Step 6.

Step 7.

Adjust R116 on Power Driver PCB (see Figures

3 and 10) until minimum distortion is obser ved

on distort ion me asu ring instrumen t .

Close fro nt panel and secure with four screw s

previously removed .

ADJUSTMENT OF OUTPU T "Q" BALANCE CONTROLS

Outp ut "Q" Balance Cont rols R 140 and R141 on Power

Driver PCB (see Figur e 3) balance the bias current of power

transistors 01, 02 , 0 3 and 0 4. Inadequate adjustment of

these controls may resu lt in distortion and exces sive cu rrent

drain from one or mo re power transistors. If adjustment is

indica ted (such as replaceme nt of one or mor e power tra n-

sistors), use the follow ing recom mended procedu re:

Step 1.

Step 2.

Turn VOLUME control fully count erclockw ise

(0).

Remove four screws securing front panel, then

lower pane l for access to interior.

.------- CAUTION----- --

High voltage may be encountered when

Step 3.

Step 4.

Step 5.

Step 6.

the chass is is open ed for service. This

procedure should be referred to a quali-

fied serv ice technicia n.

Turn Output "Q" Balance Control s R140 and

R141 fully clockwise (see Figure 3) .

Turn on powe r and allow a 5-minu te war mup

period.

Adjust R140 and R 141 by one of the follow ing

method s [method (a) is preferred] :

(a) Locate wire attached to termi nal 1 of

outp ut tran sformer T2. Conn ect a clam p-

on milliam mete r to this wire and adjust

R14 0 coun terclockwi se for a "Q" cur-

rent of 30 mA. Change connection of

milliammet er to wire attached to termina l

3 of outpu t tran sformer T2 and adjust

R141 fo r a "Q" current of 30 mA.

(b) Rem ove two screws securing Power Driver

PCB to cha ssis and lower PCB on hin ged

conn ector. Connect a millivol tm eter

acros s resisto r R4 (see Figur e 8), starti ng

with highest scale to protec t meter . Ad-

just R140 for meter reading of 10 mV.

Chan ge con nection of millivoltm eter to

read across resistor R5 and adjust R141

for meter readi ng of 10 mV. Rem ove

millivo ltmet er and secure PCB to chassis

with two screws previously remov ed .

Close front panel and secure with four screws

removed in Step 2.

-8-

ASSEMBLY REPLACEMENTS

Fuses

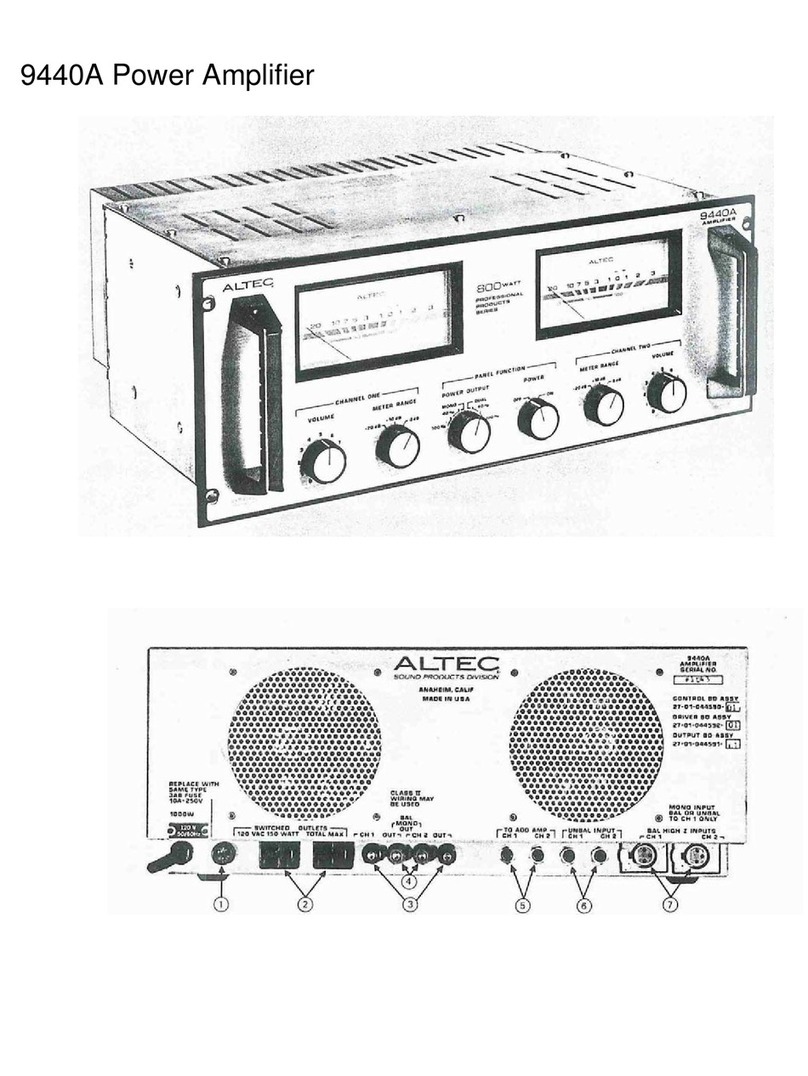

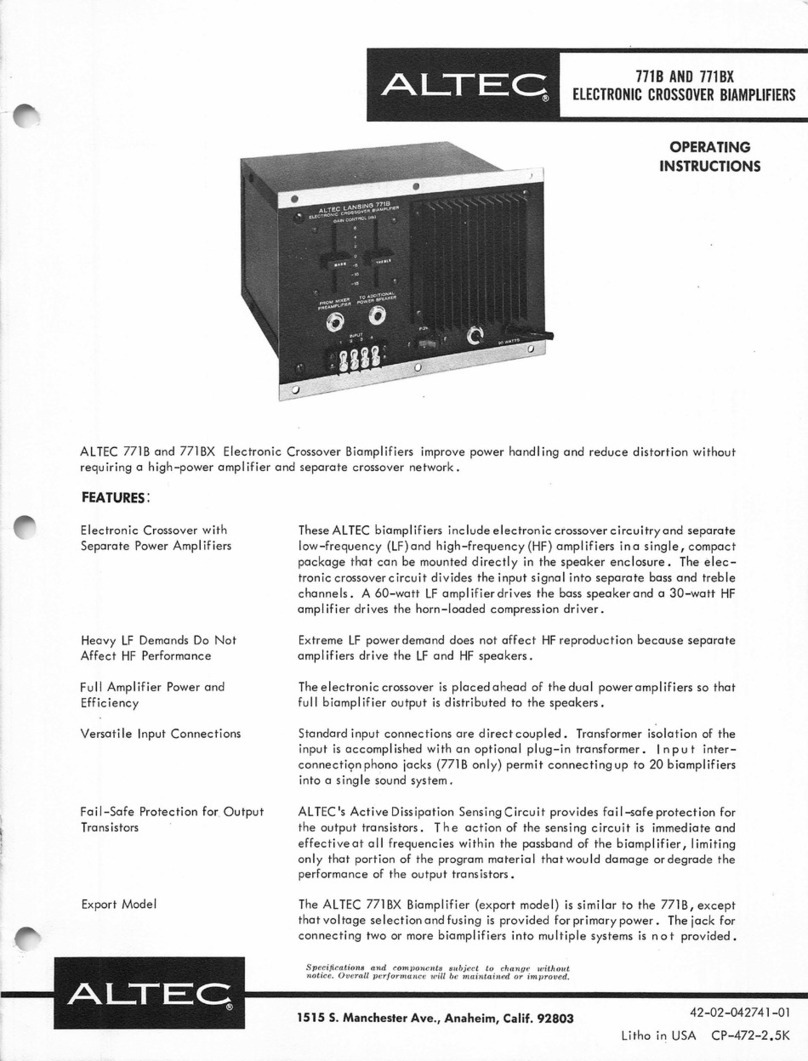

The ac primary power fuse is mounted o the front panel

(see cover photo). The battery power fuse is located on the

rear of the chassis (see Figure 4). If fuse replacement is re-

qui red, determine and correct any cause of fa ilure before re-

placing fuse. Install an ident ical fuse (see PARTS LIST) by

unscrewing fuse holder, replacing fuse and resecuring fuse

holder .

Pilot Lamp

The pilot lamp is located on the front panel (see cover

photo). If replacement is required, unsc rew the red pilot

lamp shield to expose the bulb. Press bulb inward and turn

counterclockwis e (ccw) to remove . Install an identical bulb

(see PARTS LIST), then replace red pilot-la mp shield .

Power DriverPCB

If the amplifier fails because of a faulty power driver PCB,

operation may be restored by rep lacing the PCB with a new

or repaired PCB. Use the following procedu re.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Remove four screws securing front panel. Open

and lower pane l for access to PCB (see Figure 3).

Remove two screws securing PCB to chassis

brac kets .

Carefully remove PCB from con nector.

Carefully insert new or repair ed power driver

PCB into conne ctor . Do not war p, bend or twist

the board or conductor may fra cture .

Secure PCB with two screws removed in Step 2.

Perform ADJUSTMENT OF POWER DRIVER

BALANCE CONTROL procedu re.

RECOMMENDED SERVICE TECHNIQUE

If systematic troubleshooting shows need fo r parts replace-

ment, observe the following precautions .

Transistor Orientation

Solid-state com ponents are packaged in various case sizes

and types with various lead orientations (see Figure 7 ). Be-

fore removing a solid-state component fro m tie points or

from a PCB, sketch the lead orientation with respect to the

tie points or PCB.

Form the leads of the new component to co nform with the

leads of the par t being replaced to aid in making proper

connections. Before removing small transis tors, note posi -

tion of index tab with respect to the PCB or socket. Cut

the leads of the new transistor to the requ ired length and

insert them, properly indexed , into the PCB or socket.