Allpro SPC-500 User manual

OPERATINGINSTRUCTIONS

ANDOWNER’SMANUAL

READINSTRUCTIONSCAREFULLY:Readandfollowallinstructions.Placeinstructions

ina safeplace forfuture reference.Do notallow anyonewho hasnot readthese

instructionsto assemble,light, adjustor operatethis tool.

SPC-500

Model #

HOT SHOT

Model SPC-500

05/13 Revision L2 #72615

(Propane Torch)

2OperatingInstructionsandOwner’sManual

If you smell gas: (Under certain conditions odor may fade (Refer to page 6)

- Shut off gas to the device.

- DO NOT try to light appliance.

-Extinguishanyopenflame.

-Checkthedevice forleaksusingsoapywater.

- DO NOT attempt to relightthe deviceuntil allleaks are repairedand thereis no

gassmell.

DO NOT use this device in areas where gasoline or other

liquids having flammable vapors are stored or used.

CAUTION:

Thisdevice isintendedforoutdooruseonly.

NEVERdirecttorch flametowardhose orgas tank.

DO NOT leavetorchunattendedwhile inoperation.

DO NOT stand or prop the torch on the burner end while in operation.

Always usethe strikerprovided. Neveruse amatch orlighter toignitetorch.

DO NOT applyheatorflametotanktocheckforleaksortoincreasegaspressure.

DO NOT lifttank by the valve.

When not in use the gas should be turned off at the LPgas tank(s).

CAUTION –In daylight,torchflame isbarely visible.

DO NOT place hand or body part in the path of the flame while lighting or

operatingtorch.

Thisdeviceis designedforvaporwithdrawalfrom anLPgastank(s)ONLY.

NOTE:

Placetankon levelsurface inanupright position.

Do not invert or lay tank on its side.

Glovesshouldbe wornatall timeswhenoperatingthis device.Longsleeves,long

pants,andbootsarerecommended.

HaveanABCtypefireextinguisher readilyaccessibletothe jobsite.

Read and understand instructions before use!

Retain this information for future reference.

FORYOURSAFETY!

THESTATEOFCALIFORNIAREQUIRESTHEFOLLOWINGWARNING:

WARNING:

Combustionby-productsproducedwhenusingthisproductcontaincarbonmonoxide,

achemicalknown totheStateofCaliforniato causecancerandbirth defects(or other

reproductiveharm).

3OperatingInstructions andOwner’sManual

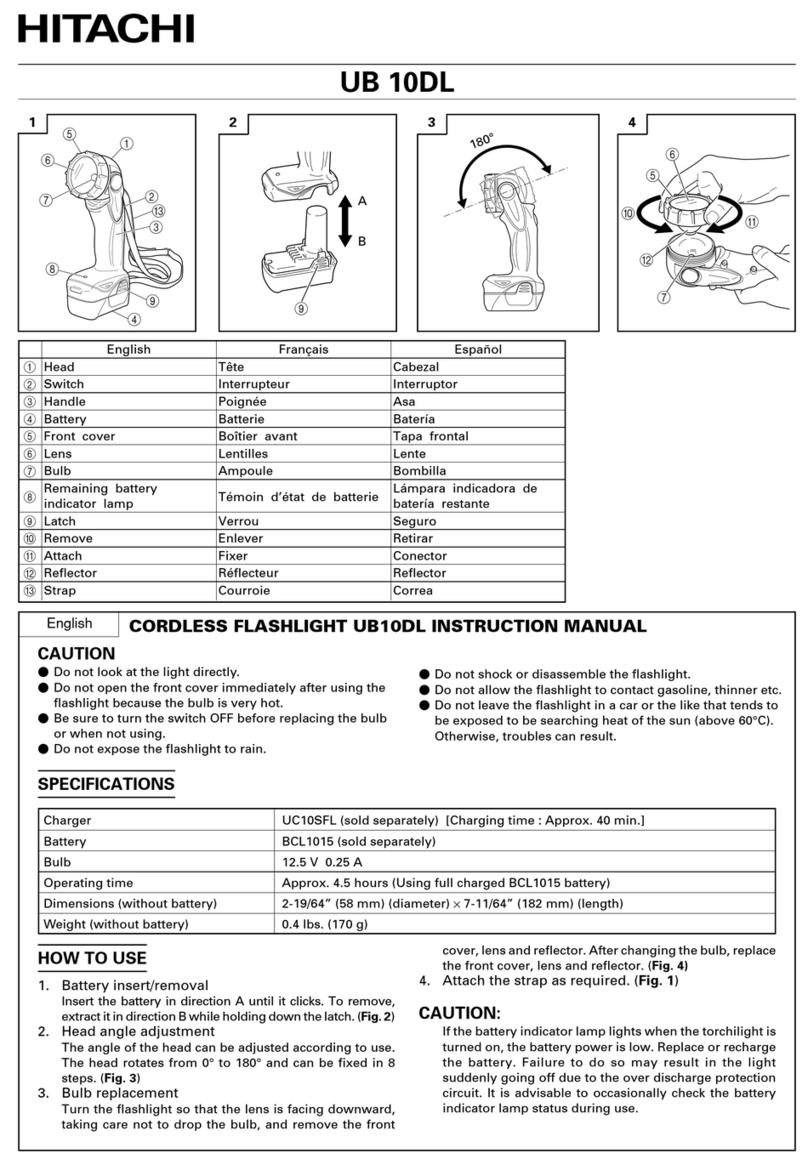

ITEM DESCRIPTION PARTNO.

1....................... HandleAssembly ...........72601

2....................... HoseAssembly ..............72602

3 ....................... Striker ...........................72603

SPC-500-Parts List

CAUTION:

Use only genuine SCHEU PRODUCTS replacement parts. Never substitute parts.

Do not use modified parts. When ordering replacement parts,use the part number

located in these instructions.

Whenordering repair parts, alwaysfurnish thefollowing information:

1) ModelNumber

2) PartNumber

3) PartDescription

3

1

2

4OperatingInstructions andOwner’sManual

1) Unpack all the components and inspect for any damage. If any damage is

discovered contact the delivery service or Scheu Products immediately.

2)Connect thehoseassemblyto thehandleassembly andtighten

counterclockwise.

NOTE: Thisisa left-handedthreadconnection.

Connectionto theSupply Tank:

NOTE: TheLP(LiquidPetroleum)gas tankusedwiththis deviceshouldbenolessthana

20lb. capacity. Itshouldalso meetor exceedNFPA58“Standard forthe Storage and

HandlingofLiquefiedPetroleumGases”.

1) Inspect the nut/nipple (excess shut-off valve) connection of the hose

assembly.Check for any dents or damage. The o-ring must be present. If

damage is found or the o-ring is missing call Scheu Products for the proper

replacement parts.

2) Connect the excess shut-off valve end of the host assembly to the shut-

off valve of a LP gas tank and tighten counterclockwise.

NOTE: Ifyour LPgas tankdoesnothave ashut-offvalve,exchange thetankfor

onewith a shut-off valve.

OPERATINGCHARACTERISTICS

Model BTU Operating InletPressure

TemperatureRange Range

SPC-500 500,000* -10oF to 100oF 17 psi to 170 psi

AssemblyInstructions:

Un-assembled Assembled

CAUTION:

Thisdeviceis designedforvaporwithdrawal fromanLPgastank(s)ONLY.Useofany

othergas mayresultin devicefailure orpersonalinjury.

*Tanksizeandtanktemperature candirectlyaffectBTUoutput

5OperatingInstructions andOwner’sManual

HOTSHOT

Model SPC500

Assembly, Testing &

Operating Instructions

SCHEUPRODUCTSCOMPANY

CAUTION:

DO NOT operate ifany leaksarepresent.Aleakmay createa firehazard.

DO NOT smokearound orexposesupply tank(s)to openflamesor sparks.

DO NOT apply heator flametotankto checkfor leaks.Excessheat maycausethe

supplytankto rupture,possiblycausing personalinjury.

LightingInstructions:

NOTE:Thehoseassemblyissuppliedwithanexcess flowcontrolvalve.Opening

thesupply tankshut-offvalve rapidlycancausethe valvetoclose. Iftheexcess flowvalve

closes,closethe supplytankshut-offvalve.Opentorch adjustingvalvetoreleaseany

residualgasleft inthehose.Close torch-adjustingvalveandwait 30seconds.Slowlyopen

tankshut-offvalve.

1) Makesure torchadjustingvalveisclosed.

2) Opensupply tankshut-offvalve.

3) Withtorch nozzlepointed awayfrom anyflammable material,open torch

adjustingvalve1/8th of aturn oruntil youcan hear gasescaping.

4) Igniteusing suppliedigniter.

5) Usethe torch-adjustingvalve tocontrol thesizeand heatof flame.

USE: Whenusing tool,donot directflamedirectly intowind.

Donot allowbarrelto comecloserthan 6”tothe surfacebeing heated.

Failuretodoeither ofthesethingscouldcause flameoutage.

6OperatingInstructions andOwner’sManual

WARNING

Asphyxiation Hazard

• Do not use this heater for heating human living

quarters.

• Do not use in unventilated areas.

• The flow of combustion and ventilation air must

not be obstructed.

• Proper ventilation air must be provided to support

the combustion air requirements of the heater

being used.

FUEL GAS ODOR

LP gas and natural gas have man-made odorants added specifically for detection of fuel gas leaks.

If a gas leak occurs you should be able to smell the fuel gas. Since Propane (LP) is heavier than air you

should smell for the gas odor low to the floor. ANY GAS ODOR IS YOUR SIGNAL TO GO INTO IMMEDIATE

ACTION!

• Do not take any action that could ignite the fuel gas. Do not operate any electrical switches. Do not pull any

power supply or extension cords. Do not light matches or any other source of flame. Do not use your

telephone.

• Get everyone out of the building and away from the area immediately.

• Close all propane (LP) gas tank or cylinder fuel supply valves, or the main fuel supply valve located at the

meter if you use natural gas.

• Propane (LP) gas is heavier than air and may settle in low areas. When you have reason to suspect a

propane leak, keep out of all low areas.

• Use your neighbor’s phone and call your fuel gas supplier and your fire department. Do not re-enter the

building or area.

• Stay out of the building and away from the area until declared safe by the firefighters and your fuel gas

supplier.

• FINALLY, let the fuel gas service person and the firefighters check for escaped gas. Have them air out the

building and area before you return. Properly trained service people must repair any leaks, check for further

leakages, and then relight the appliance for you.

ODOR FADING - NO ODOR DETECTED

• Some people cannot smell well. Some people cannot smell the odor of the man-made chemical added to

propane (LP) or natural gas. You must determine if you can smell the odorant in these fuel gases.

• Learn to recognize the odor of propane (LP) gas and natural gas. Local propane (LP) gas dealers will be more

than happy to give you a scratch and sniff pamphlet. Use it to become familiar with the fuel gas odor.

• Smoking can decrease your ability to smell. Being around an odor for a period of time can affect your

sensitivity to that particular odor. Odors present in animal confinement buildings can mask fuel gas odor.

•The odorant in propane (LP) gas and natural gas is colorless and the intensity of its odor can fade

under some circumstances.

• If there is an underground leak, the movement of gas through the soil can filter the odorant.

• Propane (LP) gas odor may differ in intensity at different levels. Since Propane (LP) gas is heavier than air,

there may be more odor at lower levels.

• Always be sensitive to the slightest gas odor. If you continue to detect any gas odor, no matter how

small, treat it as a serious leak. Immediately go into action as discussed previously.

ATTENTION - CRITICAL POINTS TO REMEMBER!

• Propane (LP) gas has a distinctive odor. Learn to recognize these odors. (Reference Fuel Gas Odor and Odor

Fading sections above.

• Even If you are not property trained in the service and repair of the heater, ALWAYS be consciously aware

of the odors of propane (LP) gas and natural gas.

• If you have not been properly trained in repair and service of propane (LP) gas then do not attempt to light

heater, perform service or repairs, or make any adjustments to the heater on the propane (LP) gas fuel

system.

• A periodic sniff test around the heater or at the heater’s joints; i.e. hose, connections, etc., is a good safety

practice under any

• Refer to the specification section of the heater’s

manual, heater dataplate, or contact the Scheu

Products Company to determine combustion air

ventilation requirements of the heater.

• Lack of proper ventilation air will lead to improper

combustion.

• Improper combustion can lead to carbon monoxide

poisoning leading to serious injury or death.

Symptom of carbon monoxide poisoning can

include headaches dizziness and difficulty in

breathing.

ODOR FADE WARNING

7OperatingInstructions andOwner’sManual

Shut-OffInstructions:

1) Close torch adjusting valve.

2) Close supply tank shut-off valve.

3) Open the torch-adjusting valve briefly to release any residual gas left in

the hose.

Maintenance:

Prior to each use:

1)Visually inspect all components of the device for damage and or wear. If the

hose shows excessive abrasion wear, or the hose is cut, it must be replaced

prior to operation. If damage is found, contact Scheu Products Co. for the

proper replacement parts.

2)Visually inspect LP gas tank(s) for dents, damage to collar, damage to shut-

off valveor corroded foot ring. If any of these are present the LP gas tank(s)

must be replaced prior to operation.

3)Perform a leak test according to the leak test procedure described on page 5.

4)Ignite torch according to the lighting instructions described on page 5. Check

operation of the adjusting valve and the other components prior to proceeding.

Periodically:

1)Remove any debris or combustible material from the torch. The torch must be kept

clear and free from combustible materials.

2)The surface of the device should be cleaned with soap and water. Do not use

petroleum-based or flammable cleaner on any part of the device.

Disconnecting the Supply Tank:

1)Make sure supply tank valve is shut off.

2)Open torch adjusting valve briefly to release any residual gas left in the hose.

Close adjusting valve when complete.

3)Disconnect the P.O.L. nut/nipple located at the end of the hose assembly from the

supply tank(s).

4)Replace the protective plastic cap and plug to the hose end and

supply tank(s) respectively.

CAUTION:

DO NOT smokearound orexpose supplytank(s) toopenflame orsparks.

Always usethe strikerprovided. Neveruse amatch orlighter toignite torch.Use of

deviceother thanthestrikermay causepersonalinjury.

DO NOT place hand or any body part in the path of the flame while lighting or operating

torch.Thiscanresult inpersonal injury.

CAUTION:

DO NOT smokearound orexposesupply tank(s)to openflamesor sparks.

Torchend ofhandle assemblywill increasein temperatureimmediately aftershutting off.

8OperatingInstructions andOwner’sManual

Storage:

Neverstore atorchthat isstill hot.When thetorch isstored indoors,the connection

betweenthe LPgas tank(s)andthedevice mustbedisconnected andthetank(s)removed

from the device and stored outdoors in accordance with Chapter 5 of the “Standard for the

StorageandHandling ofLiquefied PetroleumGases” ANSI/NFPA58.

NOTE:

· Storagetemperatureshallnotexceed120degreesF(49degreesC).

· Placetank onlevel surfacein anupright position.Do notinvert orlay tankon its side.

SafetyInformation:

Safetypublicationsrelated tosafepracticeanduse:

CSA2-94 “U.S.Requirementsfor HandHeldLPTorchesfor usewithfuel supply”

ANSIZ49.1 “Safety in Welding and Cutting”

NFPA54 “NationalFuel GasCode”

NFPA58 “StandardfortheStorageandHandlingofLiquefiedPetroleum Gases”

CAUTION:

DO NOT smokearound orexposesupply tank(s)to openflamesor sparks.

CAUTION:

DO NOT smokearound orexpose supplytank(s)toopen flameor sparks.

Thehoseassembly shallbeprotected fromtraffic,crushing, andhotsurfaces.Thismay

causeprematurewearofthehose.

DO NOT lift tank by the valve. Lifting the tank by the valve may result in damage to

thevalve.

9OperatingInstructions andOwner’sManual

Scheu Products Co. reserves the right to make changes at any time, without notice

or obligation, in colors, specifications, accessories, materials and models.

WARNING:

USEONLYMANUFACTURER’SREPLACEMENTPARTS.USEOFANYOTHERPARTSCOULD

CAUSEINJURYORDEATH.REPLACEMENTPARTSAREONLYAVAILABLEDIRECTFROMTHE

FACTORYANDMUSTBEINSTALLEDBYAQUALIFIEDSERVICEAGENCY.

PARTSORDERINGINFORMATION:

PURCHASING: Accessories may be purchased at any Scheu Products Co. local

dealer or direct from the factory

FORINFORMATIONREGARDINGSERVICE

Please call Toll-Free 800-325-7057

www.allpro-heaters.com

Our office hours are 7:00 AM – 4:00 PM, PT, Monday through Friday.

Pleaseinclude themodel number, dateofpurchase, anddescription ofprobleminall

communication.

OPERATINGINSTRUCTIONS

ANDOWNER’SMANUAL SPC500

Model #

LIMITEDWARRANTY

Scheu Products Co. warrants its HOT SHOT to be free from defects in material

and workmanship for a period of 90 days from date of purchase. Scheu

Products Co.will repair or replace this product free of charge if it has been

proven to be defective within the 90 day period, and is returned at customer

expense with proof of purchase to Scheu Products Co. within the warranty

period.

Table of contents