6

General Information

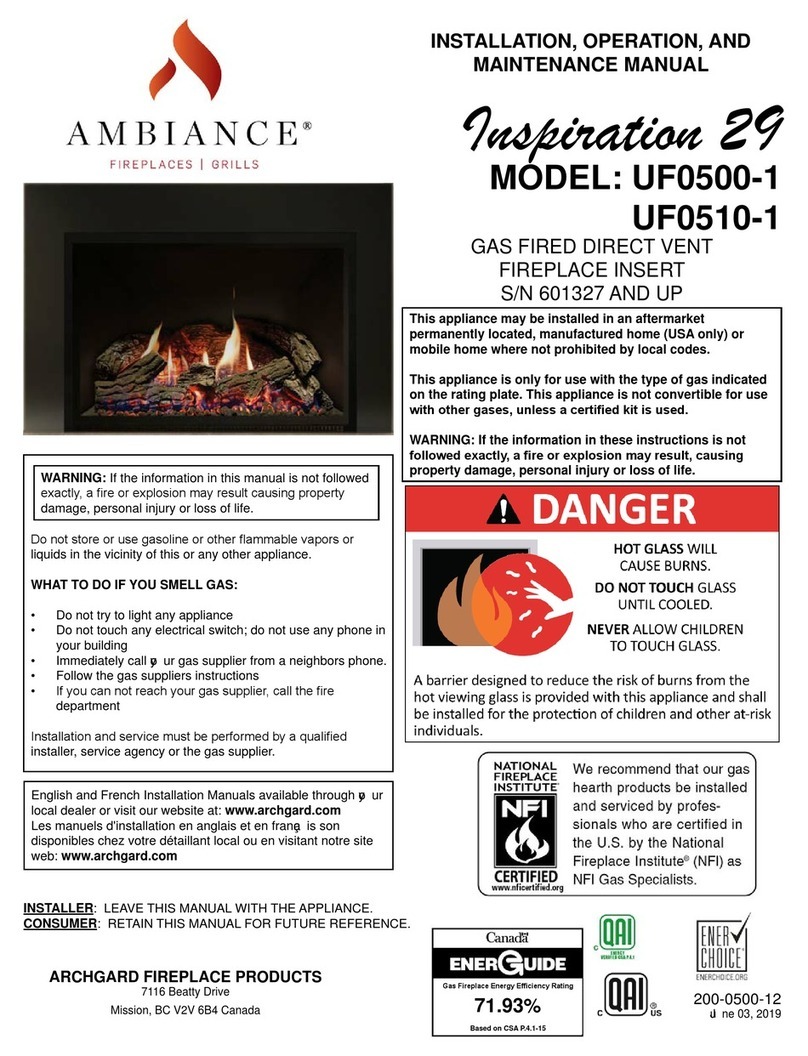

4.0 Rating Plate

SAMPLE

LISTED VENTED GAS FIREPLACE HEATER and GAS-FIRED APPLIANCES FOR USE AT HIGH ALTITUDES. Tested to: ANSI

Z21.88-2019 / CSA 2.33-2019, CSA 2.17-2017, CSA P.4.1-15, and CSA 22.2 No.3-M1988 (R2014). This vented gas replace heater

is not for use with air lters. Certied for use in both CANADA and USA.

VENTED GAS FIREPLACE HEATER-NOT FOR USE WITH SOLID FUEL.

NG LPG

Input rating 17,500 - 31,500 BTU/hr

(5.1 - 9.2 kW)

16,000 - 31,500 BTU/hr

(4.69 - 9.2 kW)

Manifold Pressure 1.1 - 3.8 in. W.C. (0.2 - 0.94 kPa) 2.9 - 11.0 in. W.C. (0.7 - 2.7 kPa)

Orifice size #37 DMS (2.64 mm dia.) #51 DMS (1.73 mm dia.)

Supply pressure (Min - Max) 5.0 - 14.0 in. W.C. (1.2 - 3.5 kPa) 12.0 - 14.0 in. W.C. (2.8 - 3.5 kPa)

Burner Primary Air Setting 1/8” (3mm) Open 1/4” (6.4mm) Open

Altitude 0 - 4500 (0 - 1372 m) 0 - 4500 (0 - 1372 m)

Gas Control SIT 885 Proflame II Dynamic Start with Continuous POD

Electrical rating 120 VAC, 60 Hz less than 2 A.

P.4.1 Fireplace Efficiency (FE) 71.93%

Replacement fan Part no. RF-305-0624 fan or blower assembly must be used

Keep burner and control compartment clean. See Instructions

accompanying the heater.

Optional fuel conversion kit : See Manual

Minimum opening Dimensions:

303/4”(781 mm)W x 20”(508 mm)H x 18” (457 mm)D

Minimum Chimney Flue Size:

4” (100 mm) x 7” (176 mm)

Minimum clearances to Combustibles:

Sides from glass door frame: 7” (178 mm)

Mantle: max 8” (203 mm) at min 35” (889 mm) from bottom of

appliance

See Manual for additional dimensions and clearances

This appliance must be installed in accordance with local codes, if any; if none, follow the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

Natural Gas and Propane Installation Codes, CSA B149,1. Electrical connections and grounding must be in accordance with local codes, if any;

if none, follow the current CAN/CSA C22.1 in Canada and ANSI/NFPA 70 in the US. This appliance is certified for installation in a bedroom or

a bed sitting room. This appliance is only for use with the gas indicated on the rating plate and may be installed in an aermarket, permanently

located, manufactured (mobile) home where not prohibited by local codes. See owner’s manual for details. This appliance is not convertible

with other gases, unless a certified kit is used.

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause injury or property damage. Refer to the owner’s

information manual provided with this appliance. For assistance or additional information consult a qualified installer, service

agency, or the gas supplier. This appliance must be properly connected to a Direct Vent venting system in accordance with the

manufacturer’s installation instructions.

WARNING: Failure to install this appliance per the manufacturer’s instructions or failure to use only parts specifically approved with this

appliance may result in property damage or personal injury.

WARNING: Do not operate the appliance until all sections have been assembled and installed in accordance with the manufacturer’s

instructions.

WARNING: Operation of this appliance when not connected to a properly installed and maintained venting system can result in carbon

monoxide (CO) poisoning and possible death.

ONLY DOORS CERTIFIED WITH THE APPLIANCE SHALL BE USED.

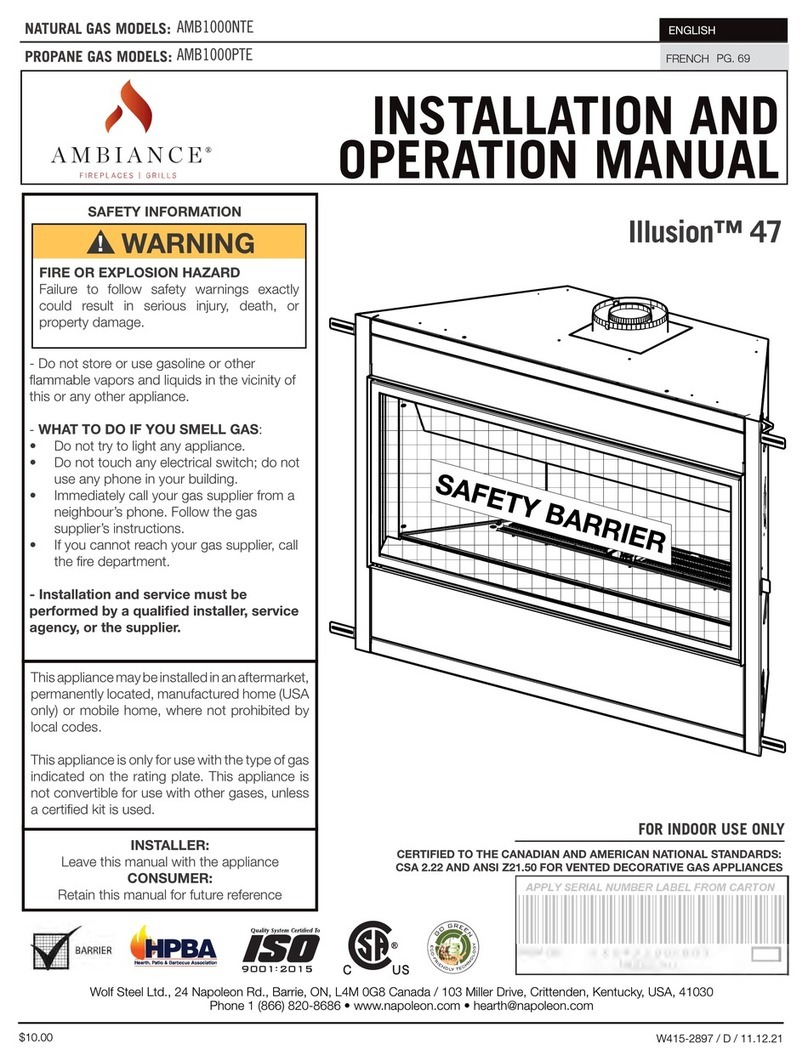

For use only with barrier part # URP-890-0200. Follow installation instructions.

Made in Canada by:

Archgard Industries Ltd.

7116 Beatty Dr., Mission, B.C.

August 2022 303-6050-10

MANUFACTURE DATE:

MODEL: UF0500-2

Manufactured as Natural Gas