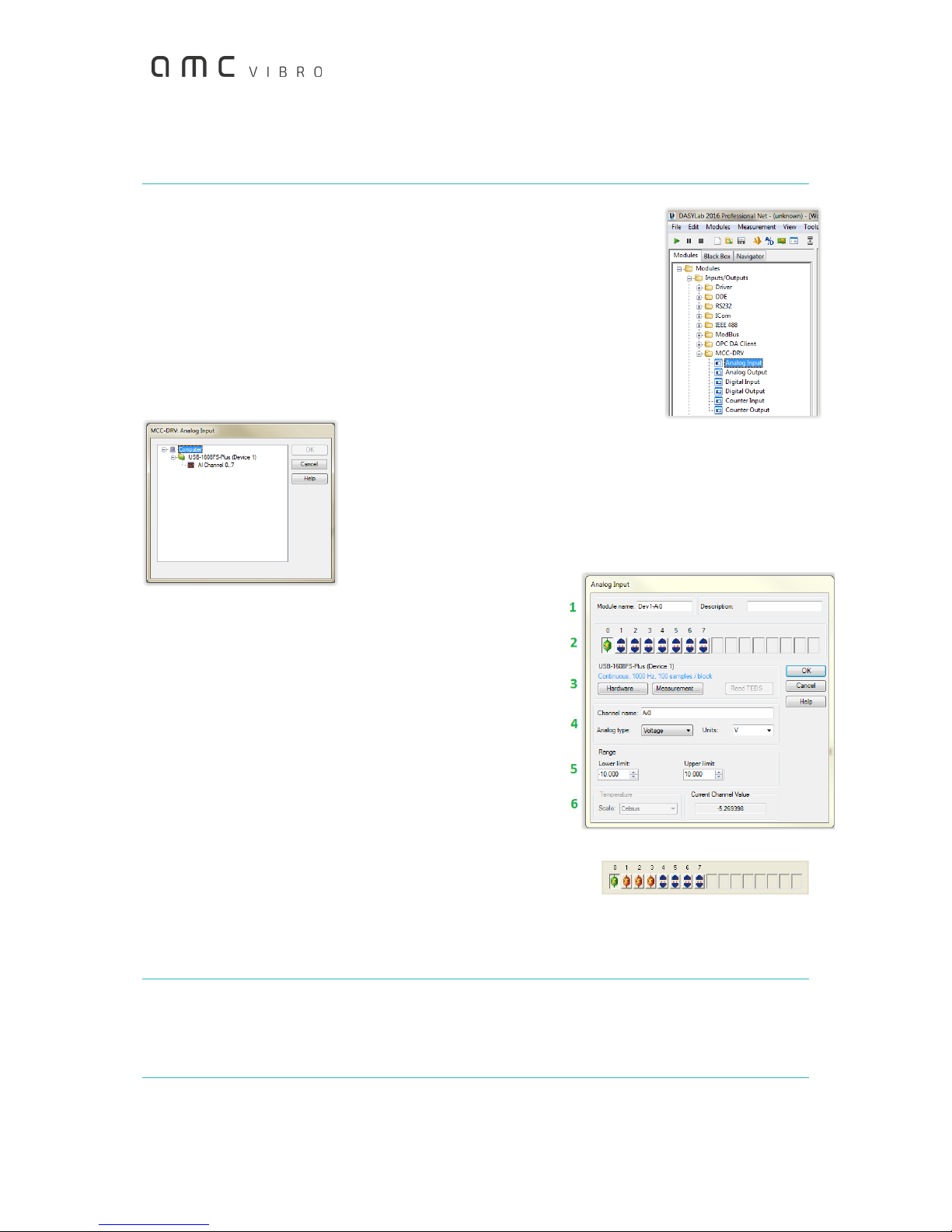

9. Using the AVA 4001 module in DASYLab® 16

After running properly configured DASYLab® software the analog inputs will

be available to the user. The inputs are listed in the following tab: Modules >

Inputs/Outputs > MCC-DRV. The in AVA 4001 module only 4 analog inputs are

available, while remaining 4 analog inputs, the outputs and the counters are not

available.

To use an analog input, just drag it inside the worksheet (or you may double-

click it and indicate the module’s position on the worksheet). A window will

appear as shown in the figure below. Mark All Channel 0..7 and confirm your

choice by clicking the OK button.

The user can configure the number of active

analog inputs, measurement range separately for each channel as well

as the sampling frequency.

Double-clicking the analog input window on the worksheet opens the

window shown below. This window needs to be discussed in detail, as

it gives the user the option to configure the AVA module parameters

for operation in DASYLab. The following areas can be distinguished:

1. You can enter your own module name in the Module name

field and provide a short description in the Description field.

2. It is possible to activate analog inputs in this area. The

symbol with disconnected blue sockets stands for an

inactive input. A double-click on the symbol activates the

corresponding input and switches the symbol to connected

sockets with a lightning.

A single click on the active input changes its color from red

to green. The changes of settings, which are explained in the

following points, refer to the input marked in this way.

The next figure presents a situation, in which four input channels are active, while the first is marked

for editing settings.

If necessary, an input can be deactivated by double right-clicking the icon of the active input.

Attention

In AVA 4001 module, inputs 4 - 7 are not used. Activating them will reduce the maximum available

sampling frequency.