Micro Meg™ Pocket Megohmmeter

Operation and Maintenance

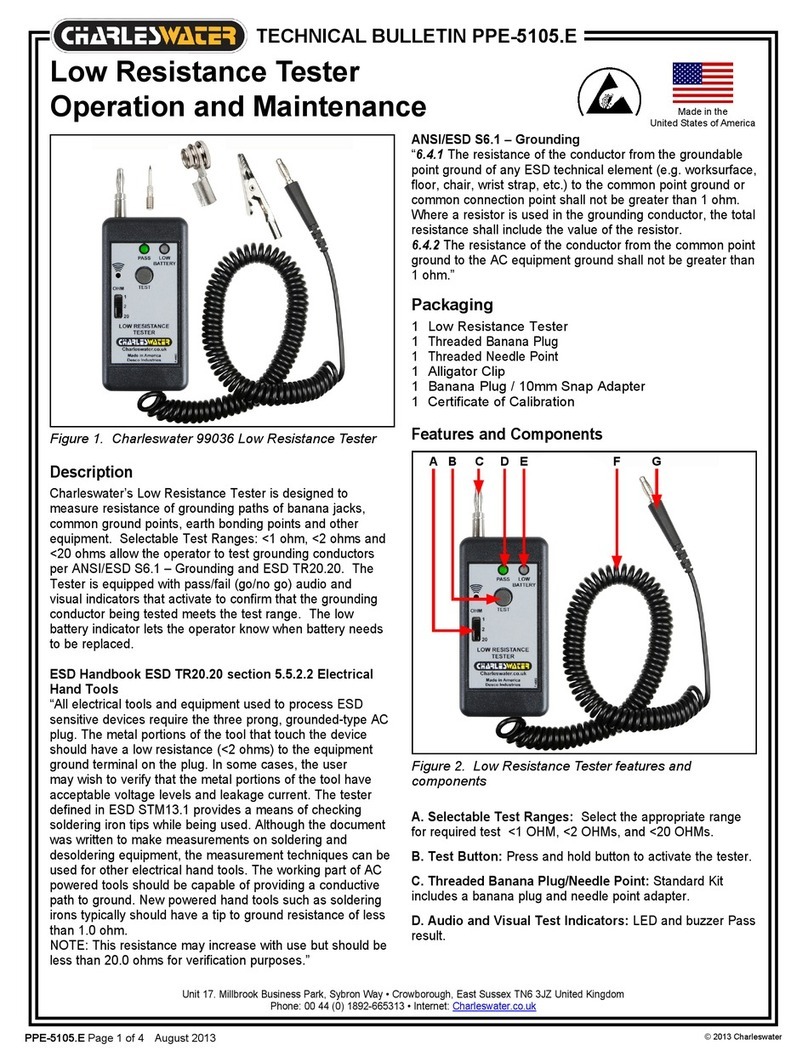

Figure 1. 99035 MicroMeg Pocket

Megohmmeter

Description

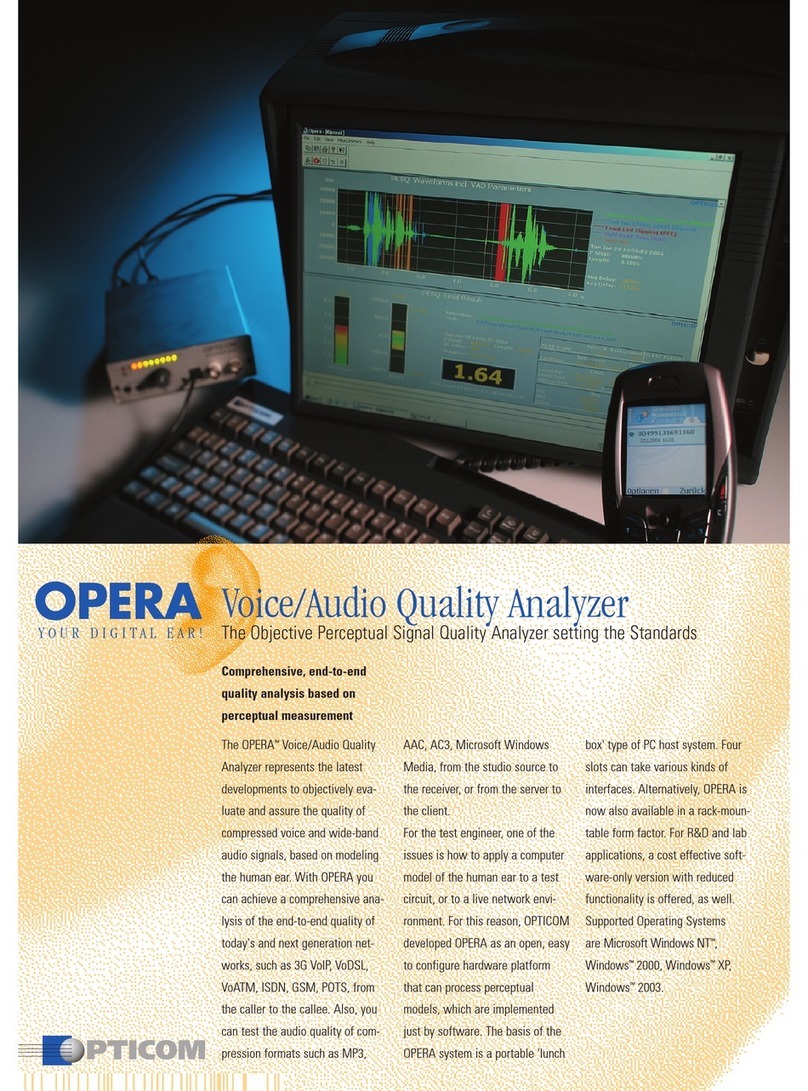

The Charleswater

99035

Micro

Meg Pocket Megohmmeter is a

portable test instrument designed

for measuring both surface and

surface-to-ground resistance of static

dissipative and conductive materials.

Seven color-coded LEDs, read from

right to left, easily identify static

dissipative and conductive ranges.

The Micro Meg will test materials

with surface resistivity of 1x10E5

to 1x10E10. This test instrument is

ideally suited for Quality Control and

Field Service personnel as well as

for use in routine auditing of your

ESD protective materials. The Micro

Meg features simple one-button

operation and a 9V battery for ease

of use and maximum portability. This

auto-ranging instrument weighs only

six ounces. The high-impact plastic

case ensures durability despite the

meter’s light weight.

The Micro Meg has not been

designed to meet IEC 61340-4-1

test equipment requirements and

therefore measurements obtained

with this device may not agree with

measurements taken according to

the EN 61340-5-1 Test method A.1

test procedure. This test instrument is

intended for use only as an auxiliary

tool for monitoring surface resistance

performance.

If you are interested in obtaining a

meter which does meet all the test

equipment requirements of IEC

61340-4-1, we recommend our model

99105 Surface Resistance Test Kit.

For more information on this product

ask for Techical Bulletin PPE-5075.E.

Installation

Remove the meter from the carton

and inspect for damage. Each unit

should be fully charged and includes:

1 Micro Meg Pocket Megohmmeter

1 Surface-to-Ground, cord assembly

1 9V battery

Properly store the megohmmeter and

its component assemblies when not

in use.

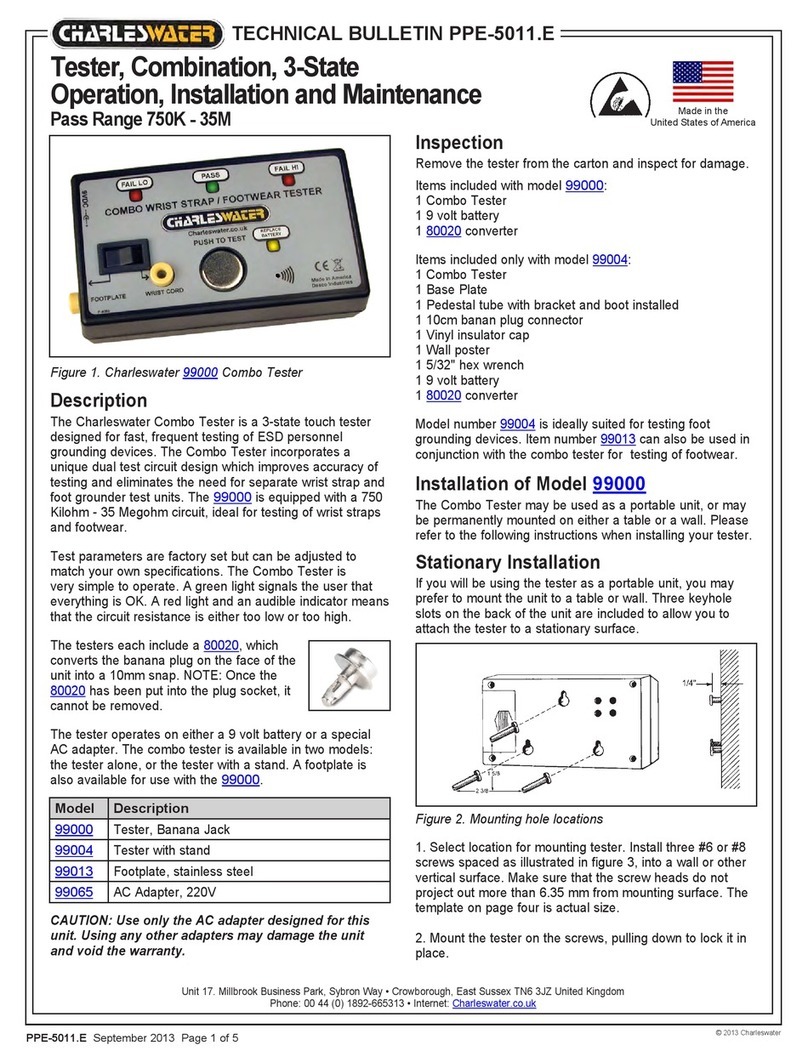

Operation

The Micro Meg will perform Surface

Resistivity and Surface-to-Ground

resistance measurements. Work

surfaces and materials to be tested

should be cleaned prior to testing

to ensure that surface dirt and

contamination do not affect results.

It is recommended that non-silicone

and non-alcohol based cleaners

such as Charleswater’s Reztore™

Surface and Mat Cleaner be used for

regular cleaning of ESD protective

work surfaces. When non-ESD

surfaces are being used, Reztore™

Topical Antistat is recommended for

eliminating static charge generation.

Surface and Surface-to-Ground

resistance readings are indicated by

the series of LEDs on the face of the

meter. The LEDs are read from right

to left as follows:

1. RED – Meter on and battery

functioning

2. GREEN – 5 x 10E10

3. GREEN – 1 x 10E9

4. GREEN – 1 x 10E8

5. GREEN – 1 x 10E7

6. YELLOW – 1 x 10E6

7. YELLOW – 1 x 10E5

Each LED indicates one order of

magnitude of resistance. If the test

surface is conductive to less than

10E5, all the LEDs will be lit. If

it is neither conductive nor static

dissipative, only the red “On” LED will

be lit.

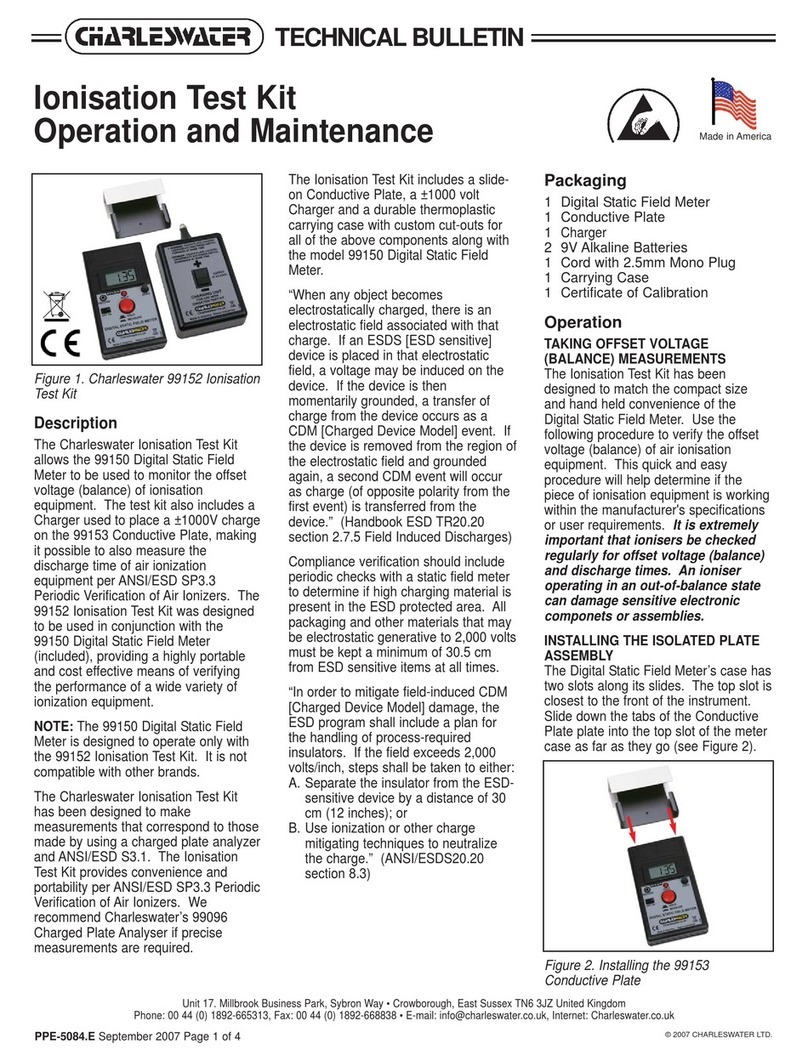

Surface

Resistivity

Measurements

Surface resistivity measurements

are made using only the meter

without the cord assembly. When

the white button is depressed a test

voltage of 9 VDC is applied to the

meter’s center electrode. The second

resistivity electrode will supply the

resistance bridge and provide the

measurement. To perform surface

resistivity tests, follow these simple

instructions:

A. Check battery operation by

depressing the white button on the

center of the megohmmeter. The red

“On” lamp at the far right should light

to indicate that the unit is functioning

properly.

B. Place the meter on the surface

being tested. All three electrodes

should make contact with the surface.

C. Press the white button. The

surface resistance will be indicated

by the number of LEDs which light

up. The more lights illuminated,

the greater the conductivity of the

surface. The measurement is in

ohms/square.

Made in the

United States of America

TECHNICAL BULLETIN PPE-5046.E

Unit 17. Millbrook Business Park, Sybron Way • Crowborough, East Sussex TN6 3JZ United Kingdom

Phone: 00 44 (0) 1892-665313, Fax: 00 44 (0) 1892-668838 • Internet: Charleswater.co.uk

PPE-5046.E September 2011 Page 1 of 3

© 2011 CHARLESWATER LTD.

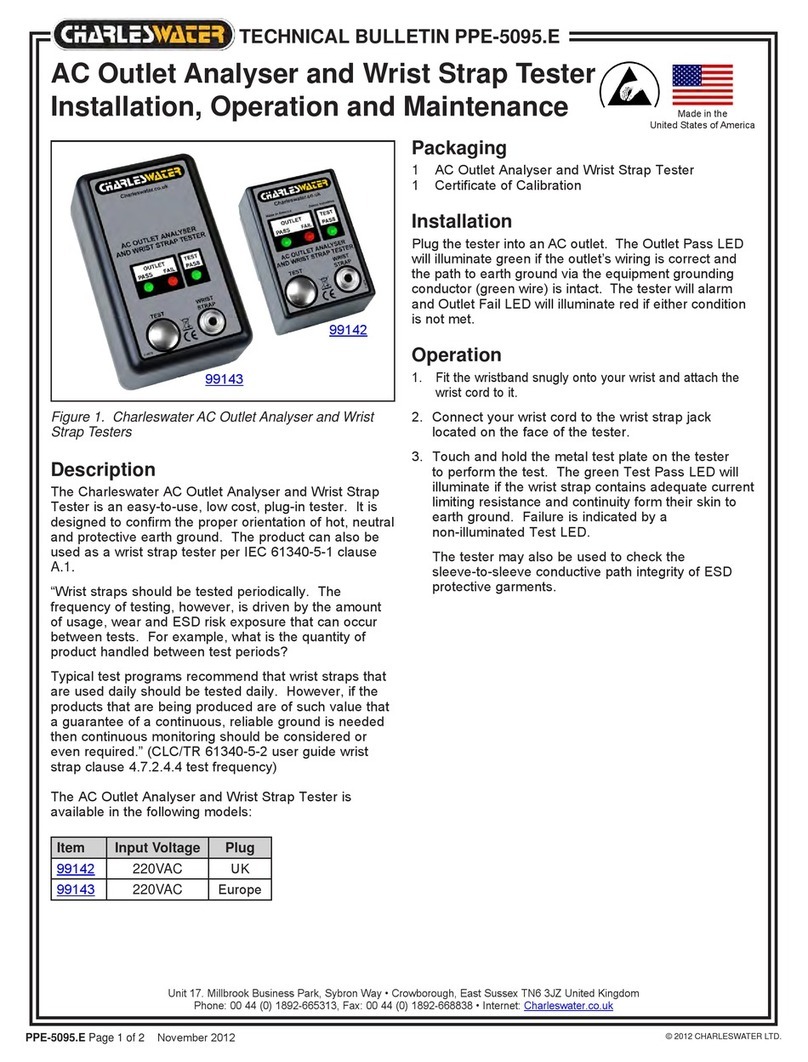

Figure 2. Cleaning the work surface

before testing.