The distances shown in the MAXIMUM column should never be

exceeded. For distances greater than 3200', it is recommended that

your local utility be contacted to install a service feeder for the

installation.

Wiring from external controls such as guard shack, telephone entry,

keypad or card reader systems should be brought to the operator by a

conduit separate from the 115 VAC electrical hookup. Low voltage

control wires MUST NEVER be routed in the same conduit as A.C.

power wires. ALWAYS CONSULT AND FOLLOW ALL LOCAL

ELECTRICAL CODES.

PLACING THE VEHICLE DETECTOR LOOPS

Proper placement of vehicle detector wire loops is critical if the loops

are to provide satisfactory, extended service. The most important

considerations are: 1) Proper wire type and, 2) Good, tight connections

from the loop to the loop terminating connector. When a "Stand

Alone" vehicle detector is used, the detection loop is connected to the

wire harness on the detector itself. (See WIRING VEHICLE

DETECTORS, Page 14.)

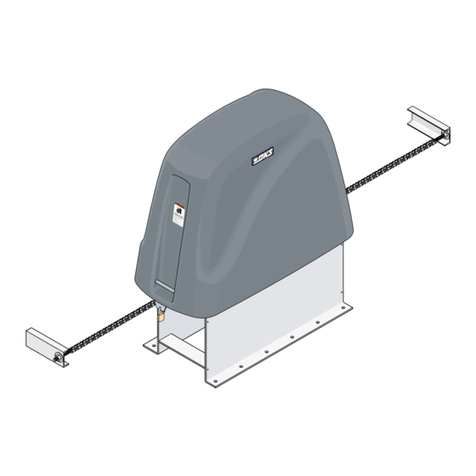

The RSX1000 provides for connecting the output of two loop systems:

1) A “reversing” loop that will prevent the gate from closing on a

vehicle that has stopped in the path of the gate and 2) A “free exit” loop

that will open the gate by detecting a vehicle which is inside the gated

area and wishes to leave. If “free exit” detection is not desired, this

loop will not be needed. Note the "reversing” loop is normally made up

of two independent loop layouts connected to one detector. See Figure

8.

Two different types of installations will usually be encountered: 1) If

the driveway material is already in place, saw cuts will be needed to

accommodate the loop wires.

2) For loops where the paving material will be installed after the loop is

positioned, it is necessary that the loop wires be placed in Schedule 40

PVC pipe to maintain uniform loop spacing with respect to the surface

of the pavement. The loop should be placed 1.5 inches below the

surface of the pavement and at least 2" above any reinforcing steel The

lead in wires need not be in PVC, but must have at least six (6) twists

per running foot.

For a saw-cut installation, observe the method recommended in Figure

9 for the corners. When installing a two-loop reversing system it is best

to bring the twisted lead wires from each loop to the operator so that the

loops may be properly phased. The saw cut must be to a depth of 1.5

inches, clean and with no sharp corners. After placing the wires, it is

essential that the wires be held tightly in place by the foam backing and

that no voids exist that can collect water which might freeze and push

the loop wires out of the slot. The sealant used should match the

paving material and should not be hard setting. The lead in wires must

have at least six (6) twists per foot.

NO SPLICES ARE ALLOWED IN THE LOOP OR THE LEAD IN

WIRE TO THE FIRST JUNCTION BOX Above ground splices may

be used providing the wire is twisted, soldered and moisture sealed.

For best long term results, do not use wire nuts anywhere in the loop

system. For connections to the loop detector, gas tight crimp type

terminals should be used, and soldered if possible.

THE WIRE USED FOR THE LOOPS MUST BE HEAT AND

WATER RESISTANT. CROSS-LINK POLYETHYLENE

INSULATED, TYPE XLPE OR RHW IS BEST. U.S.E. IS ALSO

SATISFACTORY. DO NOT USE PVC

INSULATED WIRE. WIRE SIZE SHOULD

BE #16 GA STRANDED OR LARGER.