1

2 Guided tour of the Super Maramu 2000

2.1 Electric power from the AMEL point of view

Most of the electrical equipment in board of the Super Maramu 2000 works with in 24 V DC.

This energy is stored in batteries that need to be charged regularly. Ideally, charging

should be done promptly produce when needed.

When the boat is in a harbour, connected to the shore power, batteries are charged

automatically with the 30 A charger (optional) which is less greedy than the 0 A.

When the boat sails, a lot of 24 V equipment (automatic pilot, electronics, rig and sail furling

system, winches, refrigerators, lightning, …) work with the batteries’ energy. If we don’t pay

attention, they will be quickly discharged. Thus the generator should be switched on

regularly to charge the 24 V batteries. If it is possible, schedule not a daily long time, but 3

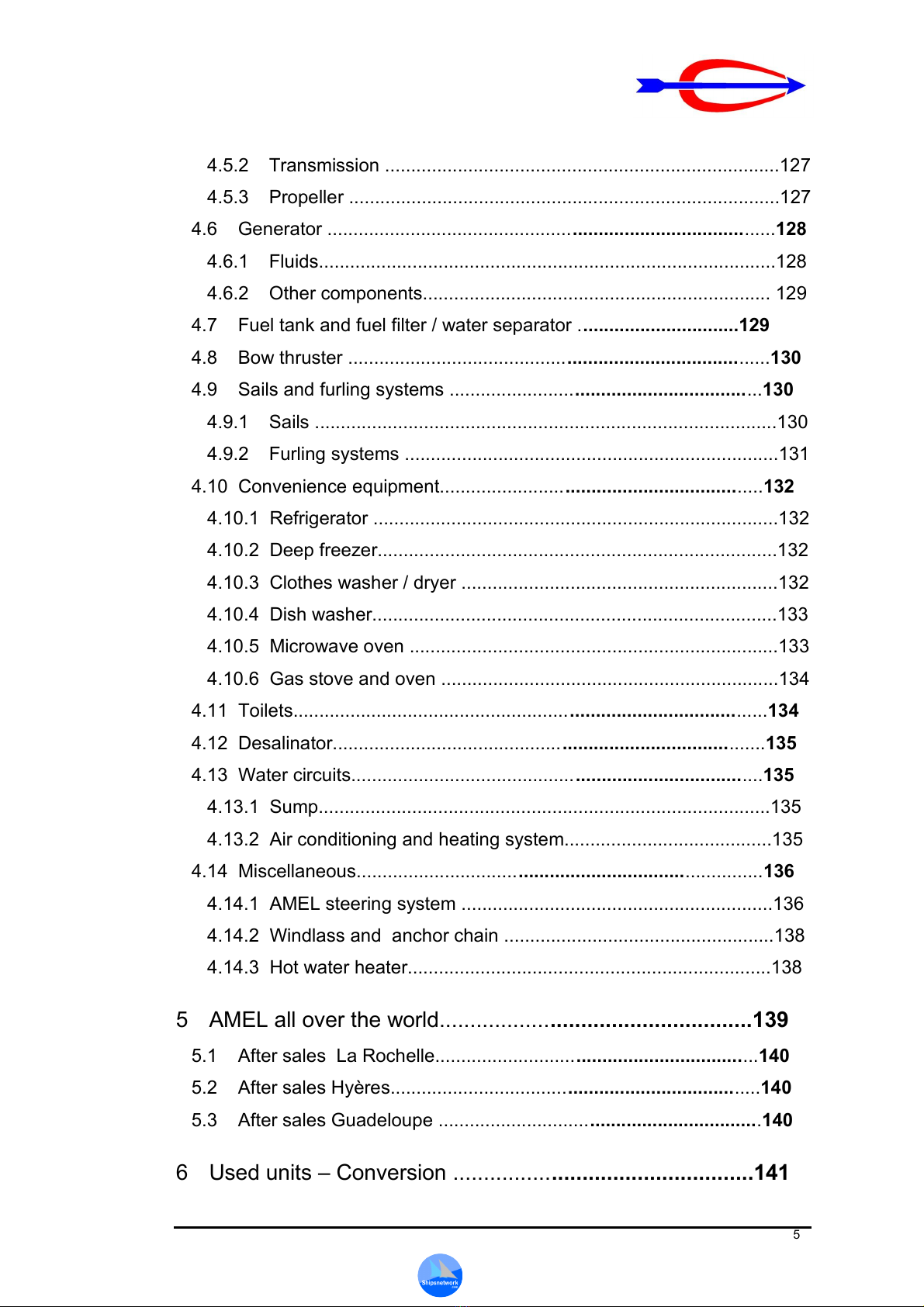

shorter periods of 1 and a half to 2 hours. The next chart shows a solution, but your own

experience can improve it.

1 time early

in the morning 1 time near 13 or 14 PM 1 time near 19 or 20 PM

generator

+

0 A charger (first)

+

30 A charger (1 min after)

During the night, automatic

pilot, lights, refrigerators,

electronics, have discharged

batteries. The generator

delivers 220 V, useful at

breakfast to warm water, wash

up, warm the boat, …

Good for batteries, generator,

refrigerators, pumps, …

220 V is useful for hot water,

microwave oven, dishwasher,

air conditioning, …

At dinner time, for the same

reasons as previously, and to

have good batteries for the

night.

At the harbour : 30 A charger

In the open sea : 50 A charger + 30 A charger (1 min after)

to 6 hours seem to be reasonable, regarding to the needs of the crew.

When the boat is at anchorage, 24 V uses are less, and 3 to 4 hours of generator’s work

should be enough.

Batteries wear out, not due to their age, but according to their number of cycles of Charge /

Discharge. That is why batteries of an occupied boat, but most of the time connected to

shore power, will last longer (4 years max.) than batteries on a boat who sails or at the

anchorage most of the time. In that case, lifetime of the batteries will probably not exceed 18

months.

Batteries usually fail because they are not charged enough.