Installation Instruction FS80-C

Issue Date 0912

The performance specifications conform to acceptable industry standard. For application to conditions beyond these specifications, consult the local Johnson Controls office. Johnson Controls,

Inc., shall not be liable for damages resulting from misapplication or misuse of its products. ©2009 Johnson Controls, Inc.

www.johnsoncontrols.com

1

FS80-C Flow Switch

Application

1) FS80-C Flow Switch responds to fluid flow in lines carrying water ethylene

glycol or other non-hazardous fluids.

2) FS80-C Flow Switch use a variety of paddle sizes to respond to fluid flow

rates in applications with pipe sizes greater than 1-inch trade size.

3) Single-Pole Double-Throw (SPDT) flow switch that can be wired to energize

one device and de-energize another device powered from the same source

when liquid flow either exceeds or drop below the set flow rates.

4) FS80-C use with fluid pressures up to 1.5MPa.

5) Maximum Velocity: 3m/sec.

6) Fluid temperature range: -25

℃

to 110

℃

fluid temperatures need above

ambient dew point; Ambient temperature range: -20

℃

to 60

℃

7) FS80-C Flow Switch with IP55 enclosure.

ELECTRICAL RATINGS

Electrical

rating

Horse

power

(HP)

Full Load

Amperes

(A)

Locked

Rotor

Amperes(A)

Non-

inductive

Amperes(A)

Pilot Duty

110VAC 1 16 96 16

220VAC 1 8 48 16

125VA at 24

~

277VAC

PERATI N

The SPDT switch on the FS80-C has color-coded terminals. Red is common

and closed to Blue upon flow increase and to Yellow upon flow decrease. See

Figure 1 and Table 1 for switch action and flow rates.

Fig.1 Switch Action

INSTALLATI N AND WIRING

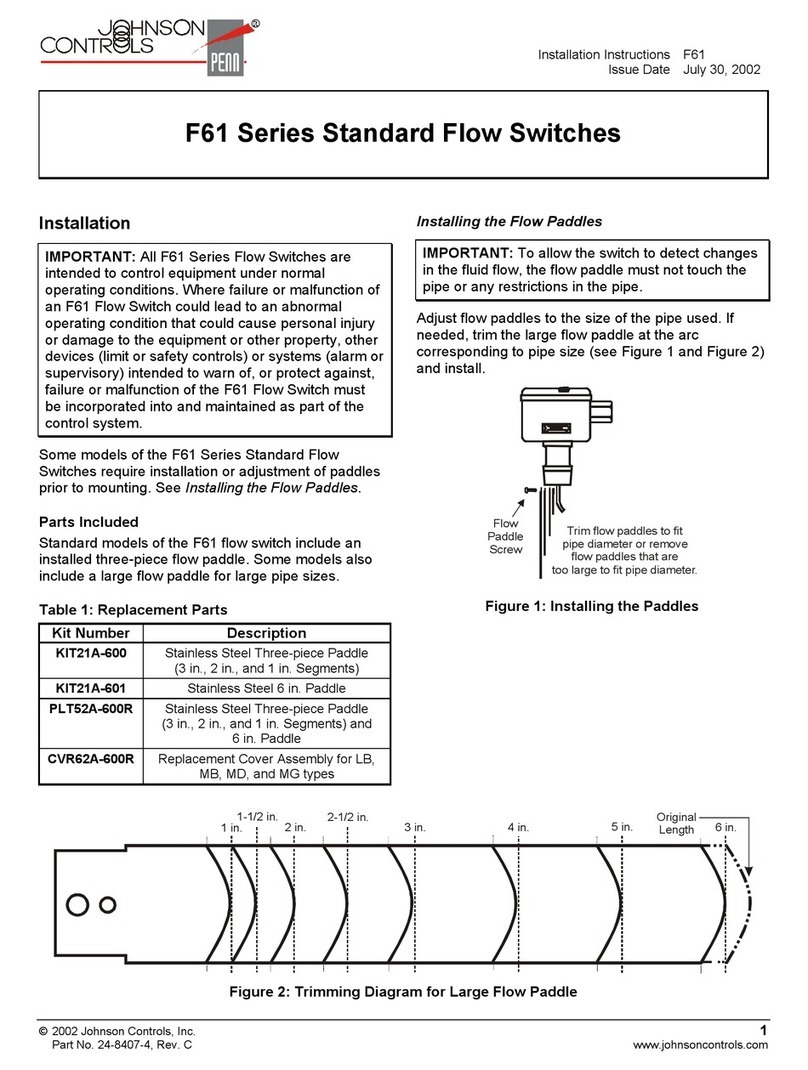

Adjusting the Flow Switch Paddle

FS80-C Flow Switch comes with 4-piece paddle (1 in. 2 in . 3 in. and 6 in.

segments). Adjust the paddle to the size of the pipe in which it will be

installed. If needed use the template (see Figure 5) and trim the large

paddle at the arc corresponding to pipe size and install.

Example, if 3” pipe is used, Install 1” , 2” and 3” segments (see Figure 2), if

1-1/2 pipe is used, trim the 2” paddle to the pipe size or use the 1” paddle

segment.

Figure 2 Paddle Installation Example

Mount the FS80-C in a section of pipe where there is a straight run of at least

five pipe diameters on each side of the Flow Switch. See Figure 3.

Figure 3 Typical Installation

The switch should be mounted so the terminals or wire leads are easily

accessible for wiring.

Note

:

These flow switch must not be subjected to water hammer. If a fast-closing

valve is located downstream of the flow switch a suitable water hammer arrester

must be used. See figure 4.

Figure 4 Arrester Location Schematic

Mount the flow switch in a standard 1 in.x 1 in.x 1 in. tee for 1 in. pipe

installation. Use a reducing tee for larger sizes of pipe to keep the flow switch

close to the pipe and provide adequate paddle length in th flow stream.

Example: Use a 2 in.x 2 in.x 1 in. tee for a 2 in. pipe. If a standard 2 in.x 2 in.x 2 in.

tee is used install a face or hex bushing in the top opening to reduce it to 1 in.

Screw the flow switch in position so the flat of the paddle is at a right angle to

the flow. The arrow on the side of the case must point in the direction of the

flow.

FS80-C flow switch may be mounted in a horizontal pipe line or a vertical

pipe line with upward liquid flow. It is not recommended for installations

where flow is downward. When mounted in a vertical pipe with upward flow

the switch will trip at a slightly higher flow than shown in table 1 Typical Flo

Rates due to the effect of gravity on the switch mechanism.

Wiring

IMP RTANT

:

Do not use FS80-C on systems with flow velocity greater

IMP RTANT

:

::

:

FS80-C Flow Switch is designed for use only as operating

controls. Where an operating control failure would result in personal

injury and/or loss of property, it is the responsibility of the installer to

add devices (safety, limit controls) that protect against, or systems

(alarm. Supervisory systems) that warn of, control failure.

WARNING: Shock hazard

Disconnect the power supply before the wiring connections are made

electrical shock or damage to the equipment

IMP RTANT:To allow the switch to detect changes in the flow condition,

the paddle must not touch the pipe or any restrictions in the pipe.

CAUTI N: Equipment damage hazard.

To avoid damaging the switch, do not tighten the switch to the tee by

grasping the switch enclosure. Use only the wrench flats provided (see

Figure 6).