Allied Systems LONG REACH CCHA Manual

145-034, REV. 5/18

Installation, Maintenance and

Service Manual

CCHA

Carton Clamp with Load Stabilizer

245-034, REV. 5/18

TABLE OF CONTENTS

SECTION 1 NAMEPLATE LOCATION

.......................................................Date received:

3

SECTION 2 MODEL NUMBER DESCRIPTION

.......................................... Series Model Number:

4

SECTION 3 SAFETY SUMMARY

3.1 Safety Information.........................................5

3.2 Safety Regulations........................................5

3.3 Safety Symbols.............................................5

3.4 Labeling ........................................................6

3.5 Training..........................................................6

3.6 Personnel Safety...........................................6

3.7 Pre-start Checks...........................................7

3.8 Operation Warnings......................................7

3.9 Hydraulic Hazards .......................................7

3.10 Electrical Hazards.......................................7

3.11 Maintenance Warnings ...............................8

3.12 Load Handling ............................................8

3.13 Load Positioning .........................................9

3.14 Operator’s Controls ...................................9

3.15 Industry Standards ...................................10

3.16 Clamp Open Control.................................10

SECTION 4 INSTALLATION PROCEDURE

4.1 Truck Requirements....................................12

4.2 Attachment Installation ...............................12

4.5 Hydraulic Connections................................13

SECTION 5 SERVICE PROCEDURE

5.1 Attachment Removal ..................................14

5.2 Arm Removal..............................................14

5.3 Arm Installation...........................................14

5.4 Cylinder Removal .......................................14

5.5 Cylinder Installation ....................................14

5.6 Cylinder Disassembly .................................15

5.7 Cylinder Inspection .....................................16

5.8 Cylinder Assembly......................................16

5.9 Hydraulic Valve Removal............................17

5.10 Hydraulic Valve Installation.......................17

5.11 Camber Adjustment..................................17

5.12 Toe Adjustment ........................................18

5.13 Rotating Contact Pads..............................18

SECTION 6 MAINTENANCE SCHEDULE

6.1 Schedule.....................................................19

6.2 Torque Specifications..................................19

345-034, REV. 5/18

- -

Date received:

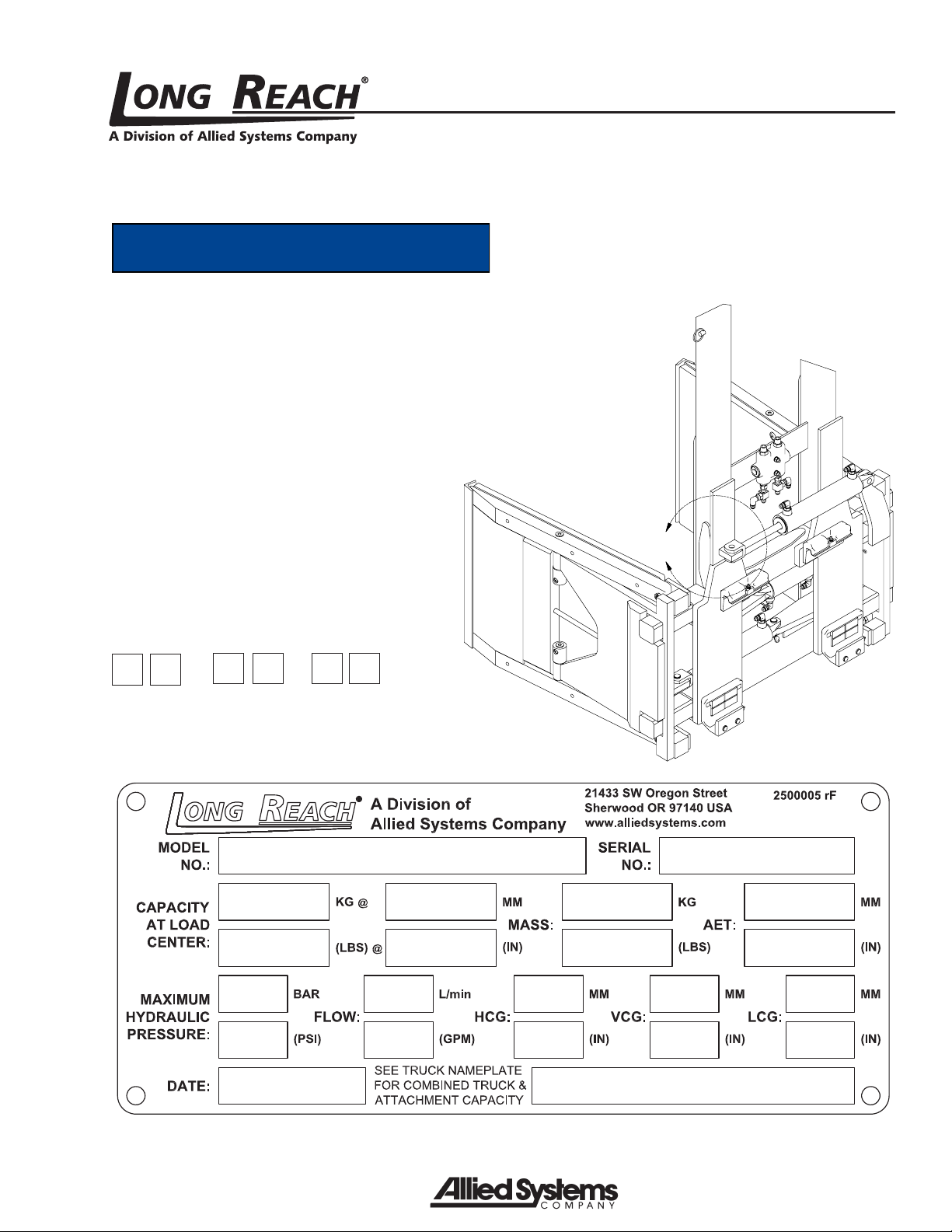

SECTION 1 NAMEPLATE LOCATION

NOTICE

When you receive your attachment, locate

the Long Reach nameplate (upper left

corner on the body). Record the infor-

mation from the nameplate, along with

the date received, at the bottom of this

page. If the nameplate is missing, look for

the serial number stamped directly into

the metal at the nameplate location and

consult the factory for details.

A

445-034, REV. 5/18

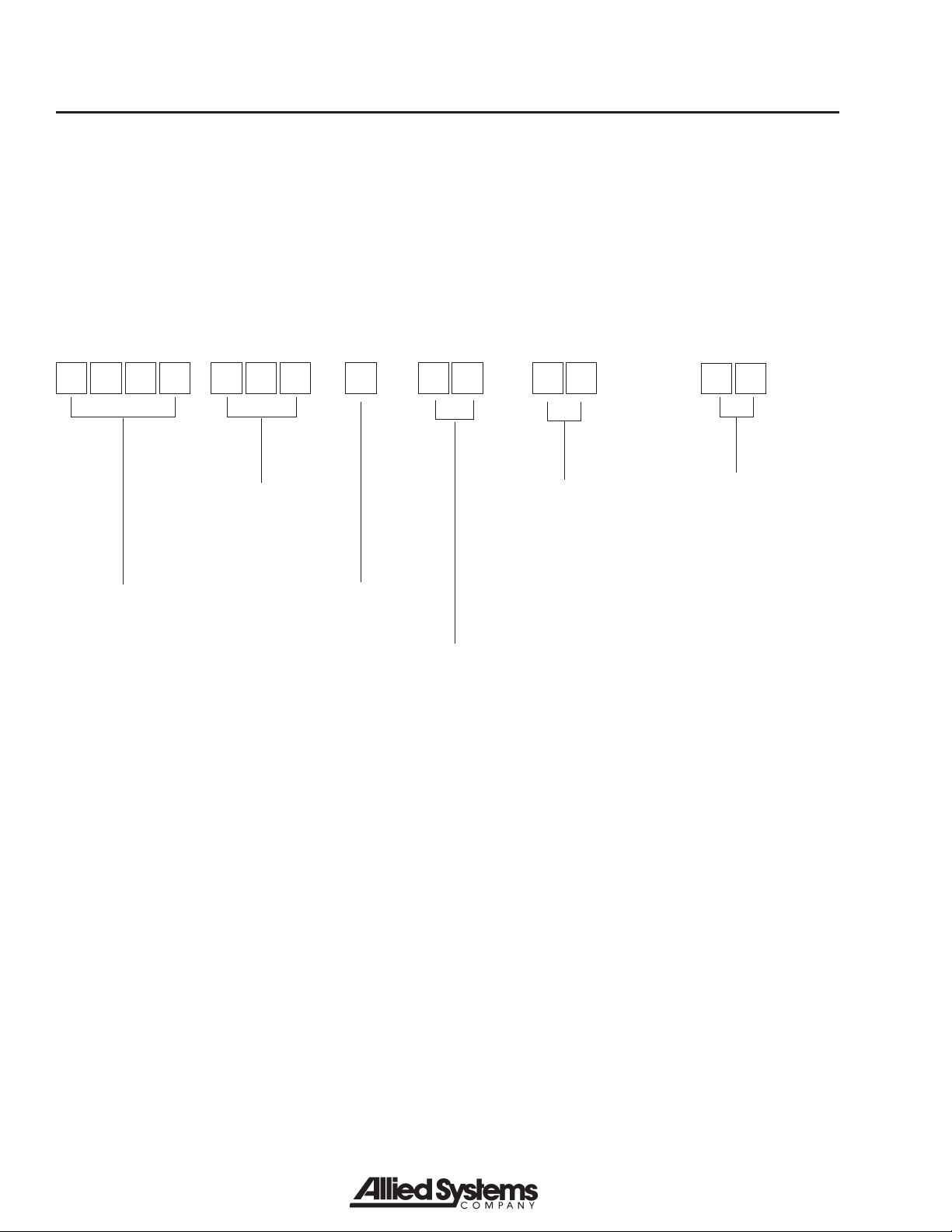

SECTION 2 MODEL NUMBER DESCRIPTION

Each clamp is identified by a model number and a serial number located on the name plate attached to the unit

prior to shipment. Long Reach’s model numbers are designed to describe how an attachment is equipped. The

guide below illustrates the information that is represented in an 18-digit model number. Always include model and

serial number when ordering parts or requesting service information.

Series Model Number:

SERIES

CCHA = Citrus

clamp; carton

clamp with

stabilizer

CAPACITY

030 = 3,000 lbs

FUNCTION

06 = Clamp range:

24.0" - 33.0"

Stabilizer range:

80.0" - 130.0"

Sideshift

STABILIZER

DIMENSIONS

40 = 40" long x 24.5"

wide stabilizer pad

MOUNTING

A = ITA Class II

CLAMP

DIMENSIONS

41 = 41.5" long x 21.5"

high clamp pads

0 A 4 10 0

C C A 0 3 4 6

H

545-034, REV. 5/18

SECTION 3 SAFETY SUMMARY

CAUTION

Indicates a hazardous situation which,

if not avoided, could result in minor or

moderate injury, or equipment damage or

void the machine warranty. Carefully read

the message that follows to prevent minor

or moderate injury.

Notice

Describes information that is useful but

not safety related.

WARNING

Multiple hazards.

Ignoring safety warnings may cause equip-

ment damage, personal injury or death.

All possible safety hazards cannot be

foreseen and included in this manual. The

operator must always be alert to possible

hazards that could endanger personnel or

damage the equipment.

3.4 Labeling

• Change capacity, operation, and maintenance

instruction plates, tags, or decals when a forklift

truck is equipped with an attachment. If the truck

is equipped with front-end attachments other than

factory installed attachments, truck must be marked

to identify the attachments and show the approxi-

mate weight of the truck and attachment combination

at maximum elevation with load laterally centered.

3.5 Training

• Make sure all operators are trained in the fork and

attachment adaptation, operation, and use limita-

tions. Retrain an operator if a new attachment is

added to the forklift. Consult the operator’s manual

for instructions on how to use the new equipment.

• Know the mechanical limitations of your forklift.

3.1 Safety Information

Safety is Everyone’s Responsibility

Whether you are new on the job or a seasoned veteran,

these safety tips may prevent injury to you, to others, or

to the materials you are handling. Always be alert, watch

out for others, and follow these suggestions:

Attachments handle material, not people.

Safety starts with common sense, good

judgement, properly maintained equip-

ment, careful operation, and properly

trained operators.

The safety instructions and warnings, as documented

in this manual and shipped with the machine, provide

the most reliable procedures for the safe operation and

maintenance of your Long Reach attachment. It’s your

responsibility to see that they are carried out.

3.2 Safety Regulations

Know your company’s safety rules. Some companies

have site-specific directions and procedures. The

methods outlined in your operator’s manual provide a

basis for safe operation of the machine. Because of

special conditions, your company’s material handling

procedures may be somewhat different from those

shown in this manual.

3.3 Safety Symbols

The following terms define the various precautions and

notices:

DANGER

Indicates a hazardous situation which, if

not avoided, will result in death or serious

injury. Carefully read the message that

follows to prevent serious injury or death.

WARNING

Indicates a hazardous situation which,

if not avoided, could result in death or

serious injury. Carefully read the message

that follows to prevent serious injury or

death.

Table of contents

Other Allied Systems Industrial Equipment manuals