B 45-015, REV. 9/21

• Always carry cylindrically shaped loads in the vertical

position, not the horizontal.

• Always clamp loads with the contact pads, if appli-

cable, not the arm or arm base.

• Never rotate a load that is off center to the centerline

of rotation. Severe damage to the rotator could result.

• Always ensure that the load is the same width as the

pallet and neatly stacked when using a carton clamp.

3.13 Load Positioning

• Be accurate in load placement. It’s important to know

what the load will do when it’s released.

• Always carry loads as close to the floor as possible,

consistent with the surface being traversed. Scraping

or bumping the floor surface with the load or the

attachment can severely damage the attachment and

cause product damage. The mast should be tilted

back.

• Always keep the load positioned as close as possible

to the horizontal center of the lift truck.

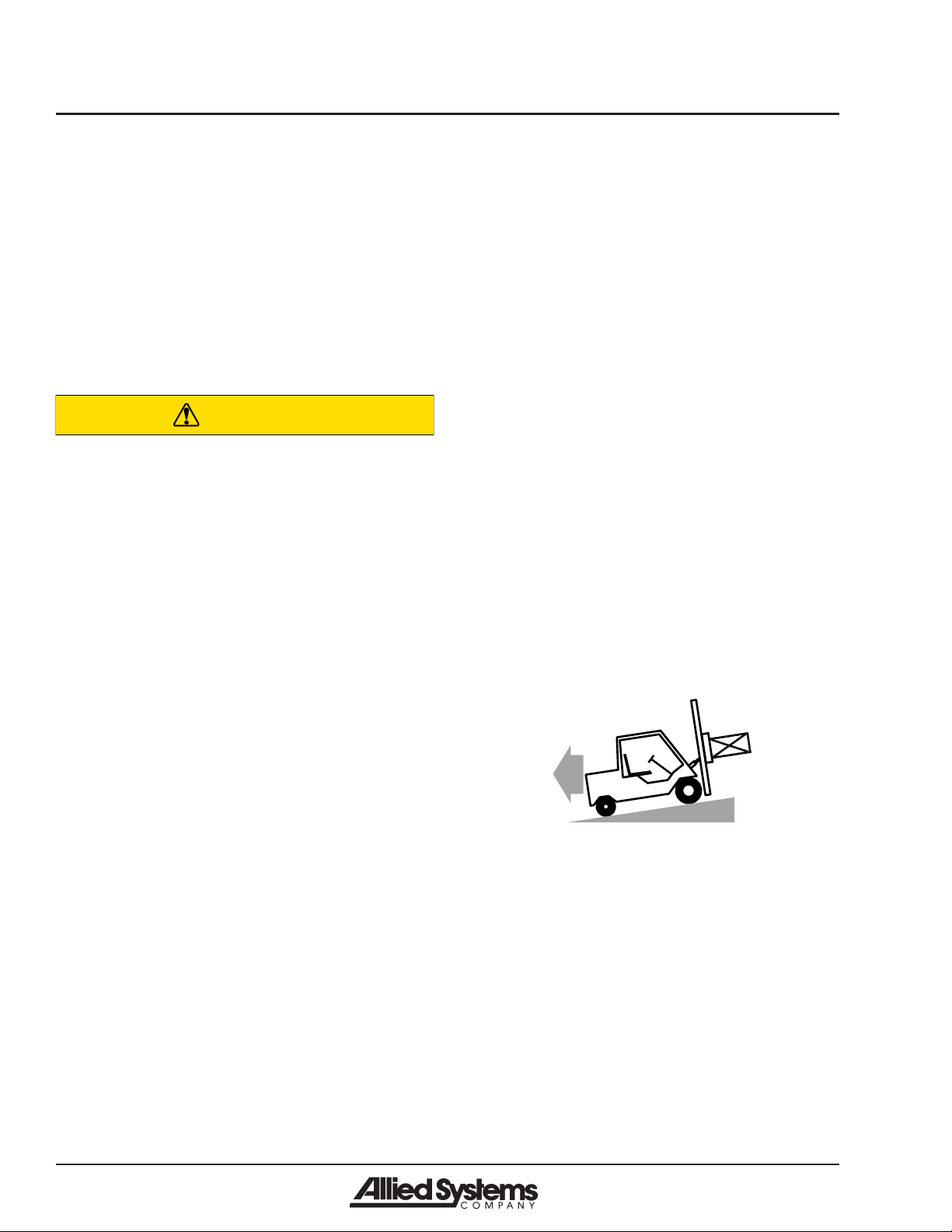

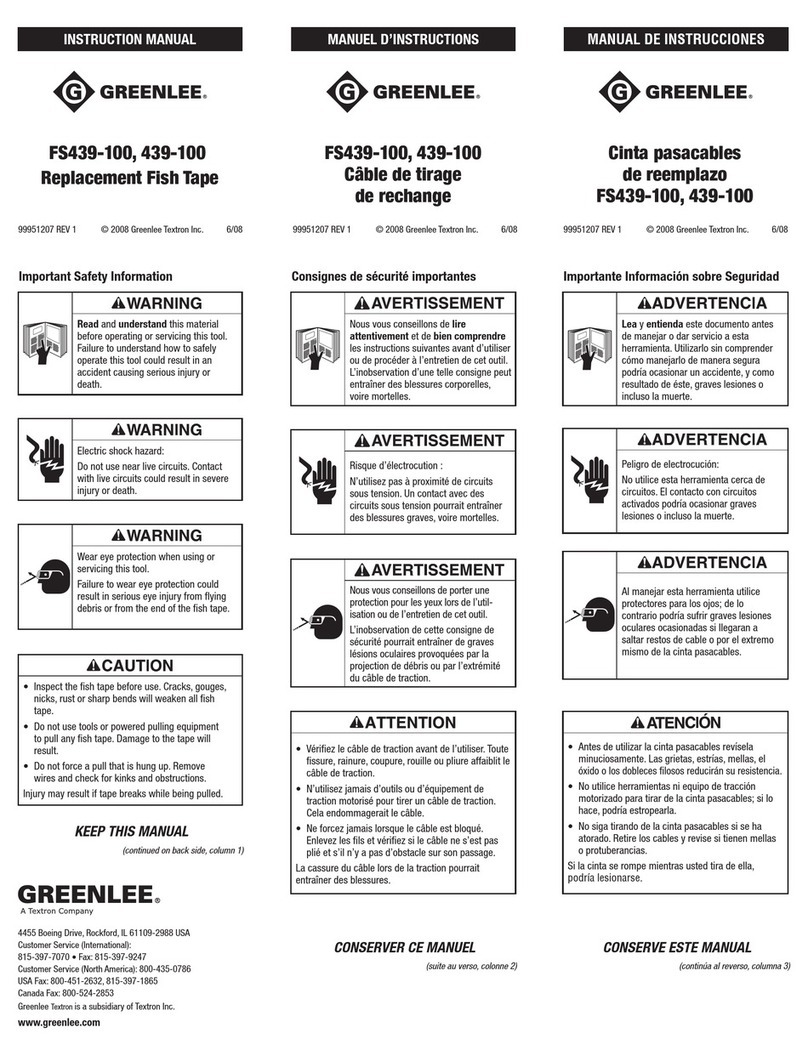

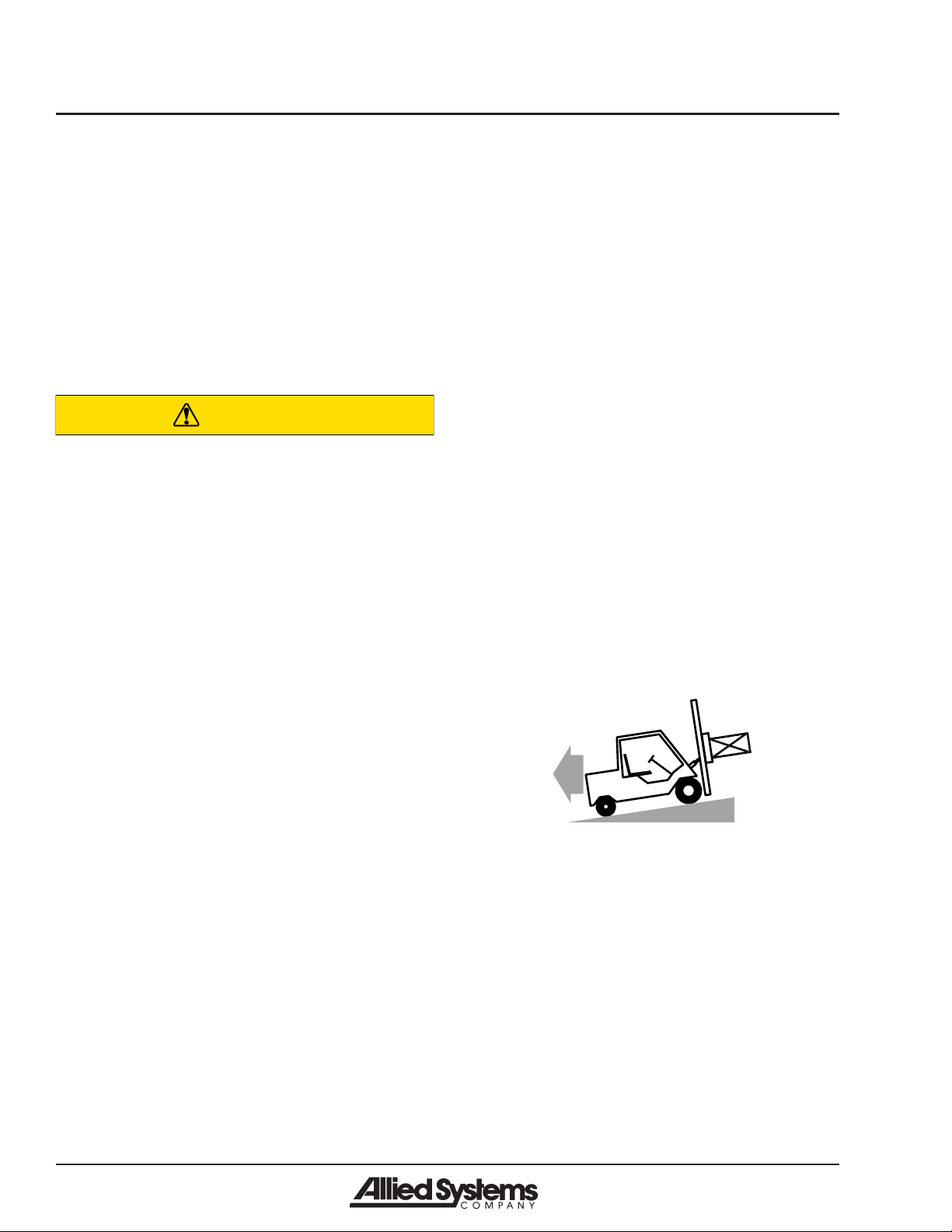

• Always back down ramps or inclines. Driving forward

down a ramp or incline with a clamped load will

lessen the stability of the truck. (Figure 3-4)

Figure 3-4

• Do not cross dock boards or dock levelers with the

attachment or carriage fully lowered. Ramming the

front or rear of the attachment against a dock board

can cause severe damage.

• Limit lift truck movement to a minimum when high

stacking. Limit sideshift movement to a minimum

when high stacking.

• Always be observant when high stacking. Look for

poorly stacked loads, overhead obstacles, broken

cartons, or damaged products in the stack.

• Travel slowly around corners. Sound horn on blind

corners. Be careful of tail swing and overhead clear-

ances. Watch in all directions. Avoid sudden stops.

• Before disconnecting hydraulic lines, be sure to lower

all loads and relieve all hydraulic pressure. The load

could fall on you, or escaping hydraulic oil could

cause severe personal injury.

• Prevent personal injury or equipment damage by

using a lifting device with a lifting capacity greater

than twice the weight of any equipment to be lifted.

3.12 Load Handling

• Treat an unloaded forklift with an attachment as

partially loaded.

CAUTION

Equipment overload hazard.

Injury or equipment damage may result if

the capacity of the truck and attachment

combined are less than the attachment

capacity.

Consult truck nameplate for truck

capacity with an attachment installed.

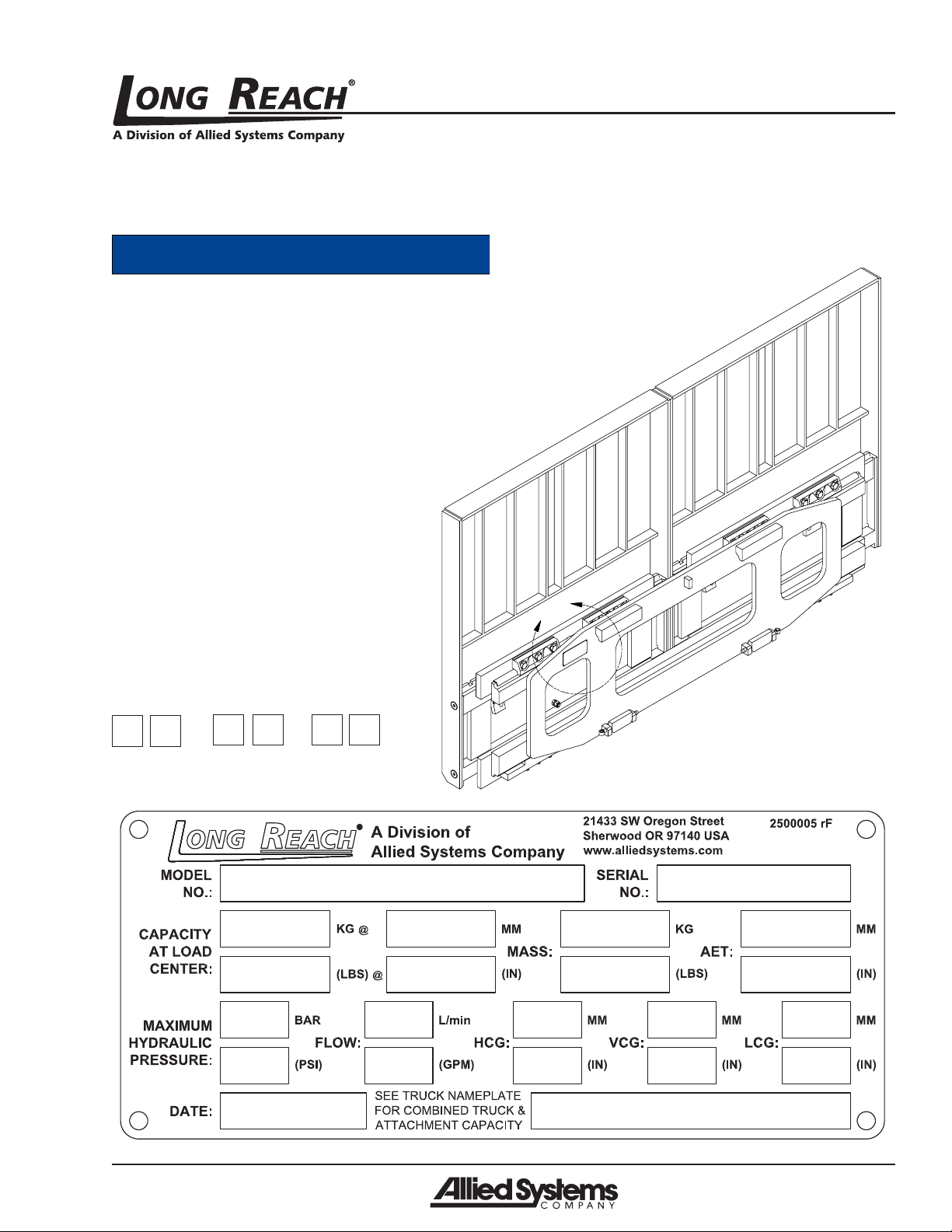

• Never overload the attachment. Refer to the attach-

ment nameplate for the rated capacity of the

attachment. Refer to the truck nameplate for the

maximum net working capacity of the truck/attach-

ment combination. Never use a load to support or

move another object. Doing so can easily exceed the

holding capacity of the attachment.

• Always check loads to be handled. Correct loads that

are broken, unbalanced, loose, or too heavy.

• Never lift, lower, side shift, pivot, rotate, or tilt loads

while traveling. Repositioning loads while traveling

affects the stability of the truck and may impede

vision or clearances.

• Do not use an attachment to open or close boxcar

doors. Doing so can severely damage the attachment

and cause loss of warranty. Damage to clamp arms

may result in product damage.

• Do not carry loose items or unsupported loads on

top of a clamped load.

• Never use chains, cables, or other devices in conjunc-

tion with an attachment for load handling.

• Never clamp loads other than what the attachment

was designed to handle.