

ba.e wire to terminal 16. Solder the other end

to terminal 28.

( ) Sold€. on€€nd of R-23, 90 ohm resisror, to ter-

minat 16. Connect,but do not soliier, the other

end to terminal 29.

27

MIJST

WIRETHE

IANGE

SWITCH

LEFT SIDE RIGHTSIDE

FJGURE

7, HOWTO

. soldpr

one

endof R-15 20K

ohmresisror'

1otPr-

' i]'ir'ri c-*", ourdo nor solder'

rhp other

end to terminal 30.

, Solder

one

"nd ot - 2 inchreo sire lo rFrminal

il.-f;;;";., b'' do nor

sorder'

the orhpr

end10

terminal 30

r pass

one

pnd

of R_14

?0KohmreFistor

lhrough

' i"#r',i is"* connocr

I'rorerminar,T

sorder

i"ii",ii,i

i, ',"'o"

'"' sorder

rerminar

re sorder

ihe otherendof R-14

to termrnar

ru

' Solder

on' eno of R-I3 200h ohm resjsror'

lo

' '.".iri"r'r' ,g. Conna'l bur do not sorder'

rhe

other end to terminal 32

, """" 6n" endof s 3 inch

harewire througr rer

-:;;i; "n,r -^'*t i ro rprminar

e sorder

ili; ."".-';;'" 8 and 20 connecr br I do not

solder,

the oLher

endLotermrnar

Jz'

" ffii":l

J":"l"1"lll""liH;"lii'1"'"ll"l'1';

other end to terminal 32

end of R-]1 2 lvlesohn resistor'

il't-"*r, Frmrnzl

2l and 'onne't il.to termrnar

ir. iii"" ""," 'onnecrions connect hxt do not

solder,

the otherendto termtnal

o+

. ' Pass

onF

pnd

of a 3 inch barewirP

ihro'rsh ler

' -Hitr;;;..""" irto

termin'l

r0 sordPr

',,.ir,

#^i:.". conne-'r'.bur

donot

soldpr'

ihe oiher end to tennrnar J4'

, r Pass

one

enooi F_!0 7 N'leSohm

l watr' resls-

' i.,.-"-,r,",,"r,rcrminai 23,

and connp.l

il to rer-

i'i""j ii l.ra'. rerminar

23bu'

do

norsorder

l"".r""i r

' solder

the

othe-

end

ro

rarnrnal

34

, I ConnP(r,

bul do not solder'

oneendol R 17 9

' i,li".rl- l-""]i rFsisro' to rerminar

04 sorder

ihe other end

to term)nar

rD

, , Connp.r,

b.ri

do notsold"r'

one

endor a red

w're

t. ienr.,r',, Zq. Soldpr

theorher

eud

ln iprm'nar

36

, ) Solo'

r onc Frd of R_19

900K ohm r"slsror'ro

' ;;:;,i tl sorder

rhe

otrer end

rotcminal 25

, , Sold"'onp endof R_24

the 9 r ohrr $'r"wouno

' ' i*"i".--'*'a wjth tl'" 'olor bands white

i.""*". *"ru andsold to lerminal 29 ConnPct

i"i'a. "'"il.ia"'ltr' orhe-

'nd IorF'minar

3r'

You have finished mounting the precisionreststors-

Recheck aU of Your work

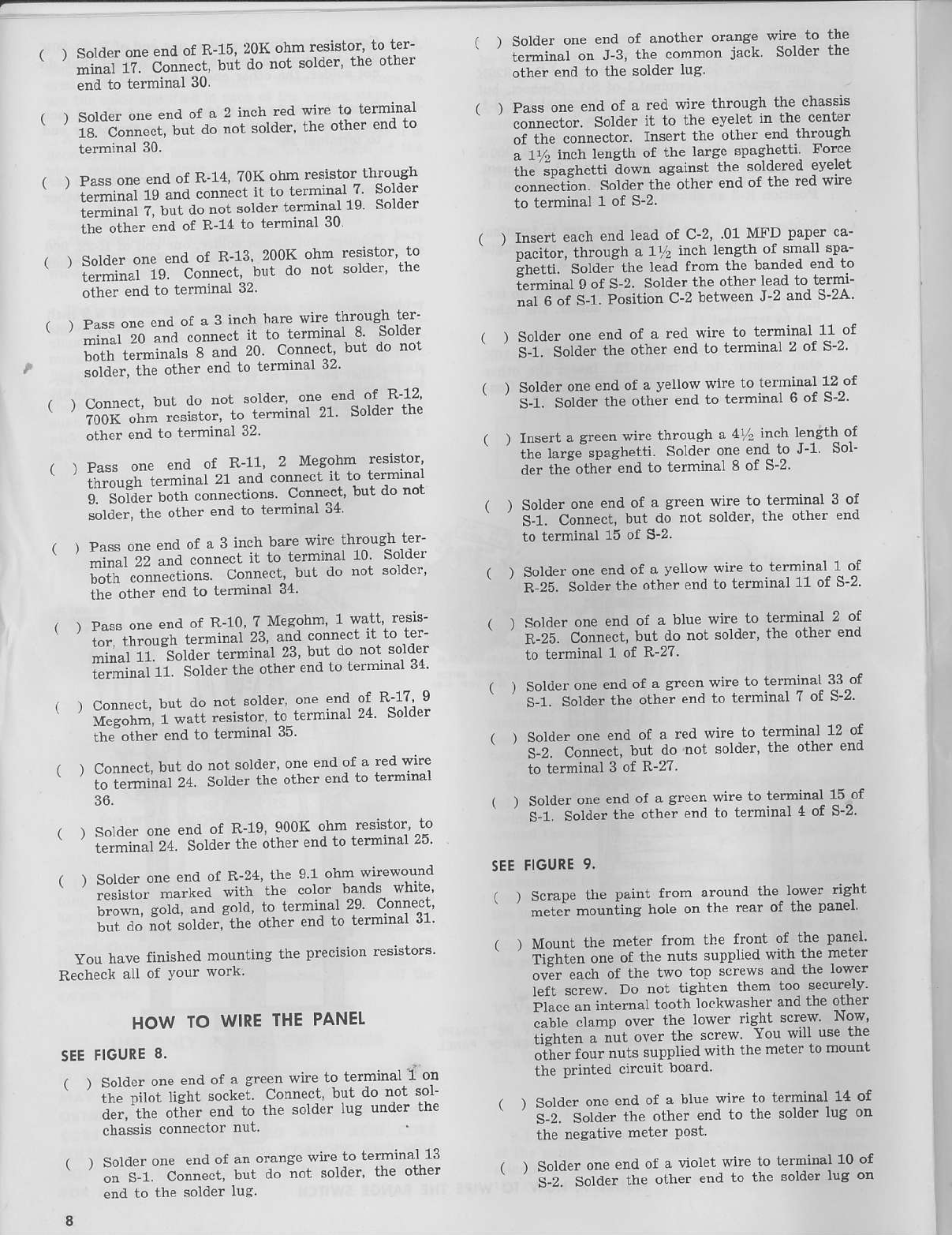

HOWIO WIRE

THEPANEL

SEE

FIGURE

8.

r r SoldFr

onp

"nd of a Cre'nwrre

ro tprminal

I on

' ;i"-;i"' lisht 'oc\ei connecr'

but do not sor-

;;;, "G t;"- end ro rhe sordp'

Iut under rhe

chassis.orneclo.

nJ1

l So

deronp erd of "n orang"

wi"" ro Ier'inal 13

' iii-r. conn"r' tr do nor soldcr' thP other

end to the solder lug

8

r r Soldpr

one end of snolhProranAe

wjre io lbe

i"^i".r o" J-3, Ihe 'ommon jack Solder

th€

other end to th€ solder lug

{ r Pass

one

endot a red wire lhrough the c}assis

;;"""-.. soloFr

ir to rhe pvFlet

in the center

"i-ii'" """*ct*. rnsert the otherendthrouah

;1 inch len#h ot the largespashalli Force

irre ioaeherri down against rhe soldered evelel

""""""tiot. SotO". 't'. olher Fndof the red wire

to t€rminal 1 of S-2

I ) lnse$ each end lead of C-2' -01 MFD paper ca-

Dacilor,

through

a 1r. in'h leng_h

of small

spa-

!r'r"r'i. Sota"irn" lead from rhebsnded

end10

ifr.inar gor s-z Solder

tneolherlPadto termi-

i.le "i s-r' Posilion

c-2 between

J-2and S-2A

r ) Solder

on. eno of a red wire lo l€rmintl 11of

i-r. Sora"r

theorher

endto terminal

2 of S-2'

I ) Soldpr

on. end

of a vFllow

$)r" lo terminal

12

of

s-i Sora."

rheotherendro lprminal6 of S-2

r ) Ioserr

a arFen

wirethrouqha 4 inchlength

of

rt'" iu.g"'"p.gt'.rri SoldPr

one

endIo I'l Sol-

derthaoft;r endto lcrminal 8 of S-2

( ) Sold€r one end of a sreen wire to terminal 3 of

' ' i-i. C.r"*t, but d; not solder, the other etrd

to terminal 15 of S-2'

i ) Solderone end of a vellow wire to terminal 1 of

' ' R-25. Solder

the other endto terminal 11 of S-2

, , Solder

one

endot a bluF

wire to terminal 2 of

c-ii. c"'*,t, bur do not solder'

rheolher end

to t€rminal 1 of R-27

( ) Solaler

oneend of a green wire to terminal 33 of

' ' i-i. -i"rJ* tr'" othe;

end

to terminar

7of s"2'

, I SoldPr

one

'nd ot a red wite ro tctminal 12 of

' i-i. --c-**r' bur do nor soldPr'

Ine olher end

to terminal 3 of R-27.

r r Solder

one

end

ot a areen

wire10

jerminal

l5 of

' i-i. soro""

rr'" orhi end lo terminal

4 of S-2

SEE

FIGURE

9.

, , Scrape

the painr from aroundthe low€r riabt

' -"*t ,."""ii"g hole on ihe rpar of the panel

, I Mounr the mpler fror lie tronr of tbe panei'

ri.n,"t *" of lhp nutssupplied

with lhemeter

."Ei *+ "r rhF tqo rops'rews andrhe lower

lefLs.rew Do nol riShlen lhem too securery

i;r*" ." i"t"t"'t to.tt' lockwasherandthe other

;;;;;;i;-" over rhe rower titht s'rew Now'

iiJi." " ,i"t ove" rbe scrPw You $ilr u€e tre

.ii". ro," nur=

"uppti"a

wirhthp

metFr

ro

mouni

the Printealcircuit board'

, ) Solder

one

end

ol a blu' wir" to rerminal

14 of

i-i. sora"" ,t'" other end ro lhp solder

lug on

the negative meter Post

, , Solderonp end of a violet wire to terminal 10 of

i-2. So.a.. the olher end ro rhe solder

lus oD

()

the positive meter post.

Solder one end of another violet wire to teminal

2 of the pilot light socket. The other end will be

connected

to the p nted circuit late!.

( ) Insert the pilot tamp into its sock€t.

NOTE

SWITCHES

ARE SHOWN

EXPANDEDAND SIMPLIFIED

rt

FIGURE8. HOWTOWIRETHE

PANEL

ry=--x

oo

I IsFAcEF

(ro

3E

YouNlEo

LAIEF)

ilUT€I

ae\**.**"

>z-

*ar**ao"-*^*a"@ _f

CABLECLAMP DETAIL

A METER

SOIJNIINC

SCREW

lo

FIGURE

9. HOW TO MOUNI AND WIRE

THEMETER

ASSEMBTING

THE

PRINTEDCIRCUITBOARD

You are .eady to mount ttle parts on the priDted

circuit boa.d. Eandl€ the board seDtly. Exarine it.

One side shows the outline and value of each part to

be mounted. That is, the capacitors, resisto.s, the

transformer, the battery, etc., are picturcd in th€ir

The solderirg technique which MUST be used on tbe

printed circuiL is somewhat ditferen{ from tlal used

io wire the swilches. Usp a 50-watt solderina p"ncil,

or a regular type solderiDg iron with a small tip. Do

not use an iron of higher wattage rating o. a solder'

ing gurl.

Mount the components

on the board. Bend the lead!

of the resistors at right anglesto the body of tle re-

sistor so the resistors will lay flat on the board. In-

se the leads tlroush the proper holes in Ure boad

and bend them to hold t}le part firmly in position,

SeeFi8u.e 10.

Touch the connection to be sold€red with the solde.

atrd the iron AT THE SAME TIME. DO NOT PRE-

HEAT the connection. This may daEage the pnnted

wiriDs pattem. REMOVE THE IRON AND THE

SOLDER as soon a! tle flux froD the core of the

soliler flows out around the comection. The solder

on the conDection should have a shinv"'silverv"

r the contrection has a dull appearance'

lils a cold solder joitrt. Usins more sold€r' again

solaterthe connection.

Do not useso much solder that

it flow! off the printed wiring otrto the board This

may cause an intemittent, or a short, between con-

Before you solder the pins of the tube sockets to

the p.inted wiritrg, insert the tubes in the socket

When you solder the pins of the tube sockets to the

pdnted wirins, touch the soldering iron and tle solder

to the pin of the tube socket, and NOT TO THE

PRINTED WnING PATTERN. When tI€ solder

flows down onto the printed wirins REMOVE both

the solder and the iroD

After you have soldered all of tlle conrectiom on

lhe Drinted board, but before you pul in the cable.

ex'

amiie the printed wiriDg sideof ihe board closelv. U

the flux from tlle core of the solder has flowed off the

olinted wirins patlern onto the board, remove it wit]l

ienaturea aliohol. This condition, ir not corrected'

may cause a leakage Patll.

SEE

FIGURE

II.

( ) Mount the g-pin niniature socket for V-2, tlte

12AU7, from the screened side of the board.

This socket can be mounted only one way Lirc

up the notch in the socket with the half_moon

shaped notch in the board. Put the12Au7 in the

socket. Solder one end of a 3/a

inch bare wire to

pin 1. Solder the other end to pin 6. Solder au

pins to the board.

( ) Mount the ?-pin mi etur€ socket for V-1, the

6AL5. Put the 6A15 in the socket Solder au

pins.

( ) Mount R-34, 10,000 ohm! AC Balance poterti-

ometer, frcm tle screened side of the board. The

three te.minals must be toward the left edge of

the boad. Bend tlle two larse, flat te.minals

out slightly so the potentiometei tu held firmly.

FIGUREIO. HOW TO MOUNT

AND sOLDER

PARTS

ON THEPRINICDCIRCUIT

AOARD.

Solde.eachterminal and also the tq'o lalge ftat

( ) Mount R-29, 10,000

ohDs DC Calibration poteD-

Uometer ir the samemaDde.. Solder the large

flat termilals aDdtbe two Bnall telmirsls.

( ) Mouni R-26, 10,000 ohms AC Calibratio4 po-

tentiometer iD t}le samemarlner witn the thee

teminals towad the te.miDals of R-29. Solder

the thr€e termiDals which go into tle printed

wiring.

( ) Mourt CR-1, the rcctili€r, by in8erting the two

te.miDals tl.ough the holes iD the upper left

corDerof the board. The pditive side must be

toward the right. Bendth€ two teminals slight-

ly to hold CR-1firmly. Solder botl terminals.

( ) Mount C-6,the 20 MFD, 150Velectrolytic filter

capacitor, with t]le "+" end next to the r€cu-

fier. Solderboth leads.

( ) Trim the lea& of T-1, the pow€r tran-sformerto

the following lengtls :

The black lead toward the upper right comer

to tY2".

Theotherblack leadto 6".

Botll sreeD

leadsto 1%".

Both rcd leadsto 2".

Removet]}e insulation fmm ya" of ttle ed of

eachlead. Hold the lead witl plien closeto tle

body of tlle traDsfomer as you remove the i!-

sulatioDsothat you donot tear the lead through

the wrappiDg arouDdtle willdbs of the tran8-

folmer. Now, cost the stripped endof eachlead

rit}r Bolder.

Mount T-1 witn tle r€d and grcetr leaals

toward

l.hecetrter

of L}leboard. Usea machinescrew

tl.oush each moutrtiDg tab of T-1, thmuah a

fbt fiber wsshor, aDdthmugh the board. Tiaht-

en a nut ov€r each screw.

( ) Insert tlrc short black lead into the hole mtrked

Bleck Pri. in the upper riaht corner of th€ boed.

R-34

10K

R-29

toK

R-26

10K

FIGURE

II. MOUNTING

TXE PARIS

B.nd it slichtly so it will stav in position and

solde! it. The olher black lead will be conn€cred

( ) Insert the green leads into the holes marked G'

Bend them slightlY- Solder th€m.

( ) Inse.t the realleads into the two holes marked

R. Bend them slightlv. Solder both

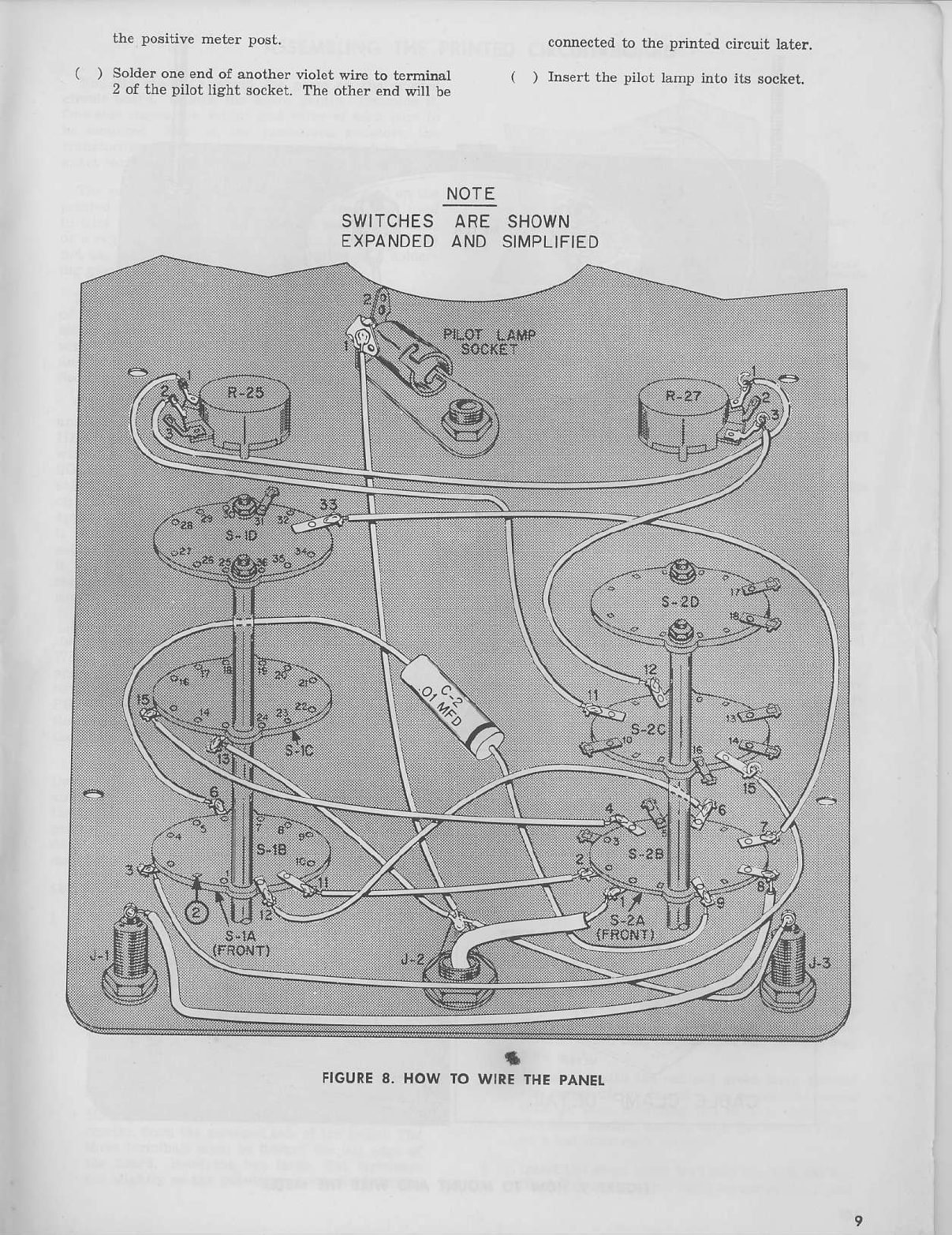

SEE

FIGURES

II AND 12.

( ) Mount the battery bracket as shown iD Figule

12. Insert a machine sclew through the battery

retaining clip through the centerhole in the bat_

t€ry br;kei, tlroush a flat fib€r washer, and

rhroueh the hole in rhe prinied circuit board

T'sht;n a nul onlo lhe screw Use the Ihin

sdew throush the hole in the end of the bracket

near T-1, anil through the cilcuit board. Place a

small flat metal washer over the scr€w on the

printed wirirg side of t]le board and tighten a

nut over the screw

12

ON IHE PRINTED

CIRCUIf

BOARO

You are now ready to mount the resisto$ and

capacitors

onthe pnnted circuit board.

( ) Mourt R'9, 3.3 M€sohm resistor (orenge,

oraDge,

ar€en)as shown

ir Figurc 11

( ) Mount C-4, .005 MFD disc capacitor.

( ) Mourt R-18,

150Kohm resistor (brown'green'

yelow).

( ) Mount R-28, 150K ohm resistor (brown, g'€en'

I

I

yellow).

( ) Moult R-33,

ange)

( ) Mount R-31,

Iow).

22K ohm resistor (r€d, red, or-

220Kohm resistor (red, r€d' YeI-

( ) Mount R-32, 100 ohm resistor (brown' black,

( ) Mount C-5, .005 MFD disc capacrtor'

( ) Mount R-30,10MegohmreEistor

(brown,

black,

blue).

( ) Mount R-36,2.2 ohm resistor (red, r€d, gold,

silver).

()

()

) MountR-5,22Megohmresistor(r€d,

red,blue).

) MountR-6,22Mesohmresistor(red,

red,blue).

) MountR-7,22Mesohmresistor(red,

red,blue).

) MountR-8,

22Meaohm

resistor(r€d,

red,blue).

) Mount R-35,10K ohm resistor (brown, black,

Mount C-1,.0?MFD disccapacitor.

MountR-4,22Mesohmresistor(red,

red,blue).

Mount C-3,.02MFD disccapacitor.Note that

th€ leadsof this capacitormust be positioned

so that th€y clear the hole for mountins the

p ntedcircuit to the panel.

Turn the circuit boardoverandsoldereach

con-

nection.Rememberto usea smalliron andthe

rosin-core solder Bupplied. REMOVE THE

FLUX if it flows out aroundthe solderedcon-

nectiotrs-Cut off eachend lead closeto the

soldercd

connection.

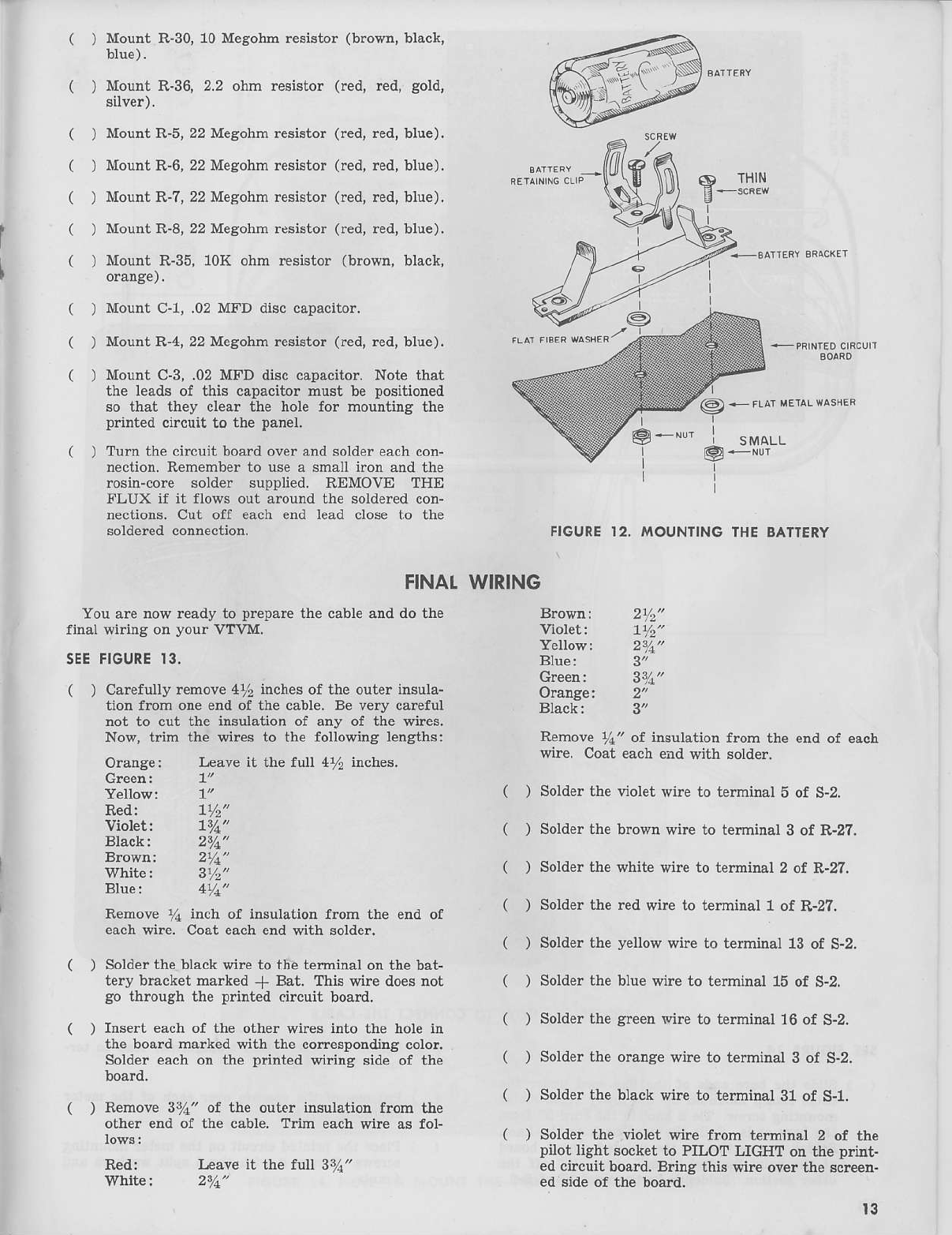

FINAT

You arenowreadyto prepare

the cableaDddothe

final wiring onyour VTVM.

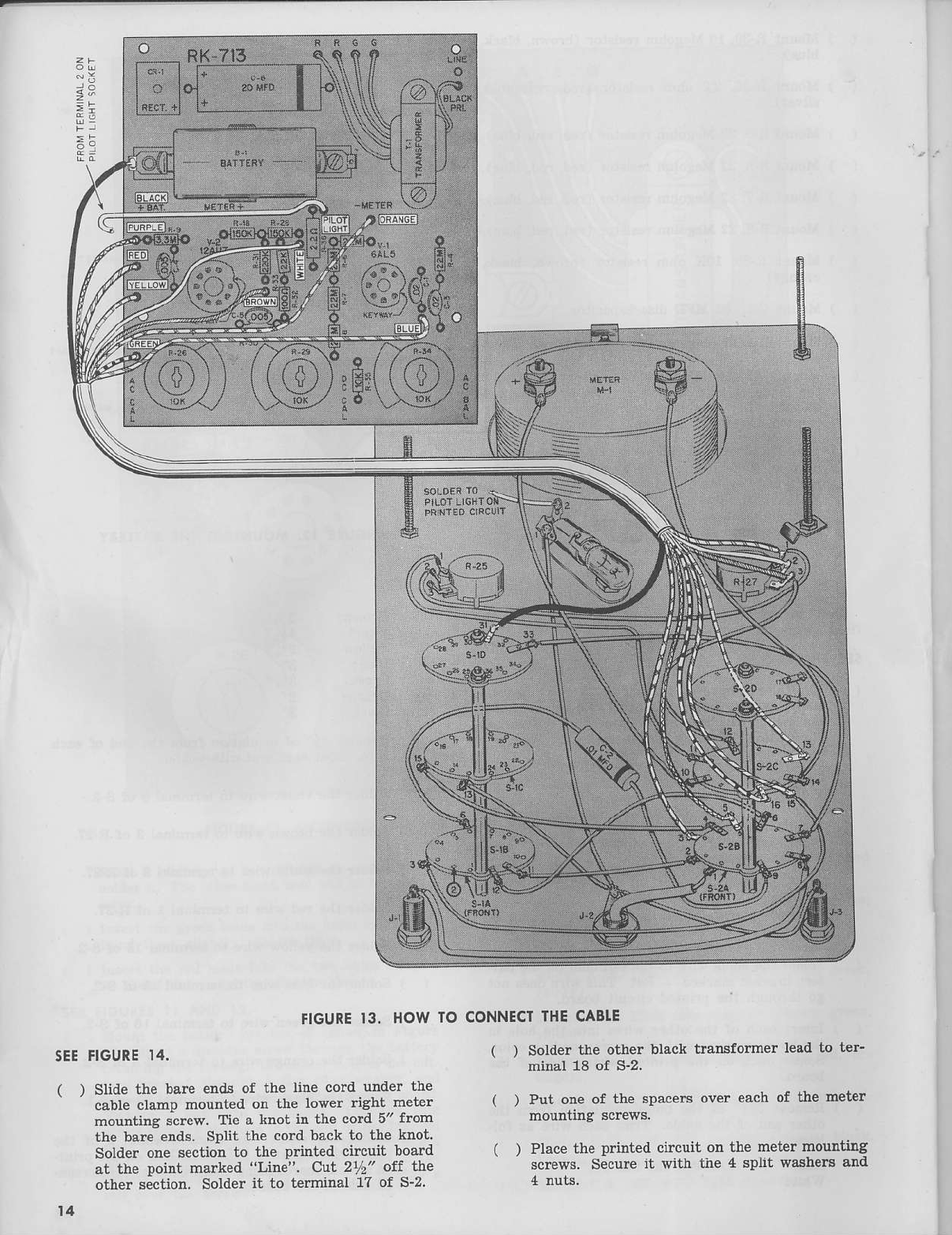

SEE

FIGURE13.

( ) Carefully

remove4% inchesof the outerinsula-

tion from oneendof the cable.Be very car€ful

not to cut the insulationof any of the wires.

Now, trim the wir€s to the followins lengthsi

Orange: Leaveit the full 4% iDches.

Green:

Yellow:

6) THIN

E

-**',

WIRING

Yellow: 211"

Blue:

112'

Bron11: 2Y4"

White: 3r/2'

BIue: 4Y1"

Remove

y1 inch of insulation

from the endof

eachwire. Coar

ea.h

endwjthsolder.

( ) Solderthebtackwireto ureterminal

onthebat-

tery bracketmarked

+ Bat- Thiswire does

not

gothroughrhe

prinred.ir.uil board.

( ) Insert eachof the other wires iDtothe holein

the boardmarkedwith the correspondi

g color.

Soidereachon the p?inted

wiring side of t]le

( ) Remove37a" of the ouler insulatior from the

other endof the cable.Trim each

wire as fol-

Red:

Violet:

Black:

Red:

7Y2"

Leaveit the fuu 31i"

@. FLrmilLM$s

g*Nr

FIGURE

]2. MOUNTINGTHE

BATTERY

Viol€t:

Orange:

Black:

Remove ya" of insulation from the etrd of each

wire. Coat eacb end with solder.

( ) Solder the violet wire to terminal 5 of S-2.

( ) Solderthe b.own rrirc to terminai 3 of R-27.

( ) Solder the white wire to terminal 2 of R-2?.

( ) Solder the led wire to terminat 1 of R-27.

( ) Solder the yellow wire to telminal 13 of S-2.

( ) Sold€r the blue wire to terminal 15 of S-2.

( ) Sold€rthe gr€en v'ire to terminal 16 of S-2.

( ) Solde. the oranse wire to teminal 3 of S-2.

( ) Sold€r tlje black wire to t€rminal 31 of S-1.

( ) Solder the viotet wire from temiltal 2 of the

pilot light socket to PILOT LIGHT on the print-

ed circuit boad. Bdns this wire over the scr€en-

ed side of the board.

l3

FIGURE

]3' HOW TO

5EE

FIGURE

I4.

( ) Slide thc ba.e ends of ihe line cord uDder the

'-rb

a lan

t olr

" d or rhn

.uvpr

rr8hl

n'l r

mounting scre$. Tie a knot in the cord 5" from

the bare ends. SPLiL

the co.d back to thc knot-

Solder one section to the printed circuit board

at th. poilL marked "Line". Cut 21r:" off the

other scction Solde. ii to terminal 1? of S_2.

t4

CONNECT

THE

CABLE

( ) Solder the other black transformer lead to ter_

mlnal 18 of S-2.

( ) Pu! one of the spaccrs over cach of the meter

mouniing screws.

( ) Place the ldnted circuit on the meter mounting

screll's. Secureii with ihe 4 sPhLwashels and

@

o

@

o

FIGURE14.HOWTOMOUNT

IHE PRINTEDCIRCUIT

BOARD t5

a

PRETIMINARY

ADJUSTMENTS

CAUTION:

NEVER

TOUCH

ANY

PART

OF

THEWIRING

WHILE

THIS

INSIRUMENT

I5

PLUGGED

INTO

A POWER

OUTLET.

NEVERUSE

OR

TESI

THEVTVM

ONOR

NEAR

A GROUNDED

METAL

BENCH.

RADIATOR,

SINK,

OR

OTHER

GROUNDED

METAL

OBJECT'

| ) Asain check

1ospe

lhal lhe while linF on lhe

k;ob of S-l lines

!p wilh lhe scaleon lhe lroni

Danel. If not, loosen the nut and move S-1 so

itut it oo"" Retishten the nut'

( ) Also check S'2.

{ | Rorale lhF shafrs

or lne oHMS ADJUST 'on'

trol, R 25, and _hP ZERO ADJUST coDlrol'

n zi, tutty couorerctort<wise

Pla'e a smallknob

on eactr

ilarr so lhat the whirP linP

poinls to

the lower left. Tighten eacit set screw-

| ) Plue lhe line.ord inro a ll7 voll' 60 cycle AC

outict. NEVER conne(r rhe VTVM lo direct

""-"nt o" yo" will ilamage the instrum€nt' If

y- -n "oi celtain as to the power available'

check rtith vour local power companv'

( ) Turn the VTVM on set the FUNCTION switch

' ; either + DC or DC volts. set the RANGE

switch to 1.5 votts The pilot lamp and tubes

;hould lisht Turn the kDob of -tle ZERO AD-

.rUST co;trol The meter needle 1{'ill deflect

ovcr at least Part of the scale'

( , Leave

the VTVI\'I

on wnilevou prPpzre

ihe lest

-eads.

This will give lhe Lubes

amplp

rim' for

wamup before calibration

:tr.tii: .""::,].i',,iill'

r*rx.9rlfi.,1'T8I'1"J,"

TEITIEAD ASSEMBI.Y

sEE

FIGURE

]5.

Th€le are three test leads to be prepared for vouf

VTVM.

( ) Removethe small setscrewfrom the cable plug

anclremove the spdng ftom the plua Slide the

sDrine LlarR' hole first) over one end ot lhe

slield"edcab-h. Remove rr inch of rhe outer in-

sulation from one end of the cable Unravel the

brsid and bend it back over the sp ng' Remove

% inch of the insulation from the inner conduc-

i;r. Insert the cable analsprins into the open

€Ddof the Plug.

The inner conductor must fit into the small hole

J the pl"g. Th€ braid and spring should fit

into thi plrls so that the setscrew wiu tishten

otr the sp;int. Tighten the setscrew solder the

inner conductor to the ey€Iet.

a ) Remove the black handle from the prod tip

Slide the haDdle over the other end of the

shielded cable.

r ) Remove i inch

of thaouterinsularion

from th'

oLl* ena

of the

shiplded

cable Trim the braid-

e.Ishieldins

back

even

wirh the rut otf insula-

tion. Remo;e r in'h of the jnsulation

from the

in.er conductor. Form a small hook in it'

. ) Cut oDe

leaal

of R-37, 1 mesohm 5% reBistor,to

"" Form a small

hool in ir. Hook R-37

LothP

i"-nerconducror

ol rheshiplded

cable.

Crimp thP

two togetler. Solder the conDection'

j

*- * L-r';

FIGURE

15.HOW

TOASSEMSIE

'HE TEST

TEADS

()

()

Trim the other lead of R-3? to % inch from the

body.

Inseri the .ld inch lead into the prod tip and out

the smalt hole near the threads on the prod tip.

Pull R-3? into the prod tip. Wrap the tead

around the baseof the prod tip. Screw the nut

back onto the prod tip. Tighten it securely so

that the lead of R-37 is held very firmly.

Removerhe redhandlefrom rhe olhFrprod rip.

Slide it over the red test lead wire. Remove 5ri"

of the insulation from one erid of the wire. Coat

the fine wires with solder. Insert the end into

the prod tip so the bared end comesthroush the

small hole. Wrap it around the baseof the p.od

tip. Screw t]Ie nut on very tightly.

Uns.rew the short red insulator from the tip

plug. Sljde

jt overtheothcrendof Lheredwire.

Remove

1"'' of the insu'ation.Tvist tl'e wires

and coat them with solder. Fill the tip plug

with solder. Insert the ba.e end into tl1e tip and

let the solder cool.

Prepare one end of the black test lead in the

The OHMS ADJUST potentiometer, R-25, positions

the meter needle at the extreme riAht of the scale

when the function switch is in the OHMS position.

The DC VOLTS chaEsisconnecto.is usedfor all DC

voltage measur€ments with the DC test prod. Tbe

black test lead must be plugged in the COMMON jack

for all of these measurements.

The AC-OHMS jack is used Jor all AC voltage atrd

resistancemeasurements. The red test lead must be

plugged into this jack. The black test lead must also

be plugged into the COMMON jack.

The COMMON jack is conn€cted directly to the

panel of the VTVM and is the return point for all

READINGTHE

sCAIESOFTHEMETER

Study the face of the meter on your VTVM. A rc-

production of the meter scales is shown below. You

will notice the scalefor r€sistanceis the top red scale.

Read this scalef.om left to right. Each of the 7 pos!

tions of the RANGE switch is marked with a resist-

ancemultiplier. h the Rx1 position any value bet]veen

0 and 1000 ohms may be read directly. Ten is the

multiplier for the next position, 100for the next, 1000

the n€xt, 10K (where K indicates 1000), 100K and 1

meg or 1,000,000.Therefore, the largest resistance

which can be measu.ed is 1000 megohms.

l(nighl

( ) ReDove %" of the insulation from the oth€r end

of the black test lead. Twist the wires and coat

th€m with solder.

( ) Loosen the screw at t]le back of the clip. Form

a hook ir the solder coatedwires. Hook the wire

around the screw in a clockwisedirection. Tight-

en the scrcw. Now, bend the two small prongs

at the back of the clip do]r'n around tlje insula-

tion of the lead.

You have fiDished wiriDg your KNIGHT \/.TVM.

Check aII of your work very carefully. A few exta

minutes spent checking your instrument may save

hours of trouble-shootina. Be especially sure all the

priDted circuit conrcctions are shiny.

MOUNIINGTHEHANDIE

( ) Push the handle mounting studs through trle

holein eachendof the handle.Insert the stud

throughthe holein the metercaseon oneside.

Use a large flat metal washer,a shakeproof

washerandoneof the largerhexnutsto fasten

it.

( ) Mount the other stud in the other sideof the

USEOFTHECONTROLS

The FUNCTION SWITCH, S-2, serves two pur-

poses. One,turns the power ofl when the switch is in

the off position. Two, selectsthe operating function

desired.

The RANGE SWITCH, S-1,provides wide choiceof

ranges for voltaae and r€sistancemeasur€ments.

The ZERO ADJUST, R-2?, coDtrols meter needle

position at the leIt zero pdition or sets the needle at

the zero-center, "0", when the function switch is in

VOLTS position.

You will notice that the next two scales (black) arc

brack€ted and marked D.C.v. or R.M.S. AII DC and

AC rms voltages are read on th€se two scales. The

vaiue of the voltage to be measured deterrnin€s which

scale to use. When making voltage measurements

atways start on a high range atrd work dowL Make

the final readins at mid-scale or higher for greater

acc racy. You will also note that the RANGE switch

is mark€d with numbers which are multiplierc for all

of the voltage scaies.

The next two scales(red) are marked P-P, or peak-

to-peak. The p€ak vaiue of a sine q,aveis 1.414time!

the rms value.Therefore, peak,to-peakvalues arc 2.83

times rms- Peak-to-peak values are read directly on

the two red scales.The first red scale,marked 0-40,

coresponds to the fi.st black scale.This is irdicated

on the meter face by 15 R.M.S. in parerthesis. The

secondred scalecoresponds to the secondblack scale

andis similarly marked 50 R.M.S.As an example,aup-

pose the RANGE switch is set at 15V and an AC volt"

age of 10 volts ms is to be measured. The meter

needlewilt stop et 10 on the ms scate.At the same

17

time you can reaaltbe peak{o'peak value of the sine

wavein the correspondins P-? scale,

or 283 volts No

calculations are necessarv

to convert rms to peak-to-

Deak

or viceversa. Greater accuracv is assuredaswell

is savine you time. Peak'to_peak voltages are used

tor waveloim measurementssuch as are encountered

in television service {ork.

The use of the decibel scnle and zero center are

explain€al in the section of this manual 'USING

YOUR VTVM'"

CATIBRATION

Before vou calibrate iour VTVM, b€ sure the meter

reerlle is at zero on the left side of the scale.

r ) Turn the instnment off. If the needle

is not at

the screw above the Pilot light'

IIse a scriber. or comparable instrument' to

move the zero'adjustment lever either risht or

left as tequired to bring the meter needl€ to

CAUTION:

Be

verv<oteful

thoi vou do notinseri

the s.riber

too deep. It lhis is done the Pointer

sprins will be domosed. The stonddrd

RETMA

wononty doesnol cover

such

dcnoge'

Replace the screw Turn the instrument on

aAain

( ) Set the FUNCTION switch, S-2, to the +DC

posirron. Aolusrment of lhe zERo ADJUST

control should move rhe needl" approximatelv

one-half scale R€set the ZERO ADJUST con-

trol for zem set S-2 to the DC position lf

there is any change in the zero, re-adjust the

ZERO ADJUST control Repeat this procedur€

urtil there is no change in the z€ro when the

FUNCTION switch is changed back and forth

ftom +DC to DC

DC CAI"IERATION

Ins€rt the black pin ja€k into the common plus

Attach the DC volts test cable to the comector on

Set the FUNCTION switch to +DC

Set th€ RANCE switch to 1 5 volts-

Use tlle battery which is included with vour VM'

Attach the DC test prod to the positive end of the

battery analthe commm test lead to the negative end

Adiust R-29. the DC calibraie control on the print-

ed ciicuit board. so that the needle

of the meter rests

exactly over the red dot at the extreme dAht edAe

of

Set the FUNCTION switch to -DC

Connect th€ test leads to the batterv iD opposite

polarity.

There should be no change in the position of the

n€ealle

over the red dot. If there is, adjust the DC

calib.ate cotrtrol until there is no change when switch'

irg back and fortl from +DC to -DC.

l8

AC CAUERATION

Set the FUNCTION switch to AC volts.

Insert the AC-OHMS pir jack into the red piD plug.

Let the leads hang free DO NOT hold tllem to

eliminate any hum Pickup

Set the RANGE switch to 1.5 volts

Adiusl R-3{, tbe AC BalanceCoorrol

on t}e pr'nl-

ed.ircuil board,

sothat lhe meter

treedle

reailEexacl-

ly zero on the left lide of the scale.

Set tle RANGE switch to 15 volts.

Touch the AC-OHMS test prod to the sreen lead of

T-1, which is not grounded.

The common test prod is already grounded to com-

Adjust R-26,the AC Calibrate Control on the pnnt-

ed cir€uit board, for 63 volts

You also can make this adjustment bv measuriDg

the voltage between the two connectionsof the liDe

Set the RANGE switch to 150volts.

Adjust th€ AC Calibtate Control for 11? volts.

OHMS CALIBRATION

Tum off the VTVM

IDstall the battery on tl1e pdnted circuit board

Turn th€ VTVM on

S€t the FUNCTION sv,ritch to ohms

Adjust R-25 for full scale.

Touch the AC-OHMS ard COMMON test leads to-

gether. The meter needle should indicate zero ohms'

FINAT

ASSEMBI.Y

( ) Install t}le met€. in the cas€ so that ttle clamp

at the top of the panel hooks against the inside

of the flanse in the css€

( ) Use the two self-tapping scr€Y{s through the

holes in the panel. Tighten them into the hole8

in the case.

HOW THEKNIGHT

VTVM WORKS

SEEFIGURE

16.

The KNIGHT VTVM utilizes the basic principle of

a vacuum tube which is: A tube can amplifv witlout

takiDs oower

from the vohagesourceapplied

to its

sri{r.ihis instrument

isexrrenelv

sensitive

andstable

;ecause

everym"asurement

is made

electronically.

A sensitive200microamperemeter is the iddicati4g

comDonent.The meter is in the cathodeci.cuit of t,he

rzeirZ twi" triode t be, V-2. P,-27,t}j,ezero adjust

control, bslancesthe two sectionsof t]!e tube Bot'hat

there is no indication on the meter due to both sec-

'ions of l}e (onrrol beinA

equatwhen

rhereis no ap-

plied voltaae. When a voltage to be measuredis f;d

inLo the gdd of V-2, this batance is upset and the

voltage can be read directly on the meter. The test

voltage and the met€r indicating cuuent are direcfly

proportionat, so that the meter is calibrated direc y.

The meter is protected, because

as stated before, the

voitaAe to be measured is applied to the tube rather

The lpsl vollage

applied

,o therubFis a maximum

oJ 3 volts. HiAher test voltages are reduced through

the voltage divider witl1 a total resistanceof 10 m*-

ohms. The DC tesl prod includes a 1 megohm resis-

lan{p in addiiion. ThF hiAh inpLl impedance

ot rhe

VTVM enables

you to mak" measurements

in uost

circuits without disturbing the circuits_

When the instrument is used for makina AC mea,

surements, the 6AL5 tube, V-1, acts as a full wave

rectifier. The output of this tube is direc y propor-

tional to the AC voltage to be measured. The DC

output is fed through the voltase divider network the

same as for DC measurem.nts and is indicat€d in ex-

actty the same way.

On the 500 and 1500 volt scalesfor AC measure-

hents, the voltage to be measuredis reducedthrough

R-3 and R-2 before it is apptied to V-1. This featu;e

p.otects V-1 and all follorving circuitry sincevoltages

greater than 150 votts ar€ not applied to the tub€.

The AC scales are calibrated in both RMS and

peak-to-peak values.

The AC balancecontiol pmvides proper meter indi-

cation for the applied AC vottage by cancelling out

the contact potential between etementsof V-1. Th€

contact potential is cancelled out by the bucking

voltaae provided by the AC halance control. This

control permits changins from AC to DC without re-

adjustina the zero of the meter.

A.t.5 rcli balrery is connected

Llrougha spries

of

mDrlrpxFrs

andthc unknown

resistance

ro be

measu!-

ed oeatinA a voltaAe divider acrosstre battery. part

ot lte resulrirg bal|ery vottaee is aDDlied

ro rhe

l2AU7 .6u"ina a dFnccrion

in the mer;;. For rhese

measurementsthe meter is catibrated in ohms.

There are two accessory probes which will mak€

your KNIGHT VTVM an even morc versatile instru-

menl. One is rhe high.voltasep"obe

$hich extends

thF rangp

of rhp instrumpnt

to 50.000

volts,when

on

the 500 volt scale-

Thc other trobe is rhp h'Ch.frequcncyprobe. l.his

probF

rurlhar p.mits work in RF circuitsup ro 250

megacycles,yieldins a direct reading in RMS volts.

The stock number of eachprobe is ljsted at the end

of the Parts List.

USING

YOUR

VTVM

CAUTION:

NEVER

TOUCH

ANY pART

OI THE

WtX-

ING

WHILE

THEINSTRUMENT

ISPIUGGED

INTO

AN

AC OUTLET.

Do not u.€ the VTVrnon o srounded

merol ben.h, rodiotor,or orhergrounded

obied.

Remove

lhe powe. trom tbe equipment

uDder

test

beforcyou attacb lhe tf,sl teads.IJ lbis caDtrol

be

done,useSPECIAL CARE not to touch grounded ob-

jects. Use only one hand at a time. craEp the test

prods on the handi€s,never on the metal tips. Stand

on a well insulated floor.

Ir is a good po.i.y lo dischsrAe fiher capacitors

before lest leads are attached

DC VOLTAGE

MEASUREMENTS

Set the FUNCTION SWITCH to + or - DC volts

. SFIthe RANCE SWITCH to a range hiAherlhan

rne vortage to be measured.

Connect the common test lead.

-Tourh or connect

rhc DCrcsr

prodro rhc hiAh

side

or rne voLrage

to be measured.

Reset rhe RANGE SWTTCH to a scare wherc a

reading wiU be obtained at almost full scare.

Read th€ DC voltage direcuy.

ZERO.CENTER

INDICATION

This- is a usefut iparurp of Lle insrrumenr srnce

born the posiuve

aod negstivF

DC vottages

may be

observed

withourchanAing

rhesprtinC

of ihe FUNC_

TION SWITCH

set rhetuNcTtoN swITcH to rDc or _ Dc

gives zero centering of Ue meler

neeojc.!:lther posilion may b. used.The two sec[ioDs

or the 124U7 may be stighrly difterenr so thar zero

center may not be oblained in bor}I posiLiuDs.

Rotzre_

th. ZERO ADJUST .ontrol so lbat the

neeore

or rbe meter i3 at the center .,0'..

. 54 thr RANGE SwmCH to a range ar least twice

rnat lo be measured

A-tter the voltage has been tested, set the RANGE

SWITCH to the lowest scatewhich allows the needle

to stay on the scale.

. When you have completed the measurcment, reset

the meter needle to t]le zero at the left of the scale.

AC VOLTAGE A.IEASUREMENI

Set the FUNCTION SWITCS to AC Votts.

Short the conmon test tead and the AC test lead

toAetner, and adjust the ZERO ADJUST coDtrol to.

position the meter ne€dle

at zero.

. Se1Ihe RANGE SWITCH to a position

higher

than

rfie voltage to be measured.

_

Connect tle common lead to the ground side of the

Touch the AC-OHMS test tead to the hot side of

Reset the RANGE SWTICH for a scale which wi]l

give an indicatioD near futl scale.

Since the human body picks up AC wben near an

ac crrcuil. lhe sensirjviry of the KNICHT VTtrM

causes tlie instrument to indicate this. Thereforc, do

not hold both test leads whed makiDg AC Eeasure_

l9

RESISTANCE

EASUREMENTg

Set the FUNCTION SWITCH to ohms.

Set t}1eRANGE SWITCH for the proper value.

Connect the common test lead to one side of the

resistor to be measured.

Set the OHMS ADJUST Coatrol so that the meter

reads exactly fuU scale.

Touch the AC-OHMS test prod to the other side of

Read the resistanceon the ohms scaleand multiply

by the muttiplier indicated by the settiDg of tlle

RANGE SWITCH.

The instrument must be plugged into an AC power

outlet when making resistance measurements aE all

indicauons ar€ throuah the electronic meter circuit.

Do not leave the FUNCTION SWITCH in the ohms

position when you have completedthe resistame mea-

surements as this may greatiy shorten the life of the

DECIEEI.

MEASUREMENTS

A unit knov{n as th€ "bel" was adoptedas a unit of

measurement for sound sincethe human ear doesnot

respond to volume of sound in proportion to stgnal

strenAth. Th€ bel is more cl€arly equivalent to human

rutios. The measurcment is usualty given in 1/10 of a

bel which is knowr as s decibel. The KNIGHT VTVM

db scaleusesa standad of 1 milliwatt into a 600 ohm

line as zero decibels. This correspondsto .774 volts

AC on the 0-1.5 volt Ecale-Using this figur€, the AC

rangesmay be conveited to db by the following €ha!t:

ranse. Make comparativevottsgereadingson each

band of a multi-bandrcceiverand rotate the main

runing

capacitorthrouaheach

band$hilemeasuring

AVC-VOLTAGE MEASUREMENTS. Make this

m€asurementat the diodeload resistor, alons t}re

AVC bus,or at the sdds of the controuedtubes.

OUTPUT INDICATION. Set the FIJNCTION

SWITCH for DC. Make the measurementwith the

test prodconnect€dto the loadresistorof the second

detectorin AM andTV receiverswhile adjustingthe

componentsfor optimum output. CoDnecttl}e test

pmd to the limiter load resistorfor an FM receiver.

BIAS-CELL VOLTAGE MEASUREMEIVTS.ThE

low scalesof 0-1.5and0-5

voltEmakesmallvoltager

easyand convenient

to readwhen biasvoltages

are

critica-l.

DETECTION OF GASSY TUBES. ff a tube is

ga€sy

anddoesnot show

up ona tubetester,thebias

voltasewill have

an abDomalvalu€when

checkedin

an Rc-coupledcircuit.

SERVICEHINTS

r you have followed all of the instructions and

diaglms carefully, your KNIGHT VTVM should

If it does not, rccheck s-11of tl1e wiring carefutly.

Most difficulties are tlle r€sult of a wi ng enor. Of-

ten it is helpful to have someone

else check the wir-

ing, preferably someonewith iadio-Tv or amateur

Be sure tlat tle shoulderedfiber washer is on the

inside of the panel on tlle AC-OHMSjack so that t}le

jack is insulatedfrom the panel.

ff this jack is not

insulated from tle panel, the house fuse will blow if

you use

you. houseliDefor calibr:ttingon AC volts;

andthe needlewill deflect fulty to the riaht on OHMS

indicatins a sho .

If a tubedoesnot liaht, and

you areabsolutelycer-

tain t-hewiring on its socket

is correct,

its heate!i3

open. Replaceit wit}l another of t}le 6amet]?e.

If the tubes light and the instrument still doesDot

bperate

properly,

checkeachposition

of the FUNC-

TION switch and the RANGE switch. Determine if

au functions are inoperative, or orly oneor two.

If the inshument operates satisfactorily on DC

volts and not on AC volts, the 6AL5 tube and it8 as-

sociated circuitry are at fault. If the mete! will not

zeroon AC, checkR-34.

If the instrument doesnot operate otr the 500and

1500volt AC scales,checkR-2 and R-3. ff t}le instru-

ment fails to operate on either AC or DC voltages,

checkthe string of multipli€rER-10,R-11,R-12,R-13,

R-14,R-15,andR-16.

ff the instlument fails to function properly oa

OHMS,fiNt checktlte battery. If this is satisfactory,

checkth€striDsof multipliersR-17,R-19,R-20,R-21,

R-22.R-23.andR-24.

ff tle instrument is erratic in op€ratroD,tlat i6

varying d€flection to the riaht on +DC volts, varyirg

defle.tion to the left on -DC volts, and a "wavy"

AC VOLTg

SCAIE

0-1.5volts

0-5 volts

015 volts

0-50

volts

0-150volts

0-500volts

0-1500volts

DECISELSCALE

Read db directly

Add 10 db to the leading

Add 20 db to the reading

Add 30 db to the leading

Add 40 db to the readins

Add 50 db to the reading

Add 60 db to the reading

For example,whenm€asuringthe gainof anampli-

fier, if the input reading

is +4.5 db otrthe 1.5volt

rangeandt]le output r€adinsis 5.5db or the 500

volt raDge,the couect readirg v{ould

be 50 plus 4.5

minus5.5or 49db,whichis tne algebraicsum.

Thedecibel

is a power

or voltageratio andmay be

usedas suchwithout specifyingthe referencelevel.

Sincethis is true, a fidelity cuwe may be run by

feedinain a sisnalof variablefrcquencybut constant

amplitude. At the referencefrequency,adjust the

input to aive

a convenientindication

(zero

db) onthe

VTVM connectedto the output. The output variatioD

maybereaddirectlyin dbaboveandbelowthe speci-

fied refererce level as t}le input frequeDcy is varied.

However, when measurins complex AC wave

shapes,such as ripple, hum, distorted and square

waves,the indicationis 35% peak-to-peak.

SPECIAL

APPI.ICATIONS

OSCILLATORGRID-BIASMEASURIMENTS. Set

the FUNCTION SWITCH to DC. Select a suitable

20

Table of contents

Other Allied Radio Test Equipment manuals

Popular Test Equipment manuals by other brands

DARKSTAR TECHNOLOGIES

DARKSTAR TECHNOLOGIES WIREMAP D620 Guide to Operation

Testboy

Testboy 111 operating instructions

Optex

Optex Water It TC-3000-DI instruction manual

Agilent Technologies

Agilent Technologies 16048A Operation and service manual

PCB Piezotronics

PCB Piezotronics 482B11 Installation and operating manual

Hanna Instruments

Hanna Instruments HI98330 instruction manual