INSTALLATION AND OPERATING INSTRUCTIONS: Clamping element, electric, LKE series

Zimmer GmbH • Im Salmenkopf 5 • D-77866 Rheinau, Germany • Phone:+49 7844 9138 5556 • Fax: +49 7844 9138 80 • www.zimmer-group.de

Installation and

operating instructions

LKE

DDOC00215

Index d

EN / 2019-05-16

Im Salmenkopf

77866 Rheinau, Germany

+49 7844 9138-5556

Fax: +49 7844 9138 80

www.zimmer-group.de

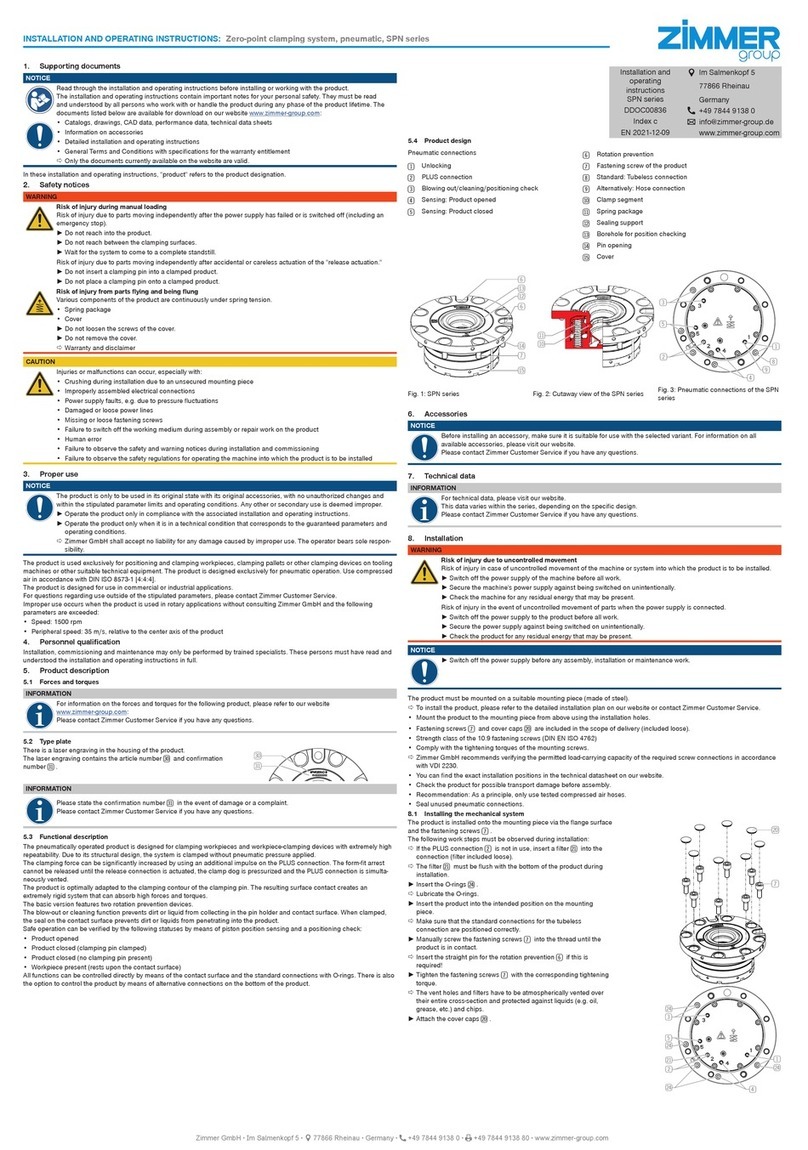

6 Connections

The element is connected via an 8-pin M12x1 plug cable.

7 Installation

NOTE:

Ensure accessibility for emergency actuation 7and of the adjustment screw 9of the element.

The element does not have any guide characteristics!

►Check the element for any damage before installing it.

• The element may only be used in conjunction with linear rail carriages.

►The mounting surface of the element (sliding block 6+ terminal box 4) has to be completely covered by the

mounting piece.

This enables the maximum possible holding force to build up. The adjacent motor housing bl does not have to be covered

by the mounting piece.

• Make sure the mounting pieces are suciently rigid (refer to section 7.1).

• Install the element using 4 screws.

• Use screws with a minimum strength class of 8.8.

Observe tightening torques http://www.schrauben-normen.de/anziehmomente.html DIN 912 or ISO 4762

• Note the screw-in depth of the screws. If the screws are screwed in too far, they can block the oating

bearing Malfunction

7.1 Design of the mounting piece

INFORMATION:

The holding force is the maximum force that can be generated in the axial direction.

The specied holding forces are tested on every clamping and braking element before delivery using a slightly

lubricated rail (ISO VG 68). Using other oil or lubricating substances can inuence the coecient of friction, which

can cause a loss of holding force in individual cases.

In course of further development, technical changes are reserved.

NOTE:

Make sure the mounting piece is suciently rigid.

The user alone is responsible to ensure that the mounting piece is suciently rigid in terms of the 2006/42/

EC Machinery Directive. ZIMMER GmbH accepts no liability for any subsequent damage to the element or

subsequent injuries to persons.

►Make sure that the mounting faces (sliding block 6) are at (0,03 mm).

►The roughness of the surface (contact surface) of the

mounting piece should not exceed the value Ra = 3,2 µm.

►The extension cord, which lengthens the connecting cable 8,

must not exceed a length of 10 m and must be shielded.

►The electric connecting cable 8must be relieved of strain at

the mounting piece. The cable must be installed in such a way

that the cable cannot rub against the rail or get pinched.

► The 3D data for the prole rails is not necessarily true to detail

in the area of the rail groove. Refer to the catalog or product

selection on our website (www.zimmer-group.com/com/plt) to

see whether an element ts on the selected rail.

7.2 Installation procedure

NOTE:

If the mounting screws are tightened when the element is not closed, the element can shift and therefore be

unable to achieve the optimum holding force! Furthermore, the guide rail could become damaged.

INFORMATION:

The element is allowed to be closed only if the associated prole rail is between the contact surfaces!

• There must be no control voltage present when an electrical connecting cable 8is connected or

disconnected!

• Avoid changing signals before the specified time (opening/closing), otherwise there may be a malfunction.

• Unauthorized opening of the housing shall void any warranty claim.

If the element is not yet connected to a power supply, the element can be opened and closed manually using the

emergency actuation 7.

Turning counterclockwise = close

Turning clockwise = open

►Set the element on the linear guide.

If a spacer plate is used, it is inserted between the element

and the mounting piece as level compensation.

►Screw the screws into the tapped holes of the sliding block 6

and tighten them only slightly.

►The element centers itself as a result of a single cycle.

►Close the element.

► Tighten the mounting screws crosswise using the specied

torque.

►Open the element.

1White DIR signal, open=1 (24V)/close=0 (0V)

2Brown Output status “closed”

3Green Output status "error"

4Yellow Voltage supply 24 V / Logic

5Grey Output status “open”

6Pink Voltage supply 24 V / Motor

7Blue Not connect

8Red Voltage supply 0 V / GND

1 Supporting documents

NOTE:

The documents mentioned below are available for download on our website www.zimmer-group.de. Only the

documents currently available on the website are valid.

• Catalogs, drawings, CAD data, technical data

• Detailed installation and operating instructions

• General Terms and Conditions of Business with specications for the warranty entitlement

2 Safety notes

CAUTION:

Non-compliance may result in severe injuries!

Injuries/malfunctions can occur especially with:

• Crushing during installation due to an unsecured mounting piece

Protection against crushing as a result of low element stroke (max. 0,4 mm).

Protection by the use of bistable design engineering.

• Missing or loose mounting screws

• Failure to switch o the working medium during assembly or repair work on the element

• Human error

• Failure to observe the safety and warning instructions during installation and start-up

These installation and operating instructions are intended for installation and maintenance technicians as

well as design engineers requiring the element for an application. Please read all installation and operation

instructions carefully before start-up and pay special attention to the following hazard warnings and notes.

3 Proper use

NOTE:

The element should only be used in its original state with its original accessories, without any unauthorized

changes and within the scope of the dened parameters for use. Zimmer GmbH shall accept no liability for any

damage caused by improper use.

In accordance with EN ISO 13849-1, the LKE element is a safety-related component of control systems. Furthermore, we

can conrm the manufacture of the product using the basic and proven safety principles (Appendix D.1 and D.2 of EN

13849-2) and thus dene the LKE element as a proven component in accordance with EN 13849-1, Chap. 6.2.4, Par. b).

The element can be used without any control engineering measures in control systems of Category B or 1; for category 2

control systems, a test channel must be provided. For use in higher control categories, the control must be implemented

using multiple channels, where each channel must implement the safety function for itself.

The element may not be used in any application other than those approved by the manufacturer.

Without additional protection or control engineering measures, the element may not:

• be installed in facilities that are used for transporting people (e.g. elevators).

• be used in vehicles.

• be used underwater or in other uids.

• be used in a corrosive environment (for example, in connection with acids).

• come in contact with abrasive media (such as grinding dust).

• come in direct contact with food.

• be used in areas with a potentially explosive atmosphere.

For questions regarding use of the LKE series element, please contact Zimmer GmbH.

4 Personnelqualication

DANGER:

Never open the housing. Intervention is not permitted and can lead to serious injuries!

Warranty and disclaimer.

The manufacturer, ZIMMER GmbH, accepts no liability in the event of damage to property or injuries to

persons.

The installation, start-up, maintenance and repairs may be undertaken only in accordance with these installation and

operating instructions and only by qualied personnel who have the professional expertise and know the conditions, as

well as the dangers, of the machine into which the element is being installed.

5 Product description

The element of the LKE series is a bistable element and is designed for static clamping or xing of system components on

prole rail guides. Based on the self-locking functional principle, when the clamp is closed there is no need for any supply

voltage for the actuator to maintain the holding force. This means that in an open state, the only signal present is the DIR

signal (refer to the table found under Point 6, “Connections”).

Fig. 1: LKE element

Fig. 2: LKE element cutaway view

The element is provided with a serial number bn. The serial number

bn is located on the housing of the element. If possible, use this serial

number bn with your project and/or end customer to achieve a clear

and, above all, consistent assignment in the event of an update or

overhaul.

The part number bm can be found using the serial number bn.

NOTE:

The clamping process during a movement (dynamic) can lead to destruction or damage of the prole rail or the

element itself.

1Prole rail guide

2Eccentric gear

3Clamping jaws

4Housing

5Electric drive

6Sliding block

7Emergency actuation

8Electrical connecting cable

9Adjustment screw

10 Motor housing