Allison Transmission AT 500 Series User manual

This manual suits for next models

18

Table of contents

Other Allison Transmission Microphone System manuals

Allison Transmission

Allison Transmission AT 540 User manual

Allison Transmission

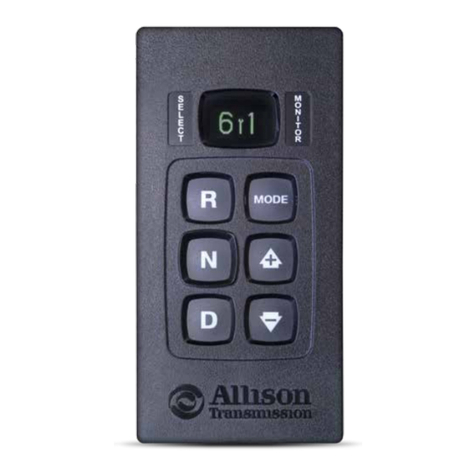

Allison Transmission shift selector User manual

Allison Transmission

Allison Transmission 1000 Series User manual

Allison Transmission

Allison Transmission Emergency Vehicle Series User manual

Allison Transmission

Allison Transmission AT Series User manual

Allison Transmission

Allison Transmission 3000 Assembly instructions

Allison Transmission

Allison Transmission 3000 MH Series User manual

Allison Transmission

Allison Transmission Motorhome Series User manual

Popular Microphone System manuals by other brands

Listen Technologies

Listen Technologies LA-123 90 Design guide

Pyle

Pyle PDWM5000 user manual

Vicon

Vicon VF-220 Series Installation & operation manual

Samson

Samson VHF Micro VHF Micro TRUE DIVERSITY WIRELESS owner's manual

Schlage

Schlage NDE80 Installation instructions and user guide

Whitesand

Whitesand WSM-100 user manual