CAUTION

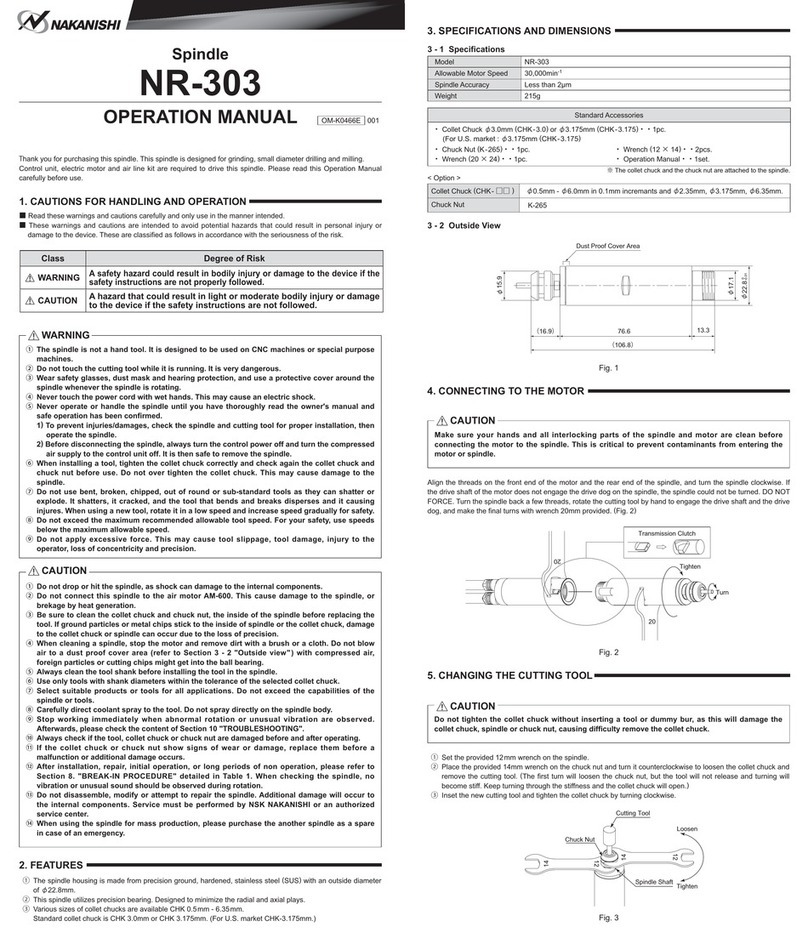

①When mounting a spindle, refer to the Clamping Area

etched on the spindle. (Fig. 5)

Fig. 5

Fastening Bolt Fastening Bolt

Split Type Holder Bushing with Slit

Slit

Spacer

Bushing Split

Fastening Bolt

Fig. 6

②When installing a spindle to the holder, recommended installation method is shown Fig 6. Refer to " ③How to

fabricate the Split Type Holder ". If this is not possible, install as shown in Fig. 7.

Fig. 7 Fig. 8

Do not allow set screws to come directly in contact

with the spindle body as shown in Fig. 8, as this

will result in damage to the spindle housing and

internal components.

When installing, never clamp directly over the

bearings, as this will result in bearing damage.

(Refer to Fig. 9)

Fastenig Bolt

Deformation

Damage of internal

Components

Bearing

Fig. 9

Fastening Bolt

Front View

Fastening Bolt

Spacer

Slit

Side View

Fastening Bolt

Screw for Removal

Spacer

Spacer

Screw for Removal

Fig. 10

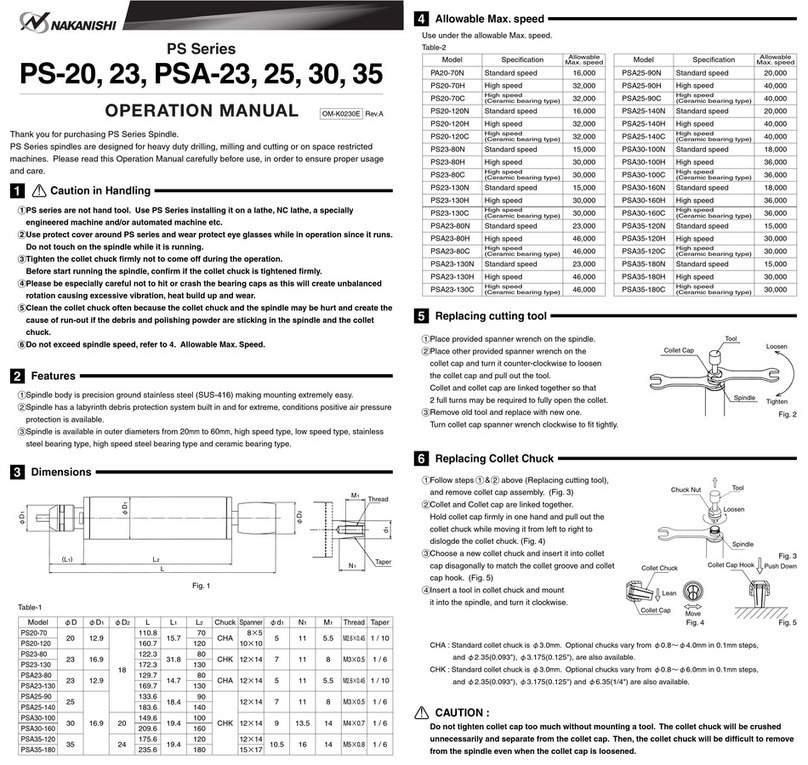

Steps

12 3 4

Air Pressure (MPa)

For Air Motor

0.1 0.2 0.3 0.4

Rotation Speed (min-1)

For Electric Motor

5,000 10,000 15,000 20,000

Rotation Time (min)

15 10 10 15

Items to Check

No Abnormal

Noises

The spindle housing temperature during

the break-in process should not exceed

20 degrees C (36 degrees F) above

ambient temperature. Should the spindle

exceed this limit, rest the spindle for at

least 20 minutes and re-start the break

in procedure from the beginning. If the

housing temperature rises again and

exceeds 20 degrees C (36 degrees F)

above ambient temperature, check the

spindle and motor for proper installation.

The spindle

housing

temperature

during the break-

in process should

not exceed

20 degrees C

(36 degrees F)

above ambient

temperature.

Table 1.

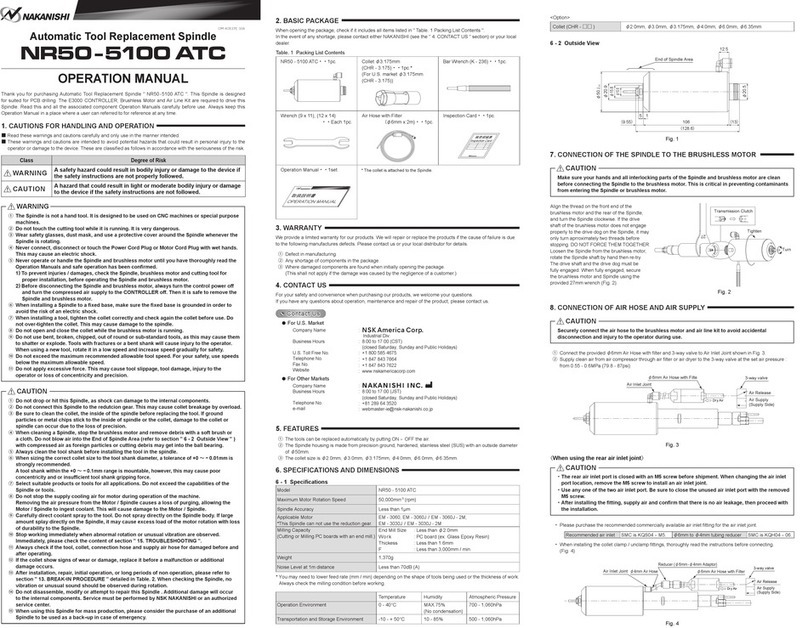

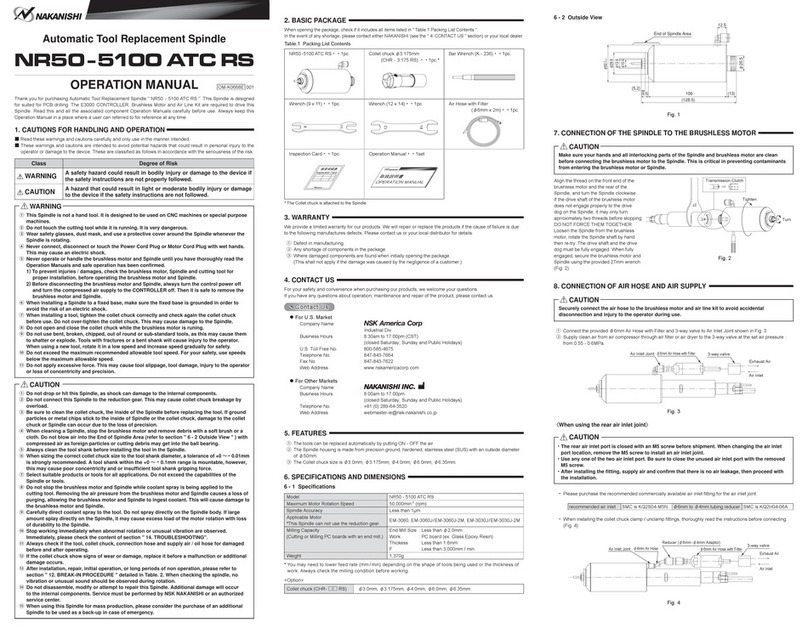

7. INSTALLATION OF THE SPINDLE

WARNING

When installing a spindle to a xed base, make sure the xed base is grounded in order to avoid

the risk of an electric shock.

CAUTION

・When installing a spindle, do not hit, drop or cause shock to the spindle. This may cause

damage to internal components and result in malfunctions.

・When mounting the spindle, be sure to mounting within clamping area etched on the spindle. If

the spindle is installed incorrectly, this will cause and damage to the spindle.

・Cautions when tightening the securing bolt of the Split Type Holder

Do not over-tighten the bolt. This may cause damage to spindle's precision.

Tighten the bolt until the spindle body can not be turned by hand within the xture.

Extreme tightening is not necessary or recommended.

Apply working force and check that the spindle is tight before using.

③How to fabricate the Split Type Holder

(1) Roughly process (carve) the inside diameter

of the Split Type Holder.

(2) Cut a slit. (Ex. Slit 2mm)

(3) Twist the Screw for Removal and Broaden

the Slit Area.

(4) Insert spacer (ex t = 2mm) into the Slit Area.

(5) Loosen the Screw for Removal, and tighten

the fastening bolt with the specied torque.

(6) Finish the Split Type Holder so that the

inside diameter of the Split Type Holder

is ȭ22.8 with its tolerance range from

-

0.01mm to

-

0.015mm, and its roundness

and cylindricity of less than 5μm.

(7) When inserting the spindle loosen the

Fastening Bolt and twist the Screw for

Removal, and broaden the Slit Area.

CAUTION

・How to confirm the tightening standard of the holder by the clamp meter (In case of use a

electric motor)

Measure the current value of the Control Unit's power cord by the clamp meter.

Fasten the holder so that the increase in the no-load current value (during rotation at the

maximum rotation speed) with the spindle fastened is 20mA (for type 100V / 120V) / 10mA

(for type 200V / 230V) or less, compared to the no-load current value (during rotation at the

maximum rotation speed) without fastening the spindle. Do not over-tighten the Fastening Bolt.

It may damage spindle's precision and shorten the life of the bearings.

・

The nal responsibility for ensuring holder's safety for use in a given application is left to the

designer of the equipment in which NAKANISHI's spindle is installed.

NAKANISHI offers spindles with a wide variety of capabilities and specications.

Please carefully check the spindle's specifications against the requirements of your

equipment and verify suitability and safety of the Holder prior to initial use.

8. BREAK-IN PROCEDURE

During transportation, storage or installation the grease inside the bearings will settle. If the spindle is suddenly run

at high-speed excessive heat will cause bearing damage. After installation, repair, initial operation, or long periods

of non operation please follow the break-in procedure detailed in Table 1.

Table 2. Overhang and Speed

Overhang (mm) Max. Speed (min-1)

20 N x 0.5

25 N x 0.3

50 N x 0.1

※N = Max. Operating Speed with 13mm overhang. Fig. 11

3.14 x Diameter (mm) x rotation speed (min-1)

1,000 x 60

Surface Speed (m/s)

=

9. CAUTIONS WHEN USING GRINDSTONES AND TOOLS

①The proper surface speed for general grindstones is 10 -30m/s.

②Do not exceed 13mm of overhang for mounted grindstones as shown in Fig. 11. If the overhang must

exceed 13mm, reduce the motor speed in accordance with table 2.

③Dress the grindstone prior to use.

④Do not use tools with bent or broken shanks, cracks or excessive run-out.

⑤For grinding, the maximum depth of cut should not exceed 0.01mm radially or axially. Reciprocate the

tool several times after each pass to eliminate tool pressure.

⑥Always operate tools within the allowable recommended speed of the tools. Use of a tool outside of the

allowable speed of the tools could cause damage to the spindle and injury to the operator.

⑦Keep the tool shank and collet chuck clean. If contaminants are left in the collet chuck or chuck nut,

excessive run-out will cause damage to the tool and or spindle.

⑧Do not strike or disassemble the spindle.

⑨Please set the tools to minimize the overhang amount. 13mm is the maximum amount of overhang to

maintain high accuracy and safety.

13

CAUTION

The maximum surface speed or rpm is always specified for a grindstone. Do not exceed the

maximum speed with reference to the calculating chart below. Always follow the grindstone

manufacturer's recommendations.

Trouble Cause Inspection / Corrective Action

Spindle does not

rotate or rotate

smoothly.

The spindles bearings have been damaged. Replace the ball bearings.

(Return to NAKANISHI dealer service.)

The motor has been damaged. Replace the motor.

(Return to NAKANISHI dealer service.)

Overheating

during rotation.

Cutting debris has contaminated the ball

bearings, and the ball bearings are damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

Low air pressure.

Check air hose connection and air pressure.

Abnormal

vibration or noise

during rotation.

The tool shank is bent. Replace the tool.

Cutting debris has contaminated the ball bearing.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

The spindles bearings have been damaged.

Tool slippage.

Collet chuck is not correctly installed. Check and clean the collet chuck.

Reinstall the collet chuck.

The collet chuck is worn. Replace the collet chuck.

High run-out.

The tool is bent. Change the tool.

Collet chuck is not correctly installed.

Secure the collet chuck correctly.

The collet chuck is worn. Replace the collet chuck.

Inside of the spindle is worn. Replace the spindle shaft.

(Return to NAKANISHI dealer service.)

Contaminants inside the collet chuck or the

spindle.

Clean the collet chuc and the inside of

the taper and spindle.

The ball bearings are worn. Replace the ball bearings.

(Return to NAKANISHI dealer service.)

10. TROUBLESHOOTING

If a problem or concern occurs, please check the following prior to consulting your dealer.

Contents are subject to change without notice.

2015.05.20 002 S

49.6

(Clamping Area)

CLAMPING AREA