Operation manual

© Amberg Technologies AG, 2012-2018 Page 3 of 84

Table of Contents

Welcome to TSP 303 ................................................................................................................ 5

1 Conventions used in this manual ................................................................................... 5

2 Software licence agreement ........................................................................................... 6

3 Software installation ........................................................................................................ 6

3.1 System requirements ........................................................................................... 6

3.2 Software installation ............................................................................................. 7

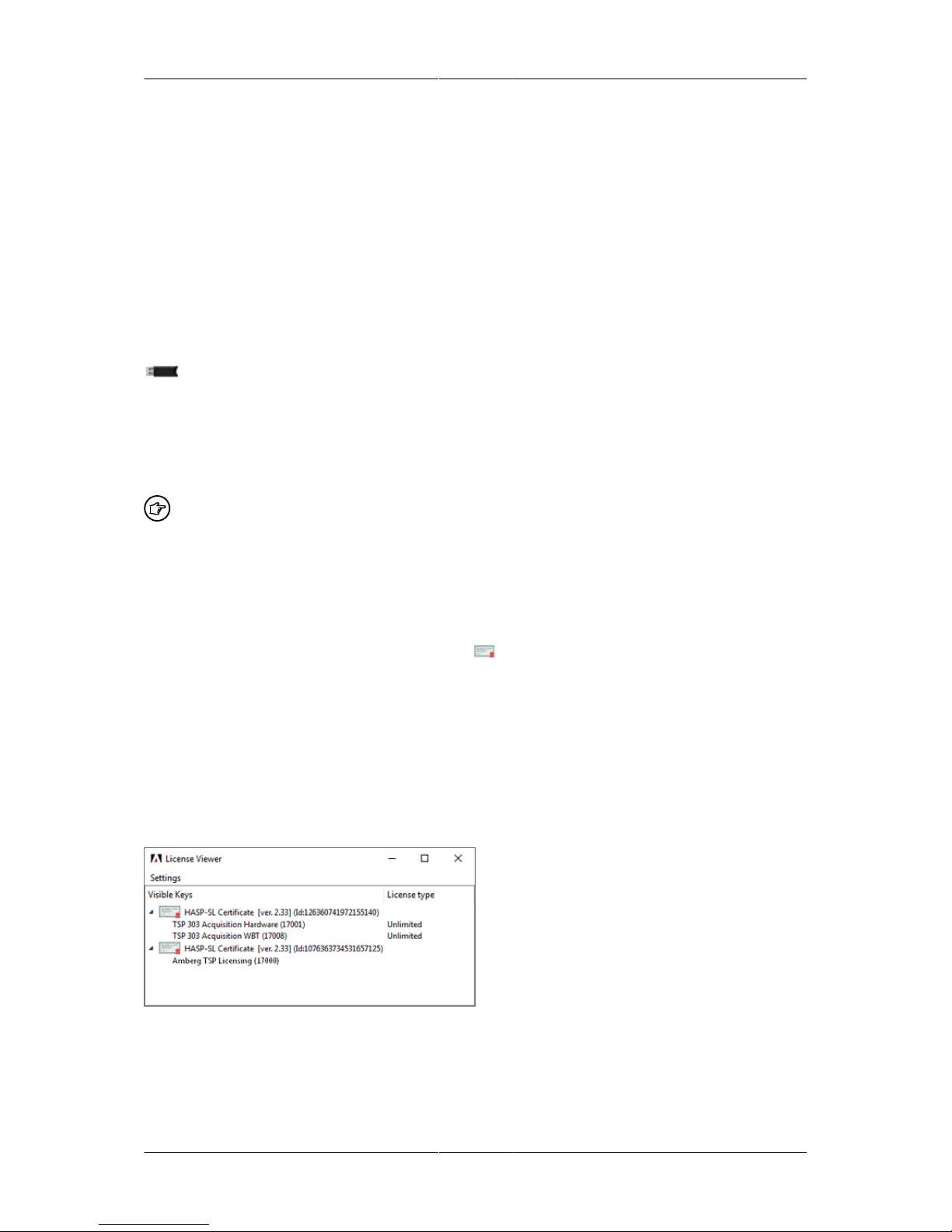

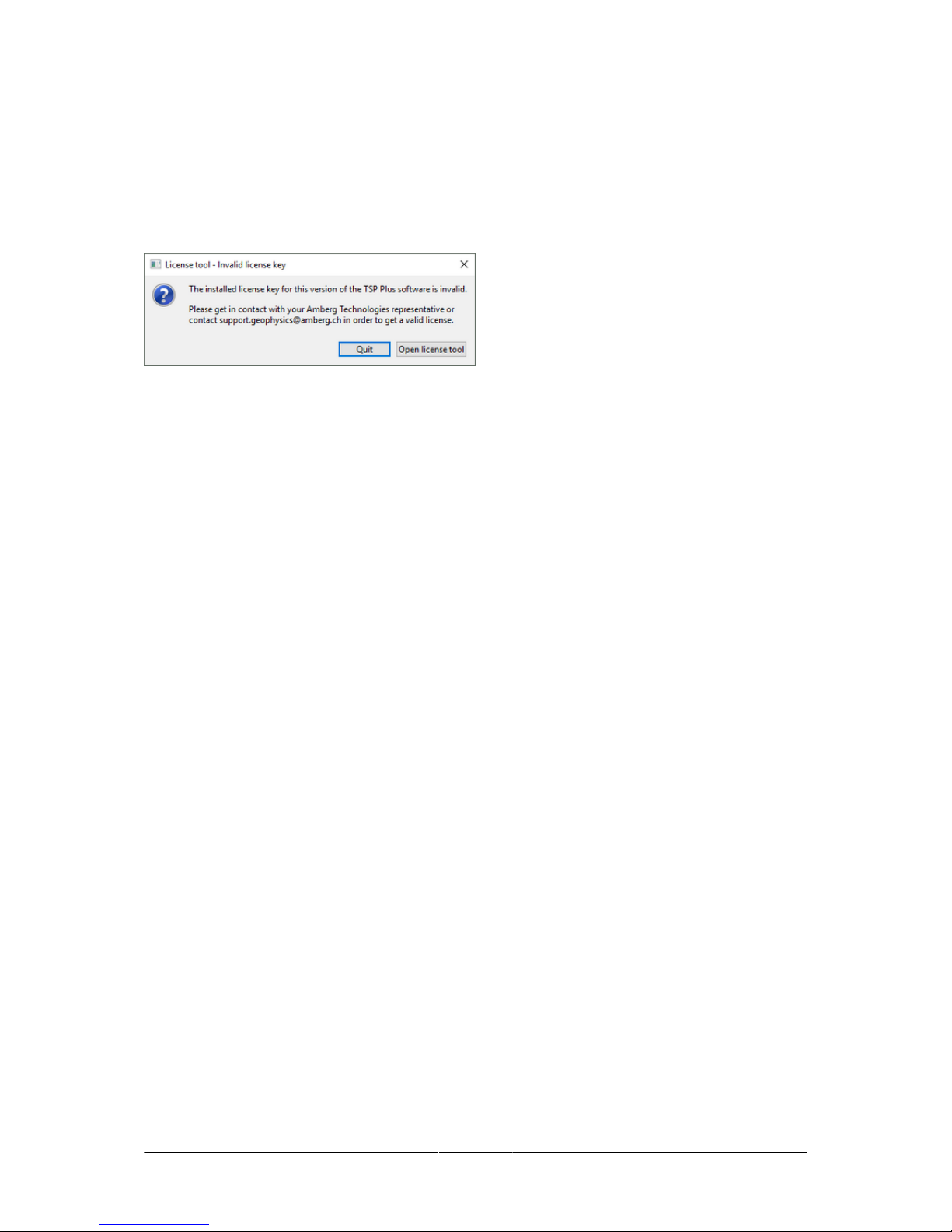

4 Software licensing ........................................................................................................... 8

4.1 Hardkey version ................................................................................................... 8

4.2 Softkey version ..................................................................................................... 8

4.3 License tool .......................................................................................................... 8

4.4 License upgrade ................................................................................................... 9

5 Maintenance & Support contract .................................................................................... 10

1 Safety directions ...................................................................................................................... 11

1.1 Disclaimer of liability .................................................................................................... 11

1.2 Use of instrument ......................................................................................................... 11

1.2.1 Intended use of instrument ............................................................................... 11

1.2.2 Prohibited uses ................................................................................................. 11

1.2.3 Limits of Use ..................................................................................................... 11

1.2.4 Prohibited modifications .................................................................................... 12

1.2.5 Danger working within tunnel environment ...................................................... 12

1.2.6 Other dangers ................................................................................................... 12

2 TSP 303 Plus system components ........................................................................................ 13

3 Preparing a TSP measurement .............................................................................................. 17

3.1 General ......................................................................................................................... 17

3.2 Marking of the measurement layout ............................................................................ 17

3.3 Drilling and protecting bore holes ............................................................................... 18

3.4 Check list of required items ......................................................................................... 19

4 Performing a TSP measurement ............................................................................................ 21

4.1 Measuring of the layout geometry ............................................................................... 21

4.2 System setup ................................................................................................................ 25

4.2.1 Assembling receiver .......................................................................................... 26

4.2.2 Checking receiver bore holes ........................................................................... 28

4.2.3 Setting the receiver ........................................................................................... 30

4.2.4 Connecting Toughbook with Recording Unit .................................................... 36

4.2.5 Checking battery charge ................................................................................... 36

4.2.6 Use of external batteries .................................................................................. 37

4.2.7 Seismic noise test ............................................................................................. 37

4.2.8 Trigger/Shot test (Trigger mode Standard) ...................................................... 38

4.2.9 Charge configuration ......................................................................................... 38

4.2.10 Detonator preparation & system setup ........................................................... 39

4.2.11 Standard system setup with explosive source ............................................... 41

4.2.12 Wire Break system setup with explosive source ............................................ 43

4.2.13 Hammer system setup with impact hammer source ...................................... 48

4.3 Seismic data acquisition .............................................................................................. 49

4.3.1 Data acquisition procedures ............................................................................. 49

4.3.2 Amberg TSP Plus Workspace .......................................................................... 53

4.3.3 Amberg TSP Plus Menus & Tool bars ............................................................. 54

4.3.4 Starting data acquisition ................................................................................... 54

4.4 Acquisition wizard ........................................................................................................ 55

4.4.1 Data affecting settings ...................................................................................... 55