Allison Transmission 3000 MH Series User manual

OWNER’S

MANUAL

ALLISON

3000 MH

4000 MH

ATD 5376 Op Manual 5/15/00 11:28 AM Page 1

i

Division of General Motors Corporation

P.O. Box 894 Indianapolis, Indiana 46206-0894

OM3349EN

MARCH 2000

Owner’s

Manual

Allison On-Highway

3000 MH, 4000 MH

Series Transmissions

(WTEC III Controls)

3000 MH, MHR, MHP, MHPR

4000 MH, MHR, MHP, MHPR

Printed in U.S.A. Copyright © 2000 General Motors Corp.

ii

WARNINGS, CAUTIONS, AND NOTES

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and

cautions described in this handbook. It is, however, important to understand that these

warnings and cautions are not exhaustive. Allison Transmission could not possibly

know, evaluate, and advise the service trade of all conceivable ways in which service

might be done or of the possible hazardous consequences of each way. The vehicle

manufacturer is responsible for providing information related to the operation of

vehicle systems (including appropriate warnings, cautions, and notes). Consequently,

Allison Transmission has not undertaken any such broad evaluation. Accordingly,

ANYONE WHO USES A SERVICE PROCEDURE OR TOOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION OR THE VEHICLE

MANUFACTURER MUST first be thoroughly satisfied that neither personal safety

nor equipment safety will be jeopardized by the service methods selected.

Proper service and repair is important to the safe, reliable operation of the equipment.

The service procedures recommended by Allison Transmission (or the vehicle

manufacturer) and described in this handbook are effective methods for performing

service operations. Some of these service operations require the use of tools specially

designed for the purpose. The special tools should be used when and as recommended.

Three types of headings are used in this manual to attract your attention. These

warnings and cautions advise of specific methods or actions that can result in personal

injury, damage to the equipment, or cause the equipment to become unsafe.

NOTE:

A note is used when an operating procedure, practice, etc., is

essential to highlight.

WARNING:

A warning is used when an operating procedure, practice,

etc., if not correctly followed, could result in personal injury or loss of life.

CAUTION:

A caution is used when an operating procedure,

practice, etc., if not strictly observed, could result in damage to or

destruction of equipment.

TRADEMARK INFORMATION

TRANSYND

TM

is a trademark of Castrol Ltd.

DEXRON

®

is a registered trademark of General Motors Corporation.

Pro-Link

®

is a registered trademark of Micro Processor Systems, Inc.

iii

TABLE OF CONTENTS

Page

Warnings, Cautions, and Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

INTRODUCTION

Keeping That Allison Advantage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

A Brief Description Of The Allison 3000 MH, 4000 MH Series Transmissions 4

WTEC III Electronic Control System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Torque Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Planetary Gears And Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cooler Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Retarder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SHIFT SELECTORS

Description of Available Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lever Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pushbutton Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Range Selection — Pushbutton And Lever Shift

Selectors With Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DRIVING TIPS

CHECK TRANS Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Accelerator Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Downshift And Direction Change Inhibitor Feature . . . . . . . . . . . . . . . . . . . . 17

Using The Engine To Slow The Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using The Hydraulic Retarder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Range Preselection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adapting Shifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cold Weather Starts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Driving On Snow Or Ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rocking Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

High Fluid Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Towing Or Pushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Turning Off The Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

iv

Page

POWER TAKEOFF OPERATION

Engine-Driven Power Takeoff (PTO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CARE AND MAINTENANCE

Periodic Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Prevent Major Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Importance Of Proper Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fluid Level Check Using The Pushbutton Or Lever Shift Selector . . . . . . . . . 29

Manual Fluid Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cold Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hot Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recommended Automatic Transmission Fluid And Viscosity Grade . . . . . . . 32

Keeping Fluid Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fluid And Internal Filter Change Interval Recommendations . . . . . . . . . . . . . 34

Transmission Fluid Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Transmission Fluid and Filter Change Procedure . . . . . . . . . . . . . . . . . . . . . . 38

DIAGNOSIS

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Diagnostic Code Display Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Diagnostic Code Listings and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ABBREVIATIONS AND DEFINITIONS

Abbreviations and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CUSTOMER SERVICE

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Service Literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Allison Transmission Distributors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Allison Transmission Regional Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1

MH SERIES

INTRODUCTION

KEEPING THAT ALLISON ADVANTAGE

Allison

MH Series transmissions

provide many advantages for the driver who must

“stop and go” or change speeds frequently. Driving is easier, safer, and more

efficient.

The

MH Series transmissions

are rugged and designed to provide long, trouble-

free service. This handbook will help you gain maximum benefits from your

ALLISON

-equipped vehicle.

HILL

SPEED

ZONE

RR

STOP

YIELD

V01724

2

Typical 3000 MH Series Transmission

OUTPUT

SPEED

SENSOR

NAMEPLATE

INPUT

SPEED

SENSOR

ASSEMBLY PADS

MAIN-PRESSURE TAP

NOTE: Inch Series Threads

BREATHER

FEEDTHROUGH HARNESS

CONNECTOR

COOLER PORTS

NOTE: Inch Series Threads

V06341

ASSEMBLY PADS

(BOTH SIDES)

BREATHER

MAIN-PRESSURE TAP

NOTE: Inch Series Threads

FEEDTHROUGH HARNESS

CONNECTOR

TORQUE CONVERTER

WITH LOCKUP CLUTCH

AND TORSIONAL DAMPER

FILL TUBE AND DIPSTICK

(Available on both sides)

3

Typical 4000 MH Series Transmission

TURBINE SPEED

SENSOR

MOUNTING

PAD

INPUT SPEED

SENSOR

NAMEPLATE

FILL TUBE AND DIPSTICK

OUTPUT SPEED

SENSOR

FEEDTHROUGH

HARNESS

CONNECTOR

V06342

COOLER PORTS

MAIN-PRESSURE TAP

MOUNTING PAD

(BOTH SIDES)

COOLER PORTS

FEEDTHROUGH

HARNESS

CONNECTOR

BREATHER

BREATHER

4

A BRIEF DESCRIPTION OF THE ALLISON

3000 MH, 4000 MH SERIES TRANSMISSIONS

Included in the Allison On-Highway Transmission family are the 3000 MH and

4000 MH Series transmissions. The transmissions described in this handbook include

the WTEC III control system, a torque converter with lockup and torsion damper, and

three planetary gear sets. These transmissions may also contain an integral retarder (the

R in the model name) or power takeoff (PTO, the P in the model name).

WTEC III ELECTRONIC CONTROL SYSTEM

The WTEC III control system is standard on all 3000 MH and 4000 MH Series. The

system consists of five major components connected by customer-furnished wiring

harnesses — Electronic Control Unit (ECU), engine throttle position sensor (or

direct electronic communication), three speed sensors, remote shift selector, and

control module (which contains solenoid valves and a pressure switch). The throttle

position sensor (or engine-to-transmission communication link), speed sensors,

pressure switch, and shift selector transmit information to the ECU. The ECU

processes this information and then sends signals to actuate specific solenoids

located on the control module in the transmission. These solenoids control both

oncoming and offgoing clutch pressures to provide closed-loop shift control by

matching rpm during a shift to a previously established desired profile that is

programmed into the ECU.

A feature of WTEC III controls is “autodetect.” Autodetect is active within the first

several engine starts, depending upon the component or sensor being detected.

These engine start cycles begin from when the transmission is installed during

vehicle manufacture. Autodetect searches for the presence of the following

transmission components or data inputs:

Seek help from your nearest Allison Transmission service outlet when any of the

above items are present, but are not responding properly.

Retarder Present, Not Present

Oil Level Sensor (OLS) Present, Not Present

Throttle Analog, J 1587, J 1939

Engine Coolant Temperature Analog, J 1939, J 1587

5

Another feature of the 3000 MH and 4000 MH Series transmission is its ability to

adapt or “learn” as it operates. Each shift is measured electronically, stored and used

by the ECU to adapt or “learn” the optimum conditions for future shifts.

TORQUE CONVERTER

The torque converter consists of three elements — pump, turbine, and stator. The

pump is the input element and is driven directly by the engine. The turbine is the

output element and is hydraulically driven by the pump. The stator is the reaction

(torque multiplying) element. When the pump turns faster than the turbine, the

torque converter is multiplying torque. When the turbine approaches the speed of the

pump, the stator starts to rotate with the pump and turbine. When this occurs, torque

multiplication stops and the torque converter functions as a fluid coupling.

The lockup clutch is located inside the torque converter and consists of

three elements — piston, clutch plate/damper, and backplate. The piston and

backplate are driven by the engine. The clutch plate/damper, located between the

piston and the backplate, is splined to the converter turbine. The lockup clutch is

engaged and released in response to electronic signals from the ECU. Lockup clutch

engagement provides a direct drive from the engine to the transmission gearing. This

eliminates converter slippage and provides maximum fuel economy and vehicle

speed. The torsional damper absorbs engine torsional vibration to prevent

transmission through the powertrain.

The lockup clutch releases at lower speeds or when the ECU detects conditions

requiring it to be released.

NOTE:

If the shift quality of low mileage vehicles, or vehicles with

new or recalibrated ECUs is unacceptable, follow the procedure

explained in the ADAPTING SHIFTS section.

NOTE:

Allison WTEC III electronic control systems are designed and

manufactured to comply with all FCC and other guidelines regarding radio

frequency interference/electromagnetic interference (RFI/EMI) for

transportation electronics. Manufacturers, assemblers, and installers of

radio-telephone or other two-way communication radios have the sole

responsibility to correctly install and integrate those devices into Allison

3000 MH and 4000 MH Series transmission-equipped vehicles to

customer satisfaction.

The ECU is programmed to provide the most suitable operating

characteristics for a specific application. This handbook does not

attempt to describe all of the possible combinations. The information

contained herein describes only the operating characteristics most

frequently requested by the vehicle manufacturer.

6

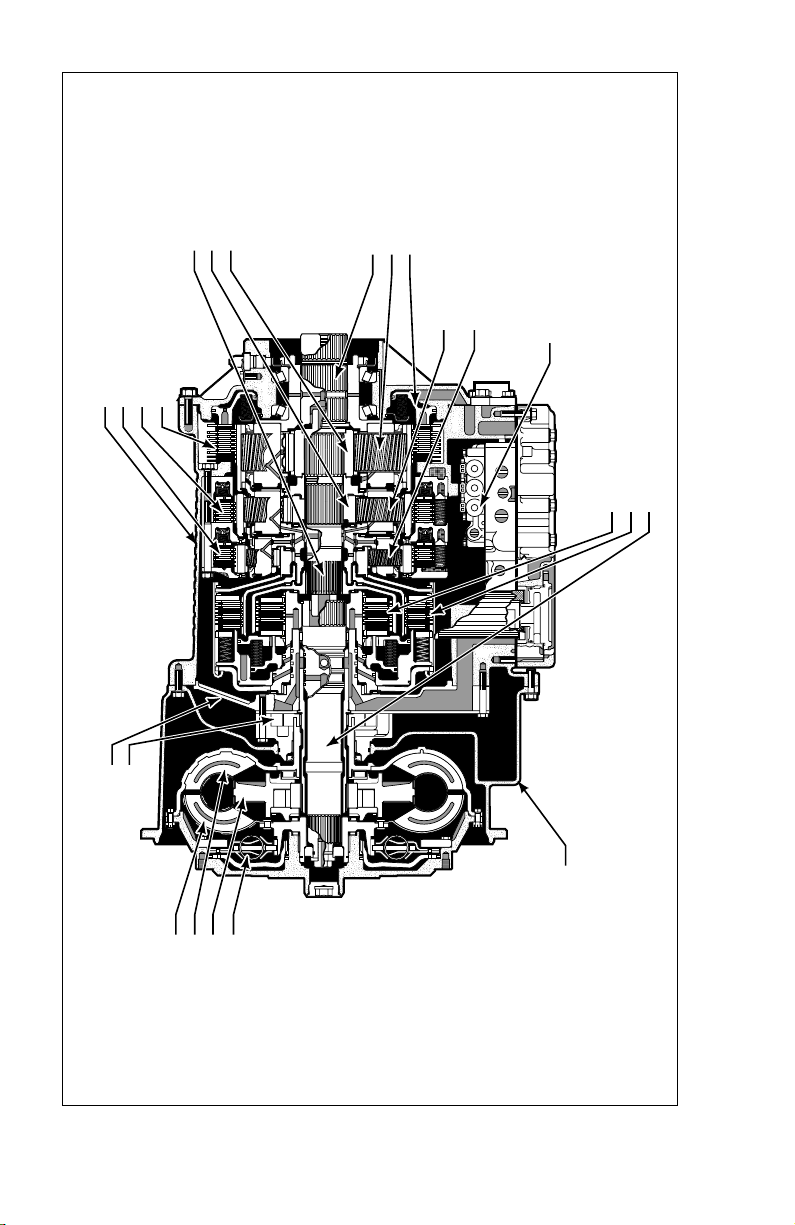

OIL LEVEL SENSOR

P2 MODULE

P1 MODULE

CONVERTER MODULE

• TURBINE

• PUMP

• LOCKUP

CLUTCH/DAMPER

• STATOR

CONVERTER HOUSING MODULE

• CONVERTER HOUSING ROTATING CLUTCH MODULE

• C1 CLUTCH

• C2 CLUTCH

• TURBINE SHAFT

CONTROL MODULE

• ELECTRO-HYDRAULIC

CONTROLS

MAIN SHAFT MODULE

• MAIN SHAFT

• P2 SUN

• P3 SUN

MAIN HOUSING MODULE

• MAIN HOUSING

• C3 CLUTCH

• C4 CLUTCH

• C5 CLUTCH

FRONT SUPPORT/OIL PUMP MODULE

• FRONT SUPPORT

• OIL PUMP

REAR COVER MODULE

• OUTPUT SHAFT

• P3

• C5 PISTON

V03348.02

Typical 3000 MH Series Transmission Cross Section

7

ROTATING CLUTCH MODULE

C1 CLUTCH

C2 CLUTCH

TURBINE SHAFT

CONTROL MODULE

ELECTRO-HYDRAULIC CONTROLS

P1 MODULE

P2 MODULE

MAIN HOUSING MODULE

MAIN HOUSING

C3 CLUTCH

C4 CLUTCH

C5 CLUTCH

MAIN SHAFT MODULE

MAIN SHAFT

P2 SUN

P3 SUN

REAR COVER MODULE

OUTPUT SHAFT

P3 MODULE

C5 PISTON

V06343

CONVERTER MODULE

TURBINE

PUMP

STATOR

LOCKUP

CLUTCH/DAMPER

CONVERTER HOUSING MODULE

CONVERTER HOUSING

FRONT SUPPORT/OIL PUMP MODULE

FRONT SUPPORT

OIL PUMP

Typical 4000 MH Series Transmission Cross Section

8

PLANETARY GEARS AND CLUTCHES

A series of three helical planetary gear sets and shafts provides the mechanical gear

ratios and direction of travel for the vehicle. The planetary gear sets are controlled

by five multiplate clutches that work in pairs to produce six forward speeds and one

reverse speed. The clutches are applied and released hydraulically in response to

electronic signals from the ECU to the appropriate solenoids.

COOLER CIRCUIT

The transmission fluid is cooled by an integral (transmission-mounted) or remote-

mounted oil cooler. Connections to the cooling circuit are located at the front or rear

of the transmission to facilitate installation of remote cooler lines. On shallow sump

models, only rear ports are available. On retarder models, only rear cooler ports may

be used. The integral cooler is located on the lower rear portion of the transmission,

replacing the remote cooler manifold. Integral cooler oil ports are internal requiring

only coolant to be routed to and from the cooler.

RETARDER

The self-contained retarder is at the output of the transmission and consists of a

vaned rotor which rotates in a vaned cavity. The rotor is splined to and driven by the

output shaft. An external accumulator holds transmission fluid until the retarder is

activated. When the retarder is activated, the fluid in the accumulator is pressurized

by the vehicle air system and directed into the retarder cavity. The interaction of the

fluid with the rotating and stationary vanes causes the retarder rotor speed, and

hence the output shaft, to decrease and slow the vehicle or to limit speed on a

downhill grade. See Page 19 for additional retarder information.

When the retarder is deactivated, the retarder cavity is evacuated and the accumula-

tor is recharged with fluid.

9

MH SERIES

DESCRIPTION OF AVAILABLE TYPES

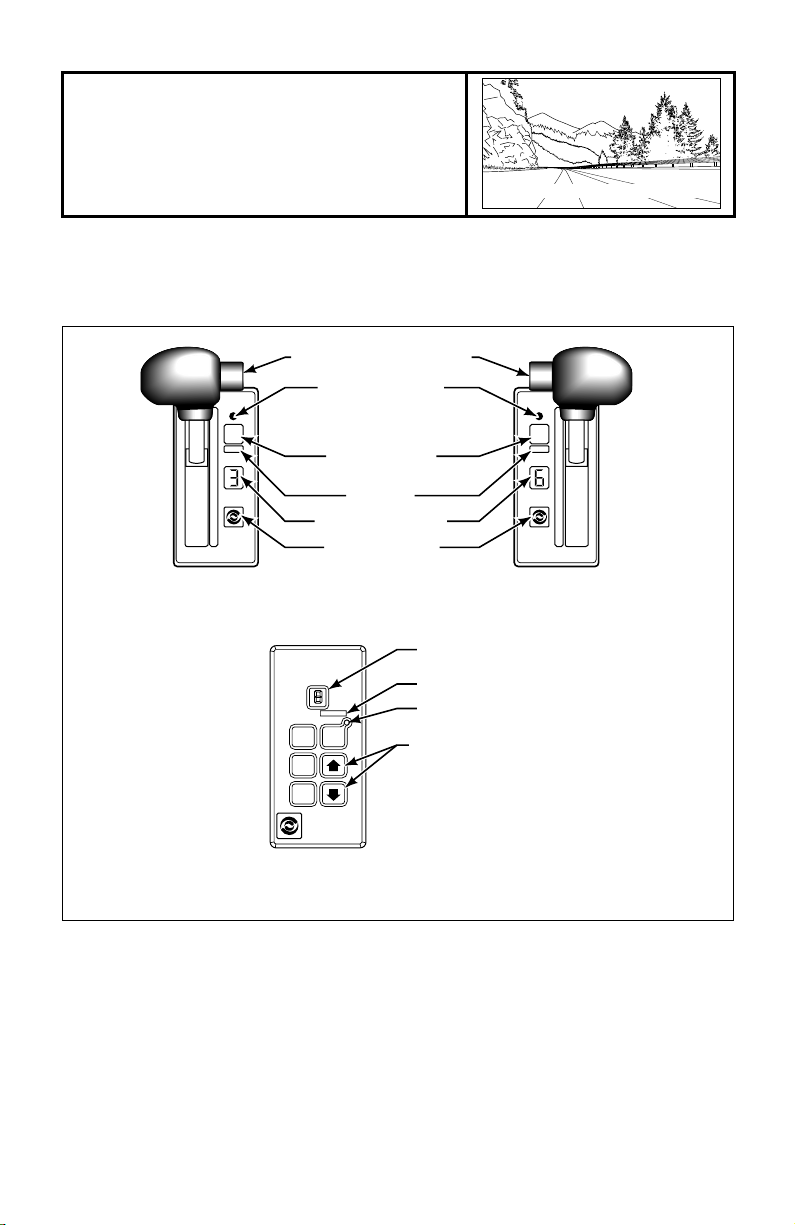

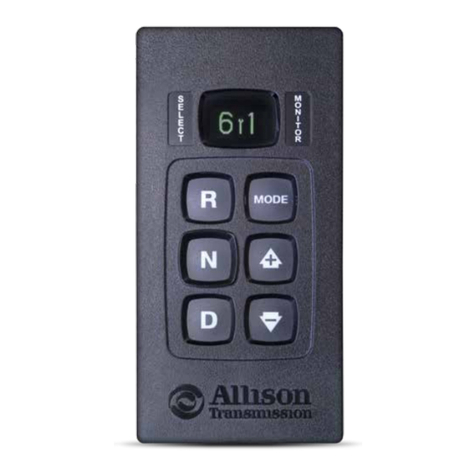

Typical WTEC III Shift Selectors

INTRODUCTION

Vehicle manufacturers may choose different types of shift selectors for their

vehicles. The shift selector in your Allison-equipped vehicle will be similar to the

lever style or the pushbutton style shown above.

1

2

3

4

5

D

N

R

MODE

R

N

D

5

4

3

2

1

MODE

R

N

D

MODE

V06344

SIX-SPEED, LEFT-HAND

LEVER SELECTOR

HOLD OVERRIDE BUTTON

DISPLAY MODE/

DIAGNOSTIC BUTTON

MODE ID

DIGITAL DISPLAY✽

MODE BUTTON

MODE INDICATOR

(LED)

SIX-SPEED, RIGHT-HAND

LEVER SELECTOR

MODE ID

MODE

INDICATOR (LED)

Push simultaneously

to enter diagnostic

mode and fluid level

check (optional)

NOTE: Number displayed is highest forward range available in selected position.

Visually check to confirm range selected. If display is flashing – shift is inhibited.

✽

DIGITAL DISPLAY✽

PUSHBUTTON

SELECTOR

SHIFT SELECTORS

10

With an Allison-equipped vehicle, it is not necessary to select the right moment to

upshift or downshift during changing road and traffic conditions. The Allison

MH Series does it for you. However, knowledge of the shift selector positions,

ranges available, and when to select them, will make vehicle control even easier. It is

recommended to select lower ranges when descending long grades (with and

without retarder) to reduce wear on service brakes. Be sure to read RANGE

SELECTION, which begins on Page 12, for related information.

LEVER SHIFT SELECTOR

General Description.

The lever shift selector is an electro-mechanical control. The

typical lever positions provided are

R

(Reverse),

N

(Neutral),

D

(Drive) and some

number of lower forward range positions. The MH Series transmissions can be

programmed to have four, five, or six forward ranges. The shift selector positions

provided should agree with the programming of the transmission electronic control

unit. The lever selector contains a hold override button, a

MODE

button, a digital

display, and a display mode button.

Hold Override Button

. The lever shift selector has three locked positions to prevent

accidentally selecting

R

(Reverse),

N

(Neutral), or

D

(Drive). Select

R, N,

or

D

by

pressing the hold override button and moving the lever to the desired position. Once

D

(Drive) is selected, lower forward range positions may be selected without

pressing the hold override button.

MODE Button

. The

MODE

button may allow the driver to enable a secondary shift

schedule or other special function that has been previously programmed into the

electronic control unit at the request of the OEM. For example, the OEM for a motor

home may have provided a secondary shift schedule for improved fuel economy.

The name of the special function (ECONOMY) should appear on the MODE ID

label adjacent to the

MODE

button. Pressing the

MODE

button activates the

ECONOMY shift schedule and illuminates the MODE INDICATOR (LED). Other

special functions which may be activated by the

MODE

button are D1 selection or

PTO enable. The

MODE

button is also used to view diagnostic code information.

Refer to the DIAGNOSIS section for further explanation. After viewing the first

diagnostic code which appears in the digital display, press the

MODE

button to

view the 2nd diagnostic code logged. Repeat this procedure to view the 3rd, 4th, and

5th code positions. The code displayed is active when the MODE INDICATOR

(LED) is illuminated.

Digital Display

. During normal operation, when

D

(Drive) is selected, the digital

display shows the highest forward range attainable for the shift schedule in use.

Abnormal operation is also indicated by the digital display. When all segments of

NOTE:

Visually check the digital display whenever the lever is moved

to be sure that the range selected is shown (i.e., if the

N

(Neutral) button

is pressed,

N

should appear in the digital display).

11

the digital display are illuminated for more than 12 seconds, the ECU did not

complete initialization. When the digital display is blank, there is no power to the

selector. When the display shows a “ ” (cateye), a selector-related fault code has

been logged. Conditions which illuminate the CHECK TRANS light will disable the

shift selector and the digital display will show the range actually attained. See

Page 16 for detailed explanation of the CHECK TRANS light. The transmission will

not shift into range if a CHECK TRANS code is active. When the display shows

either

R

or

D

has been requested and the display is flashing, the requested range has

not been achieved due to an inhibit function. Some inhibit functions are vehicle-

related and will not result in diagnostic codes. Some examples are mentioned in the

Range Selection section which follows. Check for active codes if no other inhibit

function has been located. Refer to the DIAGNOSIS section for information on

accessing codes using the shift selector. Once

D

(Drive) is attained, the transmission

will shift into the lowest range programmed for the

D

(Drive) position, usually first.

Display Mode/Diagnostic Button.

Allows access to optional fluid level check

information and diagnostic code information. Press the display mode/diagnostic

button once to obtain transmission fluid level information (when oil level sensor is

present) and a second time to obtain diagnostic code information.

PUSHBUTTON SHIFT SELECTOR

General Description

. The pushbutton shift selector has

R, N, D,

,

, a

MODE

button, and a digital display.

R Pushbutton

. Press this button to select Reverse.

N Pushbutton

. Press this button to select Neutral.

D Pushbutton

. Press this button to select Drive. The highest forward range available

will appear in the digital display window. The transmission will start out in the

lowest available forward range and advance automatically to the highest range.

,

(Arrow) Buttons

. When a lower range is desired, after

D

(Drive) has been

pressed, press the

(Down) arrow button until the desired range is shown in the

display window. Likewise, if the transmission is held in a low range by the

(Down) arrow, press the

(Up) arrow to request the next higher range.

Continuous pressing of either the

(Up) or

(Down) arrow buttons will request

the highest or lowest range available.

Access fluid level data and diagnostic codes with the pushbutton selector by

pressing the

(Up) and

(Down) arrow buttons at the same time. Refer to

Page 29, FLUID LEVEL CHECK USING THE PUSHBUTTON OR LEVER

SHIFT SELECTOR, or Page 41, DIAGNOSIS for further information. Fluid level

information is displayed (if optional oil level sensor is present) after the first

simultaneous press. Press both buttons again to obtain diagnostic data.

MODE Button

and

Digital Display

. Same function as described in the lever

selector above.

12

RANGE SELECTION — PUSHBUTTON AND LEVER SHIFT

SELECTORS WITH DIGITAL DISPLAY

RANGE

SELECTION

NOTE:

Visually check the digital display window whenever a button is

pushed or the lever is moved to be sure that the range selected is shown

(i.e., if the

N

(Neutral) button is pressed,

N

should appear in the digital

display). A flashing display indicates that the range selected was not attained

due to an active inhibit.

R

Completely stop the vehicle and let the engine return to idle before shifting

from a forward range to

R

everse or from

R

everse to a forward range. The

LED window on the

R

everse pushbutton will illuminate and

R

everse will be

attained.

1

2

3

4

5

D

N

R

MODE

R

N

D

MODE

V03497.01

PUSHBUTTON

SELECTOR

TYPICAL

LEVER

SELECTOR

WARNING: If you leave the vehicle and the engine is running, the

vehicle can move suddenly and you or others could be injured. If you

must leave the engine running, do not leave the vehicle until you:

• Put the transmission in N(Neutral)…and

• Ensure that the engine is at low idle rpm (below 1000)…and

• Apply the parking brake and emergency brakes and make sure

they are properly engaged…and

• Chock the wheels and take any other steps necessary to keep the

vehicle from moving.

WARNING: R(Reverse) may not be obtained due to an active

inhibitor. Always be sure that “R” is not flashing whenever

R(Reverse) is selected. See DOWNSHIFT AND DIRECTION

CHANGE INHIBITOR FEATURE on Page 17. Check for active

diagnostic codes if R(Reverse) is not attained.

CAUTION: Do not idle in R(Reverse) for more than five minutes.

Extended idling in R(Reverse) may cause transmission overheat-

ing and damage. Always select N(Neutral) whenever time at idle

exceeds five minutes.

(continued on next page)

13

RANGE

SELECTION

N

Use

N

eutral when you start the engine, to check vehicle accessories, and for

extended periods of engine idle operation (longer than five minutes). For

vehicles equipped with the pushbutton selector,

N

eutral is automatically set

by the ECU during startup. For vehicles equipped with the lever selector, the

vehicle will not start until

N

eutral has been manually selected. If the vehicle

starts in any range other than

N

eutral, seek service immediately. Neutral is

also used during stationary operation of the power takeoff (if your vehicle is

equipped with a PTO). The digital display will show Nwhen Neutral is

selected. Be sure to select N(Neutral) before turning off the vehicle engine.

RANGE SELECTION — PUSHBUTTON AND LEVER SHIFT

SELECTORS WITH DIGITAL DISPLAY (cont’d)

1

2

3

4

5

D

N

R

MODE

R

N

D

MODE

V03497.01

PUSHBUTTON

SELECTOR

TYPICAL

LEVER

SELECTOR

WARNING: When starting the engine, make sure the service

brakes are applied. Failure to apply the service brakes may result in

unexpected vehicle movement.

WARNING: Vehicle service brakes, parking brake, or emergency

brake must be applied whenever N(Neutral) is selected to prevent

unexpected vehicle movement. Selecting N(Neutral) does not

apply vehicle brakes, unless an auxiliary system to apply the

parking brake is installed (see Operator’s Manual for the vehicle).

WARNING: If you let the vehicle coast in N(Neutral), there is no

engine braking and you could lose control. Coasting can also cause

severe transmission damage. To help avoid injury and property

damage, do not allow the vehicle to coast in N(Neutral).

(continued on next page)

14

RANGE

SELECTION

NOTE: Turn off the vehicle HIGH IDLE switch, if present, before shifting

from N(Neutral) to D(Drive) or R(Reverse). D(Drive) or R(Reverse) will

not be attained unless the shift is made with the engine at idle. Also, be aware

of other interlocks that would prevent obtaining D(Drive) or R(Reverse).

Examples are “wheelchair lift not stored” and “service brakes not applied”

(service brake interlock present).

DThe transmission will initially attain first range when Drive is selected. As

speed increases, the transmission automatically upshifts through each range.

As the vehicle slows, the transmission automatically downshifts. The light

on the Drive pushbutton will illuminate and the appropriate range of Drive

will be attained.

RANGE SELECTION — PUSHBUTTON AND LEVER SHIFT

SELECTORS WITH DIGITAL DISPLAY (cont’d)

1

2

3

4

5

D

N

R

MODE

R

N

D

MODE

V03497.01

PUSHBUTTON

SELECTOR

TYPICAL

LEVER

SELECTOR

WARNING: Even though D(Drive) is selected, it may not be

obtained due to an active inhibitor. Always be sure that “D” is not

flashing whenever D(Drive) is selected. See DOWNSHIFT AND

DIRECTION CHANGE INHIBITOR FEATURE on Page 17.

Check for active diagnostic codes if D(Drive) is not attained.

CAUTION: Do not idle in D(Drive) for more than five minutes.

Extended idling in D(Drive) may cause transmission overheating

and damage. Always select N(Neutral) if time at idle is longer than

five minutes.

(continued on next page)

15

RANGE

SELECTION

6*

5*

4*

3

2

Occasionally, road conditions, load, or traffic conditions will make it

desirable to restrict automatic shifting to a lower range. Lower ranges

provide greater engine braking for going down grades (the lower the range,

the greater the braking effect).

The pushbutton selector utilizes arrow buttons to select individual forward

ranges. Push the (Up) or (Down) arrow to the desired range. The

digital display will show your choice of range. Even though a lower range

was selected, the transmission may not downshift until vehicle speed is

reduced (this prevents excessive engine speed in the lower range).

* Actual ranges available depend on programming by vehicle manufacturer.

1Use this range when pulling through mud and deep snow, when

maneuvering in tight spaces, or while driving up or down grades. First range

provides the vehicle with its maximum driving torque and maximum engine

braking effect. For vehicles equipped with the pushbutton selector, push the

(Down) arrow until first range appears in the select window.

RANGE SELECTION — PUSHBUTTON AND LEVER SHIFT

SELECTORS WITH DIGITAL DISPLAY (cont’d)

1

2

3

4

5

D

N

R

MODE

R

N

D

MODE

V03497.01

PUSHBUTTON

SELECTOR

TYPICAL

LEVER

SELECTOR

WARNING: If you just downshift or just use service brakes when

going downhill, you can lose control and cause injury and property

damage. To help avoid loss of control, use a combination of

downshifting, braking, and other retarding devices. Downshifting

to a lower transmission range increases engine braking and helps

you to maintain control. The transmission has a feature to prevent

automatic upshifting above the lower range selected. However,

during downhill operation, if engine governed speed is exceeded in

the lower range, the transmission may upshift to the next higher

range. This will reduce braking and could cause a loss of control.

Apply the vehicle brakes or other retarding device to prevent

exceeding engine governed speed in the lower range selected.

This manual suits for next models

7

Table of contents

Other Allison Transmission Microphone System manuals

Allison Transmission

Allison Transmission Emergency Vehicle Series User manual

Allison Transmission

Allison Transmission AT 500 Series User manual

Allison Transmission

Allison Transmission 3000 Assembly instructions

Allison Transmission

Allison Transmission AT 540 User manual

Allison Transmission

Allison Transmission shift selector User manual

Allison Transmission

Allison Transmission AT Series User manual

Allison Transmission

Allison Transmission Motorhome Series User manual

Allison Transmission

Allison Transmission 1000 Series User manual