Floeter AirBoy Nano3 User manual

nano3 - OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

1

Contents

Contents 1

Safety guidelines 2

Air cushion types 3

Machine overview 4

Technical data 4

Buttons introduction 5

Accessories 5

Operating device 6

Operating setting details 9

Parameter setting guidance 10

Maintenance Notes 11

Consumables and abrasion accessories declaration 15

Failure Code 16

Options and expandability 19

Support and Service 20

Document version 27.11.2018

OPERATING INSTRUCTIONS

2

Safety guidelines

Please read the safety guidelines and operating instructions closely before using the

machine.

- Turn off the machine and disconnect power before opening the machine or performing

any repair or maintenance work on the machine.

- Switch off the machine if it will not be used for an extended period of time.

- Do not insert any objects into the machine when it is connected to power.

- To prevent the risk of electric shock, ensure that the machine does not come into contact

with liquids.

- Do not operate the machine without the covers for the machine components.

- Keep hair and loose clothing away from the film feed mechanism.

- Place the machine only on surfaces that are adequately large, stable, flat, and horizontal.

This machine is designed for safe operation in compliance with the use, instructions, and

guidelines specified in these operating instruction.

All persons who use this machine must be familiar with the content of

these operating instructions and must carefully follow the safety

guidelines.

FLOETER shall not be responsible for damage resulting from improper use of the machine

or non-observance of the safety guidelines.

OPERATING INSTRUCTIONS

3

Air cushion types

Our standard version – Polyethylene 20 µm or Bio (home-compostable)

Type 7.1 AirWave air cushion filler 100 x 210 mm

Ideal for filling small voids and for use as an intermediate layer

Type 8.3 AirWave wrapper 420mm 4 chambers

4 chambers for use as an intermediate layer, wrapping, and

envelope

OPERATING INSTRUCTIONS

4

Machine overview

1. AC power cable

2. Power switch

3. Control panel

4. Feeding roller

5. Tension column A

6. Tension column B

7. Roll film tension

8. Air nozzle

9. Protecting cover A

10. Protecting cover B

11. Puller A

12. Sealing wheel B

13. Conveyor wheels C/D

14. High temperature belt

15. Knife/Blade

Technical data

Power supply: AC100-240V 1.6A 50/60Hz

Power consumption: 60 W

Production speed: 4 m / min

Weight: 2,5 kg

Dimensions (l / w / h): 430 / 190 / 195 mm

OPERATING INSTRUCTIONS

5

Buttons introduction

1. Temperature "+" 01~30 level

2. Temperature "-" 30~01 level

3. Air Volume "+" 01~40 level

4. Air Volume "-" 01~40 level

5. Start / Enter Film (press long time)

6. Pause / Adjust time (press long time)

Accessories

Name

Quantity

nano3 Machine

1

AC power plug

1

User manual

1

Knives / Blades

2

Spare belts

2

Pins

4

OPERATING INSTRUCTIONS

6

Operating device

1. Turn on the power switch

Connect the power cable and turn on the power switch

2. Load in the air cushion film

Load the film roll into the feeding roller and pass the film through with the air

channel side down, pull film in from the right side of tension column A,

then pull out from the middle of guide tension column B and roll film tension.

OPERATING INSTRUCTIONS

7

Pull out from the middle of guide tension column B and roll film tension

3. Feeding the film onto the air nozzle

Open the air channel and put film into air nozzle to pass through the air channel

until the film is 1cm behind the wheels.

OPERATING INSTRUCTIONS

8

4. Start film

Press the “start” button to start the feeding of the film and check the air volume

and the sealing result. Adjust the temperature and air volume according to the

desired results. Once the sealing result and volumes are perfect, you can preset

working time and enter automatic working mode.

According to the actual conditions (different types of film, different environment

temperature) adjust the temperature and air volume, and then press the

“START/IN(OUT)” button to start enter film.

5. Pause

The machine will stop automatically after running for the preset time, or you can

manually press “STOP” button to stop working when the machine running.

OPERATING INSTRUCTIONS

9

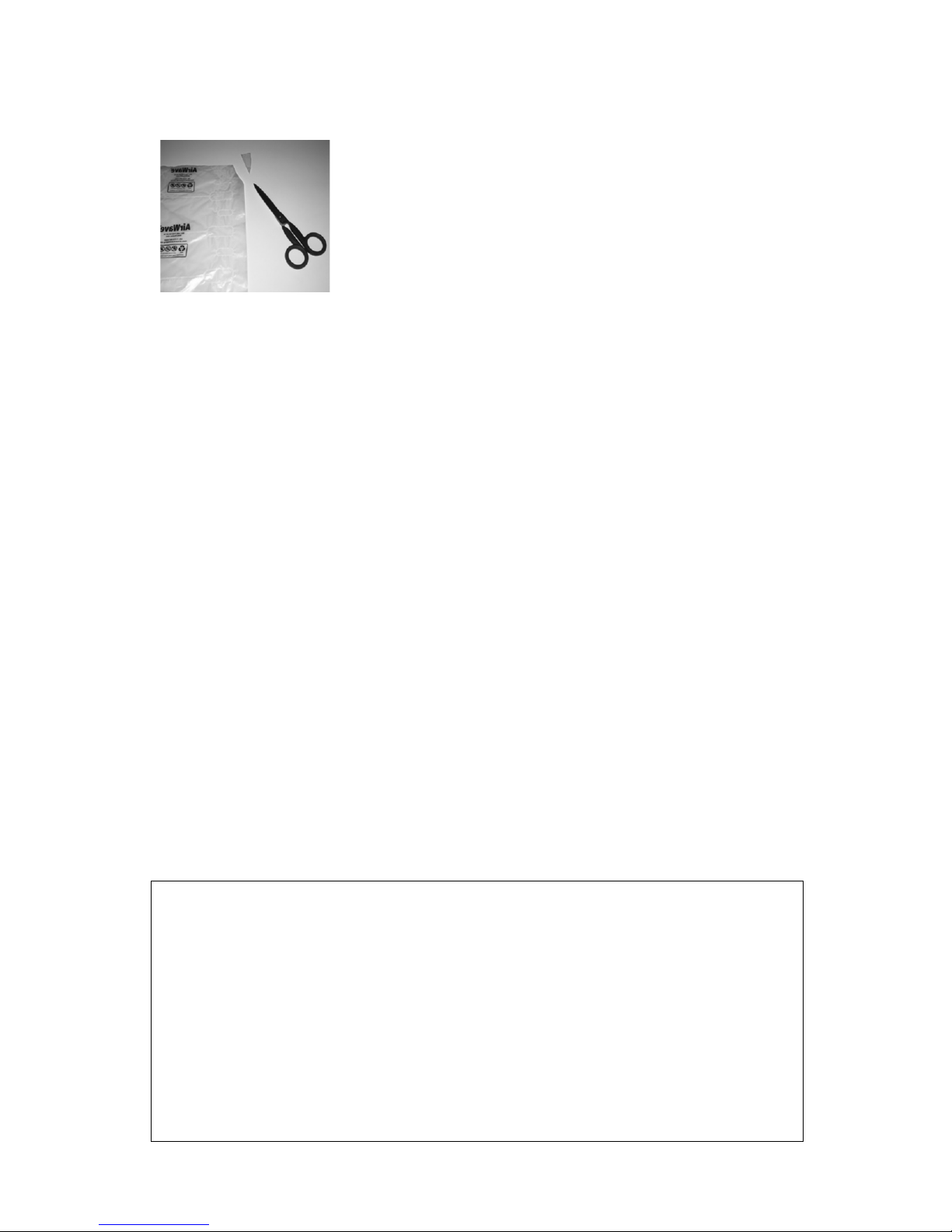

The corner of the film can be cut at an angle to

make it easier to fit the film over the air nozzle.

Operating setting details

1. Temperature setting is on the left side of panel.

Pressing the “+” button increases the temperature; pressing the “-” button

decreases.

There are 1-30 levels.

Press one time means increase or decrease 1 level. Continuous pressing rapidly

increases or decreases. (Please decrease if there are holes in the sealing bags;

please increase if sealing is not very strong)

2. Air volume setting is on the right side of panel.

Pressing the “+” button increases the air volume; pressing the “-” button

decreases. There are 1-40 levels.

Press one time means increase or decrease 1 level. (Please decrease the air

volume if there is air in the film on the left side of film tension)

3. Working time presetting:

Long press the “STOP” button to enter the run time preset mode (00:01~02:00),

the temperature “+” and “-” buttons refer to hours; the air volume “+” and “-

”buttons refer to minutes.

Please press the “STOP” button to save and exit the data.

1. Before presetting run time, please estimate the rest length of film to avoid the

long-time racing and cause the machine breaking.

A whole roll film (300 meter) needs 1 hour and 20 minutes; half roll film can

preset 30 minutes running time; less half roll film can preset 10~20 minutes.

2. The working time only be set up in advance and can not be changed while the

machine in working mode. But the air volume and temperature can be

changed anytime.

3. Users can adjust the parameter according to different required; it will save the

used parameter when each power off.

OPERATING INSTRUCTIONS

10

Parameter setting guidance

Temperature Value Setting:

1. Depending on the workplace temperature

If the workplace temperature is around 30ºC and the AirWave Standard film with

a thickness of 20μm is in use, then the reference temperature is: T=14.

AirWave Standard film (20µm): T=14

AirWave Bio film (20µm): T=10

2. If the workplace temperature is colder, you may need to slightly increase the

temperature value; if the workplace temperature is hotter, need to slightly lower

the temperature value correspondingly. The reference is around 1 level/5 ºC.

3. If roll film is thicker, the temperature value should be slightly increased

correspondingly. The reference value is around 2-3 level/5μm.

4. The temperature value should be set up correspondingly according to different

materials of film. The reference temperature value as above are based on the

standard air cushion films. The temperature value need to be adjusted again if

you use other air cushion films.

5. If the air cushion machine has operated more than 2 hours, we suggest that you

slightly lower 1 level, because continuous working will accumulate heat.

OPERATING INSTRUCTIONS

11

Air volume setting

Specification of film

AirWave type 7.1 - 210x100mm

AirWave type 8.3 - 420mm

Reference data

10

40

1. The reference air volumes as above are for the air cushion films with the

thickness of 20µm.

2. Correct air value will give better seal performance.

3. If the air volume is too high, it will hardly change the fill level, but it will cause

more wrinkles in the seal and impact on the air-tightness.

Maintenance Notes

Please regularly check the working status of machine and timely remove any buildup or

residue which can be left in the conveyor wheels.

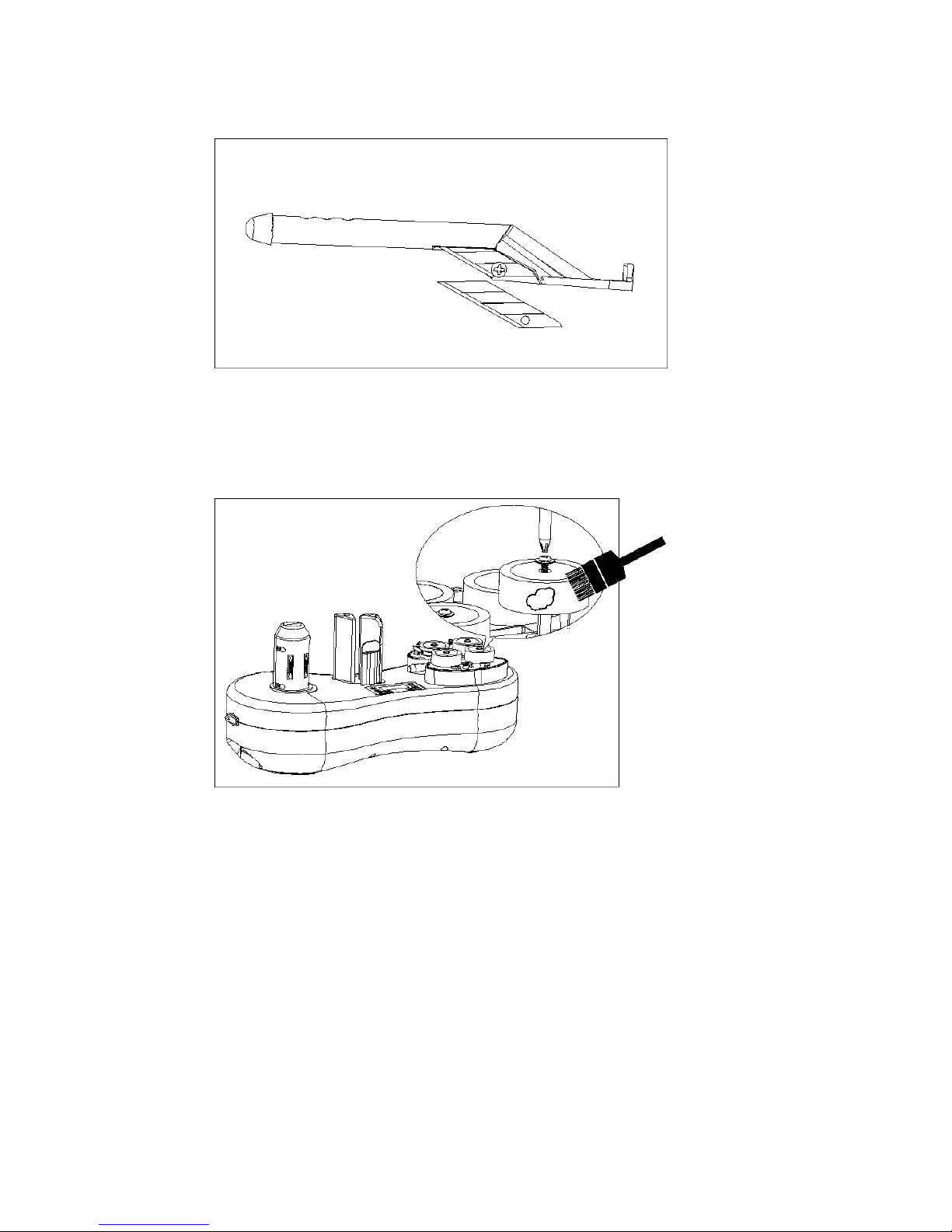

•Replace the blade

Please replace the blade if the film bunchs up on the blade or when the cut is

seriously uneven.

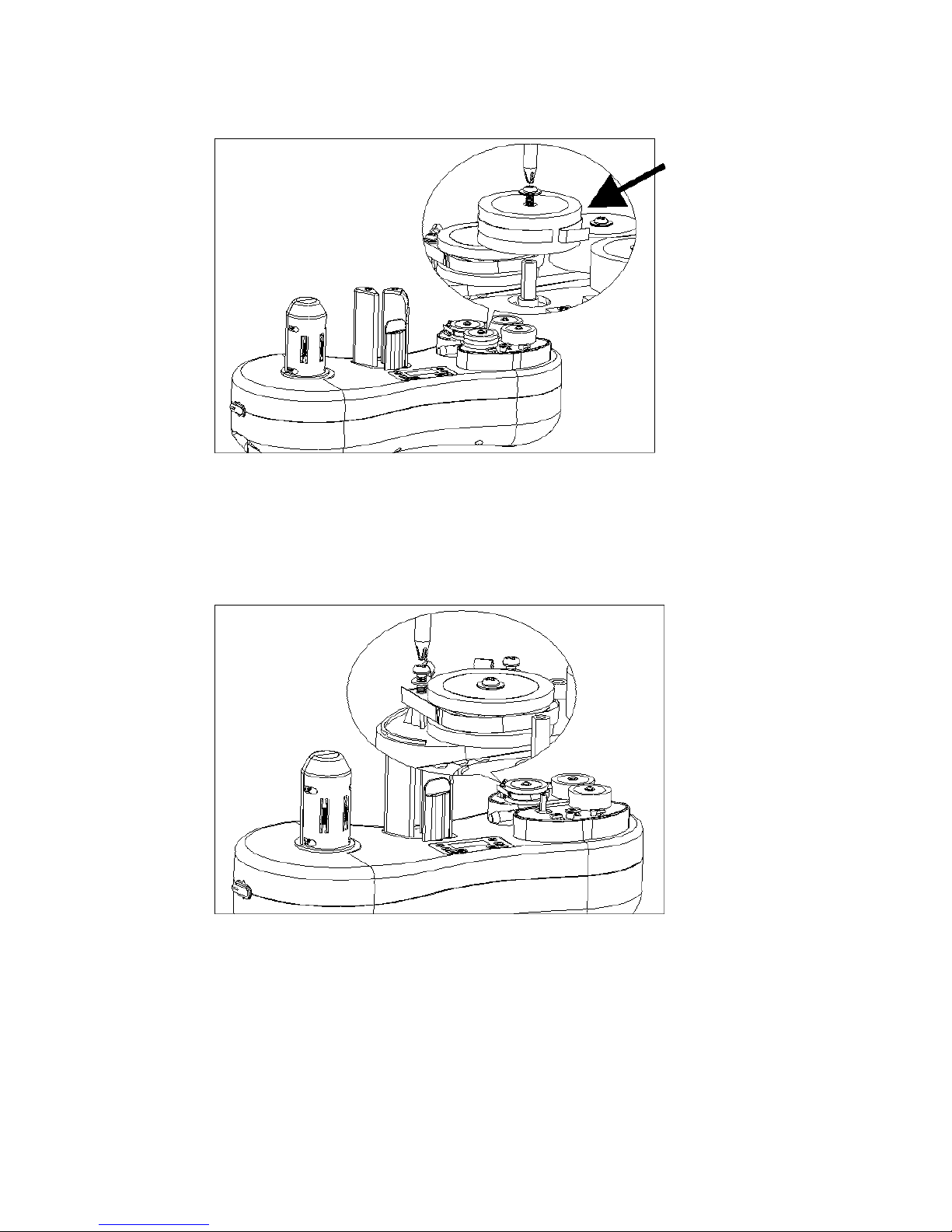

Using the screwdriver unscrew the screws of blade carrier

OPERATING INSTRUCTIONS

12

Using the screwdriver unscrew the screws of blade and change them.

•Wheels clearance

The sealing quality will be effected if there are residue of air cushion film in the

conveyor wheels, please clean them regularly.

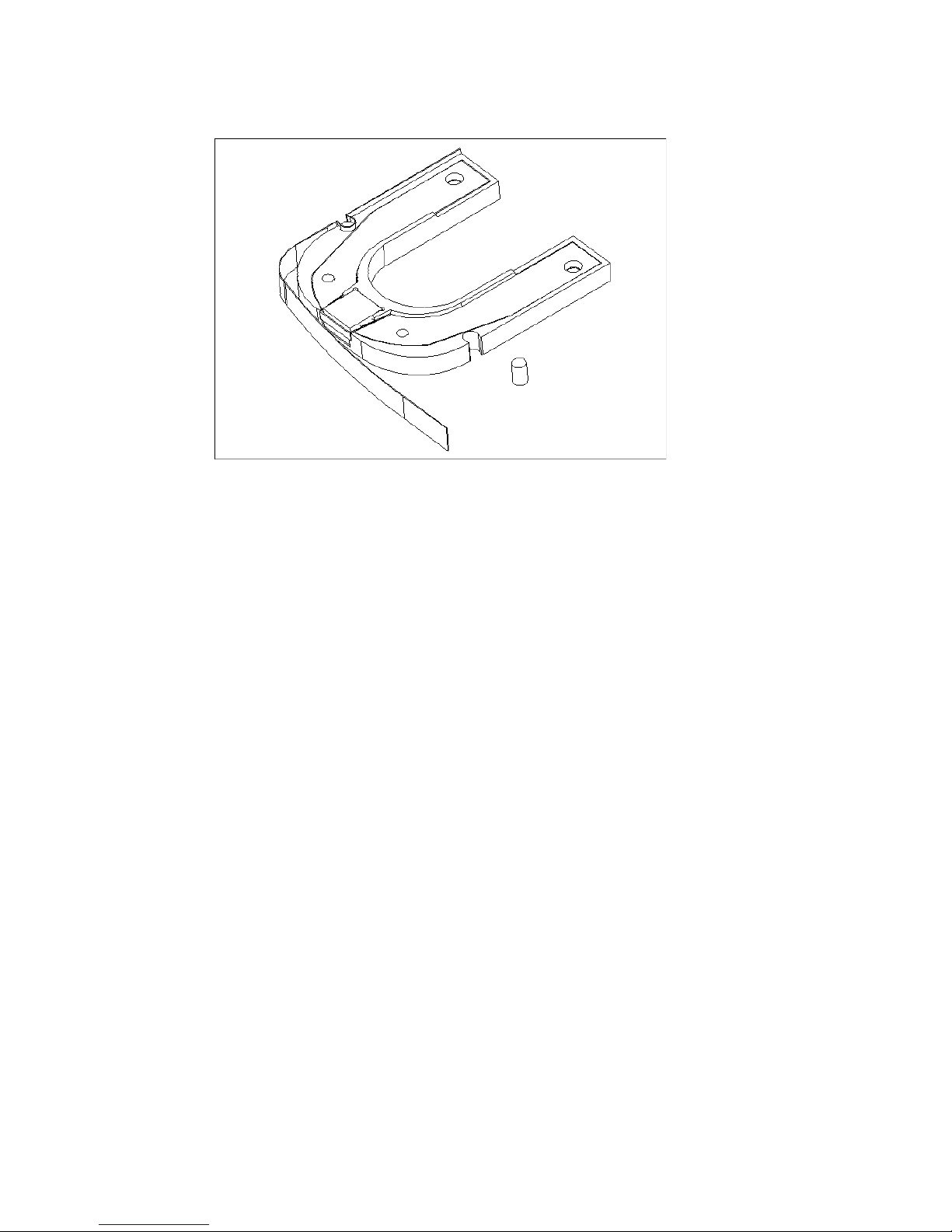

•Sealing wheels abrasion

The middle round of the sealing wheels is easily roughened. The sealing quality

can be effected if there are serious abrasions.

OPERATING INSTRUCTIONS

13

Tear off the sealing belt in the middle of sealing wheels and replace it.

•High temperature belt abrasion

Please replace the high temperature belt when there are abrasions, the heating

unit, the conveyor wheels and the sealing wheels will fail if the high temperature

belt is worn and not replaced.

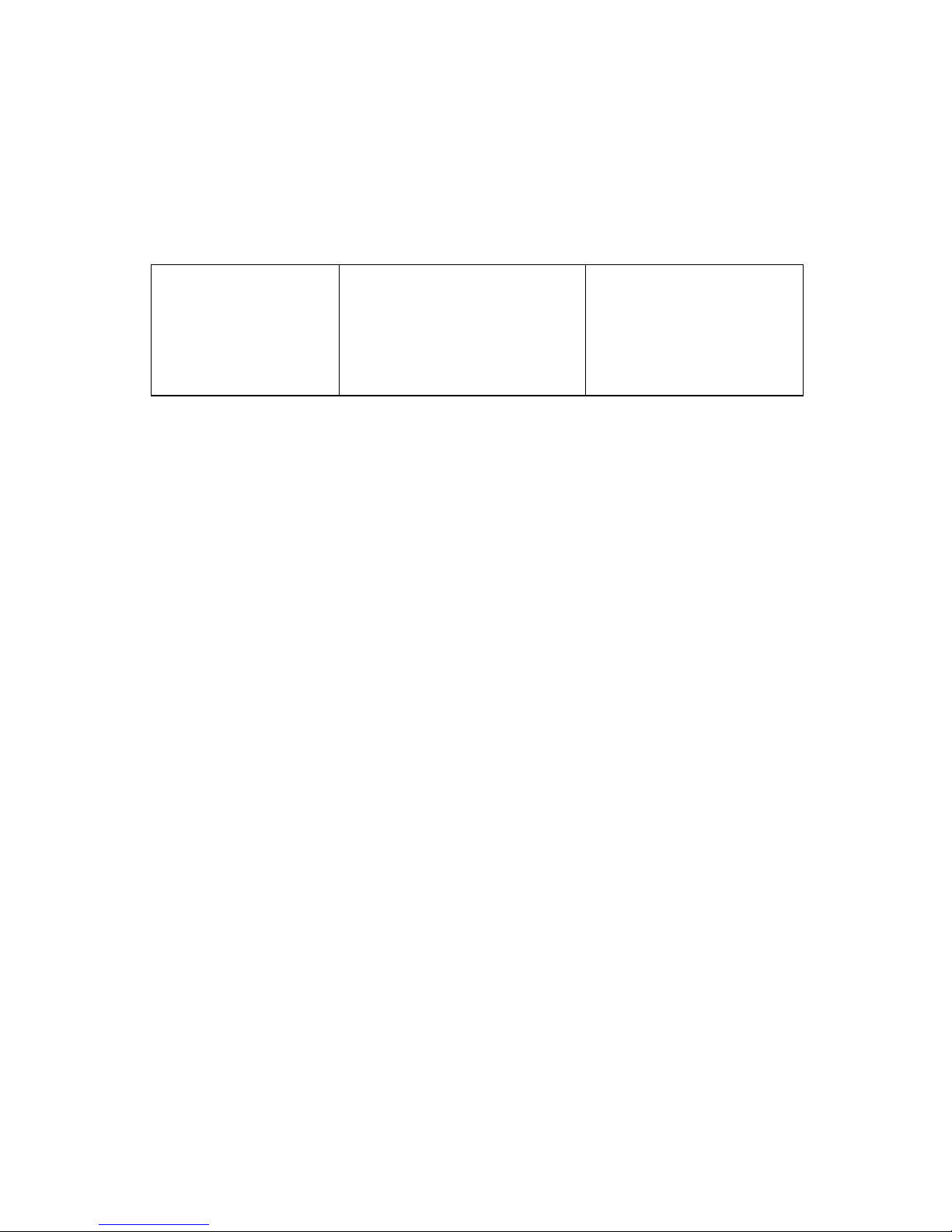

Remove the roller and take out the “U-type” high temperature module.

OPERATING INSTRUCTIONS

14

Take out the colloidal pins in the two side of high temperature module and

replace the high temperature belt

OPERATING INSTRUCTIONS

15

Consumables and abrasion accessories declaration

The knife and Teflon bands are abrasion accessories and need to be changed after

continuous use of the machine.

Wearing parts

Knife / Blade

High temperature belt

Pins

Conveyor Wheel A

Heating piece

Heating piece fixation module

2

2

4

1

1

1

OPERATING INSTRUCTIONS

16

Failure Code

Each time the power supply of this device is turned on, the device will do the self-testing.

At that time the motor will drive the conveyor wheel to complete the self-testing. Please

contact with our customer service center and we will solve these problem as soon as

possible.

A. Warning Hot - Heating module for sealing failure

Turn on the power switch of device, the screen is completely blank and the

device does not have any action (air blower and conveyor wheels). Please check

whether the cable has connected with power and please check the adapter

B. Warning Air - Air blowing module failure

If the air come to the left side of Roll film tension or the film is frequently being

pulled off, please check the air volume value and lower the value appropriately

OPERATING INSTRUCTIONS

17

C. Warning Mot - Air blowing module failure

If the film is not being sealed very well or the film is perforated please check the

temperature value and adjust appropriately. If it is not working, please check

whether the high temperature and sealing wheel B are scuffed.

FAQ

A. Turn on the power switch of device, the screen is completely blank and the

device does not have any action (air blower and conveyor wheels). Please replug

the cable to the machine and the power outlet.

B. If the air is on left side of Roll film tension or the film is frequently being pulled

off, please check the air volume value and lower the value appropriately

C. If the film is not sealing very well or the film seal is perforated please check the

temperature value and adjust appropriately. If it is not working, please check

whether the high temperature and sealing wheel B are scuffed

OPERATING INSTRUCTIONS

18

Common failure and solutions

Item

Failure

phenomenon

Reason analysis

Solution

1

Air leakage

Temperature

value is too low

Increase

temperature

value

2

Sealing is wide

and thin

Temperature

value is too high

Lower

temperature

value

3

Under-inflation

Air volume value

is too low

Increase air

volume value

4

During operation,

the foil is

jamming the

heating area.

The device has

working more

than 30minutes,

the body

temperature of

device increased.

Turn off the

device after

pulling the film

5cm away from

the device to

remove the film.

OPERATING INSTRUCTIONS

19

Options and expandability

Please contact your sales advisor for further information.

Rolling container

always brings your air cushions to the ergonomically correct

working height. Locally flexible.

Mobile table solution

Bring your machine to the ideal working height.

(compatible with Docking station)

Docking station

For a decentralized consumption with mobile rolling

container completely independent of machine position.

Roll trough

For an easy storage of endless rolled sheets in optimum

height

Contact:

FLOETER Verpackungs-Service GmbH

Robert-Bosch-Str. 17

71701 Schwieberdingen

Germany

tel: 0800 FLOETER (free within Germany)

e-mail: [email protected]

tel: +49 (0) 71 50 / 923 96-0

Table of contents