PRODUCT DESIGN

3

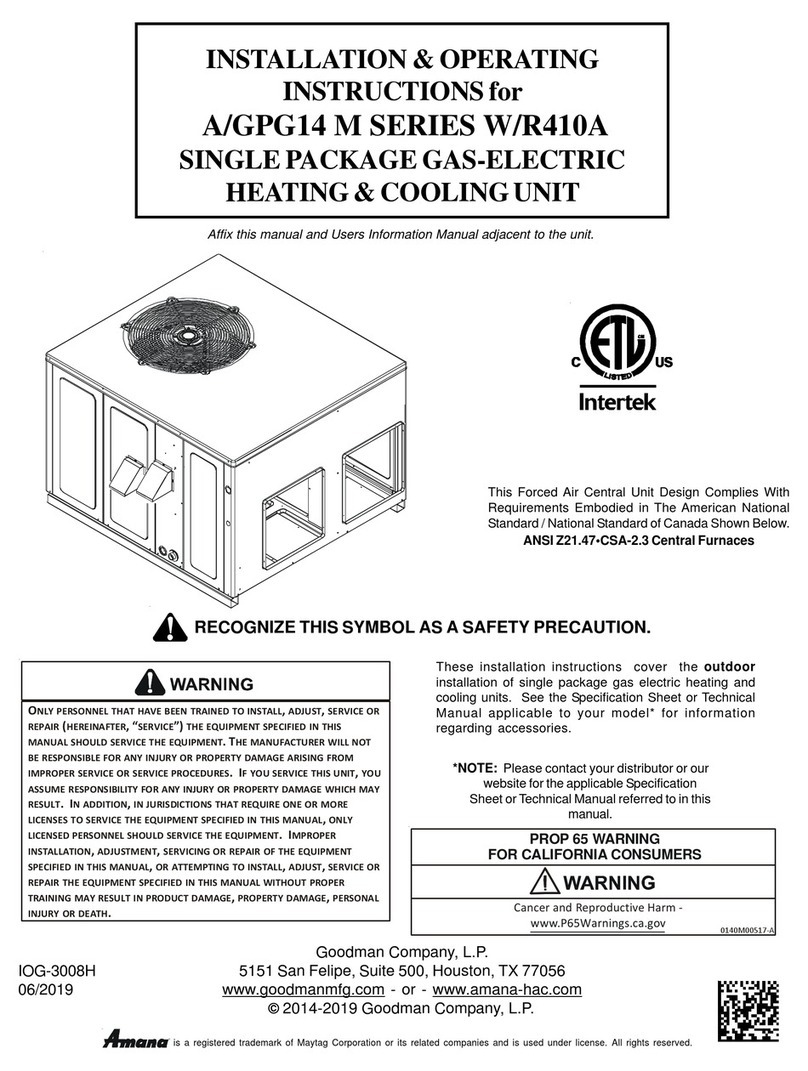

Amana PCC Package Cooling Units are designed for out-

door installations only in either residential or light commer-

cial applications.

The connecting ductwork (Supply and Return) can be con-

nected for either horizontal or vertical airflow. In the vertical

application a matching Roof Curb is recommended.

Areturn airfiltermustbeinstalledbehindthereturnairgrille(s)

or provision must be made for a filter in an accessible loca-

tionwithinthereturnairduct.Theminimumfilterareashould

not be less than those sizes listed in the Specification Sec-

tion. Under no circumstances should the unit be operated

without return air filters.

A 3/4" pipe and external drain trap is provided for removal of

condensate water from the indoor coil. (Do not reduce the

drain line size).

Refrigerant flow control is achieved by use of restrictor ori-

fices.

Thesinglephaseunitsuse permanent split capacitors (PSC)

designcompressors. Startingcomponentsarethereforenot

required. A low MFD run capacitor assists the compressor

to start and remains in the circuit during operation.

The outdoor fan and indoor blower motors are single phase

capacitor type motors (PCC60's use ECM motors).

Air for condensing (cooling cycle) is drawn through the out-

door coil by a propeller fan, and is discharged vertically out

the top of the unit. The outdoor coil is designed for .0 static.

No additional restriction (ductwork) shall be applied.

Conditioned air is drawn through the filter(s), field installed,

across the coil and back into the conditioned space by the

indoorblower.

All models of PCC series package units use the Compliant

Scrollcompressor,thereare a number of designcharacteris-

ticswhicharedifferent from the traditional reciprocatingcom-

pressor.

- DuetotheirdesignScrollcompressorsareinherentlymore

tolerant of liquid refrigerant. NOTE: Even though the

compressorsectionofaScrollcompressor is more toler-

ant of liquid refrigerant, continued floodback or flooded

start conditions may wash oil from the bearing surfaces

causingprematurebearingfailure.

- TheseScrollcompressorsusewhiteoilwhichiscompat-

ible with 3GS. 3GS oil may be used if additional oil is

required.

- Operatingpressures andampdrawsmaydifferfromstan-

dard reciprocating compressors. This information may

be found in the "Cooling Performance Data" section.

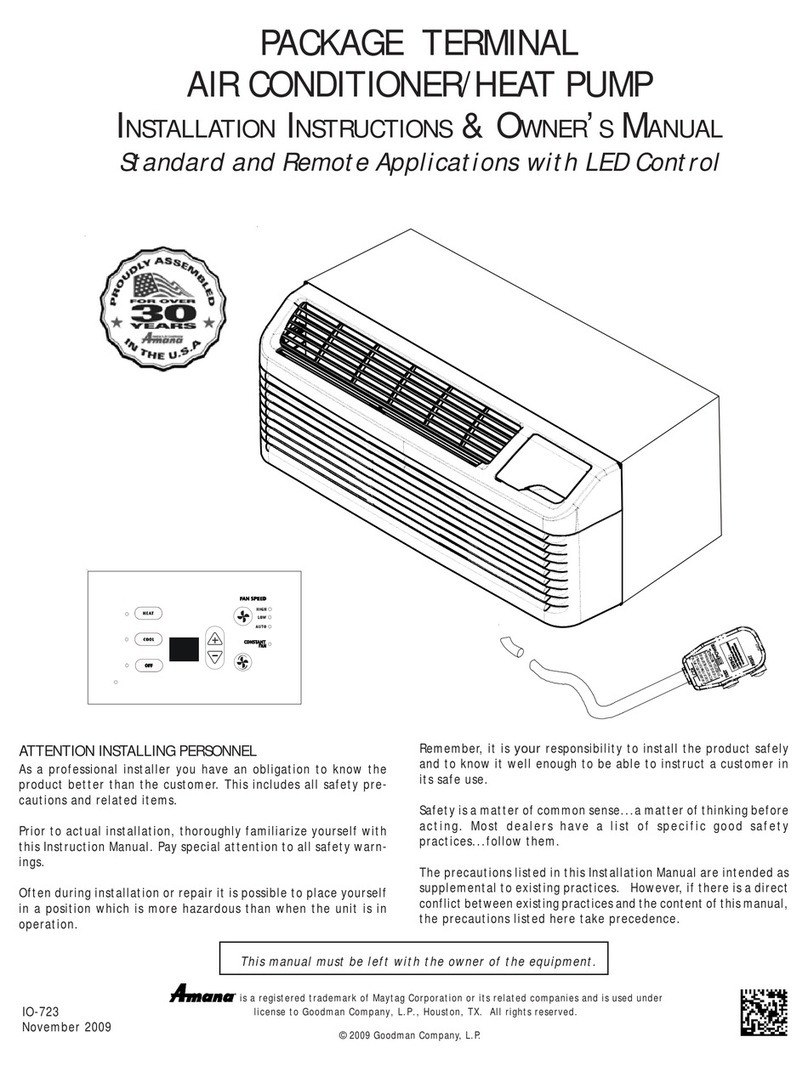

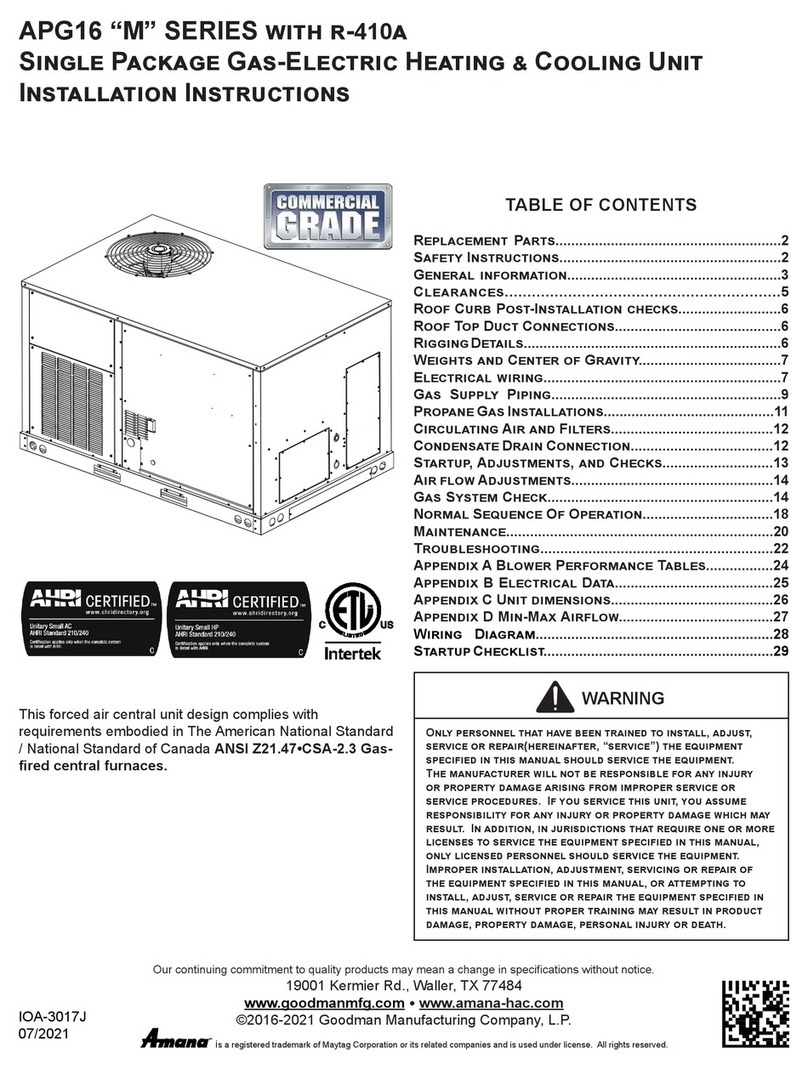

LocationandClearances

36"

Maximum

Overhang

48" Minimum

Overhang

36" Side

Clearance

for Servicing

Recommended

Minimum 36"

Clearance for

Service Required 0" Minimum

Clearance to

Combustibles

Vinyl Coated

Canvas

Connections

Insulated

Return

Duct

Insulated

Supply

Duct

24" Clearance

(Condenser End)

Ininstallations where the unitis installed above groundlevel

andnot serviceable from the ground (Example: Roof Top in-

stallations)theinstallermust provide service platform forser-

vicepersonwithrailsorguardsinaccordancewithlocal codes

orordinancesorintheirabsencewiththelatesteditionofthe

UniformMechanical Code Section 305.

NOTE: Unitcanalsouse roof curb (and platformforleveling,

where necessary) to utilize bottom discharge.

WARNING

TOPREVENTPOSSIBLE PROPERTYDAMAGE,THEUNIT

SHOULDREMAININANUPRIGHTPOSITIONDURINGALL

RIGGING AND MOVING OPERATIONS. TO FACILITATE

LIFTINGAND MOVING IFACRANE ISUSED,PLACE THE

UNITINAN ADEQUATE CABLE SLING.

IMPORTANT: If using bottom discharge with roof curb,

ductwork should be attached to the curb prior to installing

the unit.

Refer to Roof curb Installation Instructions for proper curb

installation. Curbing must be installed in compliance with

the National Roofing Contractors Association Manual.