Contents

Contents

1 General guidelines ...............................................................................................................................................................5

Symbols used ......................................................................................................................................................................5

Formatting rules...................................................................................................................................................................5

Disposal...............................................................................................................................................................................5

2 Safety.....................................................................................................................................................................................6

3 Description of the device.....................................................................................................................................................7

Intended use........................................................................................................................................................................7

Scope of delivery .................................................................................................................................................................7

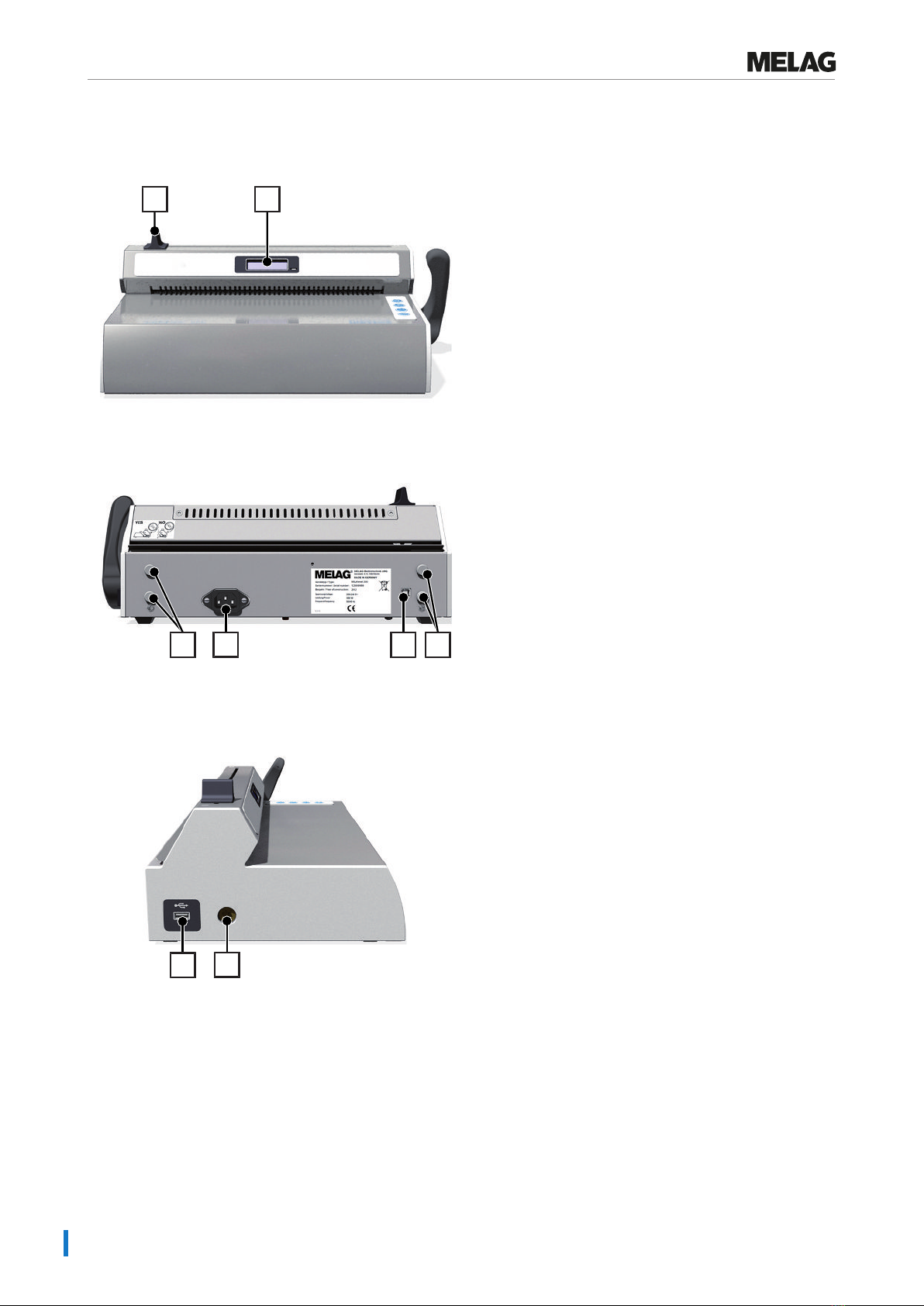

Views of the device..............................................................................................................................................................8

Symbols on the device.........................................................................................................................................................9

Menu structure...................................................................................................................................................................10

Status display and acoustic signals...................................................................................................................................11

4 Commissioning...................................................................................................................................................................12

Requirements of the installation location...........................................................................................................................12

Space requirements...........................................................................................................................................................12

Connecting the sealing device...........................................................................................................................................13

Switching on the sealing device.........................................................................................................................................13

5 Sealing.................................................................................................................................................................................14

Sealing procedure with pre-finished film pouches .............................................................................................................14

Sealing procedure for film reels.........................................................................................................................................15

6 Logging ...............................................................................................................................................................................18

Documenting the sealing process......................................................................................................................................18

Using the USB flash drive as an output medium ...............................................................................................................18

Computer as output medium .............................................................................................................................................19

Structure of the log files.....................................................................................................................................................19

7 Function checks .................................................................................................................................................................21

Function check with MELAcontrol Seal Check ..................................................................................................................21

8 Settings ...............................................................................................................................................................................23

Access settings menu........................................................................................................................................................23

Time...................................................................................................................................................................................23

Date ...................................................................................................................................................................................24

Sealing temperature ..........................................................................................................................................................24

Signal tones.......................................................................................................................................................................25

User administration............................................................................................................................................................25

Eco Mode and Standby .....................................................................................................................................................26

Force calibration ................................................................................................................................................................27

9 Maintenance........................................................................................................................................................................28

Cleaning and regular checks .............................................................................................................................................28

Maintenance ......................................................................................................................................................................28

Validation...........................................................................................................................................................................28

Software update.................................................................................................................................................................28