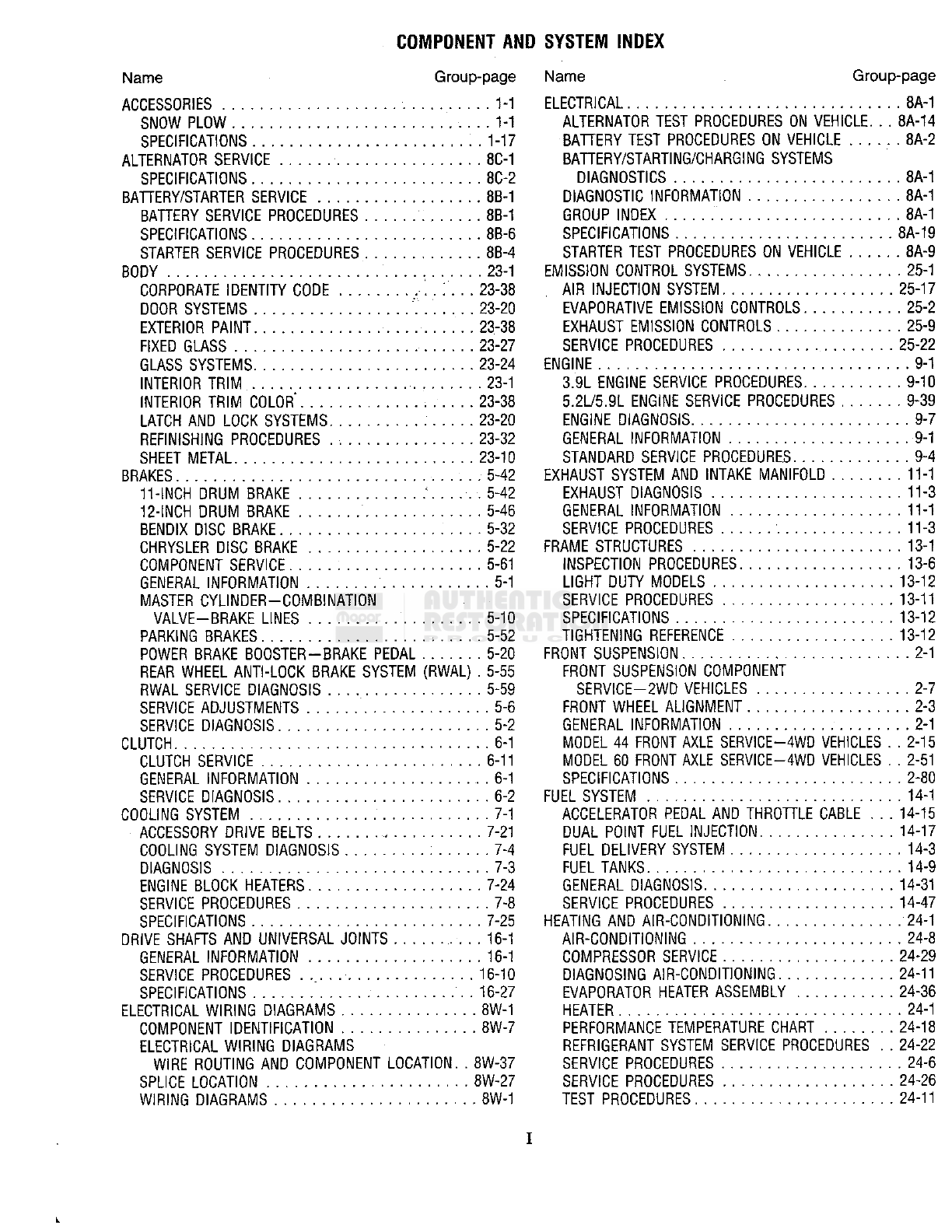

COMPONENT

ANDSYSTEM

INDEX

Name

Group-page

ACCESSORIES

1-1

SNOW

PLOW

1-1

SPECIFICATIONS.1-17

ALTERNATORSERVICE8C-1

SPECIFICATIONS8C-2

BATTERY/STARTERSERVICE8B-1

BATTERYSERVICEPROCEDURES

......

8B-1

SPECIFICATIONS8B-6

STARTERSERVICEPROCEDURES8B-4

BODY

23-1

CORPORATE

IDENTITY

CODE

23-38

DOOR

SYSTEMS

23-20

EXTERIOR

PAINT

23-38

FIXEDGLASS

23-27

GLASS

SYSTEMS.

23-24

INTERIOR

TRIM

23-1

INTERIOR

TRIM

COLOR

23-38

LATCHANDLOCKSYSTEMS

23-20

REFilMISHING

PROCEDURES

23-32

SHEET

METAL

23-10

BRAKES

5-42

11-

INCH

DRUM

BRAKE'*. 5-42

12-

INCH

DRUM

BRAKE5-46

BENDIX

DISCBRAKE5-32

CHRYSLER

DISCBRAKE5-22

COMPONENT

SERVICE. 5-61

GENERAL

INFORMATION

5-1

MASTER

CYLINDER-COMBINATION

VALVE-BRAKELINES5-10

PARKING

BRAKESV 5-52

POWER

BRAKEBOOSTER-BRAKEPEDAL5-20

REARWHEEL

ANTI-LOCK

BRAKESYSTEM

(RWAL)

. 5-55

RWAL

SERVICE

DIAGNOSIS

5-59

SERVICE

ADJUSTMENTS

5-6

SERVICE

DIAGNOSIS

5-2

CLUTCH6-1

CLUTCHSERVICE6-11

GENERAL

INFORMATION

6-1

SERVICE

DIAGNOSIS

6-2

COOLING

SYSTEM. . . . 7-1

ACCESSORY

DRIVE

BELTS7-21

COOLING

SYSTEM

DIAGNOSIS

: 7-4

DIAGNOSIS

7-3

ENGINE

BLOCKHEATERS. . . 7-24

SERVICE

PROCEDURES7-8

SPECIFICATIONS7-25

DRIVE

SHAFTSAND

UNIVERSAL

JOINTS

. . 16-1

GENERAL

INFORMATION

16-1

SERVICE

PROCEDURES16-10

SPECIFICATIONS. 16-27

ELECTRICAL

WIRING

DIAGRAMS

8W-1

COMPONENT

IDENTIFICATION

8W-7

ELECTRICAL

WIRING

DIAGRAMS

WIRE

ROUTING

AND

COMPONENT

LOCATION.

.

8W-37

SPLICE

LOCATION

8W-27

WIRING

DIAGRAMS

8W-1

Name

Group-page

ELECTRICAL

8A-1

ALTERNATORTESTPROCEDURESONVEHICLE.. . 8A-14

BATTERYTESTPROCEDURESONVEHICLE8A-2

BATTERY/STARTING/CHARGING

SYSTEMS

DIAGNOSTICS

8A-1

DIAGNOSTIC

INFORMATION

8A-1

GROUP

INDEX

......"8A-1

SPECIFICATIONS8A-19

STARTERTESTPROCEDURESONVEHICLE8A-9

EMISSION

CONTROL

SYSTEMS25-1

AIR

INJECTION

SYSTEM25-17

EVAPORATIVE

EMISSION

CONTROLS25-2

EXHAUST

EMISSION

CONTROLS25-9

SERVICE

PROCEDURES

25-22

ENGINE

. . . 9-1

3.9L

ENGINE

SERVICEPROCEDURES9-10

5.2L75.9L

ENGINE

SERVICEPROCEDURES9-39

ENGINE

DIAGNOSIS

9-7

GENERAL

INFORMATION

9-1

STANDARD

SERVICEPROCEDURES9-4

EXHAUST

SYSTEMAND

INTAKE

MANIFOLD

11-1

EXHAUST

DIAGNOSIS

11-3

GENERAL

INFORMATION

11-1

SERVICE

PROCEDURES11-3

FRAME

STRUCTURES13-1

INSPECTION

PROCEDURES13-6

LIGHT

DUTY

MODELS

13-12

SERVICE

PROCEDURES13-11

SPECIFICATIONS13-12

TIGHTENING

REFERENCE13-12

FRONT

SUSPENSION2-1

FRONT

SUSPENSION

COMPONENT

SERVICE—2WDVEHICLES2-7

FRONT

WHEEL

ALIGNMENT

2-3

GENERAL

INFORMATION

2-1

MODEL

44

FRONT

AXLESERVICE—4WDVEHICLES. . 2-15

MODEL

60

FRONT

AXLESERVICE—4WDVEHICLES. . 2-51

SPECIFICATIONS2-80

FUEL

SYSTEM14-1

ACCELERATORPEDALANDTHROTTLECABLE...14-15

DUAL

POINT

FUEL

INJECTION

14-17

FUEL

DELIVERYSYSTEM14-3

FUEL

TANKS

14-9

GENERAL

DIAGNOSIS

14-31

SERVICE

PROCEDURES14-47

HEATING

AND

AIR-CONDITIONING

.24-1

AIR-CONDITIONING

24-8

COMPRESSORSERVICE

24-29

DIAGNOSING

AIR-CONDITIONING

24-11

EVAPORATORHEATERASSEMBLY

24-36

HEATER24-1

PERFORMANCETEMPERATURE

CHART

24-18

REFRIGERANTSYSTEMSERVICEPROCEDURES. .

24-22

SERVICE

PROCEDURES24-6

SERVICE

PROCEDURES

24-26

TEST

PROCEDURES24-11

k