AMD 601XL / 601XLI / 650LS / 650LSi SLSA MAINTENANCE MANUAL

________________________________________________________________________

SECTION III

INSPECTION

GENERAL

This section provides instructions for conducting scheduled inspections, unscheduled

inspections, replacement of time limited parts and corrosion control. Repair or

replacement instructions for those components found to be unserviceable are in the

sections covering the applicable aircraft system.

Lubrication and servicing intervals should be adjusted to take into account the aircraft

operating conditions.

All of the inspections are generally visual inspections unless otherwise specified. They

are to be performed by trained and qualified personnel using appropriate tools and

adequate lighting.

Prior to commencing the scheduled inspections listed in Table 1:

a. Thoroughly clean the aircraft and engine;

b. Remove and or open the necessary inspection and access panels, the engine cowlings,

the spinner and the optional wheel fairings; and

c. Review the aircraft records for outstanding “SAFETY ALERTS”, “SERVICE

BULETINS” and “NOTIFICATIONS”. You must contact the manufacture for the

latest list of above documents.

Manufacturer can be contacted by telephone at 478-374-2759 or by fax at 478-

374-2793 or by mail at 415 Airport Road, Eastman GA, 31023 USA.

For engine and propeller Service Bulletins, Airworthiness Directives, and Service

Letters, contact the original manufacturers.

Section F2295 of the ASTM SLSA lists the Owner/Operator Responsibilities for

Continued Operational Safety Monitoring of a Light Sport Airplane. Complete and

submit Form #1 for maintenance, service and safety difficulties.

Note: In addition to the tasks specified in Table 1, do the preflight inspections described

in the Owner’s Manual. For mechanics who are not familiarized with the aircraft, use the

+40 page Pre-Flight check list as an extra guide. Available from the manufacturer.

SCHEDULED INSPECTIONS

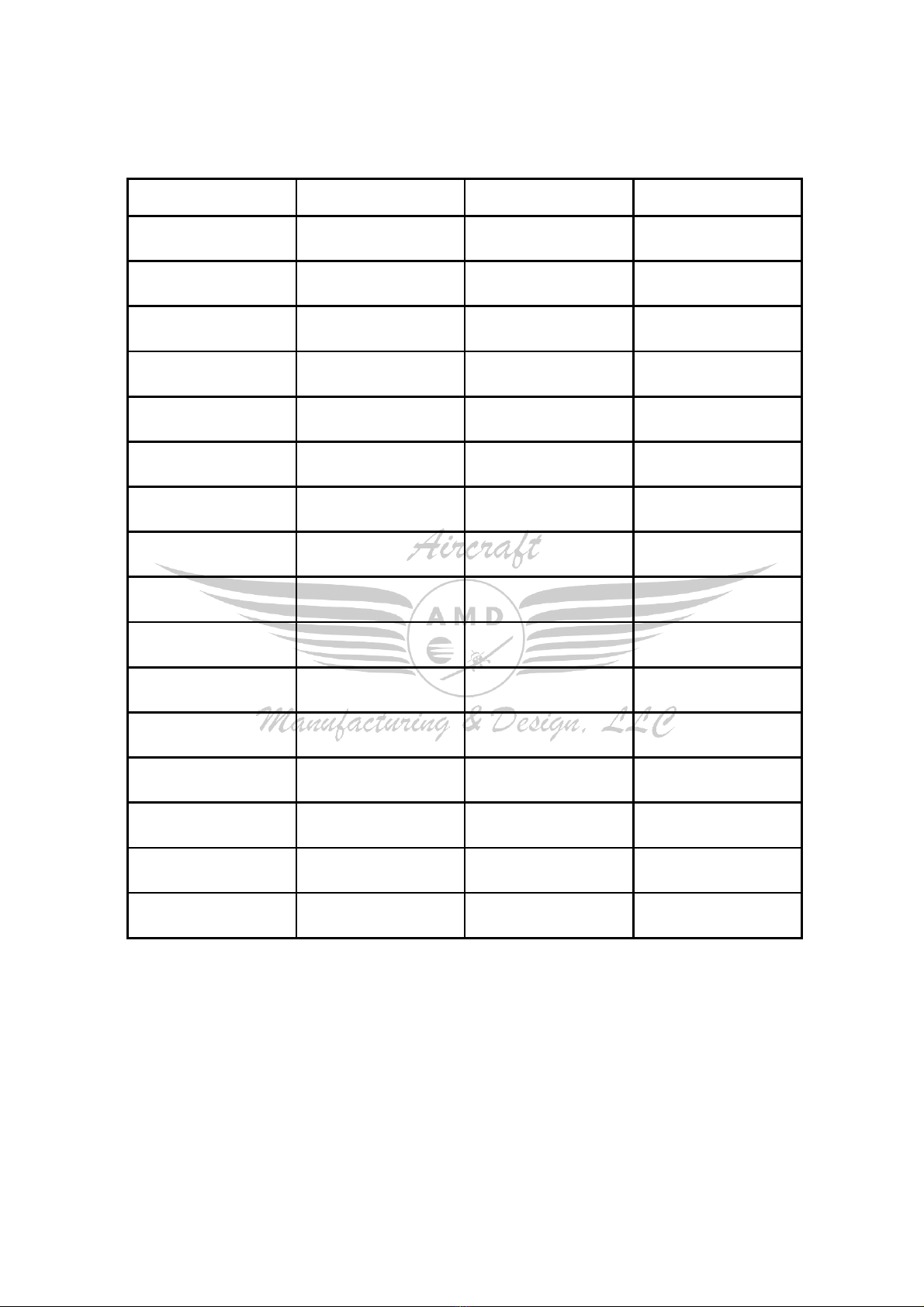

Scheduled inspections include the items listed in Table 1 Inspection Form, the

overhaul requirements for the engine and propeller, the calendar time inspections and the

one-time inspections done following specified tasks. Do the following:

Inspection Form Requirements

Perform the tasks in Table 1 at the intervals shown.

Overhaul Requirements

a. Overhaul the engine (Continental 0-200). See engine manuals

b. Overhaul the propeller. See propeller manufacturers instructions

Replacement of Airframe Time Limited Parts

No parts listed at this time.

July 09 3.1