6

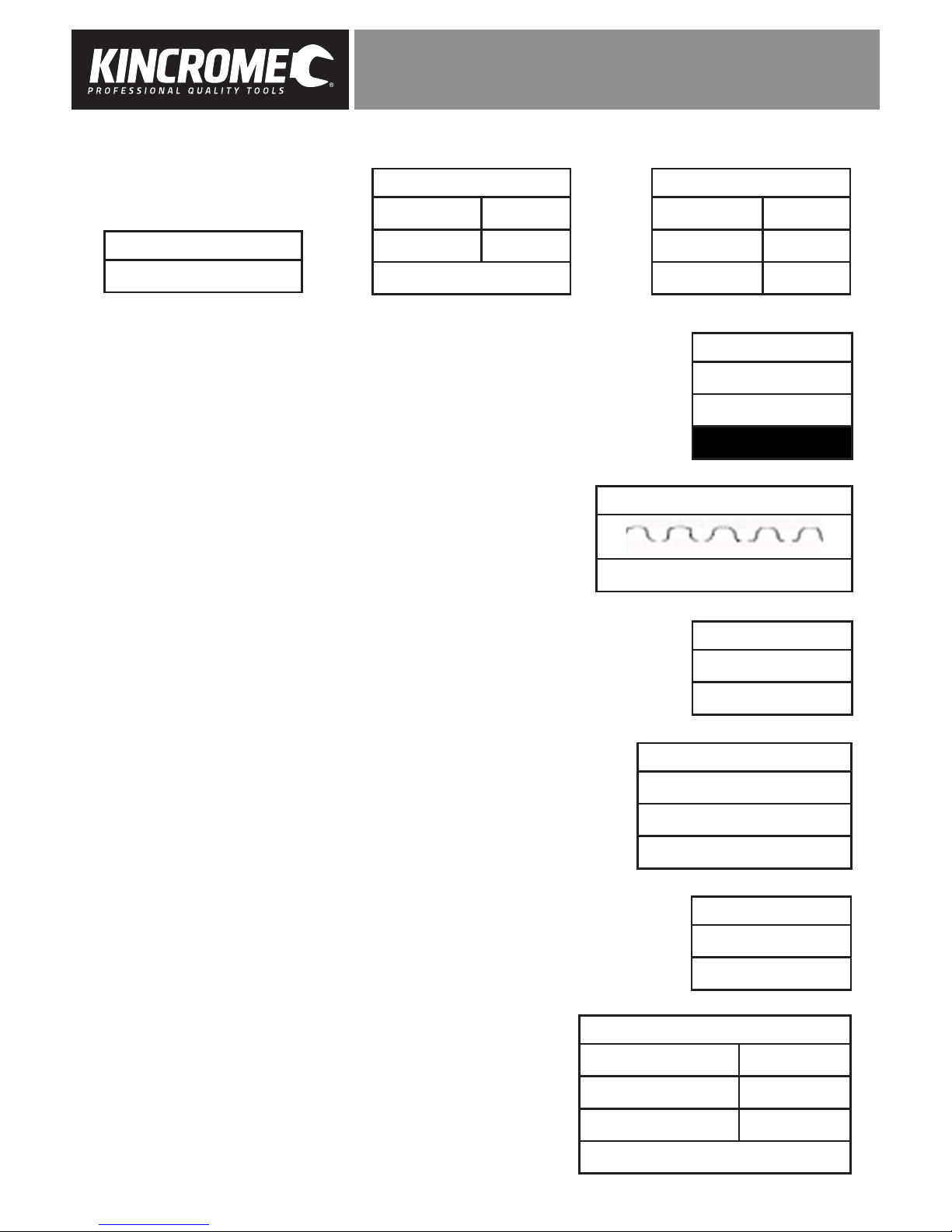

8. Battery In-Vehicle or Battery Out-Of-Vehicle Tests

Battery in vehicle means the battery is connected to the vehicles

battery cables / terminals or vehicles accessories.

Out of Vehicle means the battery is not connected to the vehicles

battery cables / terminals.

A. Battery in Vehicle

1. Connect tester as specified “Connecting the Tester” (Page 3).

2. Press Enter Key (4) to navigate to Main Menu.

3. Press Up Key (1) / Down Key (2) to navigate to” 2. Battery in Vehicle” (Fig. 13)

and press Enter Key (4), it will enter “Test In Vehicle” menu (Fig. 14).

4. Choose one of the test as shown in Fig. 14 and press Enter Key (4).

B. Battery Test

The battery tester will test each battery according to the selected test standard

and rating.

1. Press Enter Key (4) on “1. Battery Test”, the “check surface charge” prompt

screen will display a sequence of instruction (Fig.15), which you are required

to follow before proceeding.

2. Once you have turned your headlights OFF, press the Enter Key (4).

C. Select Battery Type

1. The tester will prompt to select battery type (Fig. 16). Press Up Key (1) / Down

Key (2) to select battery type (as displayed on the battery rating label), then

press Enter Key (4) to confirm.

2. Press Up Key (1) / Down Key (2) to select the correct testing standard (Fig.17)

as specified on the battery rating label. Press Enter Key (4) to select testing

standard. Refer to the Battery System Standard Description page 13.

3. Press Up Key (1) / Down Key (2) to select the battery capacity rating

(Fig. 18) as displayed on the battery rating label. Press the Enter Key (4).

Note: A single Press Up Key (1) / Down Key (2) will increase / decrease by 5Amp

intervals, Press and hold Up Key (1) / Down Key (2) will increase /decrease

the rating rapidly.

4. The tester performs the test, It takes approximately 5-10 seconds to display

the battery test result.

5. Compare to the ‘Battery Test Result Examples’ on page 5.

6. Press the Exit Key (3) to return to the start-up screen.

D. Cranking Test

1. Connect tester as specified “Connecting the Tester” on Page 3.

2. Press Enter Key (4) to navigate to Main Menu.

3. Press Up Key (1) / Down Key (2) to select the battery location, ” 2. Battery in

Vehicle” then press Enter Key (4) to confirm (Fig14).

4. “Start Engine” is prompted (Fig.19), Start the vehicle and the tester will

perform the cranking test and display the result (Fig 20, 21 & 22) on Page 7.

5. Normally a cranking voltage value lower than 9.6V is regarded as abnormal,

click the Enter Key (4).

6. Test result includes cranking voltage and cranking time.

7. After testing finished Press the Exit Key (3) to return to the start-up screen.

Note: If this is the last test, turn off vehicle engine.

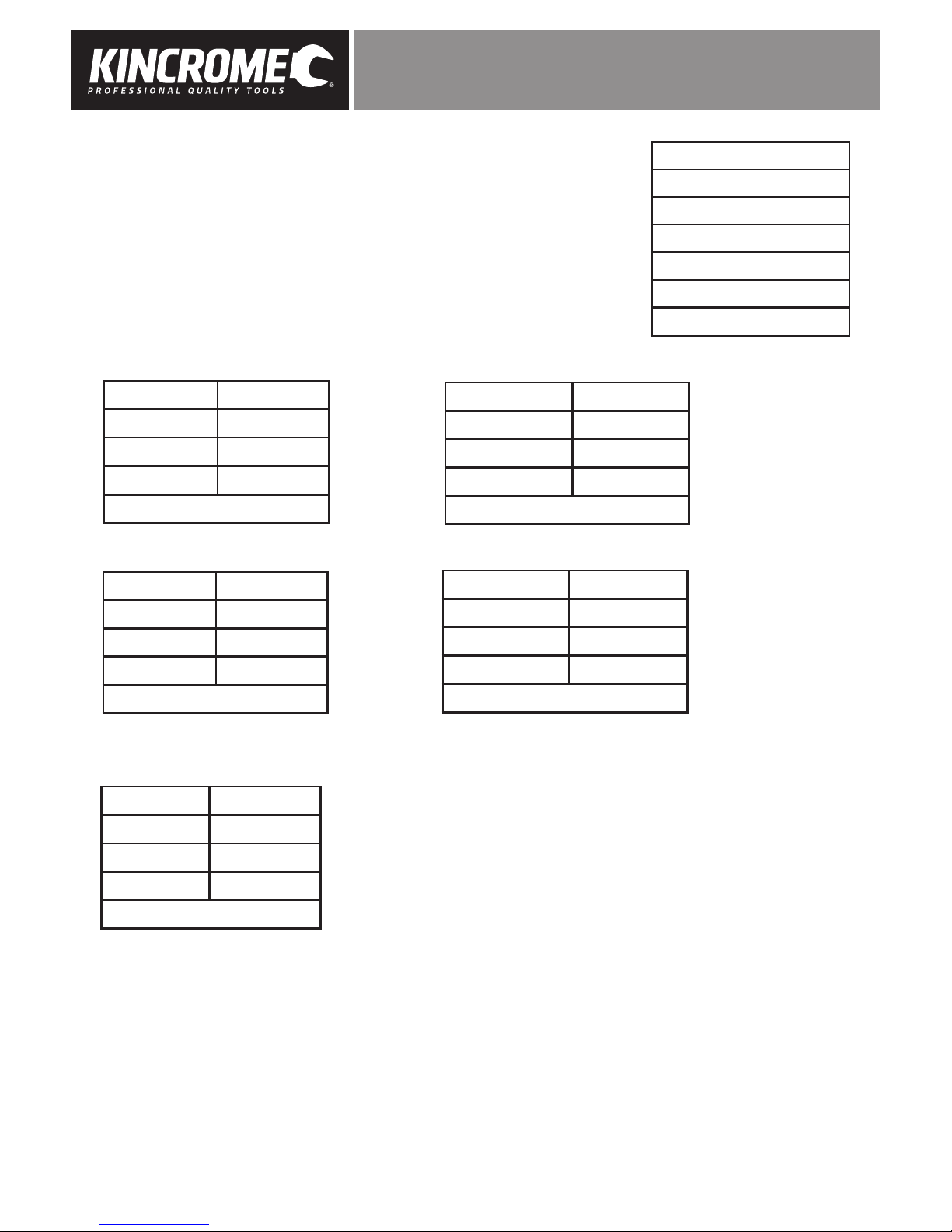

Main Menu

1. Quick Test

2. Battery in Vehicle

3. Out of Vehicle

4. Review Data

5. Print Data

6. System Setup

Test In Vehicle

1. Battery Test

2. Cranking Test

3. Charging Test

Battery Test

1. Check surface charge.

Turn lights ON

2. Turn headlights on for

approx. 10 seconds

3. Turn lights OFF

Battery Type

1. Regular Flooded

2. AGM Flat Plate

3. AGM Spiral

4. GEL

5. EFB

Select Input

CCA

Setting Rating

500

CCA

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Cranking Test

Start Engine

Fig. 19