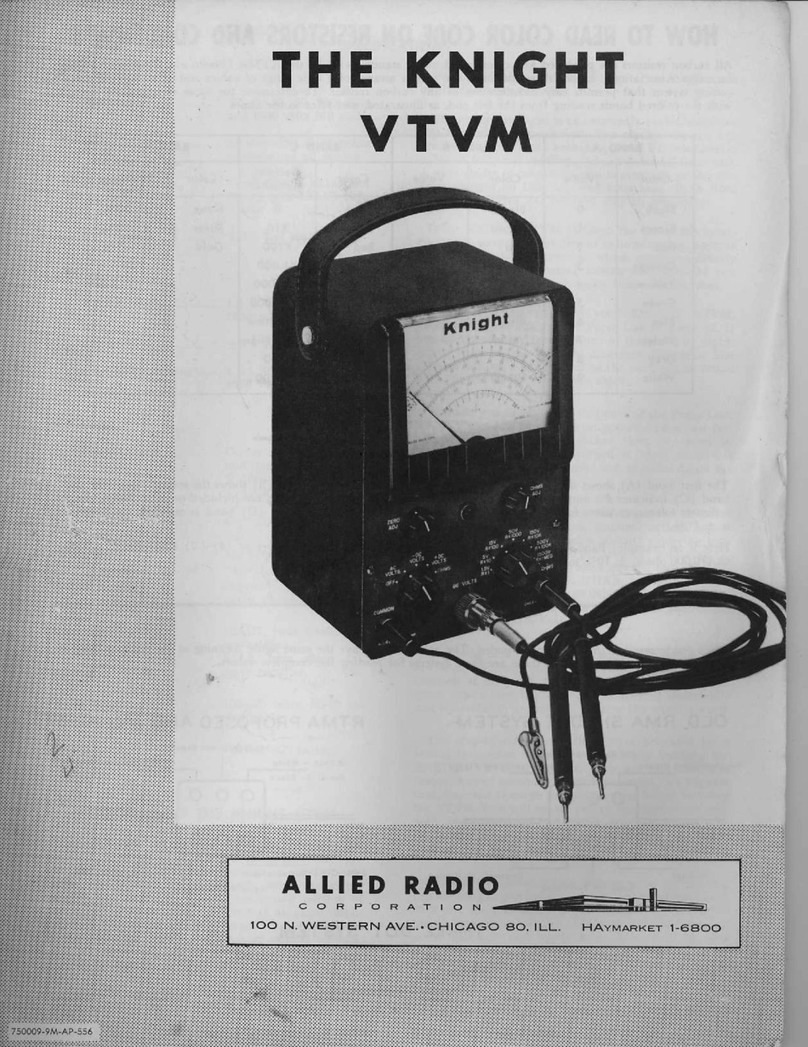

Allied Radio Knight-Kit KG-620 VTVM User manual

copyright

1956,

1963

Knight

Brectronght

Core.,

Mayivood.

iHinois

4

a

Thank

You.

..

for

your

interest

in

Knight-Kits.

This

Assembly

Manual

represents

our

many

decades

of

ex-

perience

in

developing

electronic

kits

which

bring

you

out-

standing

performance

at

dollar-saving

prices...

and

with

maximum

ease

of

construction.

As

you

go

through

the

pages

of

this

brochure,

note

how

carefully

each

stage

of

construction

is

explained—how

each

diagram

is

magnified

so

that

you

almost

have

the

feeling

a

good

instructor

is

working

at

your

side!

Knight-Kit’s

‘do

and

check’’

method

of

kit-building

insures

accurate

and

simple

assembly.

Although

your

final

product

may

represent

a

very

complicated

piece

of

electronic

equipment,

you

will

proceed

with

ease

and

assurance,

step-by-step...

and

enjoy

enormous

satisfaction

in

your

completed

working

unit.

Every

Knight-Kit

of

your

choice

is

available

to

you

on

the

Allied

Credit

Fund

Plan—

«

No

Money

Down

«24

Months

To

Pay

«Up

To

50%

Increased

Buying

Power

Your

Knight-Kit

purchase

is

backed

with

our

exclusive

and

iron-clad

guarantee—you

must

be

completely

satisfied

or

your

purchase

price

is

refunded!

It

is

always

a

pleasure

to

serve

you.

A.

D.

Davis,

President

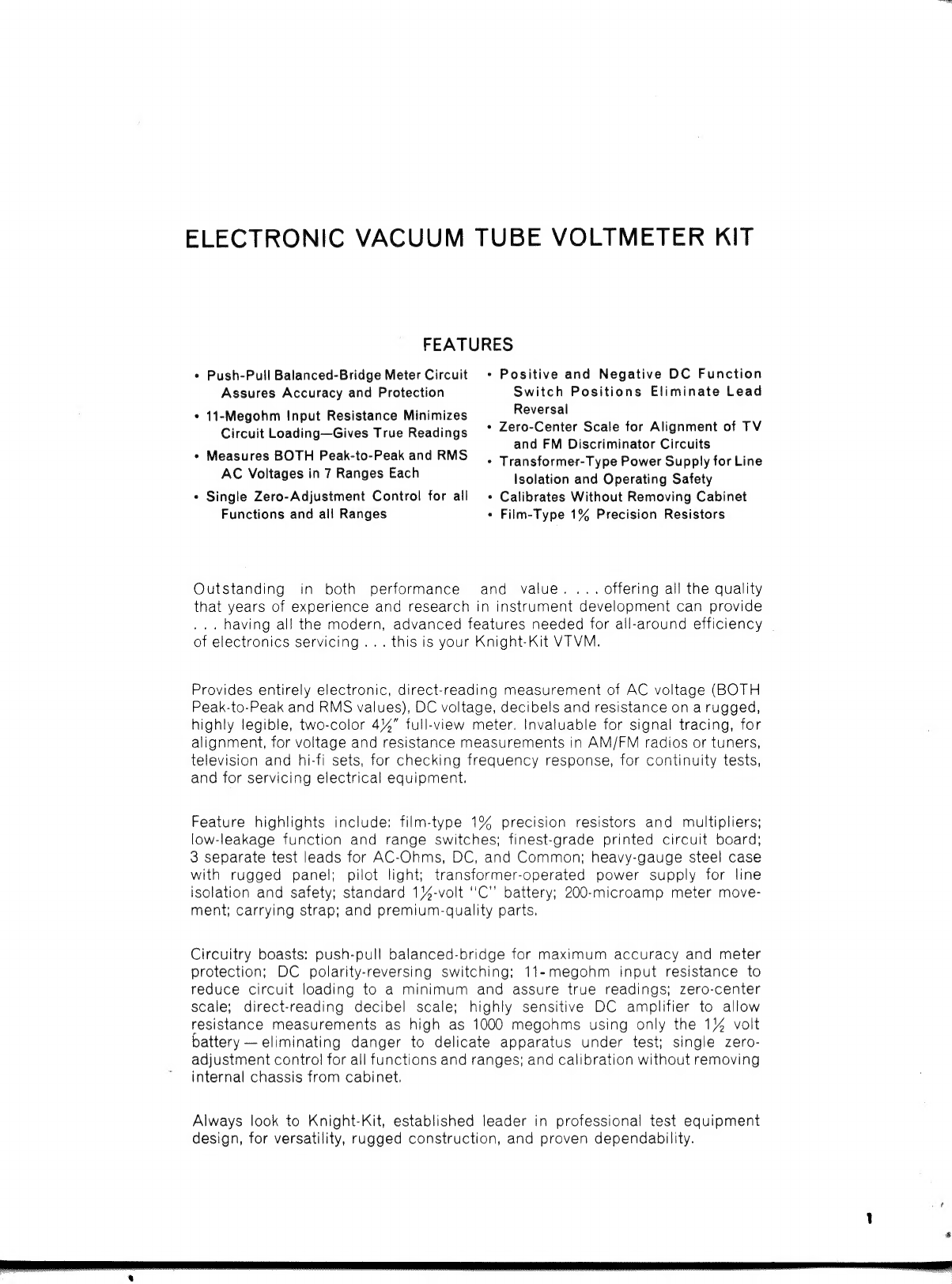

ELECTRONIC

VACUUM

TUBE

VOLTMETER

KIT

FEATURES

*

Push-Pull

Balanced-Bridge

Meter

Circuit

+»

Positive

and

Negative

DC

Function

Assures

Accuracy

and

Protection

Switch

Positions

Eliminate

Lead

Reversal

*

Zero-Center

Scale

for

Alignment

of

TV

and

FM

Discriminator

Circuits

*

Measures

BOTH

Peak-to-Peak

and

RMS,

Transformer-Type

Power

Supply

for

Line

*

11-Megohm

Input

Resistance

Minimizes

Circuit

Loading—Gives

True

Readings

AC

Voltages

in

7

Ranges

Each

isolation

and

Operating

Safety

*

Single

Zero-Adjustment

Control

for

all

+

Calibrates

Without

Removing

Cabinet

Functions

and

all

Ranges

«

Film-Type

1%

Precision

Resistors

Outstanding

in

both

performance

and

value.

...

offering

all

the

quality

that

years

of

experience

and

research

in

instrument

development

can

provide

...

having

all

the

modern,

advanced

features

needed

for

all-around

efficiency

of

electronics

servicing

...

this

is

your

Knight-Kit

VTVM.

Provides

entirely

electronic,

direct-reading

measurement

of

AC

voltage

(BOTH

Peak-to-Peak

and

RMS

values),

DC

voltage,

decibels

and

resistance

on

a

rugged,

highly

legible,

two-color

44%”

full-view

meter.

Invaluable

for

signal

tracing,

for

alignment,

for

voltage

and

resistance

measurements

in

AM/FM

radios

or

tuners,

television

and

hi-fi

sets,

for

checking

frequency

response,

for

continuity

tests,

and

for

servicing

electrical

equipment.

Feature

highlights

include:

film-type

1%

precision

resistors

and

multipliers;

low-leakage

function

and

range

switches;

finest-grade

printed

circuit

board;

3

separate

test

leads

for

AC-Ohms,

DC,

and

Common;

heavy-gauge

steel

case

with

rugged

panel:

pilot

light:

transformer-operated

power

supply

for

line

isolation

and

safety;

standard

1%-volt

‘‘C’’

battery;

200-microamp

meter

move-

ment;

carrying

strap;

and

premium-quality

parts,

Circuitry

boasts:

push-pull

balanced-bridge

for

maximum

accuracy

and

meter

protection;

DC

polarity-reversing

switching;

11-megohm

input

resistance

to

reduce

circuit

loading

to

a

minimum

and

assure

true

readings;

zero-center

scale;

direct-reading

decibel

scale;

highly

sensitive

DC

amplifier

to

allow

resistance

measurements

as

high

as

1000

megohms

using

only

the

1%

volt

battery

—

eliminating

danger

to

delicate

apparatus

under

test;

single

zero-

adjustment

control

for

all

functions

and

ranges;

and

calibration

without

removing

internal

chassis

from

cabinet.

Always

look

to

Knight-Kit,

established

leader

in

professional

test

equipment

design,

for

versatility,

rugged

construction,

and

proven

dependability.

SPECIFICATIONS

DC

Voltmeter:

RangeS..........00...000

cee

1.5,

5,

15, 50,

150,

500,

and

1500

volts

full

scale.

Input

Resistance..............

11

Megohms

(1

Megohm

in

probe)

on

all

ranges.

Circult:.

3:4.

gh

akon

Push-

Pull

balanced

bridge with

12AU7

twin

triode.

ACCULACY......

cece

eee

+3%

full

scale.

AC

Voltmeter:

RMS

Ranges...................

1.5,

5,

15,

50,

150,

500,

1500

volts

full

scale.

ACCULACY...0..

eee

+5%

full

scale.

Peak-to-Peak

Ranges......4,

14, 40,

140,

400,

1400,

4000

volts.

Ohmmeter:

Ranges...

i.2c.ocacc

eave:

Center

scale

at

10

with

multipliers

X

1,

x

10,

x

100,

x

1000,

x

10K,

*

100K,

x

1Meg.

Meter:

414”

200

»A

movement.

Multipliers:

1%

precision

type.

12AU7,

twin

triode

me-

ter

bridge.

6AL5,

twin

diode

full

wave

rectifier.

Tube

Complement:

110-125

volts,

60

cycles

AC,

Power

Supply:

Battery:

1.5

volt

“C”

battery.

HOW

TO

BUILD

THE

KNIGHT

VTVM

Your

KNIGHT

VTVM

uses

a

printed

circuit

which

assures

you

that

the

VTVM

will

be

an

accurate,

reli-

able

test

instrument

regardless

of

age.

A

sheet

of

cop-

per

is

bonded

to

a

sheet

of

phenolic.

When

the

wiring

pattern

has

been

determined,

the

unused

portion

of

the

copper

sheet

is

etched

off

leaving

an

exact

dupli-

cation

of

the

engineering

prototype.

Exact

duplication

is

one

of

the

greatest

advantages

of

printed

circuits,

and

prevents

variation

in

wiring

and

performance

from

instrument

to

instrument.

Your

KNIGHT

VTVM

is

all

electronic.

That

is,

the

bridge

circuit

is

used

for

every

measurement

of

DC

2

voltage,

resistance,

and

AC

voltage

after

rectification

by

the

full-wave

rectifier.

The

meter

employed

is

an

extremely

stable,

sensitive

200

microampere

movement.

The

multipliers

are

1%

precision

type.

Overall

accuracy

of

the

DC

functions

is

+3%

of

full

scale

reading,

and

+-5%

on

AC

functions.

A

wide

choice

of

measurements

is

provided

giving

you

seven

ranges

on

DC,

AC,

and

resistance.

Both

RMS

and

peak-to-peak

AC

voltages

may

be

measured.

Your

KNIGHT

VTVM,

through

the

use

of

the

print-

ed

circuit,

saves

a

great

deal

of

tedious

wiring,

assures

you

of

a

finished

instrument

which

compares

closely

to

the

original

engineering

model,

and

provides

you

with

an

instrument

worth

many

times

its

low

cost.

Before

starting

to

build

your

KNIGHT

VTVM,

check

each

part

against

the

Parts

List

on

page

23.

If

you

are

unable

to

identify

some

of

the

parts

by

sight,

locate

them

on

the

pictorial

diagrams.

Capacitor

and

resistor

values,

if

not

printed

on

the

part,

can

be

found

with

the

aid

of

the

color

code

chart.

Hardware

is

listed

in

the

last

part

of

the

Parts

List.

To

keep

our

kits

at

the

lowest

possible

price,

we

fre-

quently

weigh

hardware

rather

than

to

count

it.

Therefore,

do

not

be

concerned

if

more

nuts

and

machine

screws,

for

example,

are

supplied

than

are

specified

in

the

Parts

List.

The

only

tools

required

for

building

your

KNIGHT

VTVM

are:

Long-nose

pliers,

diagonal

cutters,

screw-

driver,

set-screw

driver,

and

a

soldering

iron.

Study

the

pictorial

diagrams

and

note

how

the

parts

are

mounted.

These

pictorial

diagrams

show

the

actual

location

of

all

parts

and

wiring.

The

schematic

dia-

gram

shows

how

the

parts

are

connected

electrically

and

is

helpful

in

understanding

how

the

circuits

work.

The

step-by-step

instructions

were

prepared

by

a

skilled

technician

while

he

was

actually

building

the

KNIGHT

VTVM.

Therefore,

they

are

the

best

and

fastest

way

of

assembling

this

instrument.

We

suggest

that

you

read

through

the

instructions

before

building

the

VTVM.

This

will

enable

you

to

familiarize

yourself

with

the

procedure

and

avoid

possible

errors.

We

invite

you

to

use

the

blank

parentheses,

(

),

before

each

step

to

check

it

off

after

you

have

completed

it.

Each

step

is

clearly

illustrated

on

an

accompanying

line

drawing.

Some

builders

prefer

to

“cross

out”

each

wire

and

component

on

the

drawings

with

a

colored

pencil

after

it

is

installed.

While

an

excellent

way

to

avoid

mistakes,

and

highly

recommended

by

us,

this

procedure

results

in

drawings

that

are

difficult

to

re-

use.

For

this

reason

each

wiring

view

is

reproduced

on

a

separate,

folded

sheet

of

paper.

You

are

now

ready

to

build

your

KNIGHT

VTVM.

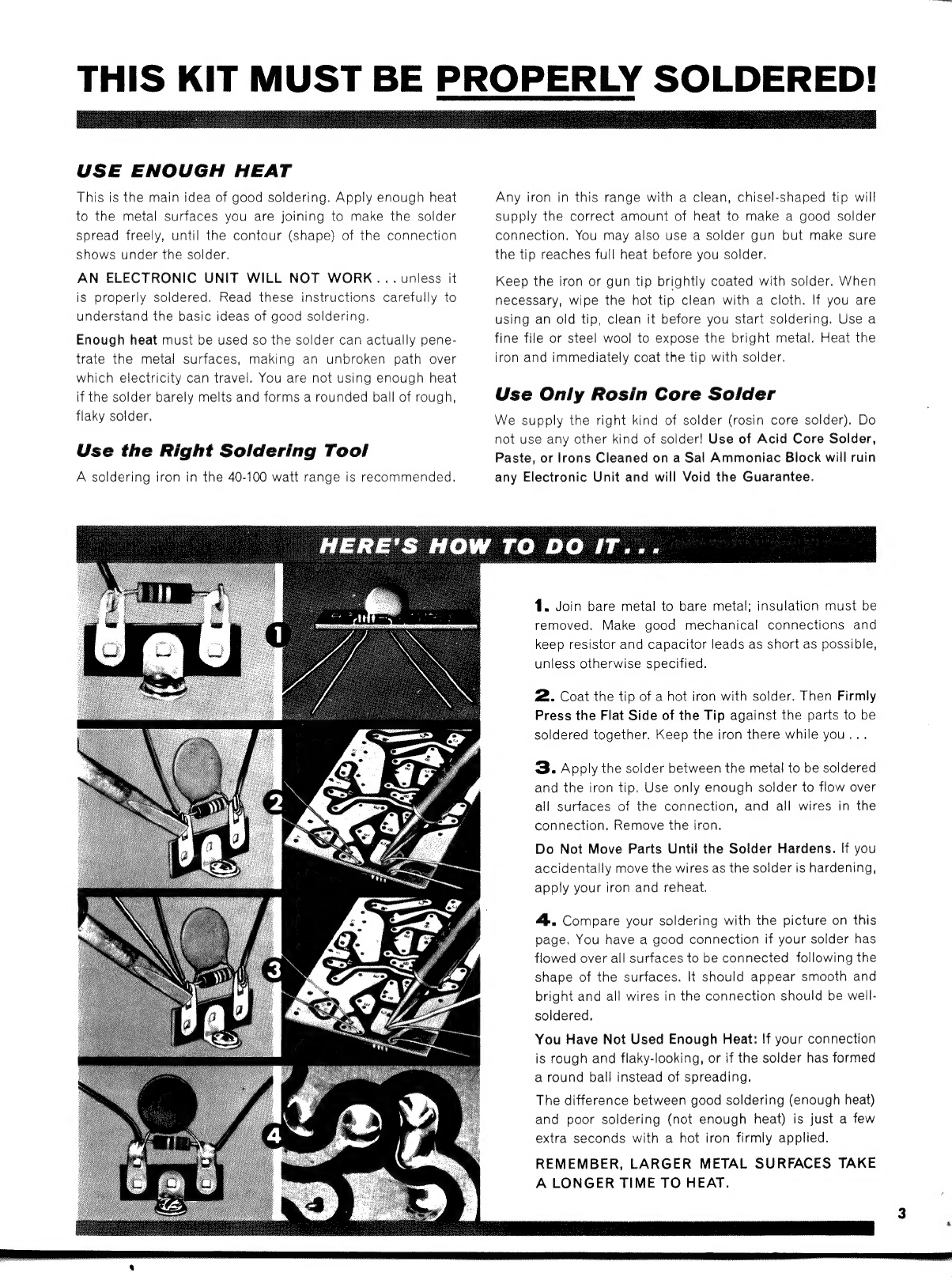

THIS

KIT

MUST

BE

PROPERLY

SOLDERED!

USE

ENOUGH

HEAT

This

is

the

main

idea

of

good

soldering.

Apply

enough

heat

to

the

metal

surfaces

you

are

joining

to

make

the

solder

spread

freely,

until

the

contour

(shape)

of

the

connection

shows

under

the

solder.

AN

ELECTRONIC

UNIT

WILL

NOT

WORK...

unless

it

is

properly

soldered.

Read

these

instructions

carefully

to

understand

the

basic

ideas

of

good

soldering.

Enough

heat

must

be

used

so

the

solder

can

actually

pene-

trate

the

metal

surfaces,

making

an

unbroken

path

over

which

electricity

can

travel.

You

are

not

using

enough

heat

if

the

solder

barely

melts

and

forms

a

rounded

ball

of

rough,

flaky

solder.

Use

the

Right

Soldering

Tool

A

soldering

iron

in

the

40-100

watt

range

is

recommended.

Any

iron

in

this

range

with

a

clean,

chisel-shaped

tip

will

supply

the

correct

amount

of

heat

to

make

a

good

solder

connection.

You

may

also

use

a

solder

gun

but

make

sure

the

tip

reaches

full

heat

before

you

solder.

Keep

the

iron

or

gun

tip

brightly

coated

with

solder,

When

necessary,

wipe

the

hot

tip

clean

with

a

cloth.

If

you

are

using

an

old

tip,

clean

it

before

you

start

soldering.

Use

a

fine

file

or

steel

wool

to

expose

the

bright

metal.

Heat

the

iron

and

immediately

coat

the

tip

with

solder.

Use

Only

Rosin

Core

Solder

We

supply

the

right

kind

of

solder

(rosin

core

solder).

Do

not

use

any

other

kind

of

solder!

Use

of

Acid

Core

Solder,

Paste,

or

lrons

Cleaned

on

a

Sal

Ammoniac

Block

will

ruin

any

Electronic

Unit

and

will

Void

the

Guarantee.

1.

Join

bare

metal

to

bare

metal;

insulation

must

be

removed.

Make

good

mechanical

connections

and

keep

resistor

and

capacitor

leads

as

short

as

possible,

unless

otherwise

specified.

2.

Coat

the

tip

of

a

hot

iron

with

solder.

Then

Firmly

Press

the

Flat

Side

of

the

Tip

against

the

parts

to

be

soldered

together.

Keep

the

iron

there

while

you...

3.

Apply

the

solder

between

the

metal

to

be

soldered

and

the

iron

tip.

Use

only

enough

solder

to

flow

over

all

surfaces

of

the

connection,

and

all

wires

in

the

connection.

Remove

the

iron.

Do

Not

Move

Parts

Until

the

Solder

Hardens.

If

you

accidentally

move

the

wires

as

the

solder

is

hardening,

apply

your

iron

and

reheat.

4..

Compare

your

soldering

with

the

picture

on

this

page.

You

have

a

good

connection

if

your

solder

has

flowed

over

all

surfaces

to

be

connected

following

the

shape

of

the

surfaces.

It

should

appear

smooth

and

bright

and

all

wires

in

the

connection

should

be

well-

soldered,

You

Have

Not

Used

Enough

Heat:

If

your

connection

is

rough

and

flaky-looking,

or

if

the

solder

has

formed

a

round

ball

instead

of

spreading.

The

difference

between

good

soldering

(enough

heat)

and

poor

soldering

(not

enough

heat)

is

just

a

few

extra

seconds

with

a

hot

iron

firmly

applied.

REMEMBER,

LARGER

METAL

SURFACES

TAKE

A

LONGER

TIME

TO

HEAT.

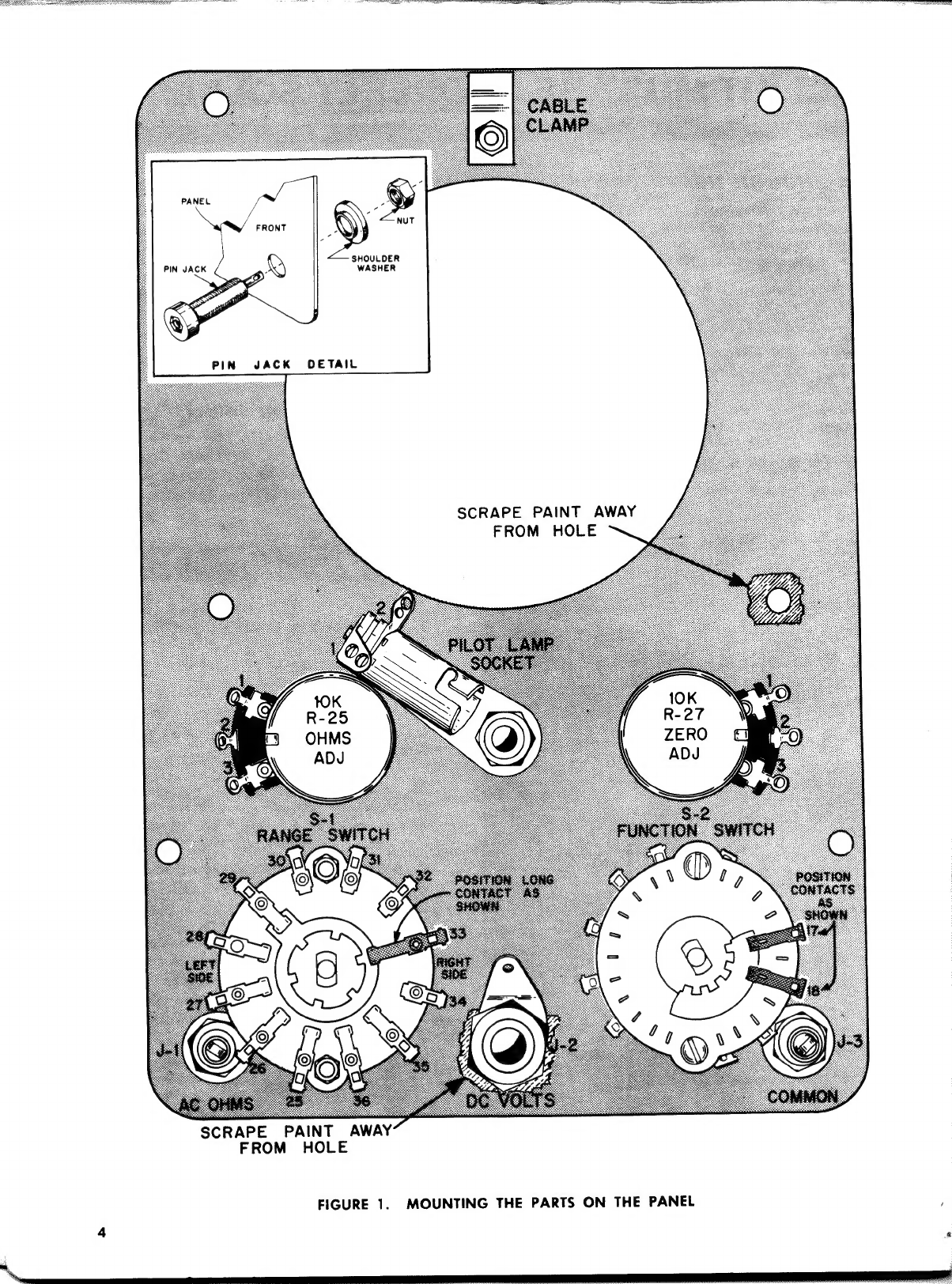

SHOULDER

PIN

JACK

So

WASHER

PIN

JACK

DETAIL

SCRAPE

PAINT

AWAY

FROM

HOLE

SCRAPE

PAINT

AWAY

FROM

HOLE

FIGURE

1.

MOUNTING

THE

PARTS

ON

THE

PANEL

:

MOUNTING

THE

PARTS

ON

THE

PANEL

Before

you

begin

mounting

the

parts,

place

a

pad

or

a

soft

cloth

on

your

work

table

to

protect

the

finish

on

the

front

panel.

SEE

FIGURES

1

AND

2

(

)

Insert

the

short

flat

head

screw

through

the

hole

in

the

top

center

of

the

panel.

Place

an

external

lockwasher

over

the

screw.

Next

put

one

of

the

cable

clamps

over

the

screw.

Now,

put

on

an

in-

ternal

lockwasher

and

tighten

a

nut

over

it

very

securely.

See

Figure

2.

Bw

|

'

'

INTERNAL

LOCKWASHER

GQ

|

'CABINET

MOUNTING

CLIP

Sere

CLAMP)

!

EXTERNAL

LOCKWASHER

FIGURE

2.

HOW

TO

ASSEMBLE

THE

CABINET

CLAMP

( )

Mount

R-25,

10K

ohms

OHMS

ADJUST

potenti-

ometer,

in

the

large

hole

in

the

left

center

of

the

panel.

Use

two

nuts

to

mount

this

control

as

shown

in

Figure

3.

MOUNTING

/

HOLES.

~%

SHE

=

$y)

))

4

controg

»

CONTREL

HEX

NUTS

(2)

FIGURE

3.

HOW

TO

MOUNT

A

CONTROL

(

)

Mount

R-27,

10K

ohm

ZERO

ADJUST

potenti-

ometer,

in

the

large

hole

in

the

right

center

of

the

panel,

in

the

same

manner.

(

)

Mount

the

‘pilot

light

socket

between

R-25

and

R-27.

The

bracket

must

be

positioned

as

shown

in

Figure

1,

but

must

not

touch

R-25.

(

)

Mount

J-1,

the

red

pin

jack,

in

the

lower

left

corner

of

the

panel.

Use

a

shouldered

fiber

washer

on

the

inside

of

the

panel

to

insulate

the

jack

from

the

panel.

Now,

tighten

a

nut

against

the

washer.

Refer

to

the

pin

jack

detail

in

the

upper

left

corner

of

Figure

1.

(

)

Mount

J-3,

the

black

pin

jack,

in

the

lower

right

corner

of

the

panel

in

the

same

manner.

(

)

Scrape

the

paint

from

the

two

holes

as

shown.

(

)

Mount

J-2,

the

chassis

connector

in

the

large

hole

in

the

lower

center

of

the

panel.

This

con-

nector

is

supplied

with

a

shouldered

fiber

wash-

er.

Take

this

washer

off

and

throw

it

away.

Place

the

flat

fiber

washer

over

the

small

threaded

end

of

the

connector.

Scrape

the

paint

from

around

this

hole

on

the

rear

of

the

panel.

Insert

the

small

threaded

end

through

the

hole

in

the

panel.

Place

the

solder

lug

and

the

flat

metal

washer

on

the

connector

and

tighten

the

nut

securely.

See

Figure

4.

SOLDER

LUG

FLAT

FIBER

WASHER

WASHER

FIGURE

4.

HOW

TO

MOUNT

THE

CHASSIS

CONNECTOR

( )

Mount

S§-1,

the

long

triple

wafer

RANGE

switch

in

the

hole

in

the

lower

left

corner

of

the

panel.

The

long

contact

on

the

end

wafer

must

be

posi-

tioned

as

shown

in

Figure

1.

The

blank

space

on

the

wafer

near

the

shaft

end

must

be

toward

J-1.

Use

a

large

nut

and

a

lockwasher

on

the

inside

of

the

panel.

Fasten

it

securely

with

another

large

nut.

Place

a

large

knob

on

the

shaft.

Be

sure

the

line

on

the

knob

lines

up

ex-

actly

with

the

printed

dots

on

the

panel.

If

not,

rotate

S-1

so

the

scale

on

the

panel

and

the

line

on

the

knob

correspond.

( )

Mount

S-2,

the

other

triple

wafer

FUNCTION

switch,

in

the

other

hole

on

the

right

of

the

panel.

Use

another

large

nut

and

lockwasher

in-

side

the

panel.

Use

a

large

nut

outside

the

panel.

Again

place

a

knob

on

the

shaft

and

be

sure

that

the

line

on

the

knob

lines

up

with

the

scale

on

the

panel.

You

have

finished

mounting

the

parts

on

the

panel

until

after

the

switches

are

wired.

WIRING

AND

SOLDERING

HINTS

How

well

a

piece

of

electronic

equipment

works

of-

ten

depends

on

the

quality

of

workmanship

used

in

its

construction.

It

is

for

this

reason

that

the

following

suggestions

are

made.

These

hints

are

mainly

for

the

beginner,

however,

even

experienced

persons

may

benefit

from

a

brief

review.

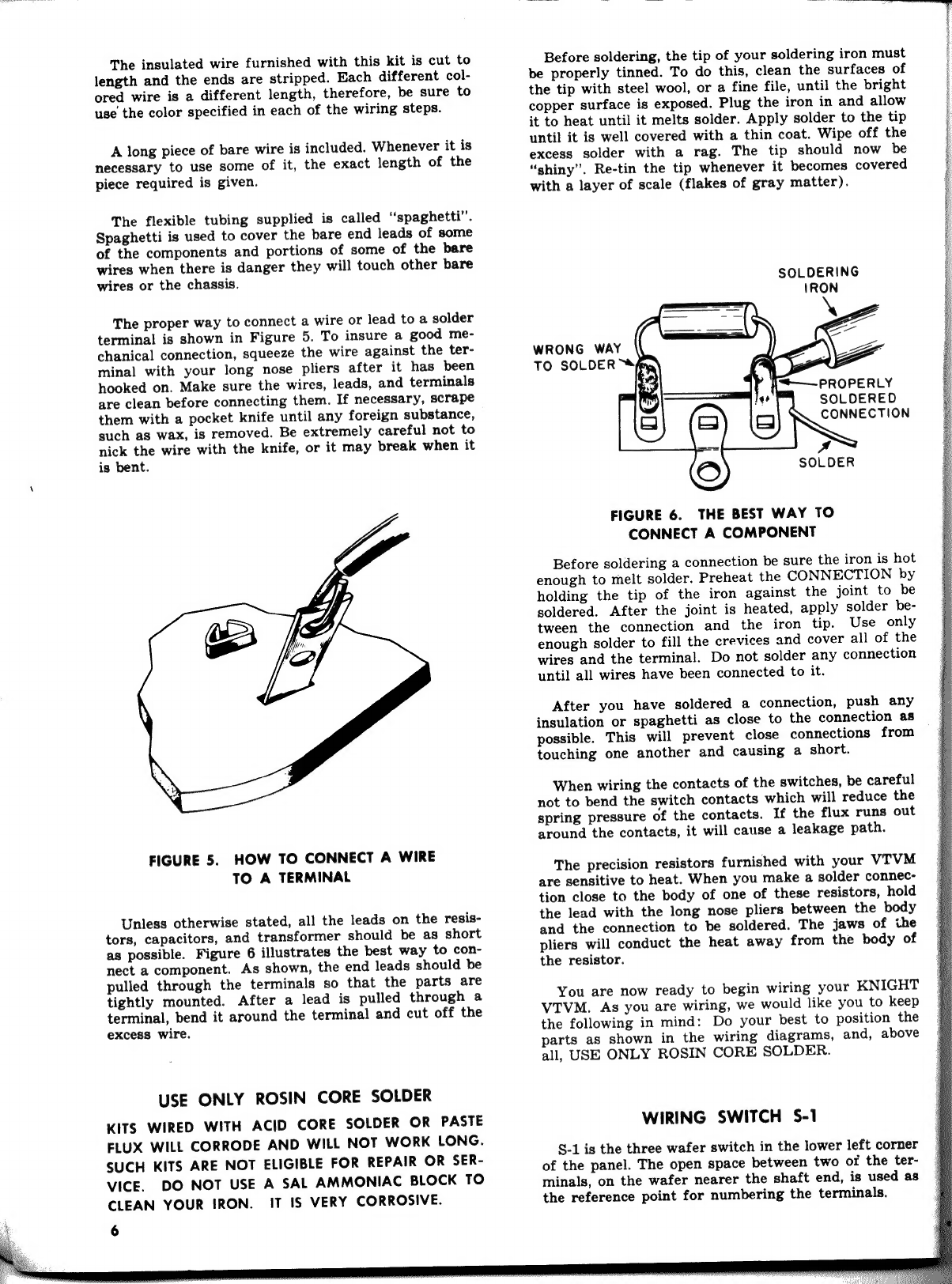

The

insulated

wire

furnished

with

this

kit

is

cut

to

length

and

the

ends

are

stripped.

Each

different

col-

ored

wire

is

a

different

length,

therefore,

be

sure

to

use

the

color

specified

in

each

of

the

wiring

steps.

A

long

piece

of

bare

wire

is

included.

Whenever

it

is

necessary

to

use

some

of

it,

the

exact

length

of

the

piece

required

is

given.

The

flexible

tubing

supplied

is

called

“spaghetti”.

Spaghetti

is

used

to

cover

the

bare

end

leads

of

some

of

the

components

and

portions

of

some

of

the

bare

wires

when

there

is

danger

they

will

touch

other

bare

wires

or

the

chassis.

The

proper

way

to

connect

a

wire

or

lead

to

a

solder

terminal

is

shown

in

Figure

5.

To

insure

a

good

me-

chanical

connection,

squeeze

the

wire

against

the

ter-

minal

with

your

long

nose

pliers

after

it

has

been

hooked

on.

Make

sure

the

wires,

leads,

and

terminals

are

clean

before

connecting

them.

If

necessary,

scrape

them

with

a

pocket

knife

until

any

foreign

substance,

such

as

wax,

is

removed.

Be

extremely

careful

not

to

nick

the

wire

with

the

knife,

or

it

may

break

when

it

is

bent.

FIGURE

5.

HOW

TO

CONNECT

A

WIRE

TO

A

TERMINAL

Unless

otherwise

stated,

all

the

leads

on

the

resis-

tors,

capacitors,

and

transformer

should

be

as

short

as

possible.

Figure

6

illustrates

the

best

way

to

con-

nect

a

component.

As

shown,

the

end

leads

should

be

pulled

through

the

terminals

so

that

the

parts

are

tightly

mounted.

After

a

lead

is

pulled

through

a

terminal,

bend

it

around

the

terminal

and

cut

off

the

excess

wire.

USE

ONLY

ROSIN

CORE

SOLDER

KITS

WIRED

WITH

ACID

CORE

SOLDER

OR

PASTE

FLUX

WILL

CORRODE

AND

WILL

NOT

WORK

LONG.

SUCH

KITS

ARE

NOT

ELIGIBLE

FOR

REPAIR

OR

SER-

VICE.

DO

NOT

USE

A

SAL

AMMONIAC

BLOCK

TO

CLEAN

YOUR

IRON.

IT

IS

VERY

CORROSIVE.

6

Before

soldering,

the

tip

of

your

soldering

iron

must

be

properly

tinned.

To

do

this,

clean

the

surfaces

of

the

tip

with

steel

wool,

or

a

fine

file,

until

the

bright

copper

surface

is

exposed.

Plug

the

iron

in

and

allow

it

to

heat

until

it

melts

solder.

Apply

solder

to

the

tip

until

it

is

well

covered

with

a

thin

coat.

Wipe

off

the

excess

solder

with

a

rag.

The

tip

should

now

be

“shiny”.

Re-tin

the

tip

whenever

it

becomes

covered

with

a

layer

of

scale

(flakes

of

gray

matter).

SOLDERING

WRONG

WAY

TO

SOLDER

“fey,

}“t+——~-

PROPERLY

SOLDERED

Roeten

A

SOLDER

FIGURE

6.

THE

BEST

WAY

TO

CONNECT

A

COMPONENT

Before

soldering

a

connection

be

sure

the

iron

is

hot

enough

to

melt

solder.

Preheat

the

CONNECTION

by

holding

the

tip

of

the

iron

against

the

joint

to

be

soldered.

After

the

joint

is

heated,

apply

solder

be-

tween

the

connection

and

the

iron

tip.

Use

only

enough

solder

to

fill

the

crevices

and

cover

all

of

the

wires

and

the

terminal.

Do

not

solder

any

connection

until

all

wires

have

been

connected

to

it.

After

you

have

soldered

a

connection,

push

any

insulation

or

spaghetti

as

close

to

the

connection

as

possible.

This

will

prevent

close

connections

from

touching

one

another

and

causing

a

short.

When

wiring

the

contacts

of

the

switches,

be

careful

not

to

bend

the

switch

contacts

which

will

reduce

the

spring

pressure

of

the

contacts.

If

the

flux

runs

out

around

the

contacts,

it

will

cause

a

leakage

path.

The

precision

resistors

furnished

with

your

VTVM

are

sensitive

to

heat.

When

you

make

a

solder

connec-

tion

close

to

the

body

of

one

of

these

resistors,

hold

the

lead

with

the

long

nose

pliers

between

the

body

and

the

connection

to

be

soldered.

The

jaws

of

the

pliers

will

conduct

the

heat

away

from

the

body

of

the

resistor.

You

are

now

ready

to

begin

wiring

your

KNIGHT

VTVM.

As

you

are

wiring,

we

would

like

you

to

keep

the

following

in

mind:

Do

your

best

to

position

the

parts

as

shown

in

the

wiring

diagrams,

and,

above

all,

USE

ONLY

ROSIN

CORE

SOLDER.

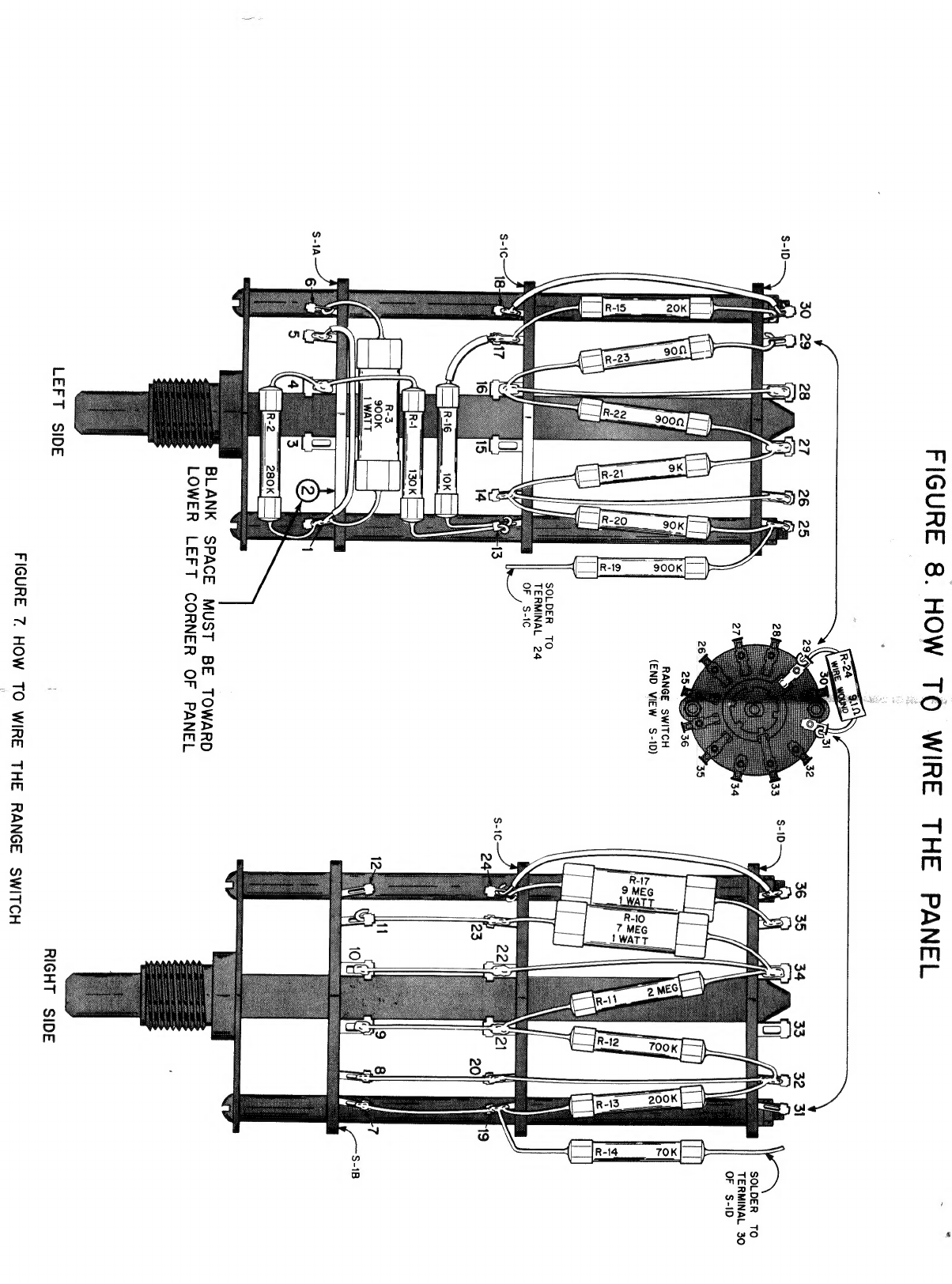

WIRING

SWITCH

S-1

§-1

is

the

three

wafer

switch

in

the

lower

left

corner

of

the

panel.

The

open

space

between

two

of

the

ter-

minals,

on

the

wafer

nearer

the

shaft

end,

is

used

as

the

reference

point

for

numbering

the

terminals.

SEE

FIGURE

7.

(

)

Connect,

but

do

not

solder,

one

end

of

R-16,

10K

ohm

resistor,

to

terminal

13.

Insert

the

other

CAUTION:

The

precision

resistors

mounted

on

the

end

through

a

1%

inch

length

of

spaghetti.

Con-

range

switch

S-1

must

not

touch

each

other,

nearby

nect,

but

do

not

solder,

it

to

terminal

17.

ee

a

the

a

nie

ae

alone

utes

( )

Connect,

but

do

not

solder,

one

end

of

R-20,

90K

ee

ae

dl

s

Pars

He

pita

a

a

Uae

Rent

ie

anes

ohm

resistor,

to

terminal

14.

Connect,

but

do

aeauansas

“pail

Seeacsee

age

A

Se

Re

eee

not

solder,

the

other

end

to

terminal

25.

resistors,

keep

the

leads

short,

as

shown

in

the

illus-

tration.

Clip

off

excess

lead

lengths.

( )

Connect,

but

do

not

solder,

one

end

of

a

2

inch

( )

Connect,

but

do

not

solder,

one

end

of

R-2,

280K

esata

a

Denne.

14.

Solder

the

other

end

ohm

resistor,

to

terminal

1

of

S-1.

Connect,

but

5

do

not

solder,

the

other

end

to

terminal

4

of

S-1.

(

)

Solder

one

end

of

R-21,

9K

ohm

resistor

to

ter-

Position

R-2

as

shown

in

Figure

7.

minal

14.

Connect,

but

do

not

solder,

the

other

(

)

Connect,

but

do

not

solder,

one

end

of

R-3,

900K

end

to

terminal

27.

;

ohm,

1

watt,

resistor,

to

terminal

1.

Connect,

( )

Connect,

but

do

not

solder,

one

end

of

R-22,

900

but

do

not

solder,

the

other

end

to

terminal

6.

ohm

resistor,

to

terminal

16.

Solder

the

other

Position

R-3

as

shown

in

Figure

7.

end

to

terminal

27.

(

)

Solder

one

end

of

a

2

inch

bare

wire

to

terminal

( )

Connect,

but

do

not

solder,

one

end

of

a

2

inch

1.

Insert

the

other

end

through

a

114

inch

length

bare

wire

to

terminal

16.

Solder

the

other

end

of

spaghetti.

Solder

it

to

terminal

5.

to

terminal

28.

(

)

Solder

one

end

of

R-1,

130K

ohm

resistor,

to

( )

Solder

one

end

of

R-23,

90

ohm

resistor,

to

ter-

terminal

4.

Connect,

but

do

not

solder,

the

other

minal

16.

Connect,

but

do

not

solder,

the

other

end

to

terminal

13.

end

to

terminal

29.

VL)

j

ay

enna

eT

RB

ni

ie

Ss

31

30

29 28

27

26

25

29

y

e

$-10

(

¥

28,

33

SOLDER

TO

TERMINAL

30

27

34

i

ca

26

35

4a

Wa

|go

“er

g

Zi

8

©

Sag

fs

RANGE

SWITCH

q

a

a

(END

VIEW

S-1D}

Psy

fm

“

a

g

os

&

«

&

cl

fife

&

Wy

\

|

L\)

a

UT

SOLDER

TO

TERMINAL

24

0

OF

S-fC

$-1C:

18:

17

‘

J

¥

13

$-1C

16

15

14

—Tr-1

10K

R-l

130K

|

R-3

900K

1

WATT

me

s-A—“g

,

td

0

3

'

5

4

3

roc]r-2

280k|_

BLANK

SPACE

MUST

BE

TOWARD

LOWER

LEFT

CORNER

OF

PANEL

LEFT

SIDE

RIGHT

SIDE

FIGURE

7.

HOW

TO

WIRE

THE

RANGE

SWITCH

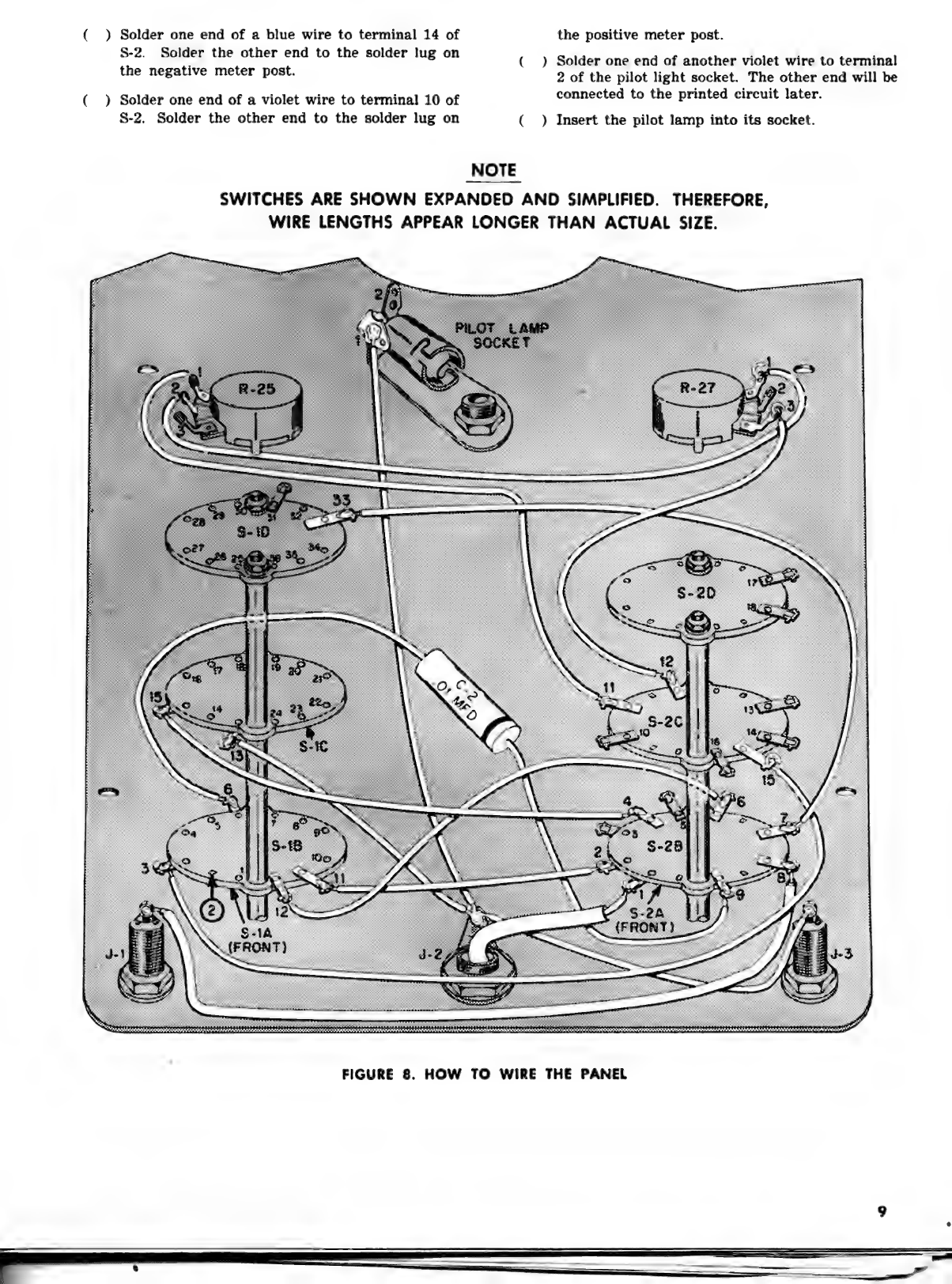

FIGURE

8.

HOW

TO

WIRE

THE

PANEL

.

R-24

)

va!

a

(2)

32

30

29

28

27

26

25

by

2

28

33

SOLDER

TO

TERMINAL

30

27

34

OF

S-ID

26

35

25

36

RANGE

SWITCH

(END

VIEW

S-1D)

SOLDER

TO

TERMINAL

24

OF

S-IC

S-1C

S-1B

BLANK

SPACE

MUST

BE

TOWARD

LOWER

LEFT

CORNER

OF

PANEL

LEFT

SIDE

RIGHT

SIDE

FIGURE

7

HOW

TO

WIRE

THE

RANGE

SWITCH

pees

area

om

ae

G3alslIdWIS

ONY

QGSAQNVdxX3

NMOHS

3YY

SSHOLIMS

3LON

SORES

OEE

SS

Solder

one

end

of

R-15,

20K

ohm

resistor,

to

ter-

minal

17.

Connect,

but

do

not

solder,

the

other

end

to

terminal

30.

Solder

one

end

of

a

2

inch

red

wire

to

terminal

18.

Connect,

but

do

not

solder,

the

other

end

to

terminal

30.

Pass

one

end

of

R-14,

70K

ohm

resistor

through

terminal

19

and

connect

it

to

terminal

7.

Solder

terminal

7,

but

do

not

solder

terminal

19.

Solder

the

other

end

of

R-14

to

terminal

30.

Solder

one

end

of

R-13,

200K

ohm

resistor,

to

terminal

19.

Connect,

but

do

not

solder,

the

other

end

to

terminal

32.

Pass

one

end

of

a

3

inch

hare

wire

through

ter-

minal

20

and

connect

it

to

terminal

8.

Solder

both

terminals

8

and

20.

Connect,

but

do

not

solder,

the

other

end

to

terminal

32.

Connect,

but

do

not

solder,

one

end

of

R-12,

700K

ohm

resistor,

to

terminal

21.

Solder

the

other

end

to

terminal

32.

Pass

one

end

of

R-11,

2

Megohm

resistor,

through

terminal

21

and

connect

it

to

terminal

9.

Solder

both

connections.

Connect,

but

do

not

solder,

the

other

end

to

terminal

34.

Pass

one

end

of

a

3

inch

bare

wire

through

ter-

minal

22

and

connect

it

to

terminal

10.

Solder

poth

connections.

Connect,

but

do

not

solder,

the

other

end

to

terminal

34.

Pass

one

end

of

R-10,

7

Megohm,

1

watt,

resis-

tor,

through

terminal

23,

and

connect

it

to

ter-

minal

11.

Solder

terminal

23,

but

do

not

solder

terminal

11.

Solder

the

other

end

to

terminal

34.

Connect,

but

do

not

solder,

one

end

of

R-17,

9

Megohm,

1

watt

resistor,

to

terminal

24.

Solder

the

other

end

to

terminal

35.

Connect,

but

do

not

solder,

one

end

of

a

red

wire

to

terminal

24.

Solder

the

other

end

to

terminal

36.

Solder

one

end

of

R-19,

900K

ohm

resistor,

to

terminal

24.

Solder

the

other

end

to

terminal

25.

Solder

one

end

of

R-24,

the

9.1

ohm

wirewound

resistor

marked

with

the

color

bands

white,

brown,

gold,

and

gold,

to

terminal

29.

Connect,

but

do

not

solder,

the

other

end

to

terminal

31.

You

have

finished

mounting

the

precision

resistors.

VERY

CAREFULLY

CHECK

EACH

CONNECTION

MADE

ON

§-1.

Compare

your

completed

switch

with

Figure

7.

A

single

error

here

will

keep

your

kit

from

operating

properly.

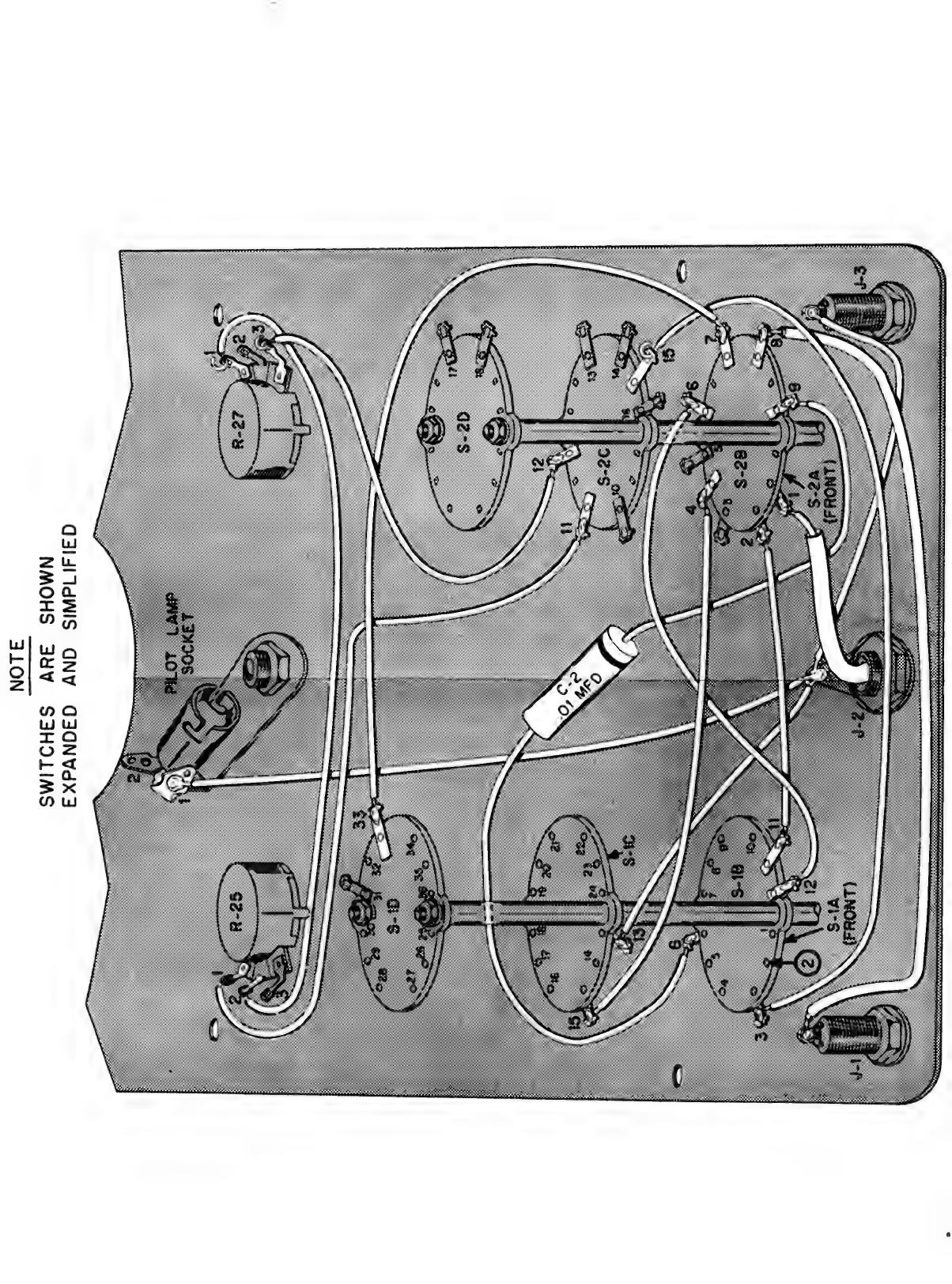

HOW

TO

WIRE

THE

PANEL

SEE

FIGURE

8.

(

)

Solder

one

end

of

a

green

wire

to

terminal

1

on

the

pilot

light

socket.

Connect,

but

do

not

sol-

der,

the

other

end

to

the

solder

lug

under

the

chassis

connector

nut.

Solder

one

end

of

an

orange

wire

to

terminal

13

on

§-1.

Connect,

but

do

not

solder,

the

other

end

to

the

solder

lug.

(

ie

Solder

one

end

of

another

orange

wire

to

the

terminal

on

J-3,

the

common

jack.

Solder

the

other

end

to

the

solder

lug.

(

)

Pass

one

end

of

a

red

wire

through

the

chassis

connector.

Solder

it

to

the

eyelet

in

the

center

of

the

connector.

Insert

the

other

end

through

a

11%

inch

length

of

the

large

spaghetti.

Force

the

spaghetti

down

against

the

soldered

eyelet

connection.

Solder

the

other

end

of

the

red

wire

to

terminal

1

of

S-2.

(_)

Insert

each

end

lead

of

C-2,

.01

MFD

paper

ca-

pacitor,

through

a

114

inch

length

of

small

spa-

ghetti.

Solder

the

lead

from

the

banded

end

to

terminal

9

of

S-2.

Solder

the

other

lead

to

termi-

nal

6

of

S-1.

Position

C-2

between

J-2

and

S-2A.

(

)

Solder

one

end

of

a

red

wire

to

terminal

11

of

S-1.

Solder

the

other

end

to

terminal

2

of

S-2.

( )

Solder

one

end

of

a

yellow

wire

to

terminal

12

of

8-1.

Solder

the

other

end

to

terminal

6

of

S-2.

( )

Insert

a

green

wire

through

a

414

inch

length

of

the

large

spaghetti.

Solder

one

end

to

J-1.

Sol-

der

the

other

end

to

terminal

8

of

S-2.

(

)

Solder

one

end

of

a

green

wire

to

terminal

3

of

S-1.

Connect,

but

do

not

solder,

the

other

end

to

terminal

15

of

S-2.

(

)

Solder

one

end

of

a

yellow

wire

to

terminal

1

of

R-25.

Solder

the

other

end

to

terminal

11

of

§-2.

(

)

Solder

one

end

of

a

blue

wire

to

terminal

2

of

R-25.

Connect,

but

do

not

solder,

the

other

end

to

terminal

1

of

R-27.

(_)

Solder

one

end

of

a

green

wire

to

terminal

33

of

S-1.

Solder

the

other

end

to

terminal

7

of

8-2.

(

)

Solder

one

end

of

a

red

wire

to

terminal

12

of

S-2.

Connect,

but

do

not

solder,

the

other

end

to

terminal

3

of

R-27.

(

)

Solder

one

end

of

a

green

wire

to

terminal

15

of

8-1.

Solder

the

other

end

to

terminal

4

of

S-2.

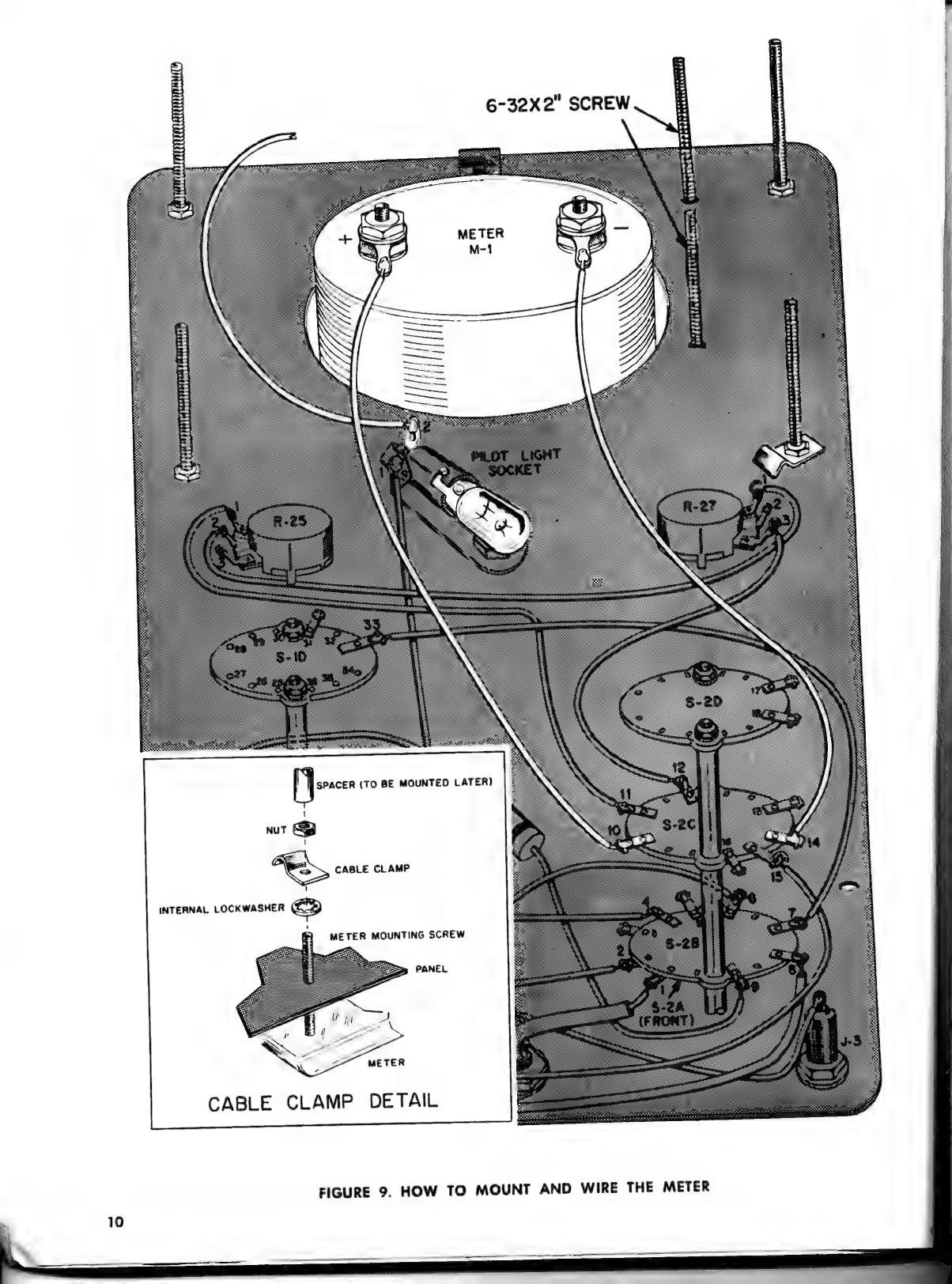

SEE

FIGURE

9.

(

)

Be

sure

the

paint

is

scraped

from

around

the

lower

right

meter

mounting

hole

on

the

rear

of

the

panel.

(

)

Insert

the

two

6-32

x

2”

screws

through

the

holes

in

the

panel

where

shown.

These

screws

are

held

in

place

by

the

meter

which

is

mounted

in

the

next

step.

(

)

Mount

the

meter

from

the

front

of

the

panel

over

the

heads

of

the

two

screws

set

in

the

panel.

Tighten

one

of

the

nuts

supplied

with

the

meter

over

each

of

the

two

top

screws

and

the

lower

left

screw.

Do

not

tighten

them

too

securely.

Place

an

internal

tooth

lockwasher

and

the

other

cable

clamp

over

the

lower

right

screw.

Now,

tighten

a

nut

over

the

screw.

The

other

four

nuts

supplied

with

the

meter

are

used

to

mount

the

printed

circuit

board.

NOTE:

If

the

meter

was

supplied

with

a

shorting

|

wire

between

the

meter

terminals,

remove

this

wire

(

)

Solder

one

end

of

a

blue

wire

to

terminal

14

of

the

positive

meter

post.

oa

solder

he

ean

fouthe

solder.

1Ue

On

(

)

Solder

one

end

of

another

violet

wire

to

terminal

the

negative

meter

post,

2

of

the

pilot

light

socket.

The

other

end

will

be

(

)

Solder

one

end

of

a

violet

wire

to

terminal

10

of

connected

to

the

printed

circuit

later.

S-2.

Solder

the

other

end

to

the

solder

lug

on

(

)

Insert

the

pilot

lamp

into

its

socket.

NOTE

SWITCHES

ARE

SHOWN

EXPANDED

AND

SIMPLIFIED.

THEREFORE,

WIRE

LENGTHS

APPEAR

LONGER

THAN

ACTUAL

SIZE.

<——o

FIGURE

8.

HOW

TO

WIRE

THE

PANEL

6-32X2"

SCREW

peerrerry

ete

rrcrreererorRED

meee

pepbpprrerstsy

AS

PFeees

MUU

a

a

ee

SOOT

Sean

pENCI

Reon

TEE

SRN

[sce

(TO

BE

MOUNTED

LATER)

nut

SQ

CABLE

CLAMP

INTERNAL

LOCKWASHER

ASSEMBLING

THE

PRINTED

CIRCUIT

BOARD

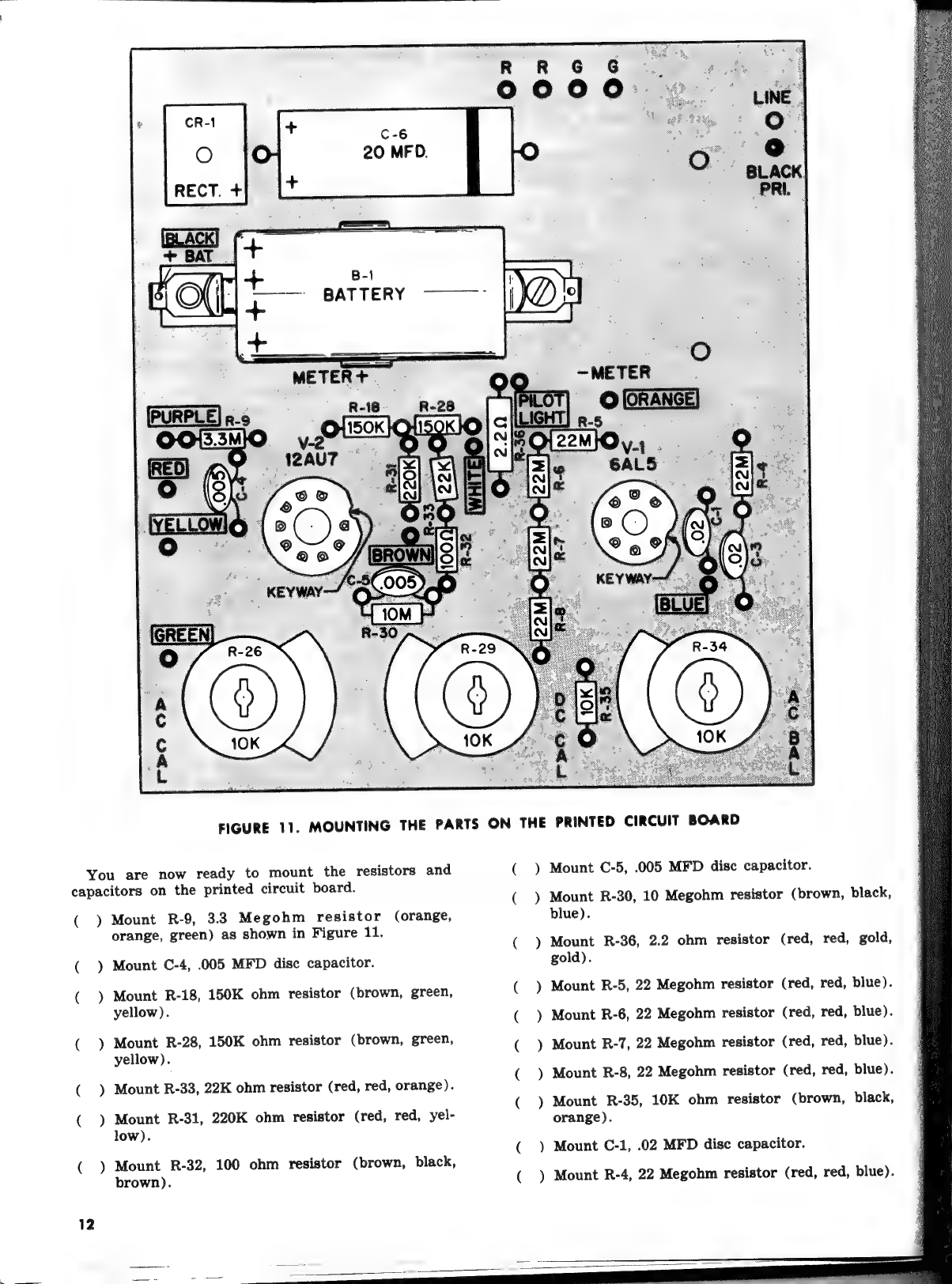

You

are

ready

to

mount

the

parts

on

the

printed

circuit

board.

Examine

it.

One

side

shows

the

out-

line

and

value

of

each

part

to

be

mounted.

That

is,

the

capacitors,

resistors,

the

transformer,

the

battery,

etc.,

are

pictured

in

their

exact

location.

The

following

procedure

assures

well

soldered

con-

nections

on

the

printed

circuit

board.

Study

it.

1.

INSERT

the

wire

leads

of

the

parts

through

the

holes

as

shown

in

Figure

11.

2.

BEND

LEADS

FLAT

against

the

foil

side

of

the

board

so

the

part

is

held

securely

in

place.

3.

SOLDER

EACH

LEAD

of

each

part

(after

all

parts

are

mounted)

right

at

the

hole

in

the

metal

foil

where

the

lead

comes

through.

Be

sure

you

heat

the

connection

until

the

solder

runs

and

spreads.

4.

CUT OFF

EACH

LEAD

as

close

as

possible

to

the

board.

Inspect

each

lead

after

cutting

it

off

to

be

sure

it

does

not

short

across

the

bakelite

from

one

foil

conductor

to

another.

This

would

cause

a

short

and

your

VTVM

won't work.

If

a

soldered

connection

should

have

a

dull

appear-

ance

it

is

not

a

good

solder

connection.

Using

more

solder,

again

solder

the

connection.

Do

not

use

so

much

solder

that

it

runs

off

the

printed

foil

wiring

onto

the

board

and

touches,

another

foil

conductor.

This

may

cause

an

intermittent

or

a

short

between

connection

points.

Before

you

solder

the

tabs

of

the

tube

sockets

to

the

metal

foil,

insert

the

tubes

in

the

sockets.

When

you

solder

the

tabs

of

the

tube

sockets

to

the

metal

foil,

heat

the

tube

socket

tab

until

the

solder

runs

down

onto

the

metal

foil

and

spreads.

After

you

have

soldered

all

the

connections

on

the

printed

circuit

board,

but

before

you

put

in

the

cable,

examine

the

metal

foil

side

of

the

board

carefully.

Again

be

sure

no

solder

or

cut-off

lead

touches

any

foil

conductor

except

the

one

to

which

it is

soldered.

Also,

be

sure

the

tabs

of

the

controls

have

not

been

bent

so

much

that

they

touch

any

other

conductor.

If

the

flux

from

the

solder

has

run

out

around

the

connections

that

is

all

right.

The

flux

is

not

conductive.

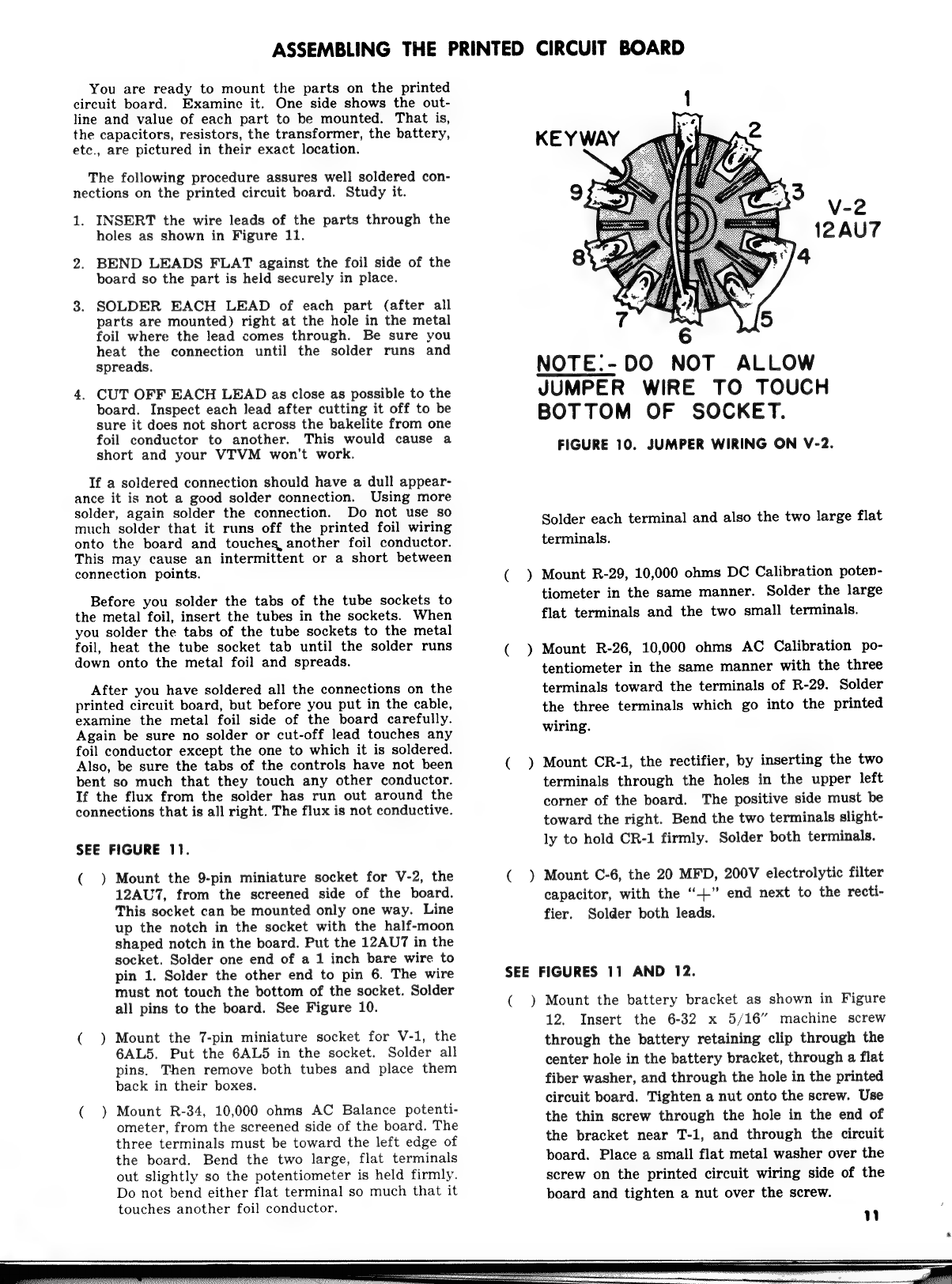

SEE

FIGURE

11.

(

)

Mount

the

9-pin

miniature

socket

for

V-2,

the

12AU7,

from

the

screened

side

of

the

board.

This

socket

can

be

mounted

only

one

way.

Line

up

the

notch

in

the

socket

with

the

half-moon

shaped

notch

in

the

board.

Put

the

12AU7

in

the

socket.

Solder

one

end

of

a

1

inch

bare

wire

to

pin

1.

Solder

the

other

end

to

pin

6.

The

wire

must

not

touch

the

bottom

of

the

socket.

Solder

all

pins

to

the

board.

See

Figure

10.

(

)

Mount

the

7-pin

miniature

socket

for

V-1,

the

6AL5.

Put

the

6AL5

in

the

socket.

Solder

all

pins.

Then

remove

both

tubes

and

place

them

back

in

their

boxes.

( )

Mount

R-34,

10,000

ohms

AC

Balance

potenti-

ometer,

from

the

screened

side

of

the

board.

The

three

terminals

must

be

toward

the

left

edge

of

the

board.

Bend

the

two

large,

flat

terminals

out

slightly

so

the

potentiometer

is

held

firmly.

Do

not

bend

either

flat

terminal

so

much

that

it

touches

another

foil

conductor.

NOTE.-DO

NOT

ALLOW

JUMPER

WIRE

TO

TOUCH

BOTTOM

OF

SOCKET.

FIGURE

10.

JUMPER

WIRING

ON

V-2.

Solder

each

terminal

and

also

the

two

large

flat

terminals.

(

)

Mount

R-29,

10,000

ohms

DC

Calibration

poten-

tiometer

in

the

same

manner.

Solder

the

large

flat

terminals

and

the

two

small

terminals.

(

)

Mount

R-26,

10,000

ohms

AC

Calibration

po-

tentiometer

in

the

same

manner

with

the

three

terminals

toward

the

terminals

of

R-29.

Solder

the

three

terminals

which

go

into

the

printed

wiring.

( )

Mount

CR-1,

the

rectifier,

by

inserting

the

two

terminals

through

the

holes

in

the

upper

left

corner

of

the

board.

The

positive

side

must

be

toward

the

right.

Bend

the

two

terminals

slight-

ly

to

hold

CR-1

firmly.

Solder

both

terminals.

(

)

Mount

C-6,

the

20

MFD,

200V

electrolytic

filter

capacitor,

with

the

“+”

end

next

to

the

recti-

fier.

Solder

both

leads.

SEE

FIGURES

11

AND

12.

(

)

Mount

the

battery

bracket

as

shown

in

Figure

12.

Insert

the

6-32

x

5/16”

machine

screw

through

the

battery

retaining

clip

through

the

center

hole

in

the

battery

bracket,

through

a

flat

fiber

washer,

and

through

the

hole

in

the

printed

circuit

board.

Tighten

a

nut

onto

the

screw.

Use

the

thin

screw

through

the

hole

in

the

end

of

the

bracket

near

T-1,

and

through

the

circuit

board.

Place

a

small

flat

metal

washer

over

the

screw

on

the

printed

circuit

wiring

side

of

the

board

and

tighten

a

nut

over

the

screw.

WwW

B-1

BATTERY

FIGURE

11.

MOUNTING

THE

PARTS

ON

THE

PRINTED

CIRCUIT

BOARD

You

are

now

ready

to

mount

the

resistors

and

capacitors

on

the

printed

circuit

board.

(

)

Mount

R-9,

3.3

Megohm

resistor

(orange,

orange,

green)

as

shown

in

Figure

11.

Mount

C-4,

.005

MFD

disc

capacitor.

Mount

R-18,

150K

ohm

resistor

(brown,

green,

yellow).

Mount

R-28,

150K

ohm

resistor

(brown,

green,

yellow).

Mount

R-33,

22K

ohm

resistor

(red,

red,

orange).

Mount

R-31,

220K

ohm

resistor

(red,

red,

yel-

low).

Mount

R-32,

100

ohm

resistor

(brown,

black,

brown).

(

(

PONS

)

)

al

)

)

Mount

C-5,

.005

MFD

disc

capacitor.

Mount

R-30,

10

Megohm

resistor

(brown,

black,

blue).

Mount

R-36,

2.2

ohm

resistor

(red,

red,

gold,

gold).

Mount

R-5,

22

Megohm

resistor

(red,

red,

blue).

Mount

R-6,

22

Megohm

resistor

(red,

red,

blue).

Mount

R-7,

22

Megohm

resistor

(red,

red,

blue).

Mount

R-8,

22

Megohm

resistor

(red,

red,

blue).

Mount

R-35,

10K

ohm

resistor

(brown,

black,

orange).

Mount

C-1,

.02

MFD

disc

capacitor.

Mount

R-4,

22

Megohm

resistor

(red,

red,

blue).

MOUNTING

BRACKET:

FIBER

WASHER

(3)

‘el

AYNSIS

J317€aV9

3HL

ONILOANNOD

ce

Oe

oe

a

rae

WALA

LH9SIN»

AN

igi

alata

ican

maa

aaa

( )

Mount

C-3,

.02

MFD

disc

capacitor.

Note

that

the

leads

of

this

capacitor

must

be

positioned

so

that

they

clear

the

hole

for

mounting

the

printed

circuit

to

the

panel.

Turn

the

circuit

board

over

and

solder

each

con-

nection.

Remember

to

use

a

small

iron

and

the

rosin-core

solder

supplied.

Be

sure

the

connec-

tion

where

R-18,

R-28,

and

R-31

join

is

well

soldered.

Cut

off

each

end

lead

close

to

the

soldered

connection.

FINAL

WIRING

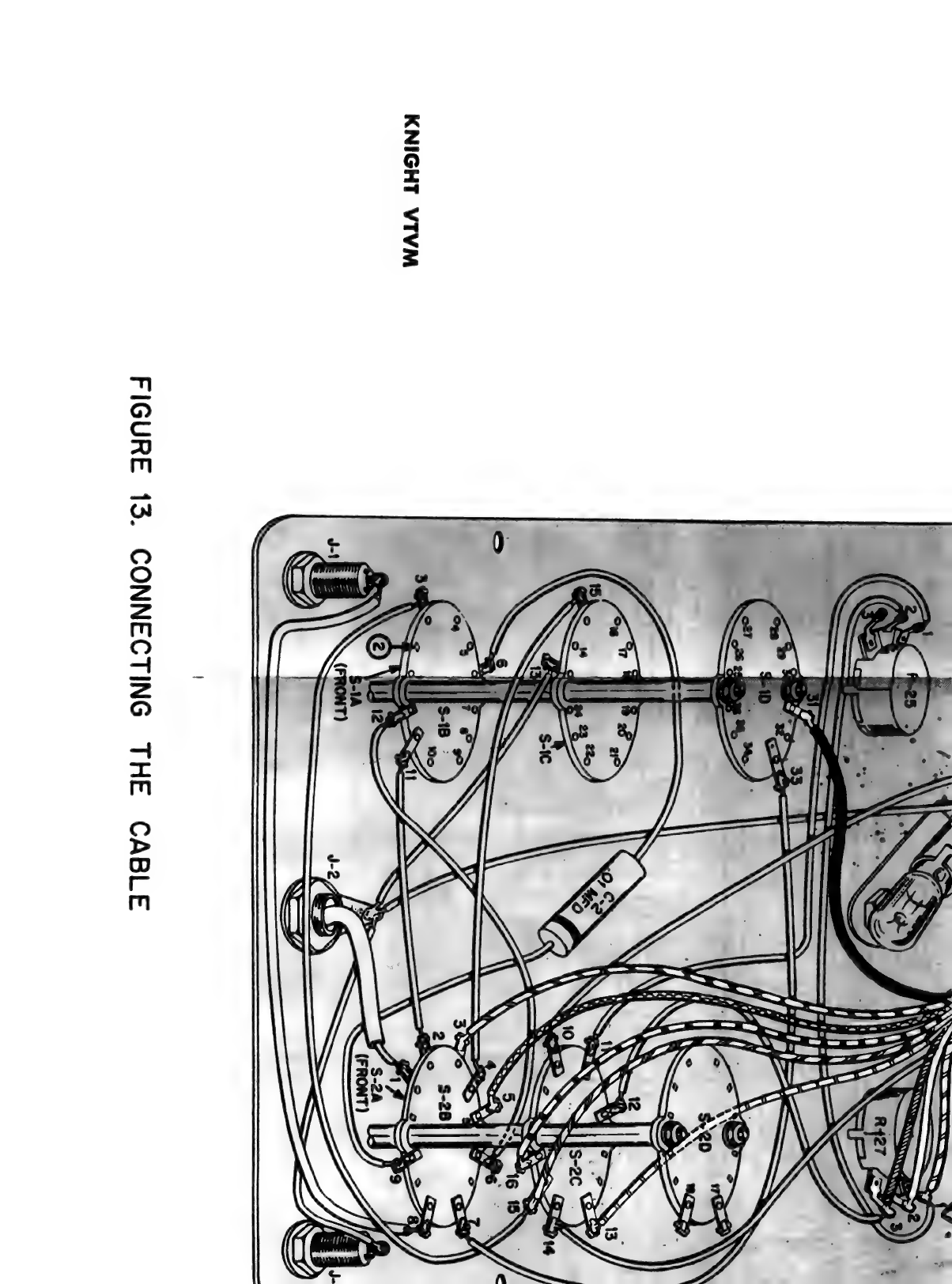

You

are

now

ready

to

prepare

the

cable

and

do

the

final

wiring

on

your

VTVM.

SEE

FIGURE

13.

(

NNN

)

~

—

~—

eee

Carefully

remove

414

inches

of

the

outer

insula-

tion

from

one

end

of

the

cable.

Be

very

careful

not

to

cut

the

insulation

of

any

of

the

wires.

Now,

trim

the

wires

to

the

following

lengths:

Orange:

Leave

it

the

full

414

inches.

Green:

1”

Yellow:

1”

Red:

1144”

Violet:

13,”

Black:

2354”

Brown:

24,”

White:

314”

Blue:

414”

Remove

14

inch

of

insulation

from

the

end

of

each

wire.

Coat

each

end

with

solder.

Solder

the

black

wire

to

the

terminal

on

the

bat-

tery

bracket

marked

+

Bat.

This

wire

does

not

go

through

the

printed

circuit

board.

Insert

each

of

the

other

wires

into

the

hole

in

the

board

marked

with

the

corresponding

color.

Solder

each

on

the

printed

wiring

side

of

the

board.

Remove

334”

of

the

outer

insulation

from

the

other

end

of

the

cable.

Trim

each

wire

as

fol-

lows:

Red:

Leave

it

the

full

334”

White:

234”

Brown:

214”

Violet:

114”

Yellow:

234,”

Blue:

3”

Green:

334”

Orange:

2”

Black:

3”

Remove

1,”

of

insulation

from

the

end

of

each

wire.

Coat

each

end

with

solder.

Solder

the

violet

wire

to

terminal

5

of

S-2.

Solder

the

brown

wire

to

terminal

3

of

R-27.

Solder

the

white

wire

to

terminal

2

of

R-27.

Solder

the

red

wire

to

terminal

1

of

R-27.

Solder

the

yellow

wire

to

terminal

13

of

S-2.

BATTERY

RETAINING

CLIP

SMALL

en

ie

oe

a

wee

*—

PRINTED

CIRCUIT

BOARD

SMALL

|

I

i

2)

———-NUT

|

i

i

Solder

the

blue

wire

to

terminal

15

of

S-2.

Solder

the

green

wire

to

terminal

16

of

S-2.

Solder

the

orange

wire

to

terminal

3

of

S-2.

Solder

the

black

wire

to

terminal

31

of

S-1.

Solder

the

violet

wire

from

terminal

2

of

the

pilot

light

socket

to

PILOT

LIGHT

on

the

print-

ed

circuit

board.

Bring

this

wire

over

the

screen-

ed

side

of

the

board.

Put

one

of

the

spacers

over

each

of

the

six

mounting

screws.

Place

three

of

the

large

fiber

washers

over

the

screw

shown.

Place

the

mounting

bracket

over

this

screw

and

the

top

right

meter

mounting

screw.

Place

four

of

the

large

fiber

washers

over

the

screw

shown.

SEE

FIGURE

14

(

)

The

printed

circuit

board

will

be

mounted

on

six

mounting

screws.

First

place

a

large

fiber

wash-

er

on

the

single

screw

in

the

corner

of

the

panel

(upper

left

corner

in

Figure

14).

Then

mount

the

board

on

the

six

screws.

Place

another

large

fiber

washer

on

top

of

the

board,

over

the

same

corner

screw.

Secure

the

board

with

a

split

wash-

er

and

nut

on

each

of

the

four

screws,

as

shown

in

Figure

14.

Trim

the

leads

of

T-1,

the

power

transformer

to

the

following

lengths:

The

black

lead

toward

the

top

right

corner

to

114”,

The

other

black

lead

to

6”.

Both

green

leads

to

114”.

Both

red

leads

to

2”.

13

FIGURE

13.

HOW

TO

CONNECT

THE

CABLE

(

14

FROM

TERMINAL

2

ON

PILOT

LIGHT

SOCKET

SWITCHES

AND

CABLE

ARE

SHOWN

EXPANDED

AND

SIMPLIFIED.

THERE-

FORE,

WIRE

LENGTHS

APPEAR

LONGER

THAN

ACTUAL

SIZE.

~

PURPLE}

go

NOTE

Remove

the

insulation

from

¥,”

of

the

end

of

each

lead.

Hold

the

lead

with

pliers

close

to

the

transformer

as

you

remove

the

insulation.

Coat

the

stripped

end

of

each

lead

with

solder.

Mount

T-1

on the

remaining

two

mounting

screws,

with

the

leads

positioned

as

shown.

Place

three

large

fiber

washers

under

the

mounting

tab