Assembly instructions BR 133-3 to 139-3 Status 03/2022 Former instructions lose their validity. 7 / 14

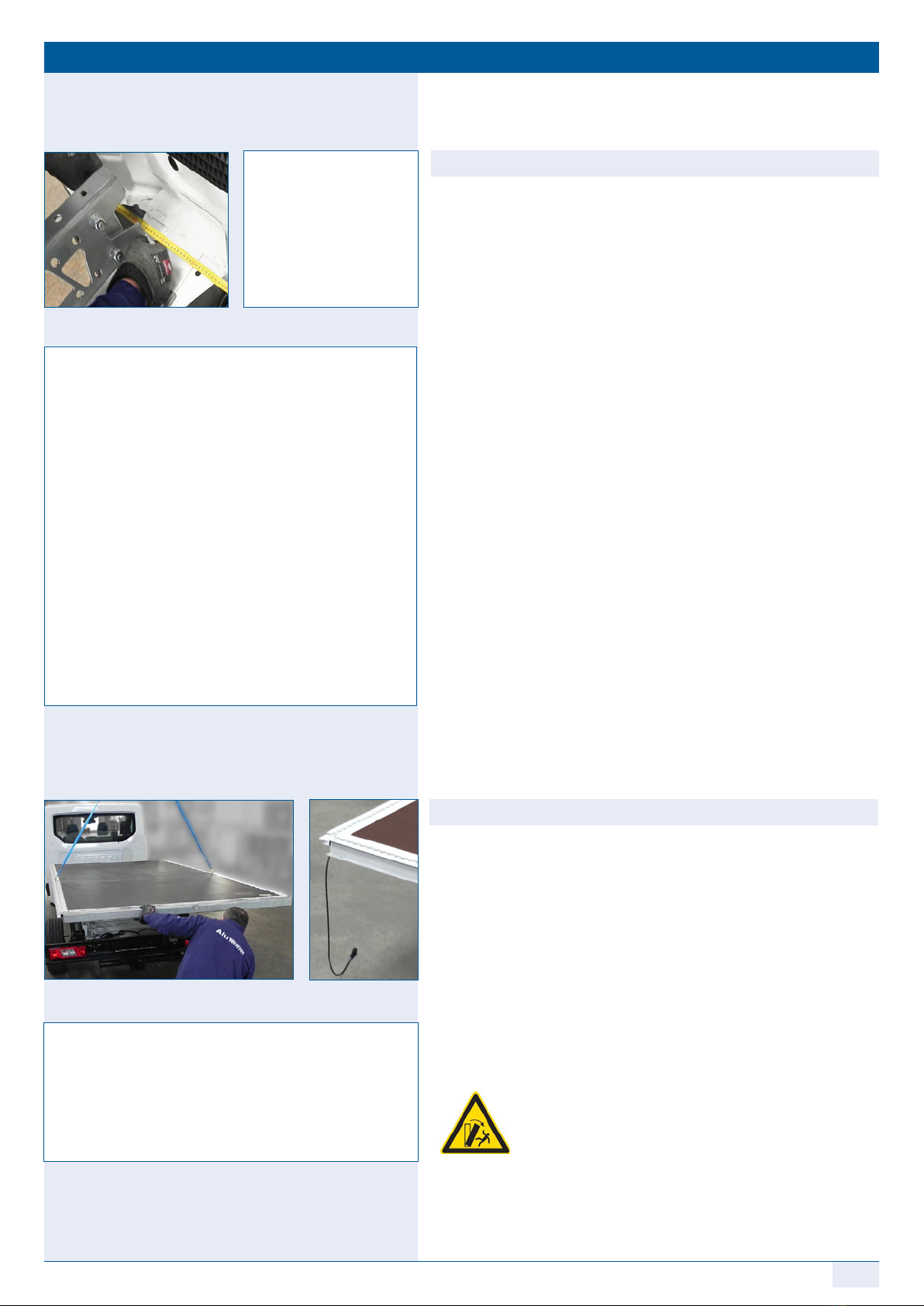

• Align an iso-floor with steel longitudinal supports so that the

screw thread inserts in the floor are located over the elongated holes

of the longitudinal supports (distance according to type sheet). The

separation distance to the driver cab is absolutely to be adhered to.

Tip: Use a mandrel (Fig. 3213) in order to bring the bores of the

longitudinal supports in line with those of the floor.

• Insert the screws MD100354 into the bores and screw them down

with several turns of the thread. If they can be screwed down with-

out impairment of the freedom of motion, tighten them crosswise

with the required torque (Fig. 3214).

• Align the rear longitudinal support close-off to the hole pattern in

the floor. Use a mandrel to check whether the hole pattern in the

longitudinal support is in line with the bore in the floor (Fig. 3215).

3.3 Assembling of the side walls

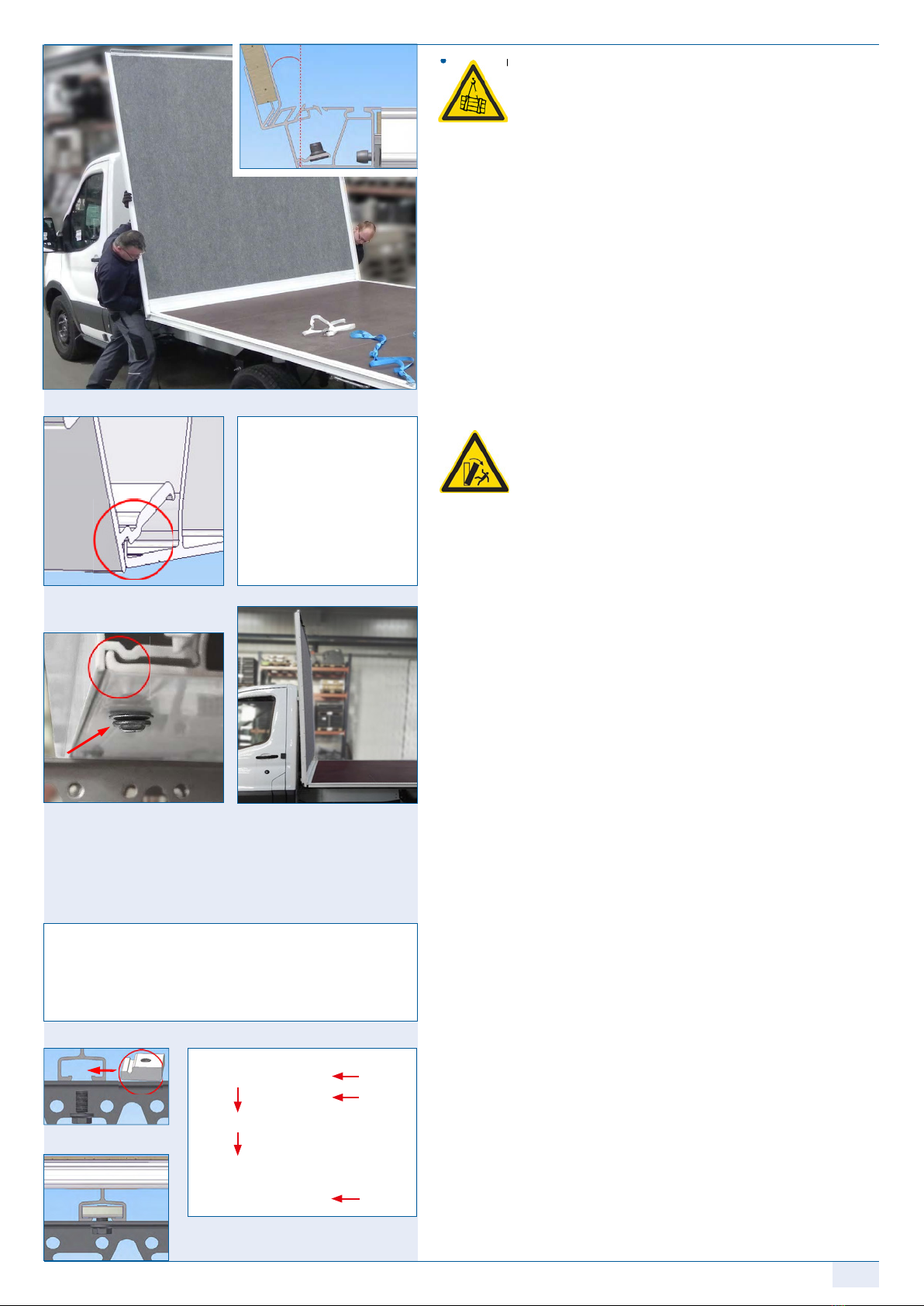

• Lift with a suitable lifting aid (crane with appropriate hoisting

gear, vacuum cross beam or lifting plate) the 1st side wall in the

centre of gravity (Fig. 331). Observe the safety instructions!

Tip: It is best to fix the rear walls with glue pliers in order to prevent

damage to the side wall.

• Ensure that no cables are present between connection points (dan-

ger of crushing of the cables). They must hang down freely on the

beginning and end of the wall (Fig. 330 a/b).

• As with the front-side wall assembly, set the lower chord of the wall

diagonally (approx. 10-15°C) into the floor profile (Fig. 331/324).

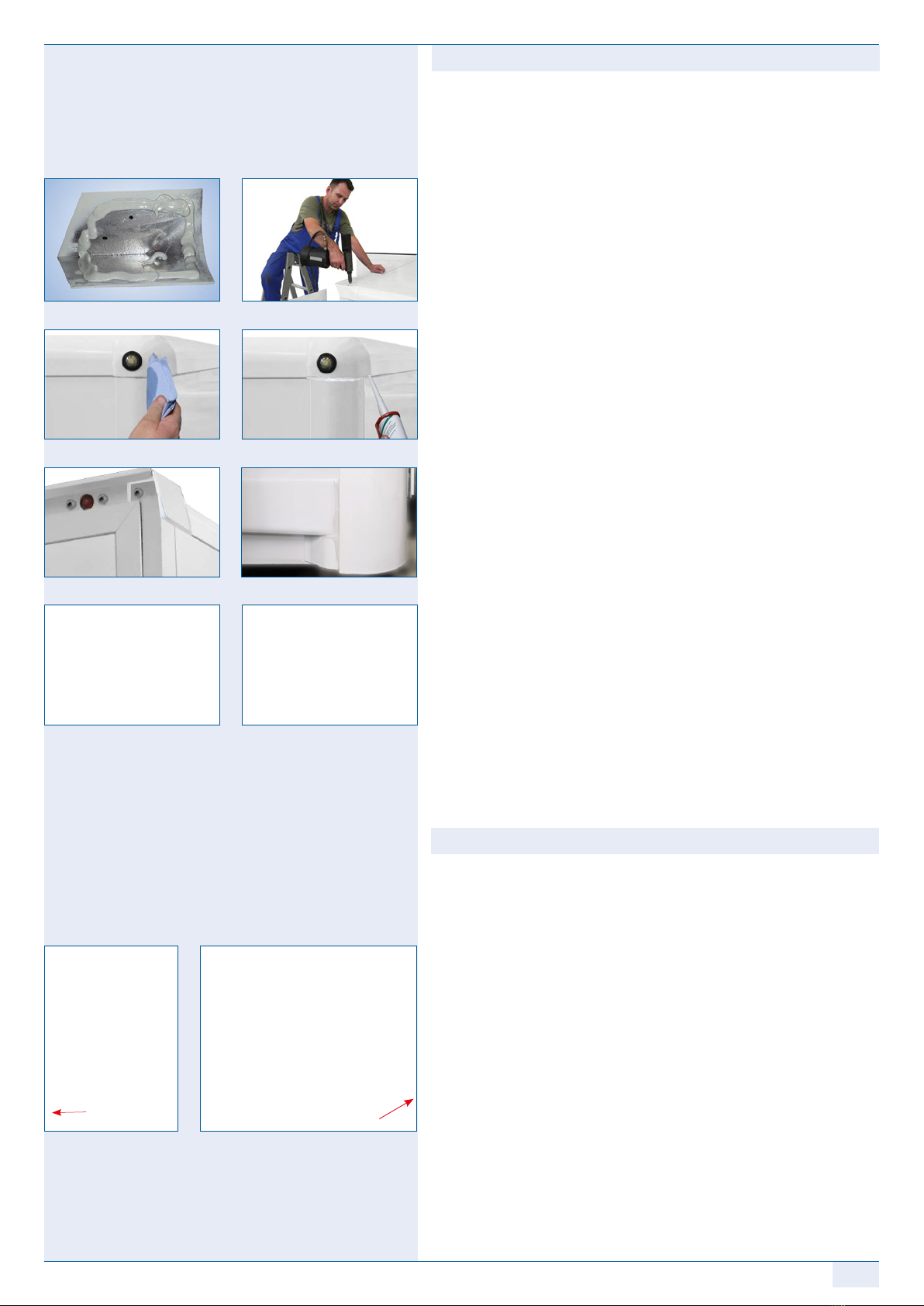

• Rotate the module assembly screws MD 100318 into the appropriate

bores in order to fix the latching point (with MD 110044), and tighten

them by several turns of the thread (Fig. 332). With the bedding of the

side wall, the corner pillar touches the frame cross beam (Fig. 333).

Further assembly is not hindered by this.

Attention: Before the raising of the side wall, the front wall

should stand vertically and the corner pillar overlap

the front-side wall panel.

• Raise the side wall up to the second latching point until it engages

with a noise ("click") (Fig. 334/336).

• Visually check whether the nose has engaged in the profile and

whether a clearance still exists, in particular in the side door area.

Where appropriate, press down in order to ensure engagement. Once

again, check for a flush line and gap dimensions (Fig. 334/327).

• The frame pillar should now fit flush with the frame cross beam and

both are at right angle to each other below (Fig. 335). Now tight-

en the screws used at the beginning securely with the appropriate

torque.

• In the interior of the box, fix all walls with the module assembly

screws for the interior area MD 100224 (Fig. 337).

Attention: Unlike those for the outer area (MD100318), these screws

have no gasket and are provided with a cylindrical

head.

• Proceed with the assembly of the 2nd side wall just like with

the 1st side wall (Fig. 338 /339).

Proceed with the assembly of the 2nd side wall just like with

Lift with a suitable lifting aid (crane with appropriate hoisting

gear, vacuum cross beam or lifting plate) the 1st side wall in the

Fig. 3213 Fig. 3214

Fig. 3215

Fig. 330a Fig. 330b

Fig. 332

Fig. 331 Fig. 333

Fig. 339

Fig. 334

Fig. 336 Fig. 337

Fig. 338

Fig. 335