BAG0007.4 08.16

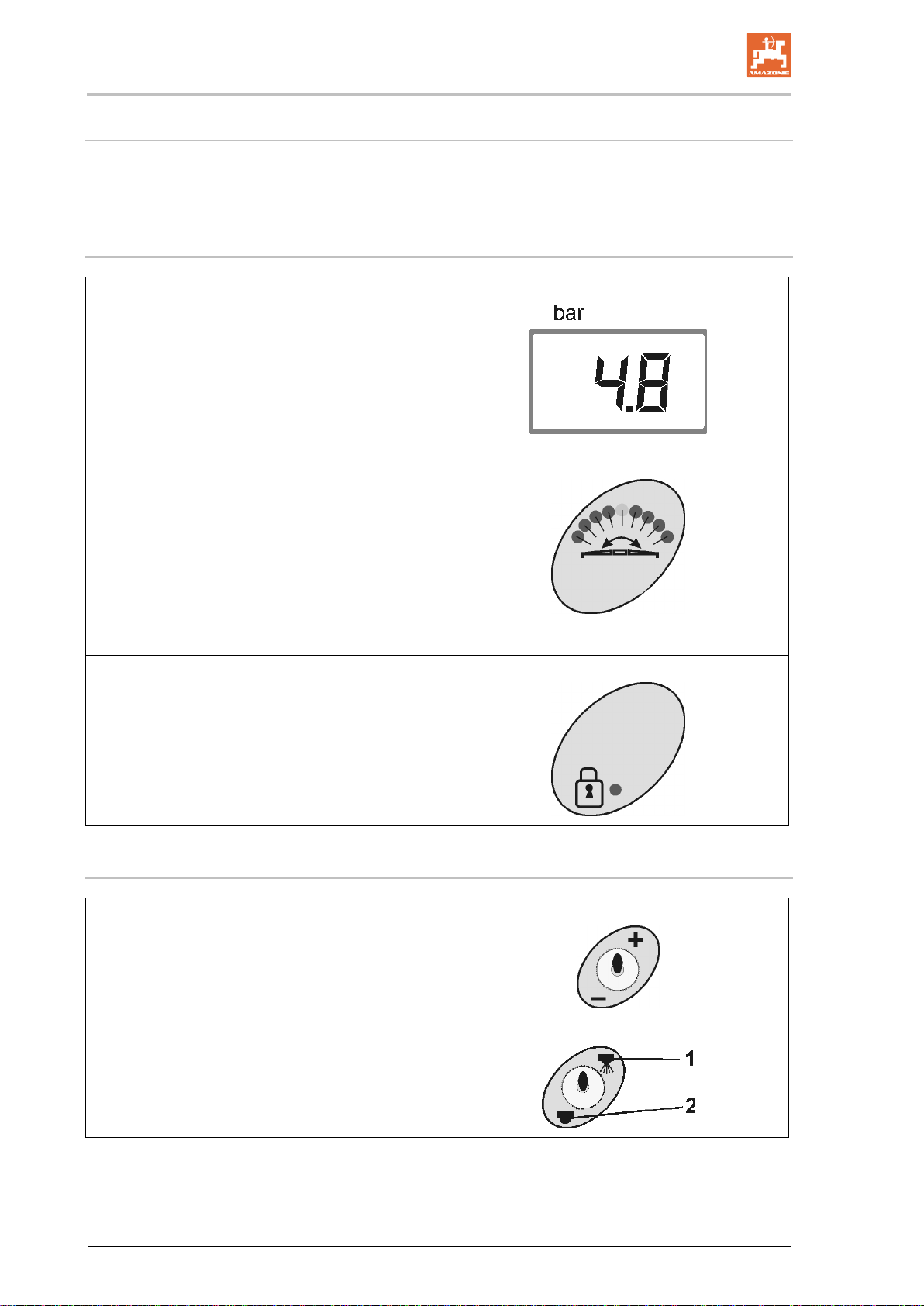

•Switch for switching on / off the boom part

width sections. The number of switches is

equal to that of the boom part width sec-

tions.

Left hand switch – boom part width section

outermost left hand side off / on.

Right hand switch – boom part width section

outermost right hand side off / on.

4.3 Description of the keys

Switching on and off the AMASET+

After switching on the pressure indication lights

up and AMASET+ is ready for operation.

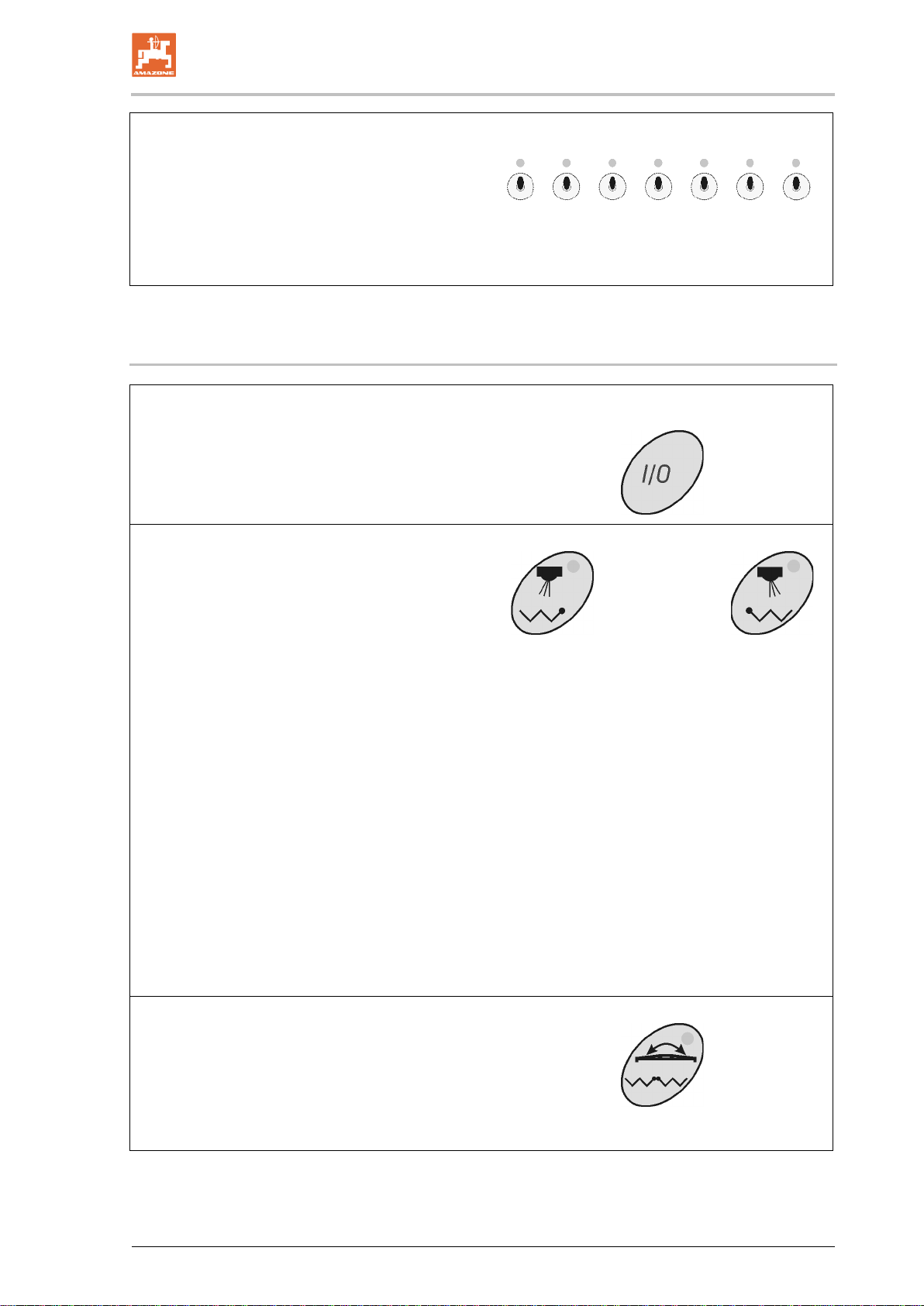

•Keys optional equipment: Left and right

hand side

These keys are available for one of the following

4 possibilities:

οEnd nozzle switching

When the end nozzle switching is

switched on (green indicator light) the

outer boom part width section is re-

duced each by 1, 2 or 3 nozzles.

οBorder spreading nozzles

When the end nozzle switching is

switched on (green indicator light) the

outer nozzle is switched off and the

border spreading nozzle is switched

on.

οOne side folding

When the boom is folded down the

one side folding can be switched on.

Control lamp illuminates:

Boom side is blocked.

Control lamp does not illuminate:

Boom side can be folded.

οKey not covered.

•Key hydraulic changeover folding of the

boom – tilt adjustment

For coupling the hydraulic functions connect tilt

adjustment and folding to a double acting control

valve on the tractor.

The light indicates when the tilt adjustment is

active.