1.2 WHAT IS INCLUDED WITH THE ELSD 2000

The ELSD 2000 shipping container should contain the

following:

• ELSD 2000 Detector

• Operating Manual

• Power Cord

• Signal Cable

• Tools:

Open-End Wrench, 3/8'' x 7/16''

Open-End Wrench, 1/4'' x 5/16''

Hex Ball Driver, 3/32'' (long)

Hex Ball Driver, 3/32'' (short)

Drift Tube Cleaning Brush

• Replacement Fuses:

3A and 6A (1 ea.)

• Flex Connect PEEK Tubing, 6'' x 0.005'' ID

• Nebulizer Gas Supply Line:

Teflon® Tubing, 50' x 1/8'' ID

1/8'' Parker Brass Nut and Ferrule*

• Drain Collection Materials:

Tygon®Drain Tubing, 4' x 3/8'' OD

Drain Waste Bottle with Lid, 500mL

3/8'' Parker Stainless Steel Nut and Teflon® Ferrule*

• Exhaust Trap Kit:

Exhaust Tubing

Collection Flask with Stopper, 500mL

Exhaust Elbow

Lead Ring

• ELSD 2000 PC Control Software**

CD-ROM

RS-232 Cable

Operating Manual

* The detector is shipped with these parts attached to their

respective ports.

**NOTE: The ELSD 2000 Detector must contain a

compatible EPROM chip to be functional with

the PC control software. Consult the

ELSD 2000 Control Software Manual for

further details.

Refer to Section 6.2, Replacement Parts, for part numbers if

replacement parts are needed.

1. INTRODUCTION

1.1 ABOUT THE ELSD 2000

The Alltech ELSD 2000 (Evaporative Light Scattering

Detector) is designed for use with High Performance Liquid

Chromatography (HPLC) systems to analyze any compound

that has sufficiently lower volatility than the mobile phase.

Some of its possible application areas include the analysis of

carbohydrates, pharmaceuticals, lipids, triglycerides,

underivitized fatty and amino acids, polymers, surfactants,

nutraceuticals, and combinatorial libraries.

Evaporative light scattering detection eliminates the common

problems associated with other HPLC detectors. RI detection

can be complicated by solvent front interferences, baseline

instability due to extreme temperature sensitivity, and

incompatibility with gradients. RI can also have a less

sensitive response than ELSD’s. Low-wavelength UV can

suffer baseline drift when using steep gradients and also

requires that the analyte have a chromophore. The ELSD is

not plagued by these limitations. Unlike these other detectors,

the ELSD can achieve stable baselines with multisolvent

gradients for improved resolution and faster separations.

Also, since the ELSD response does not depend on the

sample’s optical characteristics, the sample does not require

a chromophore or fluorophore for detection.

The ELSD 2000 offers the most advanced evaporative light

scattering detection technology available. The nebulizer has

been redesigned for increased ruggedness. Digital gas flow

control allows you to adjust flowrate directly from the front

panel or remotely via PC. You now have the option to select

from two modes of operation: Impactor ‘On’ and Impactor

‘Off’. Impactor ‘Off’ mode is ideal for analyzing non-volatile

compounds with highly organic mobile phases or with highly

aqueous/low flowrate (1.0mL/min or less) mobile phases.

This mode maximizes sensitivity for these applications by

sending the entire sample stream to the optical cell for

detection. Impactor ‘On’ mode is best for analyzing non-

volatile compounds with higher flowrate or highly aqueous

mobile phases (up to 5.0mL/min, including steep gradients),

and for analyzing semi-volatile compounds. In Impactor ‘On’

mode, larger droplets in the aerosol are removed, so optimum

mobile phase evaporation can be obtained at significantly

lower drift tube temperatures. Only the ELSD 2000 offers

dual-mode operation, which allows you to maximize sensitivity

and baseline stability for all possible mobile phases and

analytes.

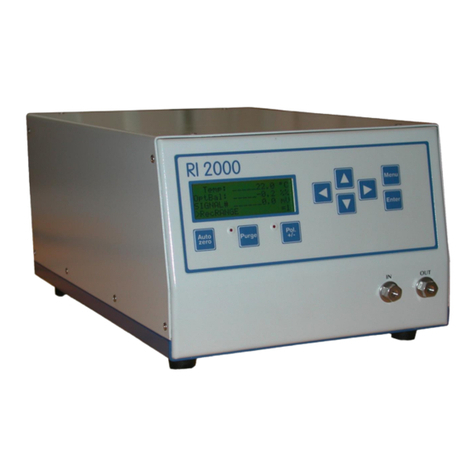

Several instrument control options are available for the ELSD

2000. Instrument parameters can be displayed and controlled

directly through the front panel using membrane-based screen

keys and a numeric keypad. Built-in software provides an

intuitive series of screens for storing and editing up to ten

methods; configuring audio alarm, fault relay, and full-scale

voltage settings; and performing diagnostic tests and

troubleshooting functions. The ELSD 2000 can also be PC

controlled using the software included with the unit or

AllChrom™Plus software (sold separately, contact Alltech for

details).