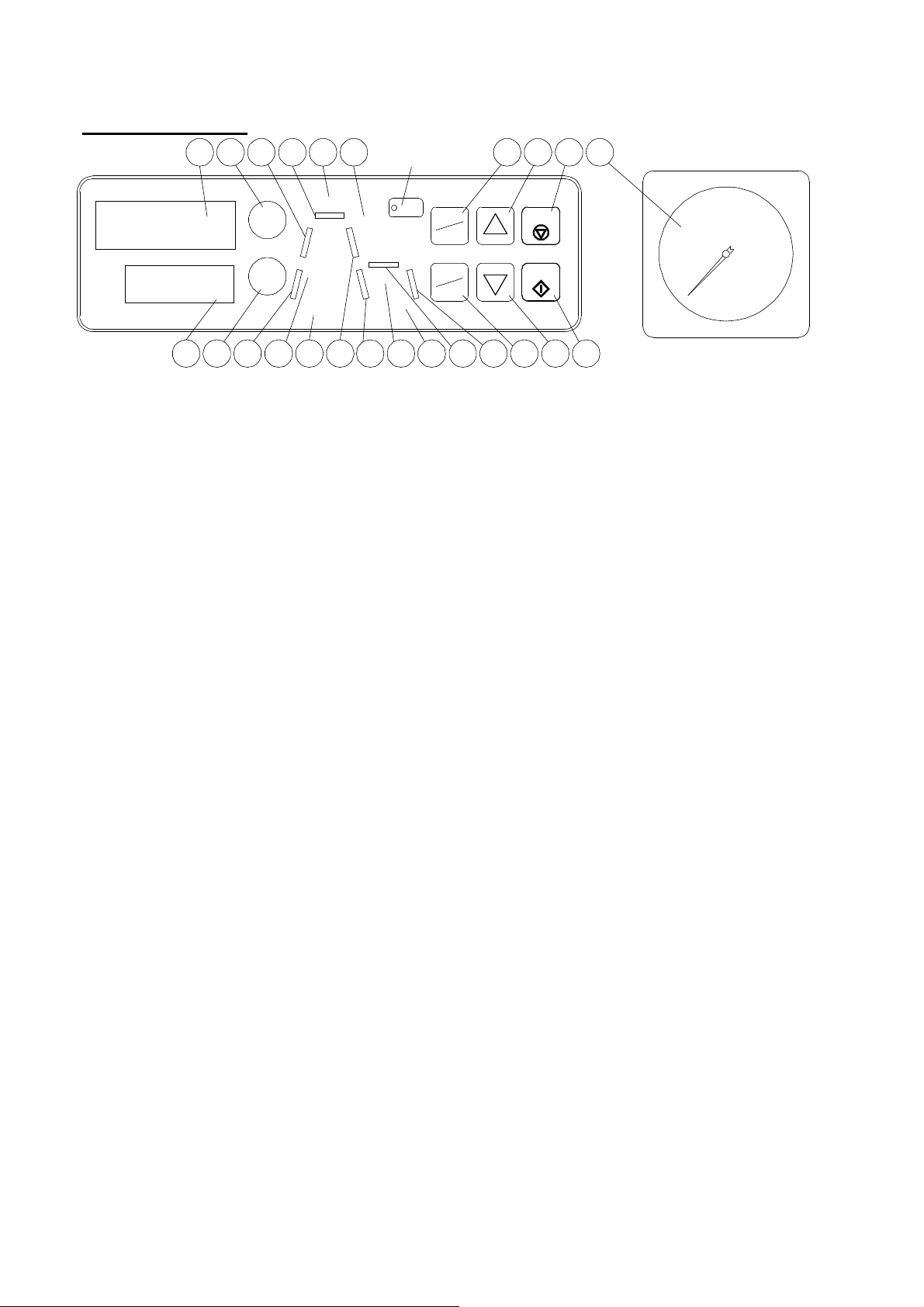

8

WARM

COMPLETE

TEMP

READY

PATTERN START

ENTER

TIME

STOP

EXHAUST

HEAT

EXHAUST

START

TIMER

STERILIZE

℃

MIN

O.T.

HR

MON DAY

4

15 5 1

113 181312212216172324 6 9

7210192014 8

Option

Operation panel

1. Pressure gauge

It indicates chamber pressure.

2. TEMPERATURE DISPLAY

It displays temperature in the chamber or setting

temperature. Also, it displays the date of an operation

reservation.

3. TIMER DISPLAY

It displays the remaining time to the process

completion. “down count” Also, it displays the time of

an operation reservation and error.

4. START KEY

Press it to start operation.

5. STOP KEY

Press it to stop operation on the way. Press it to reset

previous operation before starting operation.

6. PATTERN/ENTER KEY

Press it to fix an operation pattern and each setting.

7. TEMP/TIME KEY

Press it to check setting temperature, setting time

and the operation pattern. Press it to change setting

display’s blink.

8. CHANGE▲ KEY

Press it to increase the figure of the setting display.

9. CHANGE▼ KEY

Press it to decrease the figure of the setting display.

10. EXHAUST KEY

Press it to switch automatic exhaust ON and OFF or

set an automatic exhaust starting temperature. Press

it to exhaust manually.

11. START TIMER KEY

Press it to make a reservation of operation. Set an

operation starting time of month, day, hour, and

minute.

12. READY LAMP

The character lights up at the reservation condition.

The character blinks at setting change condition.

13. HEAT LAMP

The character lights up during heating or dissolving

process. The character blinks at dissolving setting

change condition.

14. STERILIZE LAMP

The character lights up during sterilizing process. The

character blinks at sterilizing setting change

condition.

15. EXHAUST LAMP

The character blinks during exhaust process.

The character lights up before exhaust process in

case of automatic exhaust ON.

16. WARM LAMP

The character lights up during warming process. The

character blinks at warming setting change

condition.

17. COMPLETE LAMP

The character lights up with the buzzer beeping at

the completion of all the processes. The character

blinks and reports whether lid can be opened when

pressing STOP KEY during operation.

PROCESS INDICATION BAR

They light up, blink, light off according to the status of

process.

18. HEATING-1 PROCESS LAMP

It blinks from start temperature of the sterilization to

the end of the air evacuation.

It blinks from start temperature of the dissolving to

the dissolving temperature.

19. HEATING-2 PROCESS LAMP

It blinks from the end of the air evacuation to the

sterilization temperature.

20. STERILIZATION PROCESS LAMP

It blinks during sterilization.

21. COOLING-1 PROCESS LAMP

It blinks to 100℃ after sterilization.

22. COOLING-2 PROCESS LAMP

It blinks from 99℃ after sterilization to the

completion.

23. WARMING PROCESS LAMP

It blinks during warming.

24. COOLING-3 PROCESS LAMP

It blinks from 99℃ after warming to the completion.