9

Commissioning

5. Commissioning

5.1 Preservation

Machines which are standing still after delivery ex works or are to be

stored for a longer period before commissioning, will be filled up with

preservative oil. This preservative oil has to be drained and disposed

together with the flushing oil (appr. 1/3 of the normal oil supply, which

will be flushed through the operating unit for about 30 min.).

Please mind the initial lubrication of section 5.4 before commissioning!

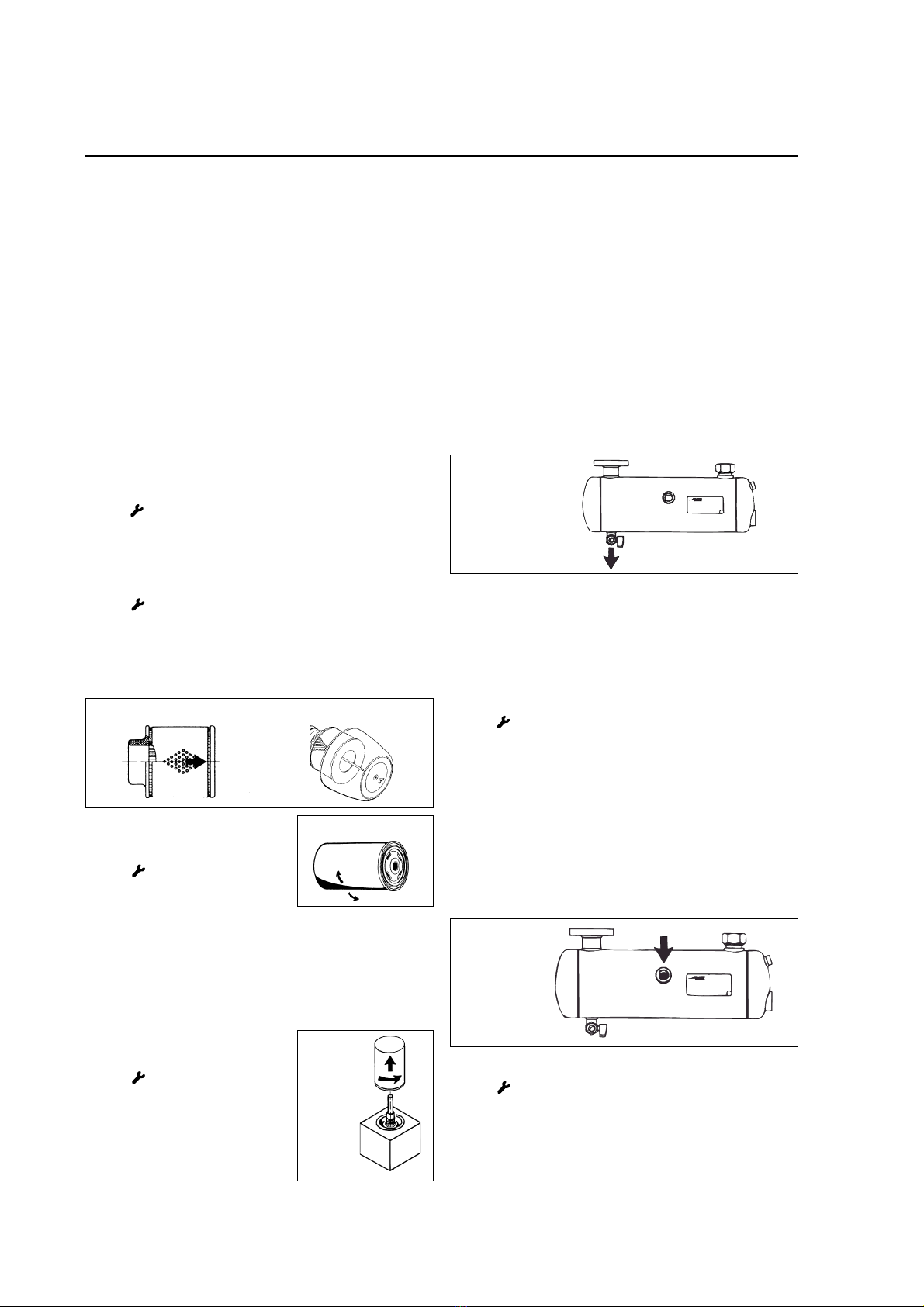

5.2 Oil level check

The maximum oil level is the lower edge of the oil filler neck (11.1).

During operation the oil level will slightly fall by internal distribution.

With rising machine temperature or even a temperature cut-off due

to low oil level, the compressor is to be filled up with fresh oil into the

oil filler neck (11.1).

5.3 Oil quality

With regard to the high load of the lube oil in oil injection cooled

screw-type compressors, we recommend to use very non-aging, water-

repellent, non-foaming, anti-corrosion oils, e.g. our SPECIAL OIL.This

oil is filled in by the works (refer to the oil tank (11) sticker).

FDifferent kinds of oils must not be mixed. In case other lubricants

are used, you should contact the after-sales service p.We only grant

our warranty for the compressors when the use of equivalent lubricants

is verified.

5.4 Initial lubrication of the compressor stage

(04) (refer to section 1.3)

FAfter a longer standstill period, e.g. between initial

commissioning and delivery ex works or after a longer works holiday,

it may happen that there is no oil in the rotor compartment of the

compressor stage (04). This oil, however, is absolutely necessary for

lubricating rotors and bearings in the starting phase. Therefore it is

necessary to fill about 0.2 l. oil into the prelube plug of the suction

valve (06). Manually rotate the compressor stage (04) in the right

direction of rotation until the sensible resistance disappears and the

oil is passed through the stage (04). Mount the prelube plug again

into the suction valve (06).

If no additional oil is available (only use the same kind of oil) the oil

can be drained from the system by means of the oil drain (11.2).

Irregular operating machines and those which are standing still for

several weeks should run for one hour every week, in idle mode, to

prevent corrosion damage.

5.5 Direction of rotating (refer to section 1.3)

FThe direction of rotation must comply with the arrow on the

electric motor (01).When checking, the machine must only be switched

on (and immediately off) for a very short time (max. 0.5 sec.) in order

not to damage the compressor stage (04). The direction of rotation

can be changed when two external conductors are exchanged.

5.6 Starting

Before starting the machine, verify that no persons can be endangered.

The sound cover hood is part of the protection against accidental

contact and leads the cooling air of the machine. It must be closed

during operation. Open the shut-off valve between compressor and

compressed-air system. Switch on the power supply.

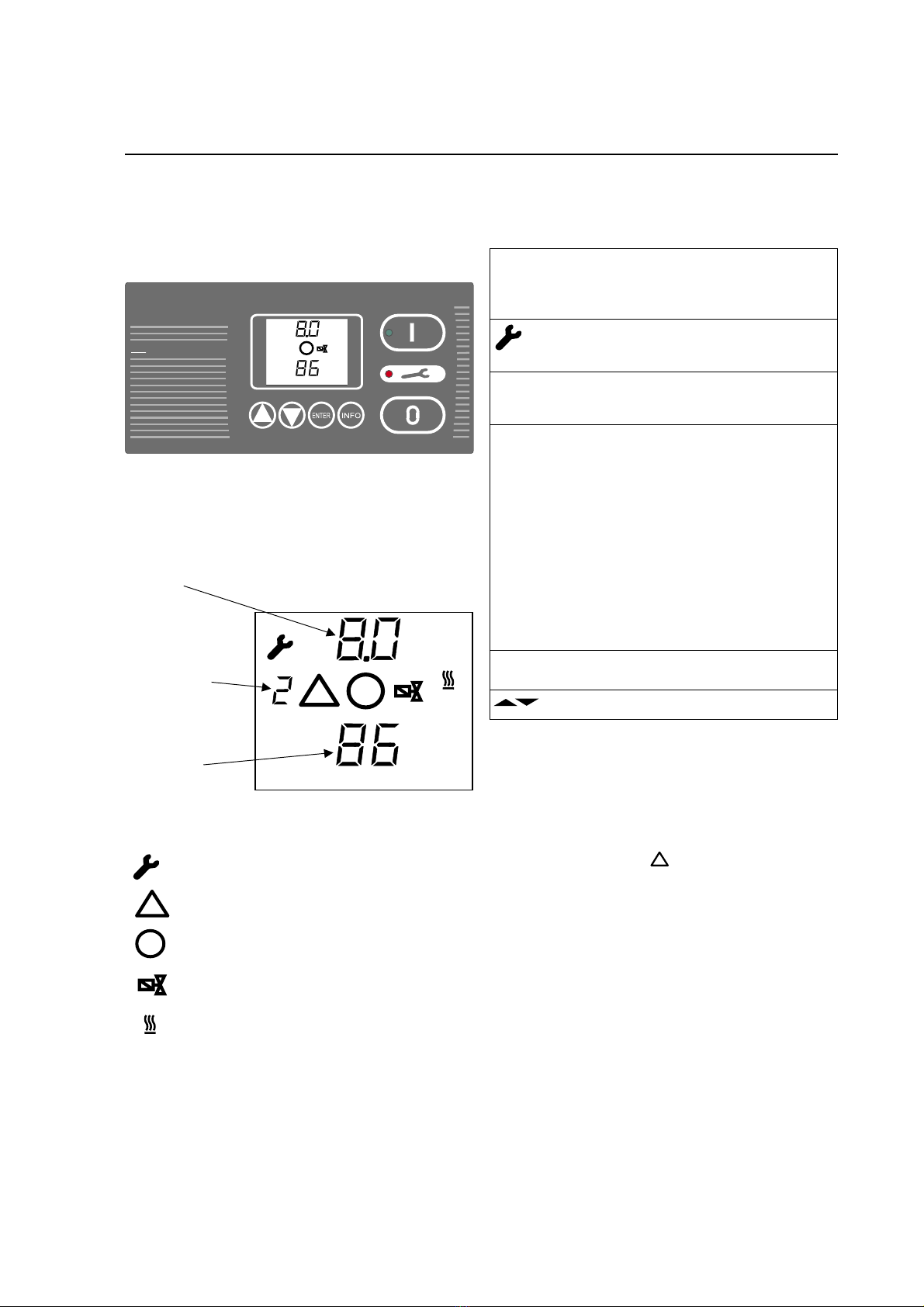

Push the start key I.The green lamp lights up and indicates operation

or, if the line pressure is above the set cut-in pressure, the start

temperature is below + 5°C or with activated remote control, only

flashes stand-by.

CAUTION! A FLASHING GREEN LAMP MEANS THE

COMPRESSOR CAN ALWAYS START UP AUTOMATICALLY

The lines carrying oil and compressed air are to be checked for leakages.

After the cut-out pressure is achieved the machine shuts down after

the set follow-up time (automatic) or changes over to idle running

(load-idle mode).

5.7 Shutdown

Push the stop key O. The green lamp extinguishes. The compressor

shuts down after the follow-up time, the suction valve (06) closes

and the oil tank (11) is relieved. The line pressure is available up to

the non-return valve integrated in the separator box, i.e. the

compressed-air recooler (09) is admitted with line pressure. Program

changing and setting of pressure or time values can only be carried

out with the required code and the compressor at standstill.

6. Compressor maintenance

6.1 General information

FAll maintenance work is to be carried out by trained specialists

with the machine switched off, at standstill, pressure-relieved and

protected against reconnection.

6.2 Pressure relief

Before any maintenance work is carried out, the pressure relief is to

be checked as follows : disconnect the compressor from the

compressed-air system by closing the shut-off valve.The pressure relief

is to be checked by venting the safety valve (12).

FThe temperature of the oil tank (11) may not be more than

+40 °C!

FAttention - caution!

It is absolutely necessary to wear face and body protection

because hot oil mist can penetrate.