Allsheng SealBio-2 User manual

Operation Manual

Version 2.0

SealBio-2

Semi Automated Plate Sealer

HANGZOU ALLSHENG INSTRUMENTS CO., LTD.

DOMINIQUE DUTSCHER SAS

Foreword

Thank you for purchasing our products: Semi Automated Plate Sealer. This

manual for users contains function and operation of the instrument. In order

to use the instrument properly, please read this manual carefully before

using the instrument.

Opening Check

Please check the instrument and appendix with the packing list when you

first open the instrument packing case. If you find there is something wrong

with the instrument and the Appendix, do contact the vendor or the

producer.

HANGZHOU ALLSHENG INSTRUMENTS CO., LTD.

Address: Building 1&2, Zheheng Science Park, Zhuantang Town, Xihu District,

Hangzhou, Zhejiang 310024, China

Telephone: +86-571-88802738,88948289

Fax: +86-571-87205673

Post code: 310024

Website: www.allsheng.com

Email: [email protected]

File version: Dec 2019, 2nd Version

DOMINIQUE DUTSCHER SAS

Safety Warnings and Guidelines

1. Important operation information of the security:

Before the users’ operation, they should have a perfect conception of how to use the

instrument. Therefore, read this manual carefully before using it.

2. Security:

The operation, maintenance and repair of the instrument should comply with the

basic guidelines and the remarked warning below. If you don’t comply with them, it

will have effect on the scheduled using life of the instrument and the protection

provided.

The heat plate with a high temperature may cause burn accident, any

contact with body part is forbidden during the instrument running.

Operation before reading the manual is forbidden. Or may cause

serious burn by heat even caused electric shock hazard during the

runtime of instrument. Read the guidelines and directions below and

carry out the countermeasure according to them.

This product is a normal and an indoor instrument which conforms to

Standard GB9706.1 (Class I, B type).

Before using the device, read the manual carefully. This unit is designed

for use in laboratory environments. The device must be used by skilled

personnel with the appropriate training.

Before power on, guarantee the voltage used should be accordant to the

voltage needed, and the rated load of electrical outlet should not lower

than the demand.

If the electric line is damaged, you should replace it with the same type.

You should assure there’s nothing on the electric line and you should

not put the electric line in the ambulatory place.

Insert the plug completely when plug in and pull out the plug directly

when need to disconnect, do not simply pull out the power cord.

The operator should not open or repair the instrument by himself, which

will result in losing the qualification of repair guarantee or cause accident.

If there is some wrong with the instrument, the company will repair it.

DOMINIQUE DUTSCHER SAS

3. The maintenance of instrument

The rotor should be cleaned by the cloth stained with a little alcohol. If there are

smutches on the instrument, clean them by soft cloth stained with cleaning cream.

4. After Service

a) Warranty Content

Regard to the fault caused by material and manufacture, within one month from the

date of delivery. The manufacture is responsible for change the new instrument.

Regard to the fault caused by material and manufacture, within 12 months from the

date of delivery. The manufacture is responsible for change or repair at its option.

Repair products must ship to specified maintenance department by purchaser and

freight charge need to be paid by purchaser. Freight charge for sending back to

purchaser will be paid by manufacturer.

Regard to the maintenance out of warranty period, manufacture will charge the

maintenance cost accordingly.

b) Warranty Scope

Above-mentioned warranty is not applicable for inappropriate maintain, improper

use and operating under improper condition, also is not applicable for the damage

which caused by repair and refit without authorization.

The instrument should be put in the place of low temperature, little dust,

no water and no sun or strong lamp. What’s more, the place should be

good aeration, no corrosively gas or strong disturbing magnetic field, far

away from central heating, camp stove and other hot resource. Don't put

the instrument in wet and dusty place. The vent on the instrument is

designed for aeration. Don’t wall up or cover the vent in order to keep

from high temperature. If you use more than one instrument the same

time, the distance between them should be more than 100cm.

Power off when you finish your work. Pull off the connector plug when

there’s long time no use of the Instrument and cover it with a cloth or

plastic paper to prevent from dust.

Pull the connector plug from the socket at once in the following cases, and

contact the vendor:

There is some liquid flowing into the instrument;

Drenched or fire burned.

Abnormal operation: such as abnormal sound or smell.

Instrument dropping or outer shell damaged.

The function has obviously changed.

DOMINIQUE DUTSCHER SAS

CONTENTS

CHAPTER 1 INTRODUCTION------------------------------------------------------------------------------ 1

CHAPTER 2 SPECIFICATIONS-------------------------------------------------------------------------------- 2

1. NORMAL OPERATION CONDITIONS:---------------------------------------------------------------- 2

2. THE BASIC PARAMETERS AND CHARACTERISTICS------------------------------------------ 2

CHAPTER 3 BASIC INSTRUCTIONS------------------------------------------------------------------------- 3

1. STRUCTURE OVERVIEW---------------------------------------------------------------------------------- 3

2. OPERATION PANEL---------------------------------------------------------------------------------------- 4

3. DISPLAY-------------------------------------------------------------------------------------------------------- 4

CHAPTER 4 OPERATION GUIDE----------------------------------------------------------------------------- 5

1. SEAL CONDITION SETTING------------------------------------------------------------------------------5

2. SEAL OPERATION-------------------------------------------------------------------------------------------6

3. HEATING PLATE CLEANING-----------------------------------------------------------------------------7

4. OTHER FUNCTION------------------------------------------------------------------------------------------ 8

CHAPTER 5 TROUBLESHOOTING GUIDE-----------------------------------------------------------------9

PROBLEMS AND ACTIONS------------------------------------------------------------------------------------ 9

ANNEX:WIRING DIAGRAM------------------------------------------------------------------------------------10

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 1 Instruction

─1─

Chapter 1 Introduction

The SealBio-2 Plate Sealer is a semi-automatic thermal sealer which is ideal for the low to

medium throughput laboratory that requires uniform and consistent sealing of micro-plates.

Unlike manual plate sealer , the SealBio-2 produces repeatable plate seals. With variable

temperature and time settings, sealing conditions are easily optimised to guarantee consistent

result, eliminating sample loss. The SealBio-2 apply in product’s quality control of many

manufacture enterprise such as plastic film, food, medical, inspection institute, scholastic

scientific research and teaching experiment.

Feature:

1. Format different micro well plates and heat seals

2. Seals plate heights: 9 to 48mm high

3. Adjustable Sealing Temperature: 80 - 200℃

4. OLED display screen, high light and no visual angle limit

5. Precise temperature, timing and pressure for consistent sealing

6. Compact footprint: only 7.0 inches (17.8cm) wide

7. Automatic counting function

8. The drawer is controlled by high grad MCU, if a hand or objects blocked the drawer when

it’s moving, the drawer motor will automatically reverse. This feature prevents injury to the

user and unit

9. Special and smart design on the drawer, it’s detachable from the main device. So user can

maintain and clean easily the heating element

10.When the unit is left idle more than 60min, it automatically switches into stand-by mode

during which the temperature of the heating element is reduced to 60°C to save energy

11. When the unit is left idle more than 120min, it switches off automatically for added safety. It

switched off the display and heating element. After, user will push any button to awaken it

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 2 Specifications

─2─

Chapter 2 Specifications

1. Normal operation conditions:

Ambient temperature: 10C35C

Relative humidity:≤70%

Power:AC200~240V, 50Hz/60Hz

2. The basic parameters and characteristics

Display

OLED

Temperature setting

80℃~200℃

Temperature accurate

1℃

Seal time

0.5s~10s,increased by 0.1 seconds

Cooling time of heating

element

≤2℃,return to normal within 25 seconds

Heating element

Electrical heating tube

Input power

300W

Dimension(D×W×H)

370mm×178mm×330mm

Weight

9.6kg

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 3 Basic Instructions

─3─

Chapter 3 Basic Instructions

This chapter mainly introduces the structure, operation keys, and displays of the instrument, as

well as preparatory work before starting. Please read this chapter before starting when uses

this instrument for the first time.

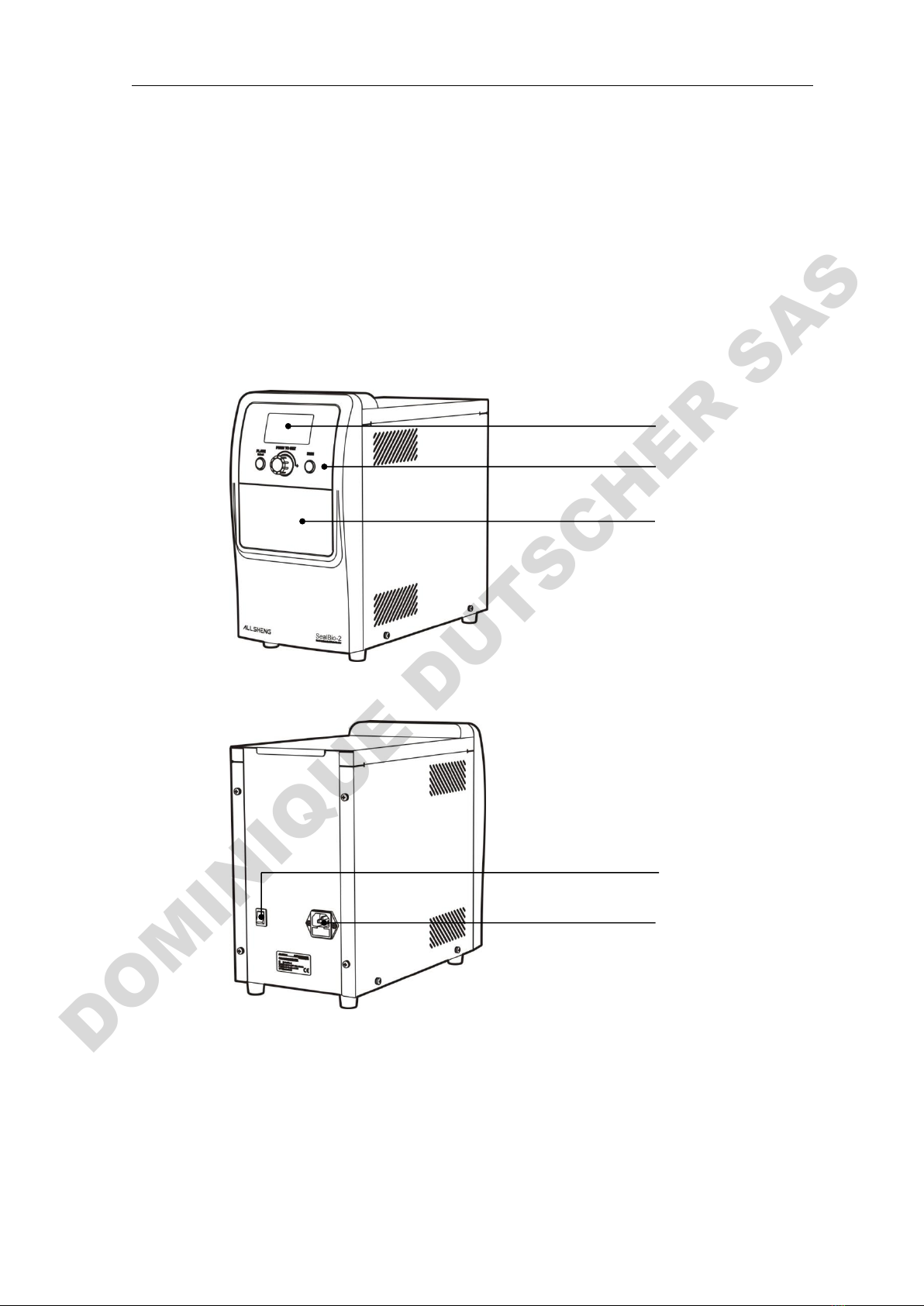

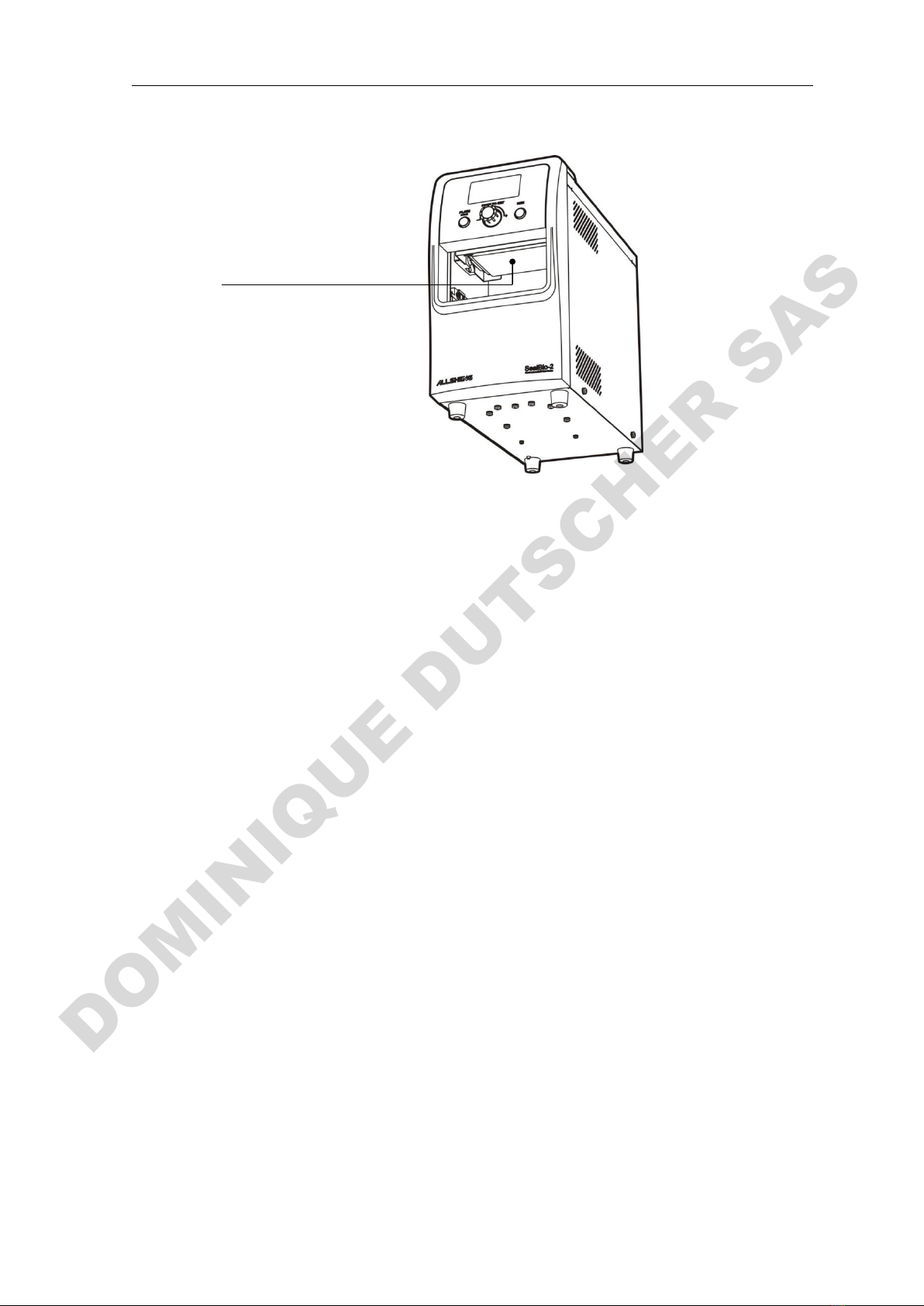

1. Structure overview

Display

Operation Panel

Drawer

Power Switch

Plug

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 3 Basic Instructions

─4─

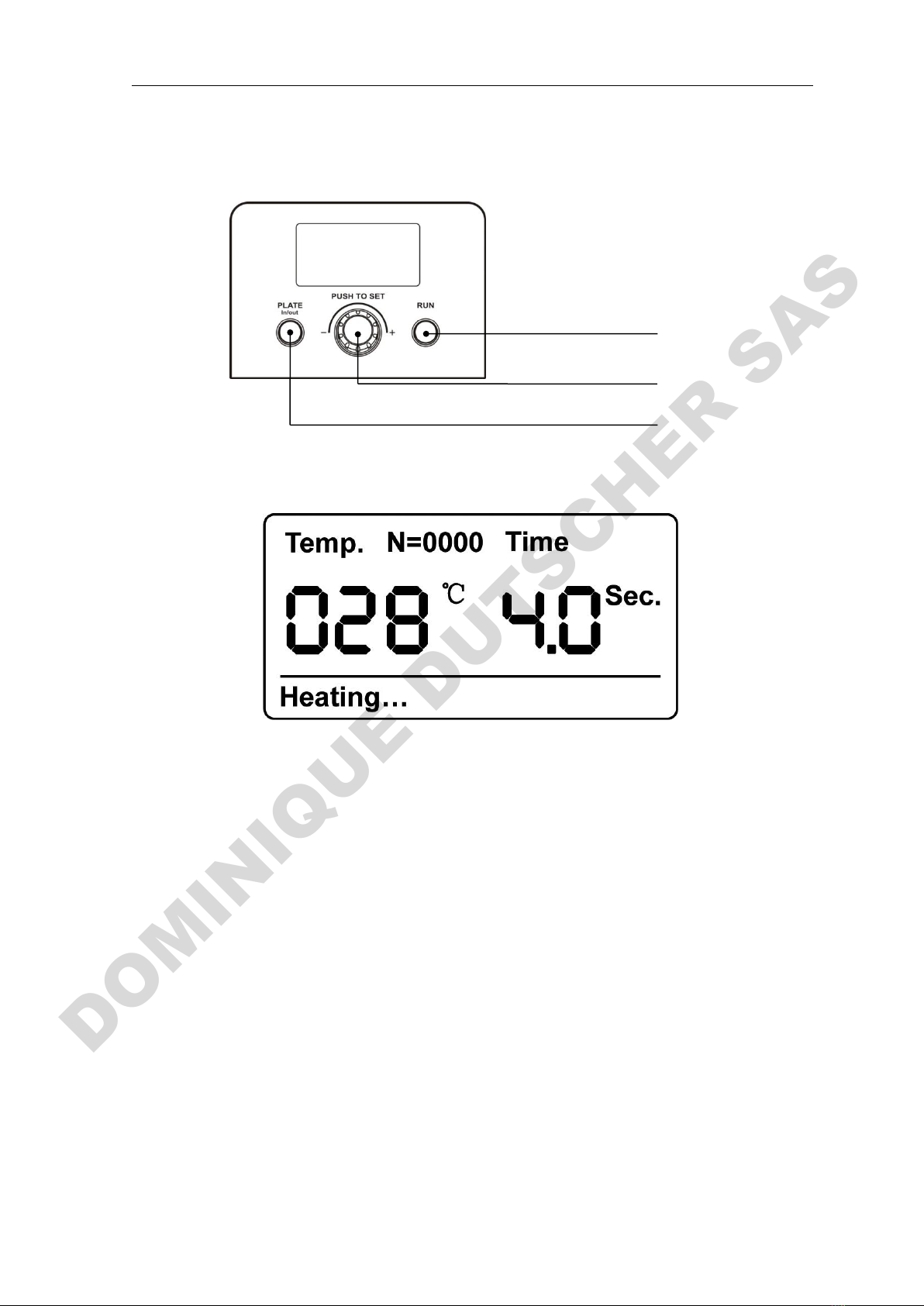

2. Operation panel

3. Display

Drawer Key

Seal Key

Setting Key

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 4 Operation Guide

─5─

Chapter 4 Operation Guide

1 Seal condition setting

1.1 Setting the seal temperature

Switch on the instrument. Then press the “PUSH TO SET” key for 3 seconds. When the display

of temperature is beginning to glitter, and turn the “PUSH TO SET” key to set the seal

temperature. Make counterclockwise rotation to lower temperature and clockwise rotation to

rise temperature. Temperature setting range is 80℃~200℃.

1.2 Setting the seal time

Press “PUSH TO SET” key again after temperature-setting. When display of time is beginning

to glitter, and turn the “PUSH TO SET” key to set seal time. Make counterclockwise rotation to

decrease time and clockwise rotation to add time. Time setting range is 0.5~10 seconds.

Remark: It will confirm the values automatic after 5 seconds.

1.3 Setting the pressure function

Remark: Adjust the pressure according to the seal quality (the trace in the plate after

seal). Turn to high pressure if the trace is light, or turn to low pressure if the trace is

much deep.

Long press “PUSH TO SET”, and press “PLATE In/Out” keys simultaneity for 3Sec. Enter into

the display of adjust pressure and turn the “PUSH TO SET” key to set seal pressure. Make

counterclockwise rotation to decrease pressure and clockwise rotation to add pressure. There

are 1~5 shifts for pressure adjustment. 1 is the lowest pressure and 5 is the highest pressure. 3

is factory default values.

It will confirm the set value automatic if no any action to instruments after 5 seconds.

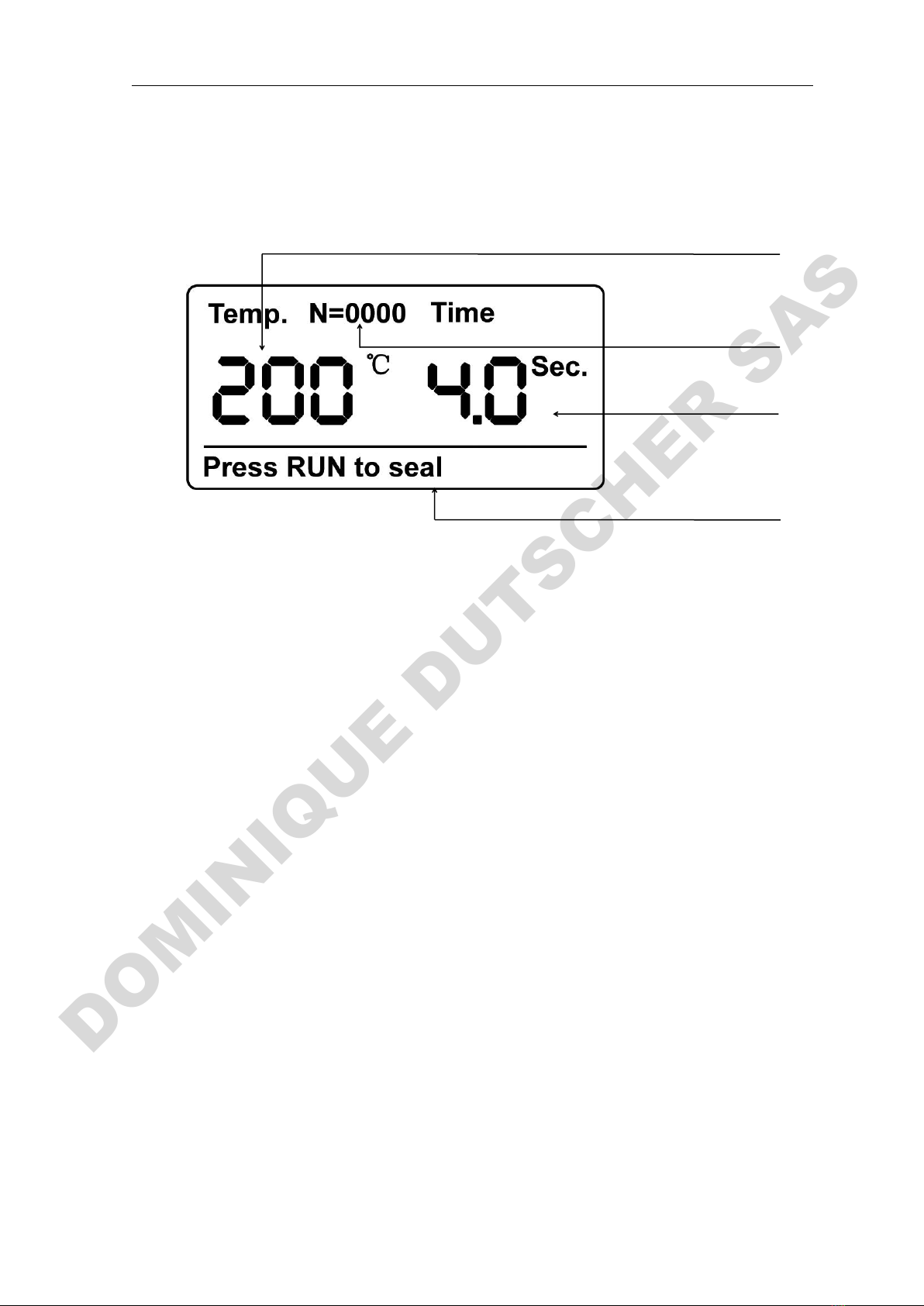

Temperature

Time

Status display

Counter

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 4 Operation Guide

─6─

Appendix: Normal seal temperature and time

No.

Item

Seal condition

setting

No.

Item

Seal condition

setting

1

Clear-Seal

170℃,2.5S

3

Pierce-Seal

180℃,4S

2

Peel-Seal

175℃,3S

4

Alfoil-Seal

180℃,4S

Above parameter just for reference, Sealing efficiency varies depending on the plate type used.

So users can adjust according to practical situation

2 Seal operation

After setting up the seal condition, seal operation as follows:

2.1 Press “PLATE In/Out” key, and pull the drawer, Then put in the standard plate adapter,

micro-plate and sealing film and the weighted sealing flake in turn.

2.2 There is “du…” sound after the temperature reached setting temperature. Press “RUN” key,

make the drawer shut up and start to seal. And the drawer will go out of automatic after finished

the seal. Then the unit can do the seal again.

weighted sealing flake

Mircoplate and sealing film

Standard plate adapter

Drawer

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 4 Operation Guide

─7─

Note: If the display temperature isn’t reach the setting temperature. The instruments

cannot seal after press the “RUN” key.

2.3 After finish the seal work, press the “PLATE In/Out” key, make the drawer shut up, then

power off the switch on the back of the unit.

3 Heating plate cleaning

3.1 If there is residue of seal film or seal plate adhere to heater plate caused by misuse, and

affect the instrument normal use, then should clean the surface of heating plate according to

following step.

3.2 Press “PLATE In/Out” key, make the drawer out, switch of the power and pull out the

power plug.

3.3 Press the key in the left side of the drawer which the arrow point in the under picture, and

pull out the drawer outward.

3.4 Clean the residue with tissue after the temperature near to ambient temperature on the

surface of heater plate.

Note: Any hard tools scraping the surface of heater plate is forbidden, that would be

damage the heater plate and affect the seal result.

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi Automated Plate Sealer Operation Manual Chapter 4 Operation Guide

─8─

3.5 Pushing the drawer which aim the slide on the both side into the deepest position slowly

after clean up.

4 Other function

4.1 No plate alarming

When the unit is running, if no plate in the unit, it will display “No plate” and alarming.

4.2 Stand-by mode

The unit will into “stand-by” mode if there is no action on instrument more the 60 minutes and

temperature will down to 60 ℃. By press any button to warm up the unit back to setting

temperature.

The unit will into “Power-down” mode if there is no action on instrument more than 120 minutes.

Display screen will turn off, power off heater supply and only a weak current supply to the main

part of control board. By press any button to warm up the unit back to setting temperature.

4.3 Power-off protection

When there is a sudden power lost during the unit running, the motor will stop. Under this

condition, moving part adjustment is forbidden. It will be automatic reset when power on again

next time.

4.4 Automatic counting function

The counter automatic increase one for sealing work once. Press the “PUSH TO SET” key for

10 seconds, the counter can reset (it will be zero).

Heater plate

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi-Automatic Microplate Heat Sealer Operation Manual Chapter 5 Troubleshooting Guide

─9─

Chapter 5 Troubleshooting Guide

Problems and actions

No.

Common problem

Possible cause

Action(s)

1

No display after power on

No power

Check power supply and

plugged properly

On/Off switch broken

Change switch

The fuse is broken

Change fuse(5X20 250V 3 A)

Others

Contact the supplier

2

Display “Err001” and alarm

“Du…” sound

Over-temperature

Contact the supplier

3

Display “Err005”, “Err006”,

and alarm “Du…” sound

Open or short circuit of

temperature sensor

Contact the supplier

4

Display “Err601” and alarm

“Du…” sound

Motor locked

Contact the supplier

5

Display “Err405” and alarm

“Du…” sound

The upper micro-switch

is broken

Contact the supplier

6

Display “Err412”

The below photo electric

switch is broken

Contact the supplier

7

Display “Err411”

The upper photo electric

switch is broken

Contact the supplier

8

Display “Err402”

The out photo electric

switch is broken

Contact the supplier

9

Display “Err401” and alarm

“Du…” sound

The enter-photo electric

switch is broken

Contact the supplier

10

“No plate“ displayed,

alarming “Du…”

No microplate or not

place it well

Replace the microplate

11

Instrument cannot run

Controll-board is broken

Contact the supplier

Motor is broken

12

Abnormal running noise

Wrong guide rail

installed

Contact the supplier

13

Buttons don’t work

Plug connector loose

Contact the supplier

Button broken

DOMINIQUE DUTSCHER SAS

SealBio-2 Semi-Automatic Microplate Heat Sealer Operation Manual Annex

─10 ─

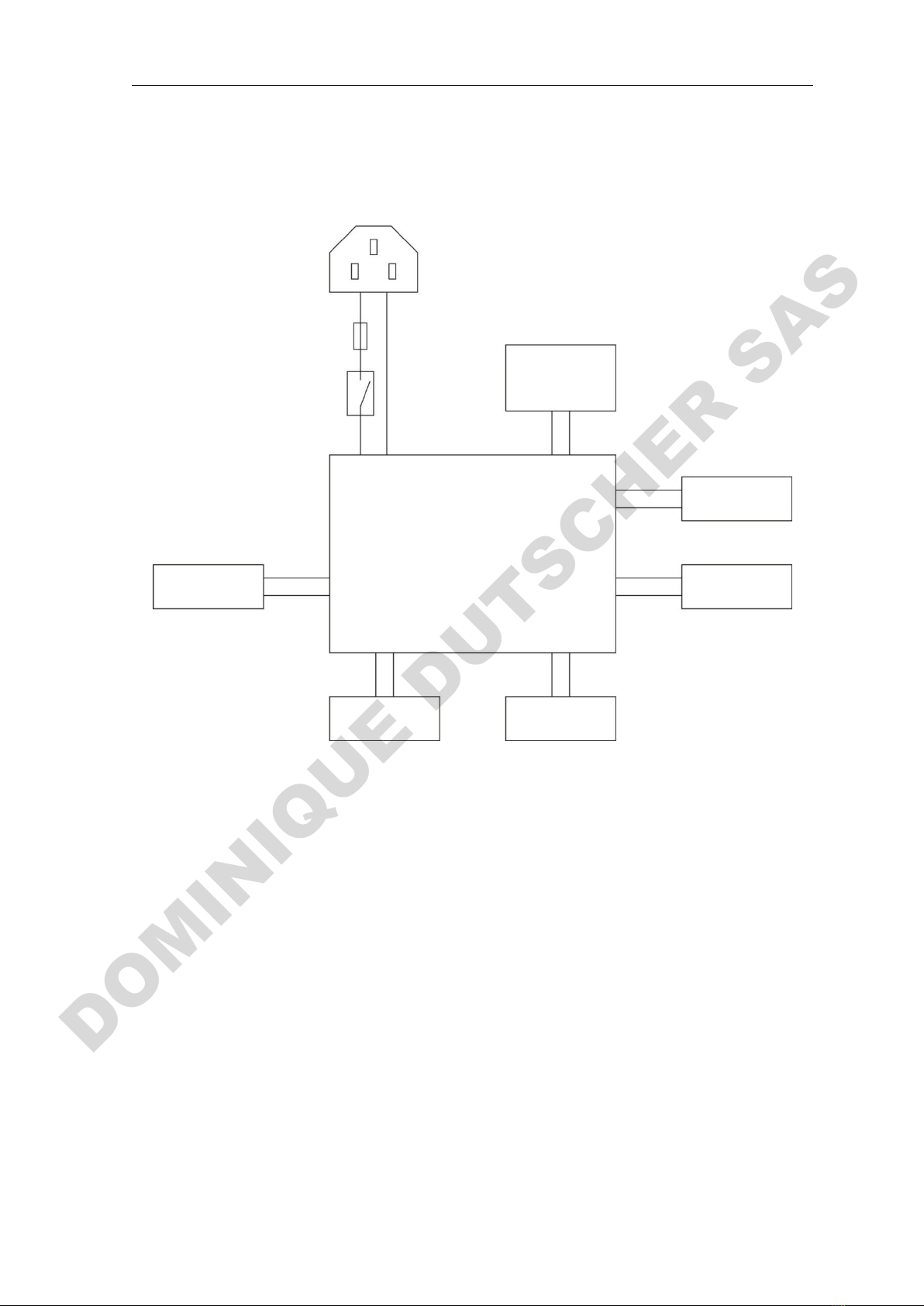

Annex:Wiring Diagram

(

for reference only, users won’t be informed if there is modification for this diagram

)

Control Board

Power Switch

Input Power

AC 200~240V,50Hz/60Hz

Fuse

250V 3A Φ5X20

Position Sensor

Display Board

Heater

X Motor

Y Motor

Temperature Sensor

DOMINIQUE DUTSCHER SAS

─11 ─

Note

DOMINIQUE DUTSCHER SAS

Table of contents