Form WA004, Page 4

Units should always be arranged to blow toward or along exposed

wall surfaces, if possible. Where two or more units are installed in

the same room, a general scheme of air circulation should be main-

tained for best results.

Suspended heaters are most effective when located as close to the

working zone as possible. However, care should be exercised to

avoid directing the discharge air directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken

into consideration when locating the unit heater so that a minimum

quantity of air will be deflected by any such obstacles. When units

are suspended in the centre of the space to be heated, the air should

be discharged along exposed walls. In large areas, unit should be

locatedto dischargeair alongexposed wallswith extraunits provided

to discharge air in toward the centre of the area. At those points

where infiltration of cold air is excessive, such as at entrance doors

and loading doors, it is desirable to locate the unit so it will discharge

directly toward the source of cold air from a distance of 4.5 to 6.0

metres.

3.0 GENERAL REQUIREMENTS

3.1 Related Documents

It is important that all gas appliances are installed by competent

persons, i.e. a registered CORGI installer, in accordance with the

relevant requirements of the following regulations.

Failure to install appliances correctly could lead to prosecution. It is

in your own interest and that of safety to ensure compliance with

the law.

THERELEVANTREGULATIONSARE...

GASSAFETY(INSTALLATIONS&USE)(Amendment)REGU-

LATIONS 1990

THEHEALTHANDSAFETY AT WORK,ETC. ACTS

••

••

•BS6230 1991 SPECIFICATION FOR THE INSTALLATION

OF GAS FIRED FORCED CONVECTION AIR HEATERS

FOR COMMERCIAL AND INDUSTRIAL SPACE HEAT-

ING OF RATED INPUT EXCEEDING 60 KW.

••

••

•BS5588 PART 1 (SECTION 1) 1990; PART 2 1985 AND

1990; AND PART 3 1983 AND 1989

••

••

•BS5440 PART 2 1989 FLUES AND AIR SUPPLY FOR GAS

APPLIANCES NOT EXCEEDING 60 KW

••

••

•BS6891 1988 LOW PRESSURE INSTALLATION PIPES

BRITISHGAS PUBLICATIONS

IGE/UP/1 PURGING PROCEDURES FOR NON-DOMESTIC

INSTALLATIONS and SOUNDNESS TESTING PROCE-

DURES FOR INDUSTRIAL INSTALLATIONS.

I.E.E. REGULATIONS FOR ELECTRICAL INSTALLATIONS

AND THE REQUIREMENTS OF THE FOLLOWING...THE

LOCALREGION OF BRITISHGASPlc

WARNING: Air heaters should not be installed

in corrosive atmospheres, i.e., near plating or

degreasing plants or in areas where there is a

firerisk.ConsultBS6230forfurtherinformation

onhazardousareas.

3.2 Heater Location

The location chosen for the heater must permit the provision of a

satisfactory flue system and an adequate air supply. The location

must also provide space for servicing and air circulation around the

unit.

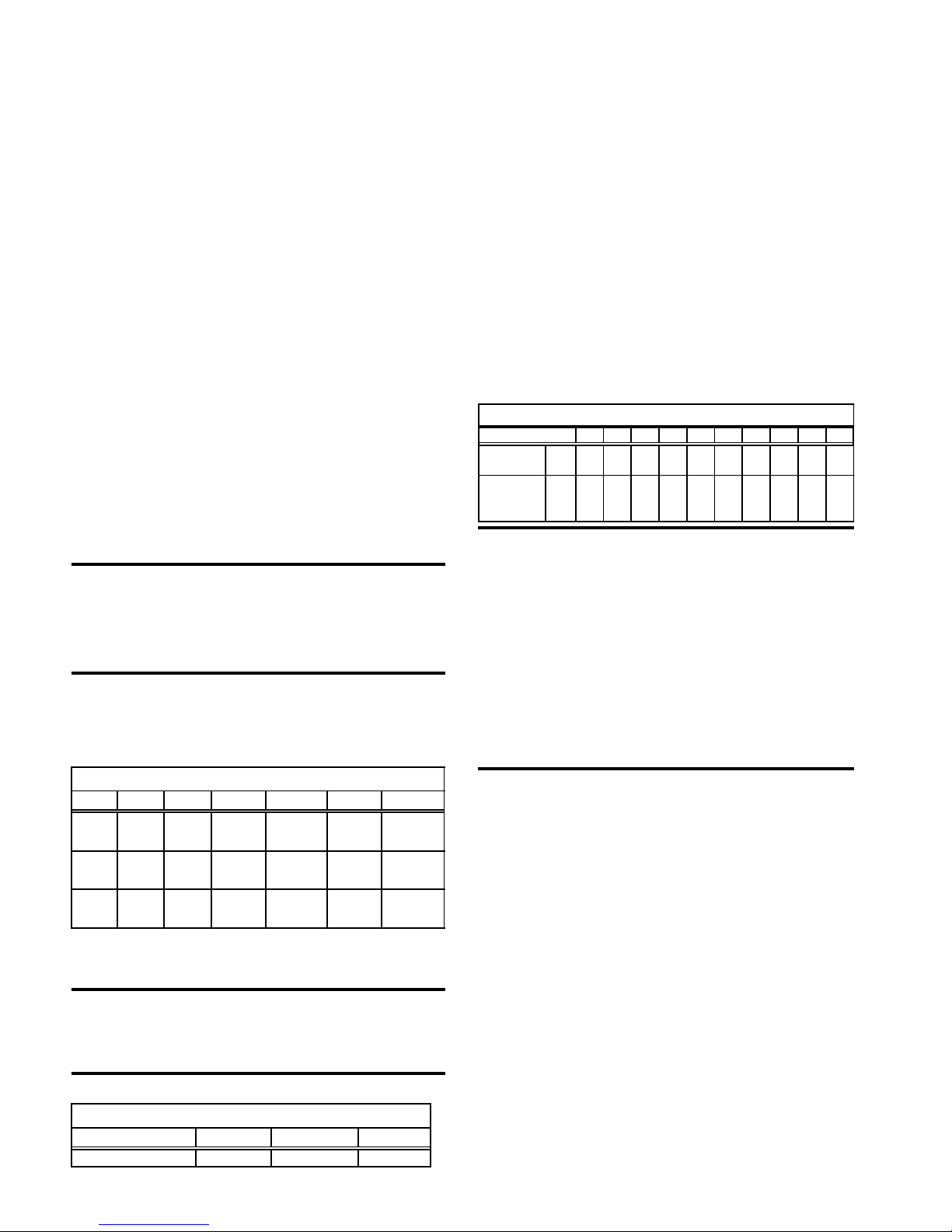

Table 4 - RequiredClearances (mm)

Sizes Top Flue Sides Bottom Rear Front

25 -

125 152 152 460 610 610 1830

165 -

250 152 152 460 610 610 2440

300 -

400 152 152 460 610 610 3050

For service purposes, rear must have 610 mm clearance. When sup-

plied with optional downturn nozzle, bottom clearance is 1.0 m.

The location should be free of draughts.

WARNING: Avoidinstalling a unitinan extremely

draughty area. Extreme draughts can shorten the

life of the heat exchanger and/or cause safety

problems.

Refer to Table 5 for recommended mounting height for UF Models.

3.3 Flue System

Each heater must be fitted with an adequately sized flue (See Table

6). Stainless steel flue pipe is recommended.

WARNING: The flue must be installed in

accordancewithBS5440Part 11990 forallmodels

up to and including Size 200 or BS6230 1991 for

all Models Size 250 and over.

Failure to provide proper flueing could result in

death,seriousinjuryand/orpropertydamage.The

unit must be installed with a flue to the outside of

thebuilding.Safeoperationofanynaturaldraught

gas burning equipment requires a properly

operating flue system, correct provision for

combustion air, and regular maintenance and

inspection.

The unit heater is fitted with an integral draught diverter. Do not use

an external draught diverter, barometric damper and/or restrictive

damper.

When condensation is possible within the flue, double wall flue pipe

is recommended. When double wall flue pipe is used, it should be a

type complying with British Standards. Double wall flue pipe re-

quires the use of a special flue socket adapter. Where condensation is

unavoidable, provision should be made for condensation to flow

freely to a point at which it can be released, preferably into a gulley.

The condensation pipe from the flue to the disposal point should be

of non-corrodible material, not less than 19 mm diameter.

The flue must terminate outside the building in a freely exposed

position so as to prevent products of combustion from entering any

opening in a building.

If the flue passes through a wall or ceiling of combustible material, it

must be enclosed by a sleeve of non-combustible material and sepa-

rated from the sleeve by at least 25 mm air gap. The temperature of

any combustible material near the flue or heater must not exceed 65o

C when the heater is in operation. The flue must also be at least 50

mm from any other combustible material.

The joint between the female flue socket of the heater and the flue

must be sealed. If twin wall flue piping is used, the appropriate

adapter must be fitted.

The joints between the flue and the roof must be made good to

prevent water ingress.

Table 6 - Flue Diameter and Minimum Hei

ht

Size 25 50 75 100 125 165 200 250 300 400

Flue Pipe

Diameter mm 100 100 125 150 175 200 200 250 250 250

Min. Height

of Flue M 1.5 1.5 1.5 1.5 2.0 2.0 2.0 2.0 2.0 2.0

Table 5 - Recommended Mounting Heights

UF Models 25 - 125 165 - 250 300 - 400

Mounting Height 2.5 - 3 m 2.5 - 3.5 m 3 - 5 m