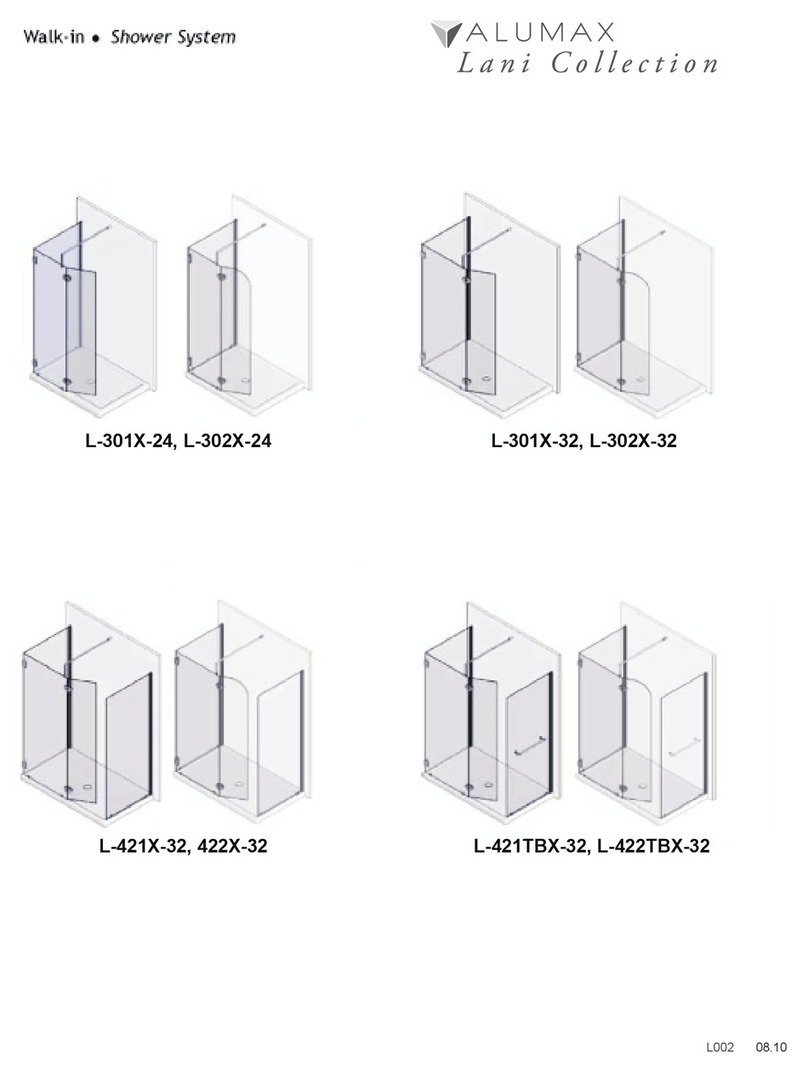

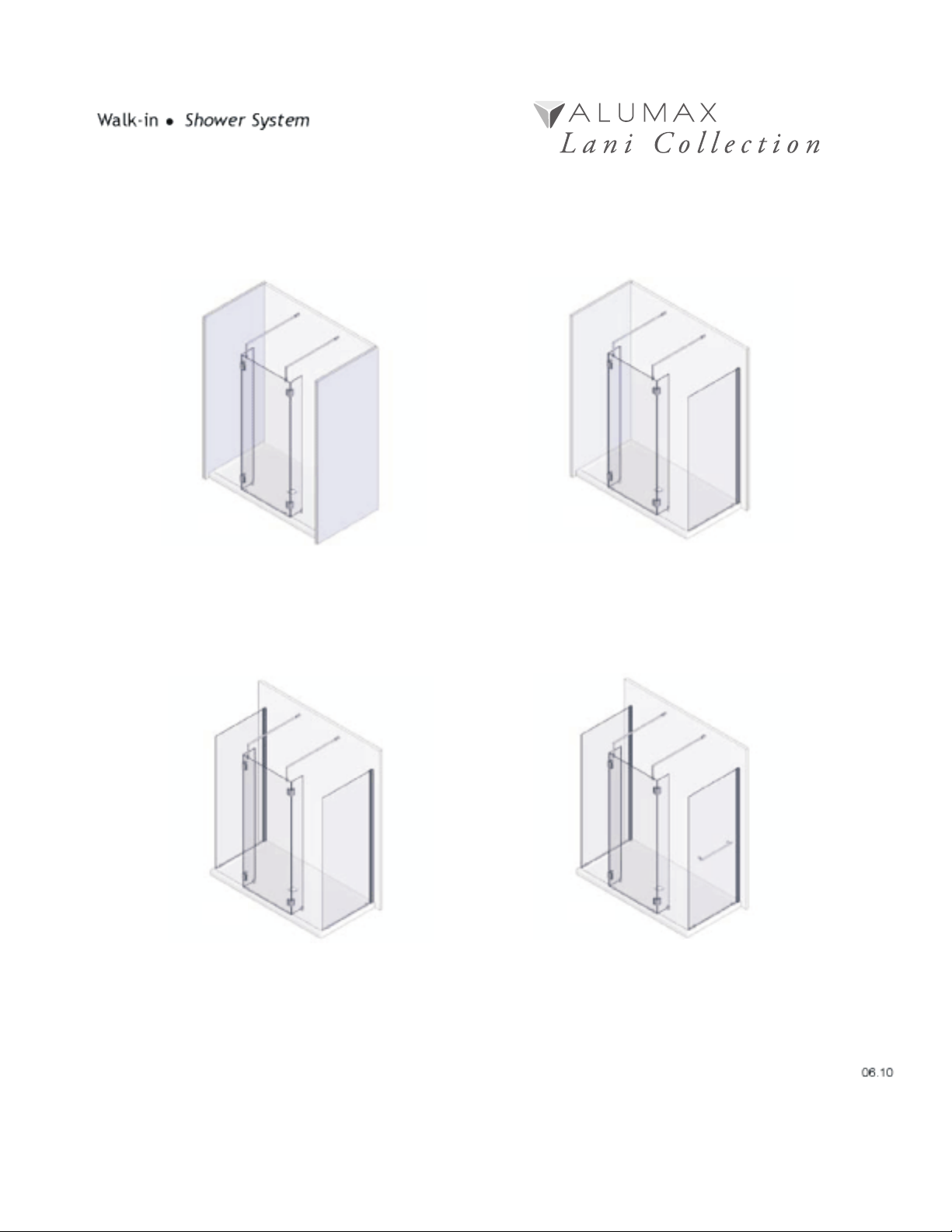

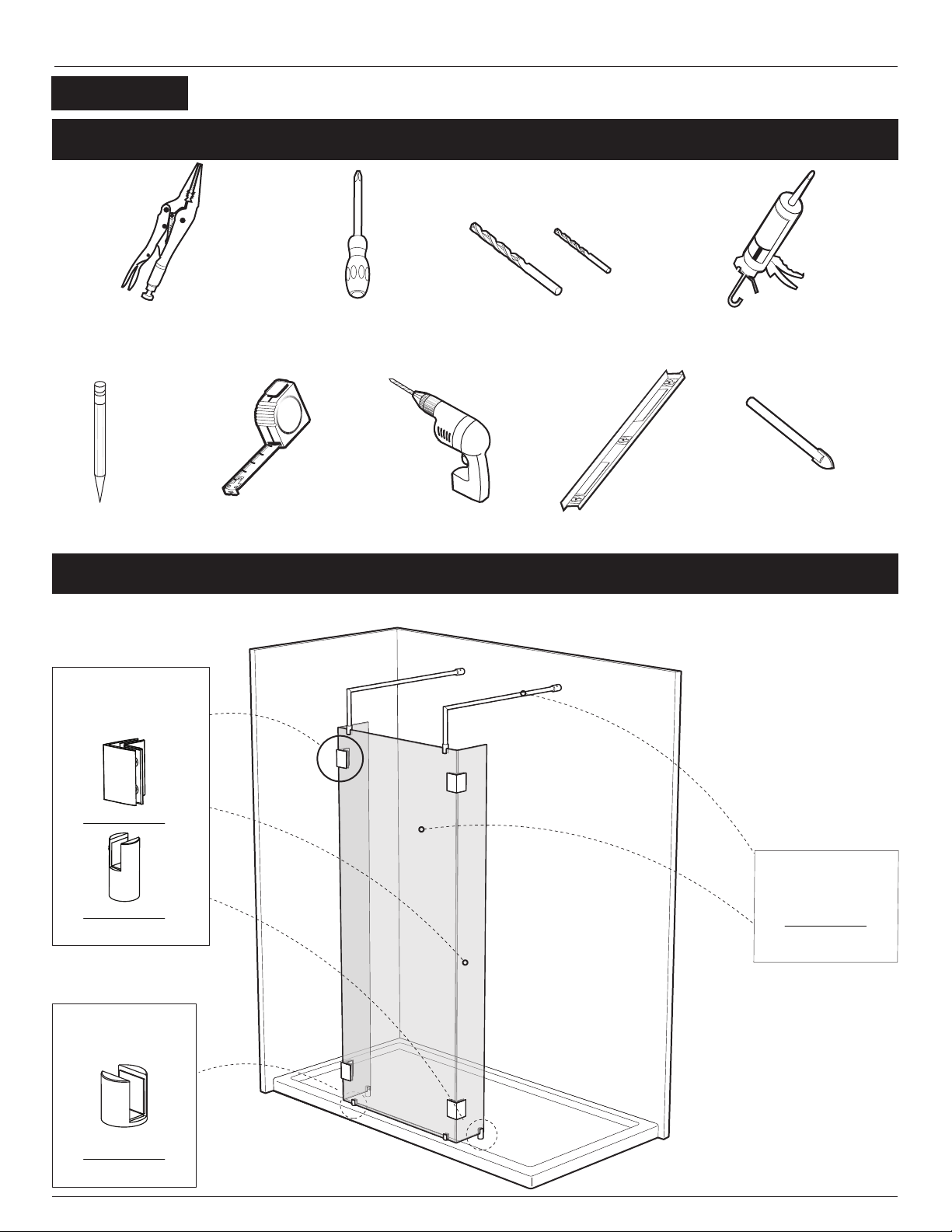

Alumax Lani L-503X-32 User manual

Other Alumax Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Kohler

Kohler Mira Sport Max J03G Installation and user guide

Moen

Moen 186117 Series installation guide

Hans Grohe

Hans Grohe Raindance Showerpipe 27235000 Instructions for use/assembly instructions

Signature Hardware

Signature Hardware ROUND SWIVEL BODY SPRAY 948942 Install

fine fixtures

fine fixtures AC3TH installation manual

LIXIL

LIXIL HP50 Series quick start guide