AMC-1040 CO / NO2 Vehicle Exhaust

4

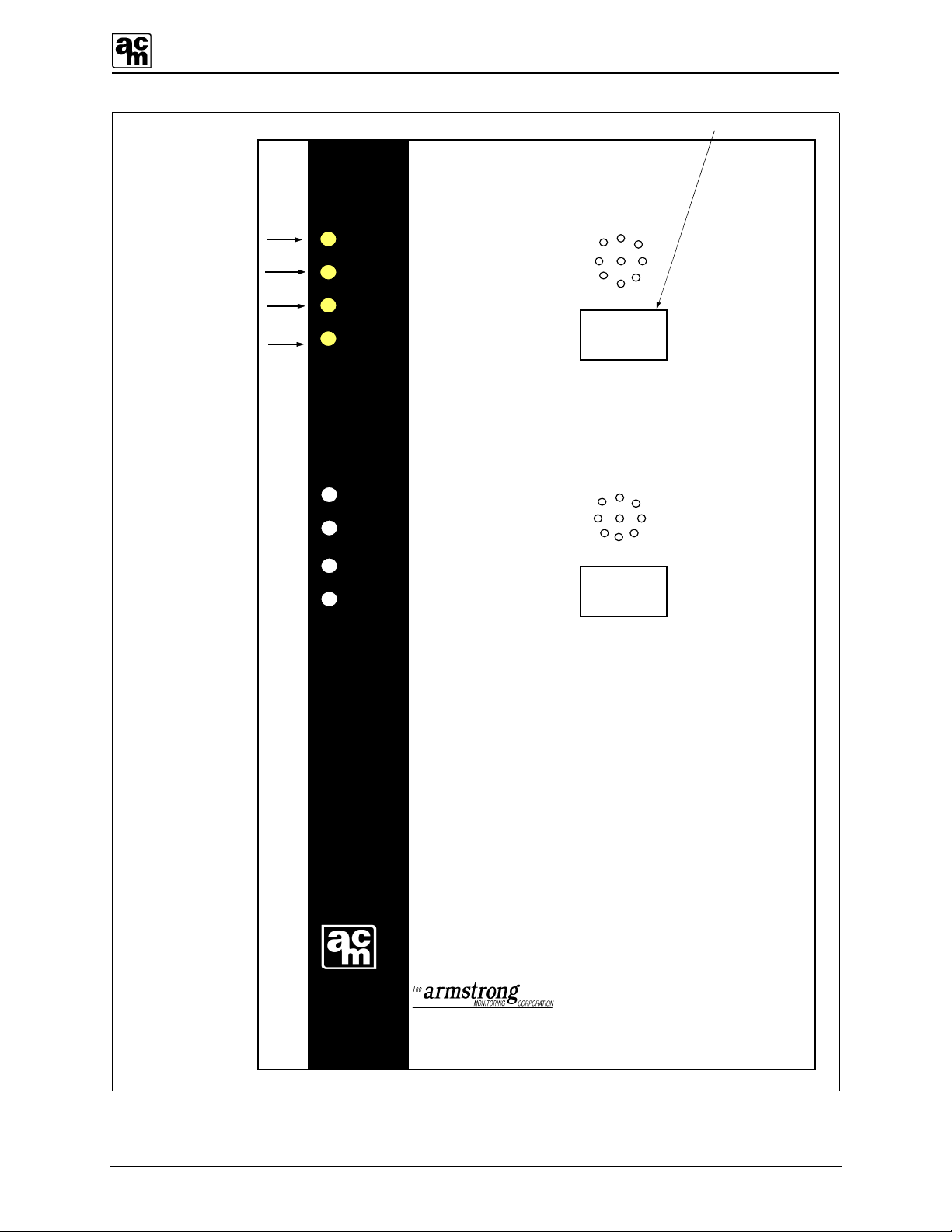

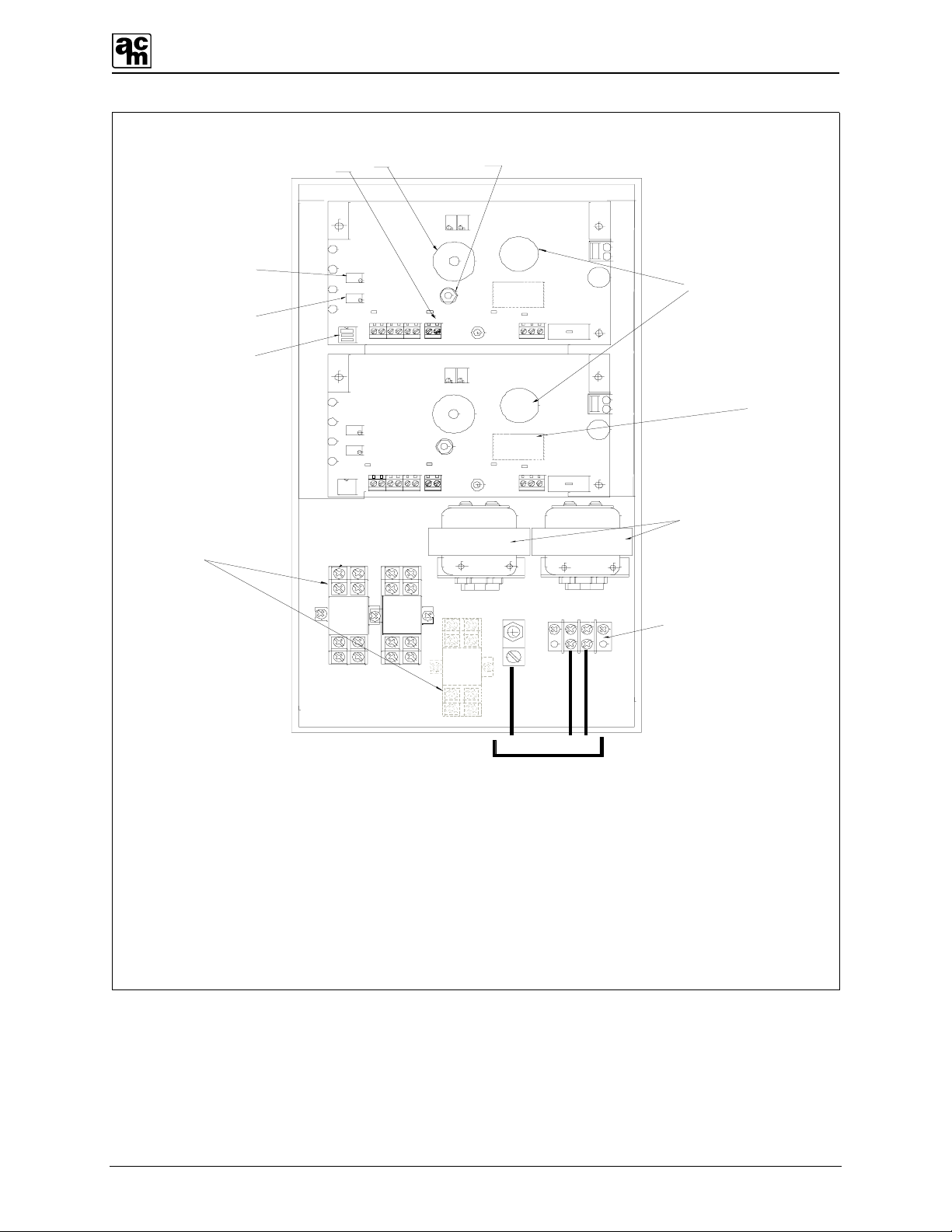

3 PRODUCT DESCRIPTION

The AMC-1040 is a two-channel gas monitoring system designed with built-in sensors to

continuously monitor surrounding air for traces of hazardous gases. Each channel comes with

the following features (see Figures 1, 2 and 3).

1. POWER ON INDICATOR: Power is indicated by a green LED.

2. FAIL INDICATOR: Sensor fail is indicated by an amber LED.

3. LOW ALARM INDICATOR: Low levels of gas are indicated by a yellow LED.

4. HIGH ALARM INDICATOR: High levels of gas are indicated by a red LED.

5. POWER TERMINAL BLOCK: For line voltage connections (120 VAC, 60 Hz.)

6. TEST SWITCH: The test switch is provided to electronically simulate alarms

in order to test the low and high alarm indicators and relays.

7. LOW ALARM ADJUST: Sets the Low alarm trip point.

8. HIGH ALARM ADJUST: Sets the High alarm trip point.

9. THREE CIRCUIT MINIATURE

SWITCH:

Each actuator on the miniature switch controls a different

circuit as shown in Figure 1.

9. a) TOP ACTUATOR: Provides a TEN-minute time delay, when the switch is ON,

to eliminate unnecessary alarms caused by momentary

exposure to high alarm conditions.

9. b) MIDDLE ACTUATOR: Provides a FIVE-minute time delay, when the switch is ON,

to eliminate unnecessary alarms caused by momentary

exposure to low alarm conditions.

9. c) BOTTOM ACTUATOR: Controls the audio alarm indicator. When ON, the buzzer

will activate when a high alarm condition occurs.

10. RELAYS:

There are up to 3 DPDT relays per monitor, which can work

with high alarm, low alarm, and fail.

11. TRANSFORMER:

Class II, step down transformer runs the internal circuitry at

low voltages.

12. AUDIO ALARM: When enabled, the buzzer will activate when a high alarm

condition occurs.

13. ANALOG OUTPUT: 4-20 mA output 250 ohms load maximum.

14. ON-BOARD SENSOR Allows local detection of gas.

15. OPTIONAL DC INPUT: Used for battery backup or a 12 VDC supply.