3 16021711 Rev. 0

Important Information .................................................. 2

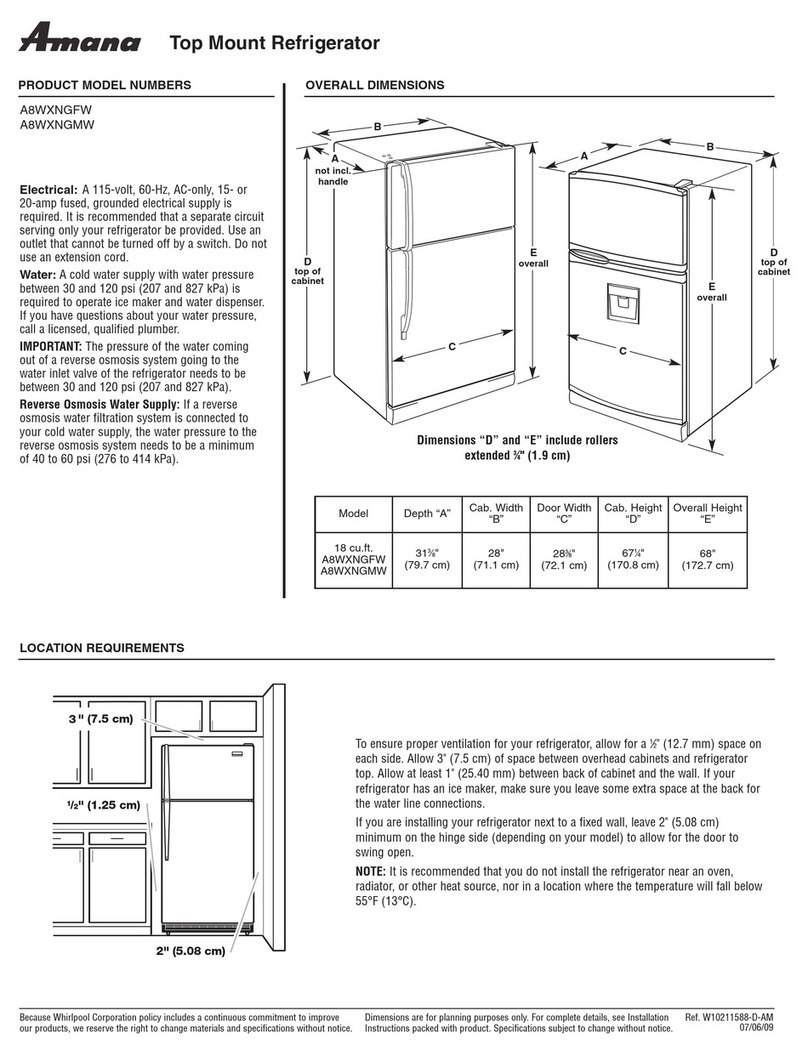

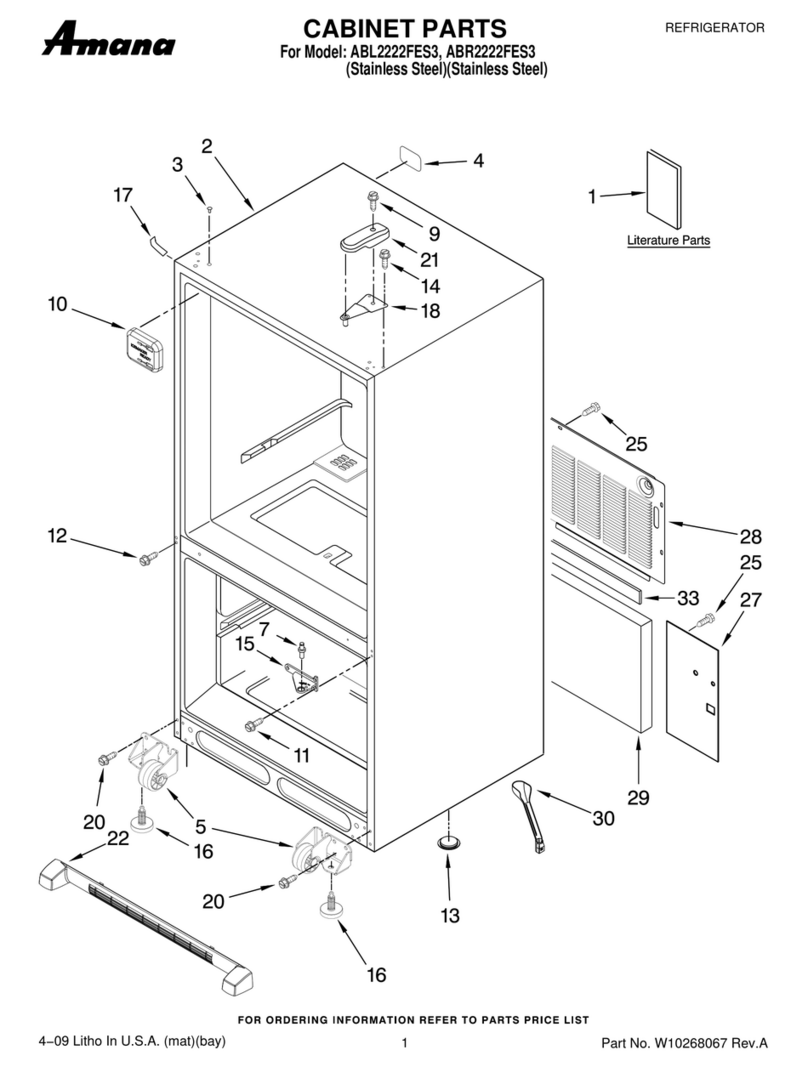

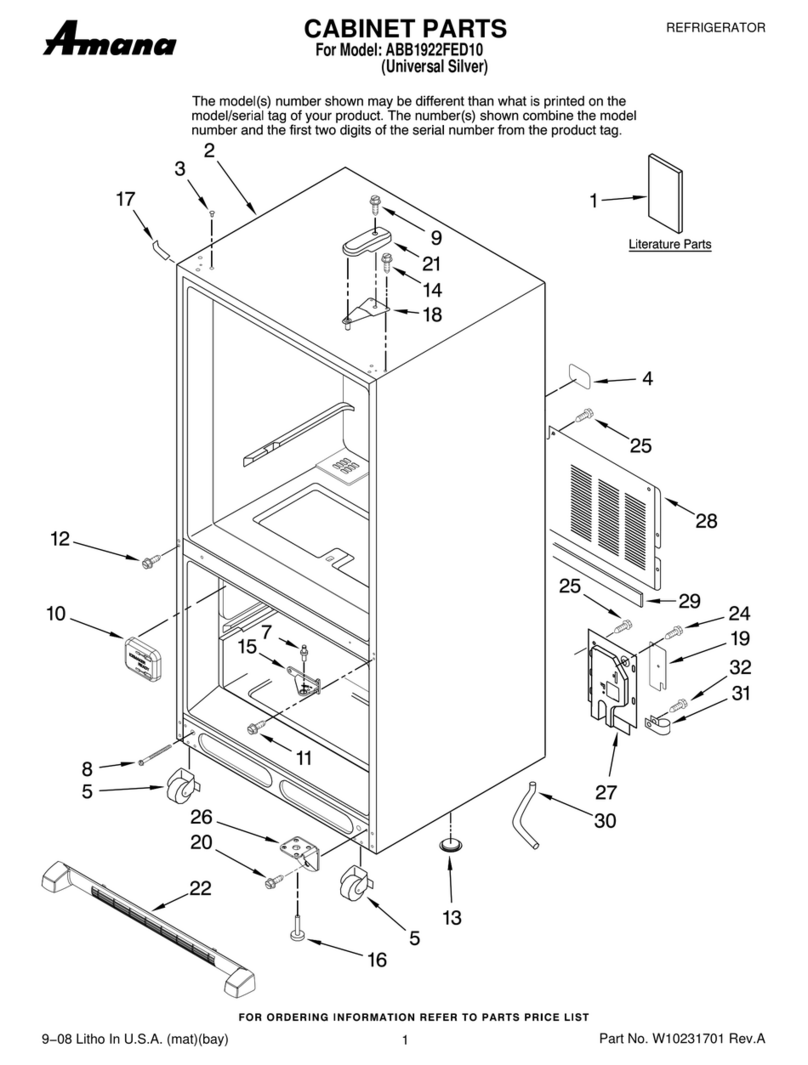

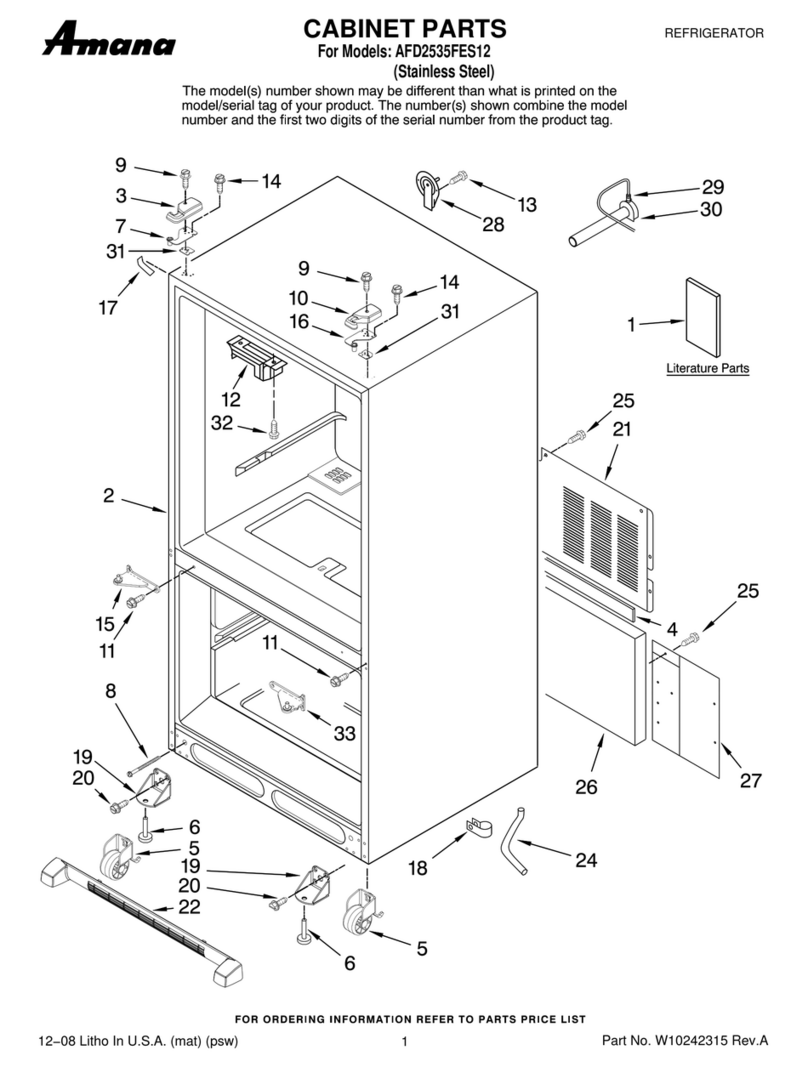

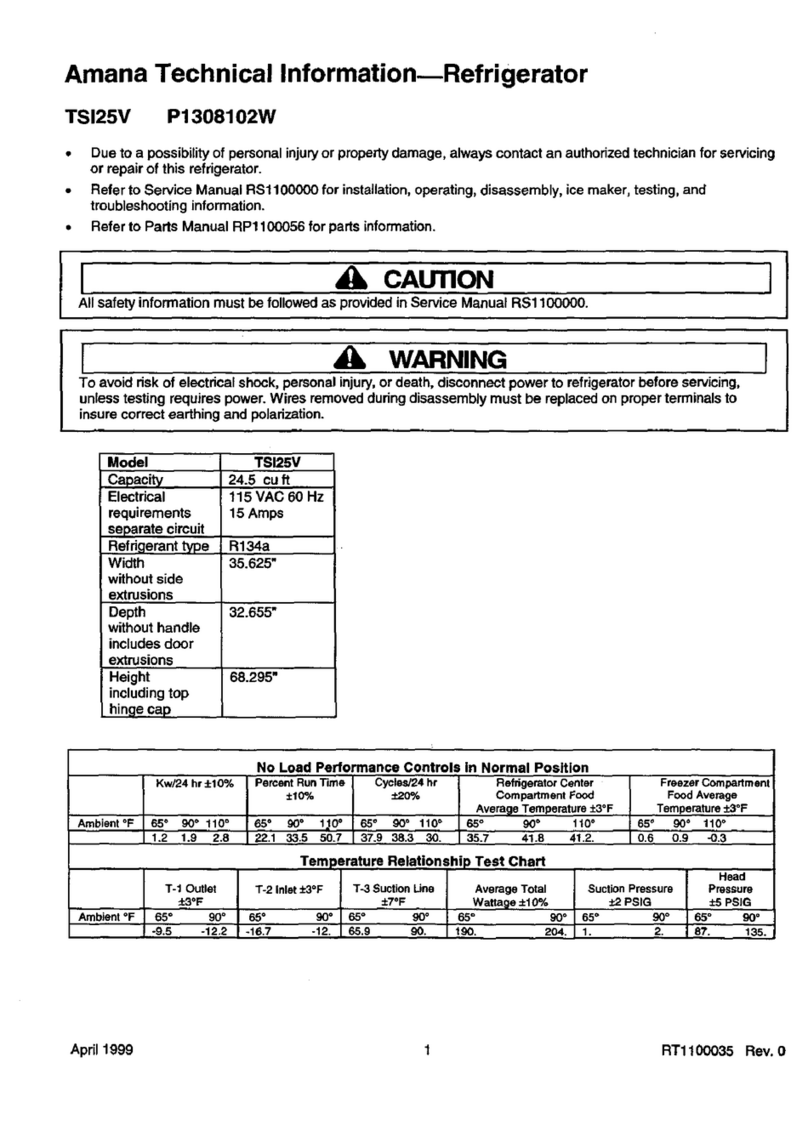

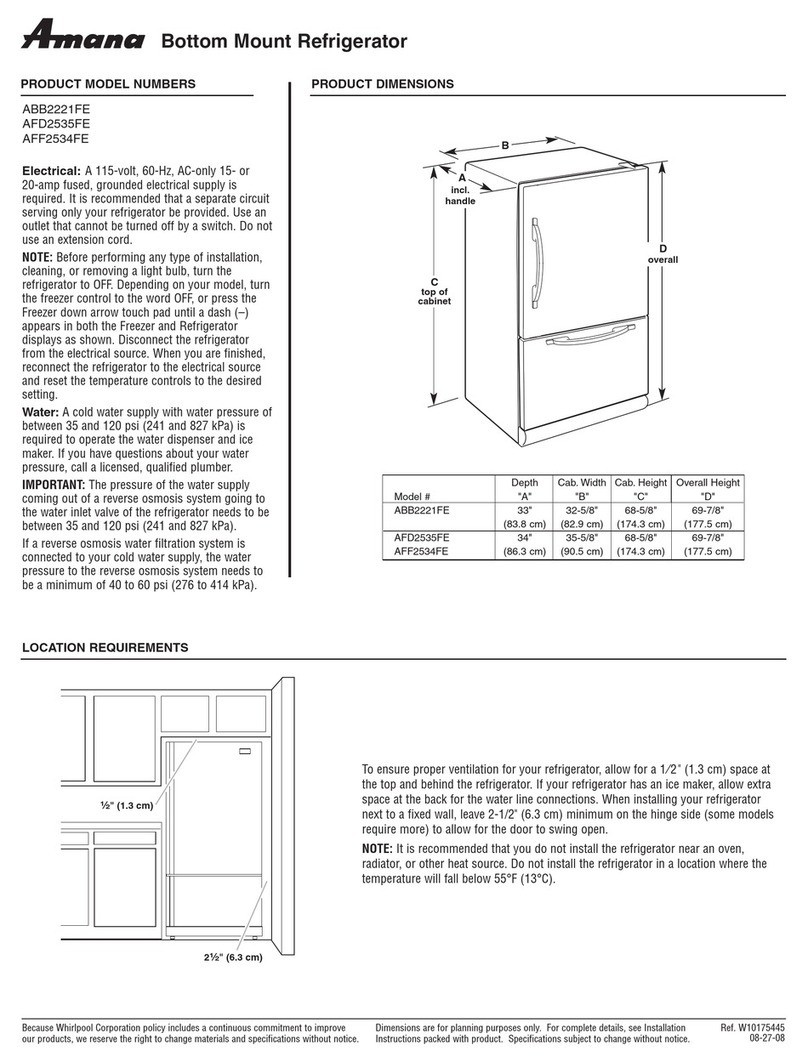

Product Design ............................................................. 4

Component Testing .......................................................

Service Procedures .................................................... 10

Service Equipment ..................................................... 10

Drier Replacement ...................................................... 10

Refrigerant Precautions ............................................... 11

Line Piercing Valves .................................................... 11

Open Lines .................................................................. 11

Compressor Operational Test ...................................... 11

Dehydrating Sealed Refrigeration System .................. 12

Leak Testing ............................................................... 12

Testing Systems Containing a

Refrigerant Charge................................................ 12

Testing Systems Containing

No Refrigerant Charge ......................................... 12

Restrictions ................................................................. 13

Symptoms ............................................................ 13

Testing for Restrictions ......................................... 13

Evacuation and Charging ........................................... 14

Evacuation ........................................................... 14

Charging .............................................................. 1

Refrigerant Charge................................................ 1

HFC134a Service Information ..................................... 16

Health, Safety, and Handling ................................ 16

Comparison of CFC12 and HFC134a Properties . 16

Replacement Service Compressor ............................. 17

Compressor Testing Procedures .......................... 17

Brazing ....................................................................... 17

Refrigerant Flow ...........................................................18

Cabinet Air Flow One Way ..........................................19

Cabinet Air Flow Two Way ............................................ 20

Ice and Water Dispenser Diagram ................................21

Water Valves Diagram................................................22

Typical External Sweat Pattern ................................23

Troubleshooting Chart .............................................24

System Diagnosis ........................................................27

Disassembly Procedures

Refrigerator Compartment ...................................... 30

Upper Light Socket & Lens................................... 30

Freezer Cold Control ............................................ 30

Defrost Timer..........................................................30

Adaptive Defrost Control ...................................... 30

Damper Control.......................................................31

Water Filter Assembly.............................................31

Water Tank Assembly..............................................31

Crisper Cover and Socket .................................... 31

Freezer Compartment

Freezer Light Socket ............................................ 31

Auger Motor Assembly ......................................... 31

Auger Motor ......................................................... 31

Auger Motor Capacitor............................................32

Evaporator Fan Motor Assembly .......................... 32

Evaporator Fan Motor and Fan Blade.....................32

Evaporator Removal...............................................32

Defrost Terminator (Thermostat) .......................... 32

Defrost Heater...................................................... 32

Ice Maker Removal.................................................33

Machine Compartment

Water Valves ........................................................ 33

Condenser Fan Motor and Blade ............................ 33

Compressor ...........................................................33

Condensate Drain Tube .......................................... 33

Condensate Drain Pan ........................................... 33

Overload/Relay ...................................................... 34

Condenser ............................................................. 34

Bottom of Cabinet

Front Leveling Rollers .......................................... 34

Rear Leveling Rollers ........................................... 34

Cabinet Doors

Door Gaskets ....................................................... 34

Dispenser Facade (Electronic Model) .................... 34

Dispenser Ice Chute Door ......................................3

Dispenser Light Socket .......................................... 3

Dispenser D/C Solenoid ......................................... 3

Dispenser Water Tube ........................................... 3

High Voltage Board (Electronic Model) ................... 3

Ice N Water Systems

Troubleshooting of button Dispenser .................. 36

Troubleshooting of Electronic Dispenser ................ 39

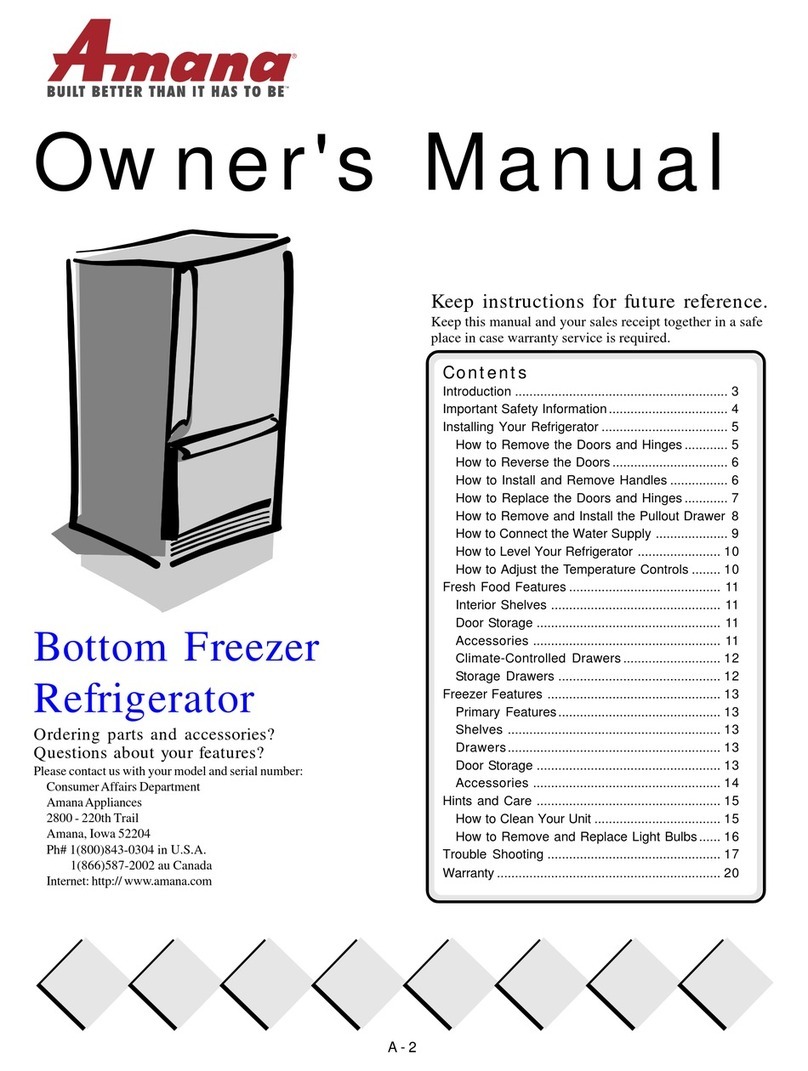

Appendix A

Owners Manual ...... .............................................A-2

Table of Contents