IKA MATRIX Orbital Delta F0.5 User manual

Other IKA Laboratory Equipment manuals

IKA

IKA MS 3 basic User manual

IKA

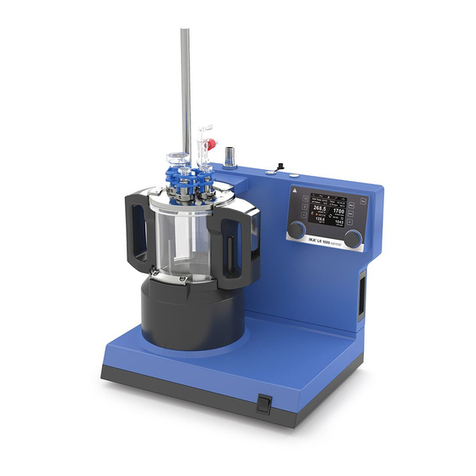

IKA LR 1000 basic User manual

IKA

IKA ULTRA-TURRAX T 25 basic User manual

IKA

IKA MS 450 Swirler User manual

IKA

IKA KS 3000 i control User manual

IKA

IKA RV 3 eco User manual

IKA

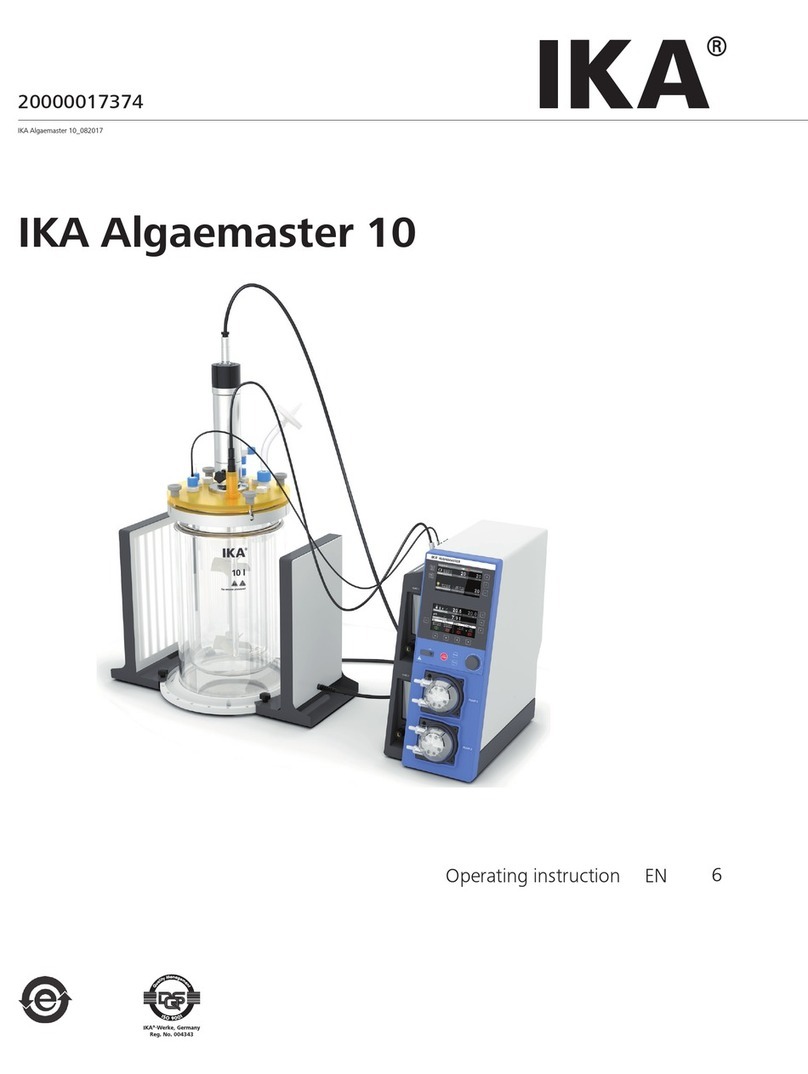

IKA Algaemaster 10 User manual

IKA

IKA MS 1 User manual

IKA

IKA LR 1000 basic User manual

IKA

IKA Dry Block Heater 1 User manual

IKA

IKA EUROSTAR digital User manual

IKA

IKA RH basic User manual

IKA

IKA ULTRA-TURRAX T 18 basic User manual

IKA

IKA IKAMAG RET basic User manual

IKA

IKA Vortex 3 User manual

IKA

IKA MF 10 User manual

IKA

IKA HB digital User manual

IKA

IKA RET control User manual

IKA

IKA HB 10 basic User manual

IKA

IKA C-MAG HS4 User manual

Popular Laboratory Equipment manuals by other brands

Qiagen

Qiagen DML 3000 user manual

Queensgate

Queensgate NANOSCAN OP400 Quick start instructions

Conviron

Conviron GEN1000-GE Operator's manual

Parr Instrument

Parr Instrument 4560 Operating instructions manual

Integra

Integra DOSE IT operating instructions

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual