Step

5.

Adjust R136 and R137 by one of the following

methods [method (a)

is

preferred]

:

(a) Locate wire attached to terminal 1 of

output transformer T2. Connect

a

clamp.

on milliammeter to this wire and adjust

R136 counterclockwise for a

"a"

cur

-

rent of 40 mA. Change connection of

milliammeter to wire attached to terminal

3

of output transformer T2 and adjust

R137 for a

"

Q

"

current of 40 mA.

(bl Remove two screws securingPower Driver

PCB to chassis and lower PCB on hinged

connector. Connect a millivoltmeter

across resistor R7 (see Figure

lo),

starling

with highest scale to protect meter. Ad

-

just R136 for meter reading of 13 mV.

Change connection of millivoltmeter to

read across resistor R8 and adjust R137

for meter reading of 13 mV. Remove

millivoltmeter and secure PCB to chassis

with two screws previously removed.

Step 6. Close front panel and secure with four screws

removed in Step 2.

ASSEMBLY REPLACEMENTS

Fuses

Step

4.

Carefully insert new or repaired power driver

PCB into connector. Do not warp, bend or twist

the board or conductor may fracture.

Step

5.

Secure PCB with two screws removed in Step

2.

Step 6. Perform ADJUSTMENT OF POWER DRIVER

BALANCE CONTROL procedure.

RECOMMENDED SERVICE TECHNIQUES

If systematic troubleshooting shows need for parts replace

-

ment, observe the following precautions.

Transistor Orientation

Solid

-

state components are packaged in various case sizes

and types with various lead orientations (see Figure

9).

Be

-

fore removing

a

solid

-

state component from tie points or

from

a

PCB, sketch the lead orientation with respect to the

tie

points or PCB.

Form the leads of the new component to conform with the

leads of the part being replaced to aid in making proper

connections. Before removing small transistors, note posi

-

tion of index tab with respect to the PCB or socket. Cut

the leads of the new transistor to the required length and

insert them, properly indexed, into the PCB or socket.

ReplacingPower Transistors

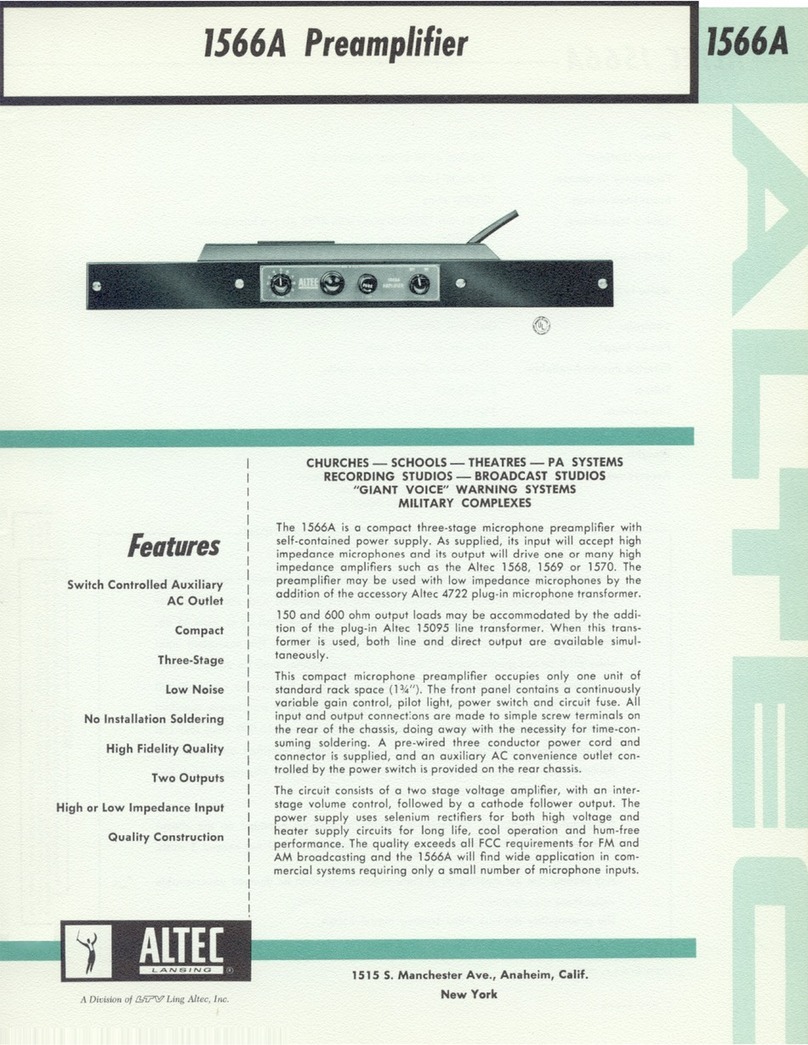

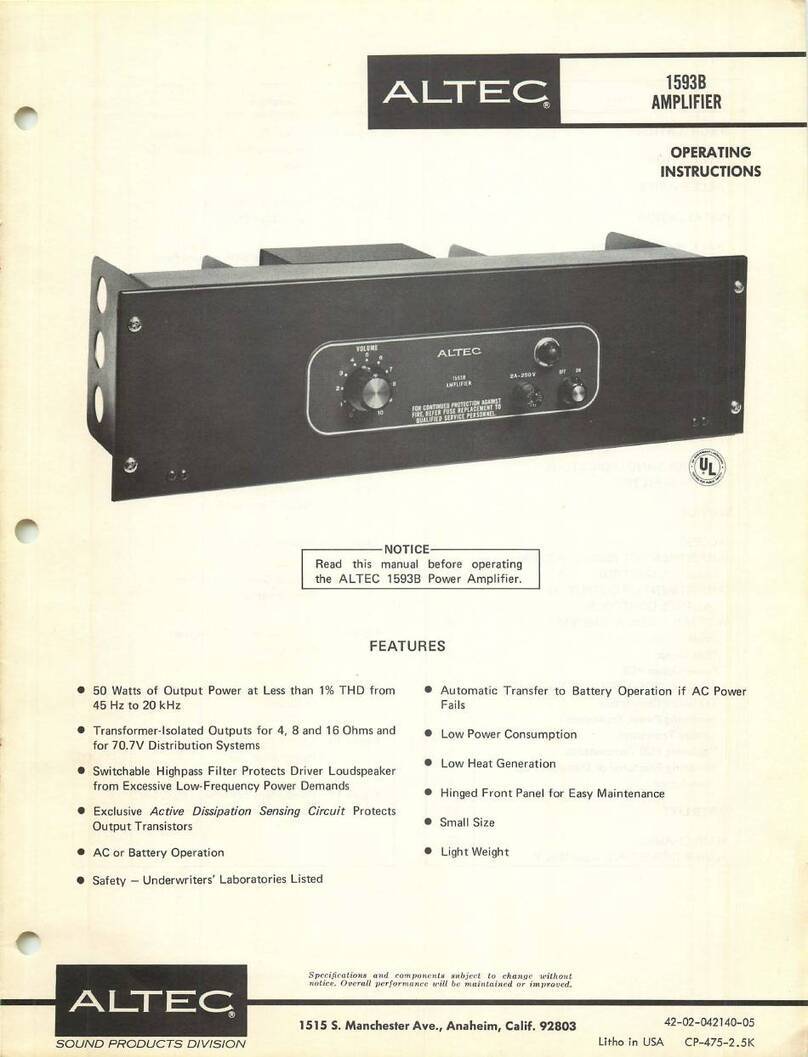

The ac primary power fuse

is

mounted on the front panel

(see

cover photo). The battery power fuse

is

located on the

rear of the chassis (see Figure 6). Iffuse replacement

is

re

-

quired, determine and correct any cause of failure before

re

-

plac~ngfuse. Install an identical fuse (see PARTS LIST) by

unscrewing fuse holder, replacing fuse and resecuring fuse

holder.

Pilot Lamp

The pilot lamp

is

located on the front panel (see cover

photo). If replacement

is

required, unscrew the red pilot

lamp shield to expose the bulb. Press bulb inward and tLlrn

~~~nter~lo~k~ise

(CCW)

to remove. Install an identical bulb

(see

PARTS LIST), then replace red pilot

-

lamp shield.

Power Driver PCB

If the amplifier fails because of

a

faulty power driver PCB.

operation may be restored by replacing the PCB with

a

new

or repairedPCB. Use the followingprocedure.

Step 1. Remove four screws securing front panel. Open

and lowerpanel for access toPCB

(see

Figure

5).

Step

2.

Remove two screws securing PCB to chassis

brackets.

Step 3. Lower hinged connector of PCB and carefully

remove PCB from connector.

Verify the following conditions exist when replacing

power transistors.

1.

Mica insulator

is

not damaged. If damaged, use new

insulator.

2.

No grit or metal particles are between transistor and

heat sink.

3. Both sides of mica insulator are covered with silicone

grease or fluid.

4. Mounting screws are tight,

TestingTransistors

Transistors should be checked with

a

transistor tester. If a

tester

is

not available, use the following procedure for test

-

ing transistorswith an ohmmeter.

Step 1. Remove suspected transistor from circuit (see

ReplacingPCB Components).

Step

2.

Connect ohmmeter leads to base and emitter.

Read on lowest ohms scale. Reverse leads and

read again. Normal readings should be

at

least

10 times greater in one direction than in the

other.

Step 3. Connect ohmmeter leads to base and collector.

Ohmmeter readings should be similar to those

obtained inStep

2.